Homogenizer transmission case structure

A transmission box and homogenizer technology, applied in transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of high friction resistance between the crankshaft and the bearing bush, high cost, and reduced service life, so as to reduce friction Effects of generating heat, reducing starting resistance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

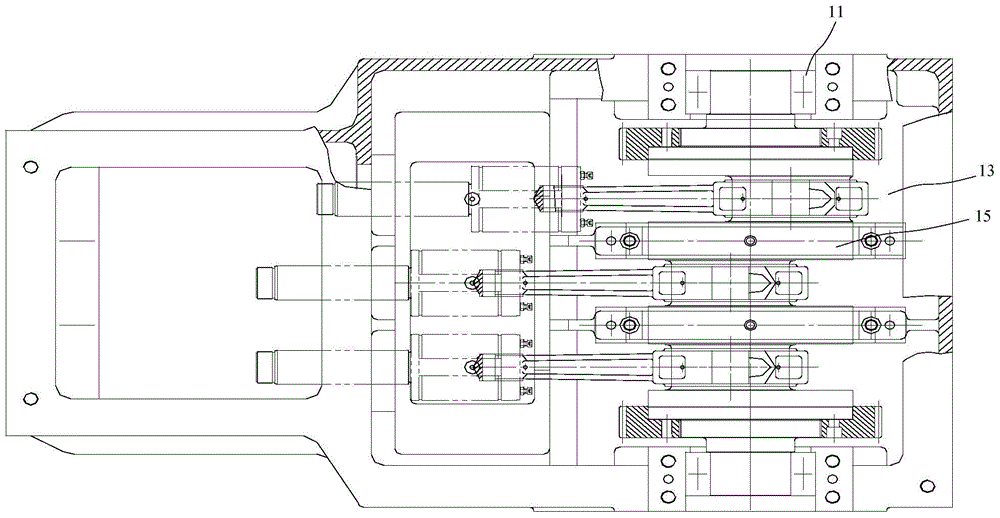

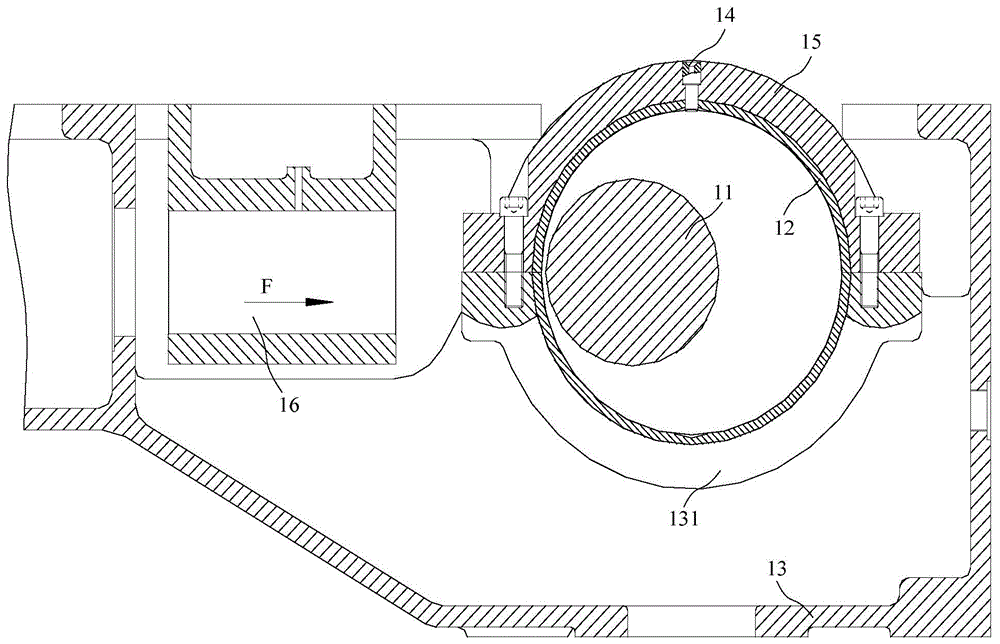

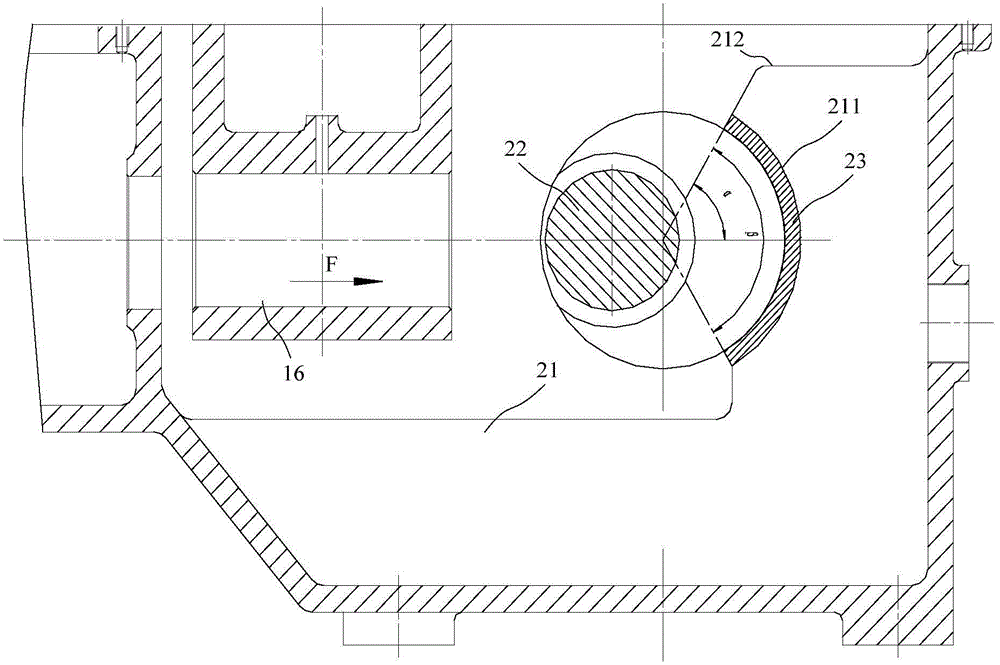

[0021] The invention provides a transmission box structure of a homogenizer, mainly related to the improved design of the middle part of the corresponding crankshaft, that is, the sliding bearing part. The structure connecting the two ends of the crankshaft to the box is the same as the existing design, so there is no Let me repeat. The present invention abandons the Hough structure, avoids the problem of cumbersome manufacturing process of the Hough structure, simplifies the box structure of the transmission box, and brings convenience to the processing. The bearing surface is set on the box corresponding to the direction of the piston force, and the bearing surface is an arc-shaped structure. Compared with the circular support in the Huff structure, the present invention can use a single piece of bearing bush to avoid leakage at the joint of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com