A self-lubricating micro-stir friction welding method with welding friction restraint

A micro-stirring and friction welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as deformation, welding failure, and difficulty in welding workpiece assembly, reduce post-weld deformation, increase heat input, Realize the effect of high-speed welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

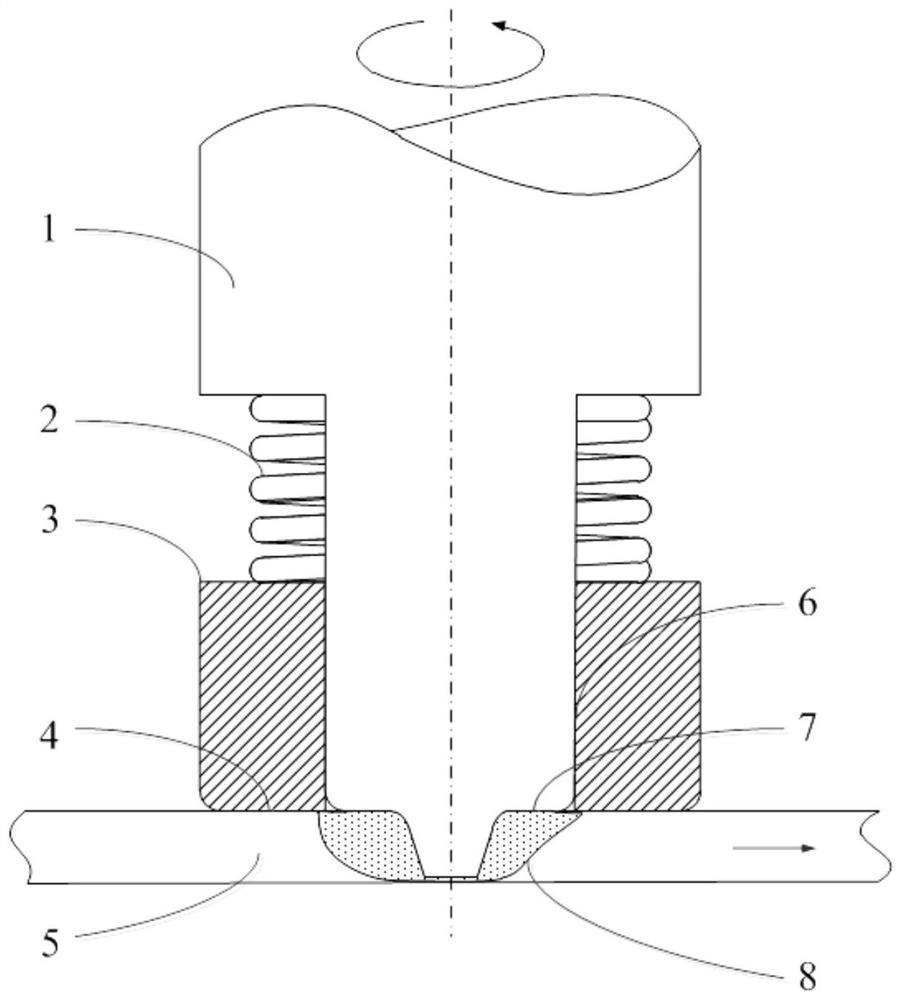

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes traditional micro-friction stir welding stirring head 1, welding thickness 0.5mm, stirring needle length 0.45mm, stirring head shaft shoulder diameter 3.6mm, auxiliary shaft shoulder 3 outer diameter 20mm, auxiliary shaft shoulder 3 The connection surface 6 with the stirring head 1 adopts two symmetrical limiting rib grooves for torque transmission; the spring 2 has 4 turns, an outer diameter of 18mm, and provides a pressing force of 3kg under normal welding compression. On the upper part of the stirring head 1, it is connected with the welding machine tool through a quick chuck. The welding speed is 10000rpm, the welding speed is 1.5m / min, and the pressing amount is 0.03mm. The auxiliary shoulder 3 is made of PEEK composite material, and the outer edge of the contact end surface 4 is chamfered with R2 to form a shape convex from the outside to the inside. The contact ...

specific Embodiment approach 2

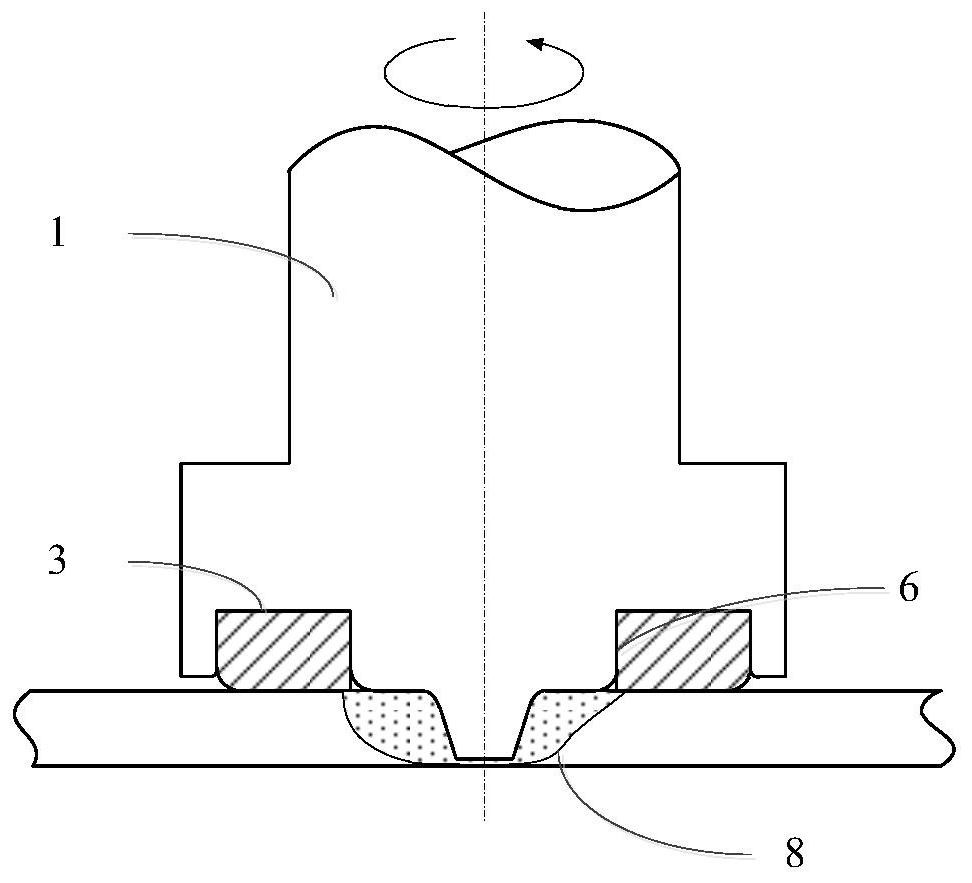

[0020] Specific implementation mode two: combination figure 2 Describe this embodiment. This embodiment includes a traditional micro-friction stir welding stirring head 1 with a welding thickness of 1 mm. On the outside of the shoulder of the stirring head 1, an annular cavity is added, and the cavity is embedded with a self-lubricating material as an auxiliary shoulder. 3. The connecting end face 6 of the auxiliary shaft shoulder 3 and the stirring head 1 adopts a tight fit and two symmetrical limit rib grooves for connection and torque transmission. The diameter of the shaft shoulder of the stirring head is 6mm, the diameter of the stirring needle is 2.5mm, and the length of the stirring needle is 0.9mm mm, the outer diameter of the auxiliary shoulder is 30mm, the welding speed is 8000rpm, the welding force is 0.06mm, and the welding speed is 1m / min. The pressing force of the auxiliary shoulder in this embodiment is controlled by the amount of pressing down of the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com