Transformer test bar

A technology of test rods and transformers, applied in instruments, parts of electrical measuring instruments, measuring devices, etc., can solve problems such as low work efficiency and poor safety, and achieve problems such as easy winding, improving work efficiency, and eliminating high-altitude operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

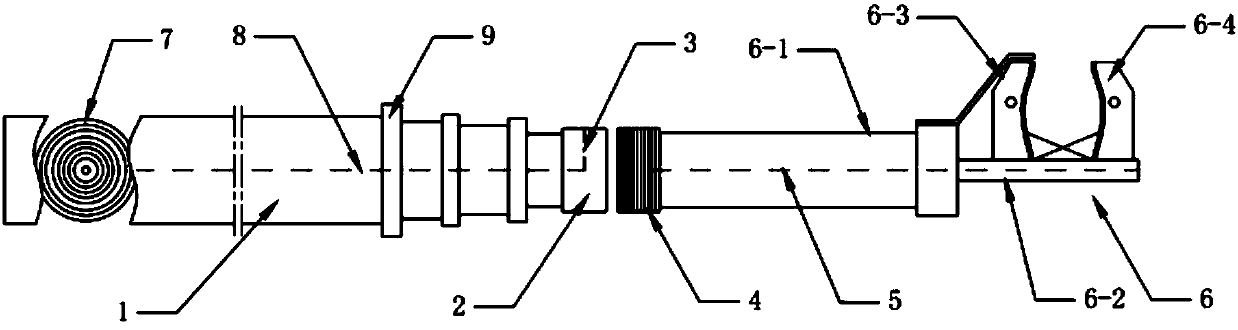

[0033] Further, see figure 1 As shown, as a specific embodiment of the transformer test rod provided by the present invention, the wire 8 is located inside the operating rod 1 .

[0034] Considering the influence of the weight of the long wire 8, the operating rod 1 is easily deformed or shaken when it is lifted up. In addition, the wire 8 is easy to swing under the action of wind. If it is not careful, it may cause the operating rod 1 to touch the adjacent live spacer equipment, causing serious damage to the on-site workers. Therefore, the wire 8 is placed inside the telescopic operating rod 1 to realize the unique design of the built-in wire, which can effectively improve the safety of the tool when used.

[0035] Further, see figure 1 As shown, as a specific embodiment of the transformer test rod provided by the present invention, the wire clamp 6 includes a connecting rod 6-1 connected at one end to the top end of the operating rod 1, and a connecting rod 6-1 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com