Cooling device of pavement cutting machine

A technology of cooling device and cutting machine, applied in the direction of road, road, road repair, etc., can solve the problems such as the inability to cool down the cutting piece, the inability to cool down, and the small contact area, so as to improve the cooling effect, reduce frictional heat generation, reduce The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

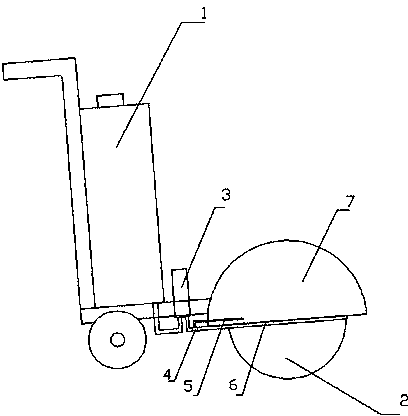

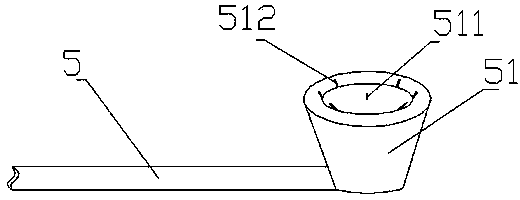

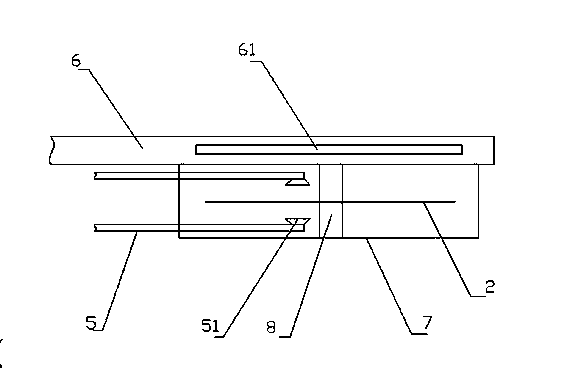

[0024] Embodiment 1: as figure 1 , figure 2 with image 3 As shown, a cooling device for a road cutting machine includes a water tank 1, a booster pump 3 and a water spray device arranged on the cutting machine. The water spray device includes a water spray pipe I5 and a water spray pipe II6. The water outlet of the water tank 1 is connected to the The water inlet pipe of the booster pump 3 is connected, and the water outlet pipe of the booster pump 3 is connected to the water spray pipe I5 in the mask 7 of the cutting piece 2 and the water spray pipe II6 arranged on the outside of the mask 7 through the tee 4 respectively. Two nozzles 51 respectively located on both sides of the cutting piece 2 are arranged on the pipe I5, and a plurality of water spray holes are arranged on the nozzle 51. The water spray holes are divided into a central water spray hole 511 and an edge water spray hole 512. Set in the central position of the nozzle 51, the water flow is sprayed perpendicu...

Embodiment 2

[0025] Example 2: as figure 1 , figure 2 with Figure 4 As shown, a cooling device for a road cutting machine includes a water tank 1, a booster pump 3 and a water spray device arranged on the cutting machine. The water spray device includes a water spray pipe I5 and a water spray pipe II6. The water outlet of the water tank 1 is connected to the The water inlet pipe of the booster pump 3 is connected, and the water outlet pipe of the booster pump 3 is connected to the water spray pipe I5 in the mask 7 of the cutting piece 2 and the water spray pipe II6 arranged on the outside of the mask 7 through the tee 4 respectively. Two nozzles 51 respectively located on both sides of the cutting piece 2 are arranged on the pipe I5, and a plurality of water spray holes are arranged on the nozzle 51. The water spray holes are divided into a central water spray hole 511 and an edge water spray hole 512. Set in the central position of the nozzle 51, the water flow is sprayed perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com