Electric winch equipment

一种电动绞盘、设备的技术,应用在机械设备、机械驱动离合器、连轴器和制动器的组合等方向,能够解决损坏、三级太阳轮与二级行星架宽度不够、绞盘无法正常使用等问题,达到提高使用效果、制动效果好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Hereinafter, the present invention will be described with reference to the accompanying drawings; however, it should be understood that the structural proportions in the accompanying drawings are only exemplary, and are not intended to limit the scope of the present disclosure.

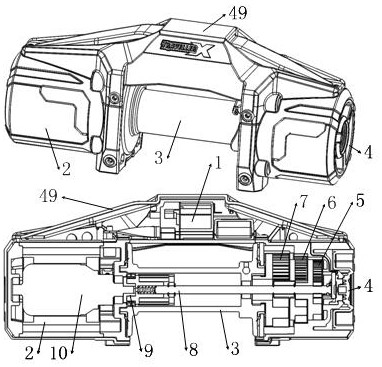

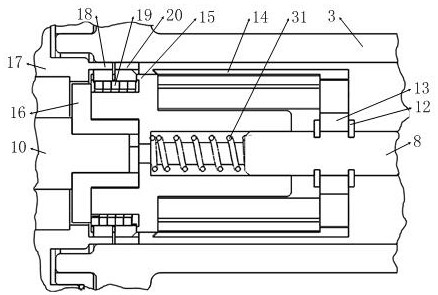

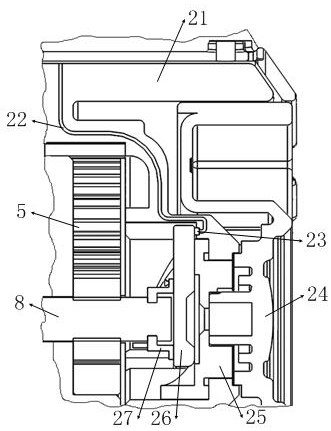

[0040]An electric winch equipment, such asfigure 1 As shown, it includes an outer shell 49, the upper side of the outer shell 49 is equipped with an electronic control module 1, the left end of the outer shell 49 is equipped with a motor module 2 and the right end is equipped with a reduction module and a clutch 4, and the lower middle of the outer shell 49 is equipped with Drum 3, the motor 10 in the motor module 2 drives the transmission shaft 8 in the drum 3 to rotate through the braking unit 9. The transmission shaft 8 drives the drum 3 to rotate through the reduction module, and the clutch 4 controls the axial movement of the transmission shaft 8; The module consists of a first-stage reduction compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com