Producing method forming and model hot enlarge fluorine plastic tube

A technology of a fluoroplastic tube and a manufacturing method, which is applied in the field of a manufacturing method and a forming die of a fluoroplastic tube with a flared horn-shaped nozzle, and can solve problems such as poor smoothness of the flared surface, foaming, and fracture at the flared portion, Achieve the effects of avoiding stress concentration and residue, easy installation and use, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

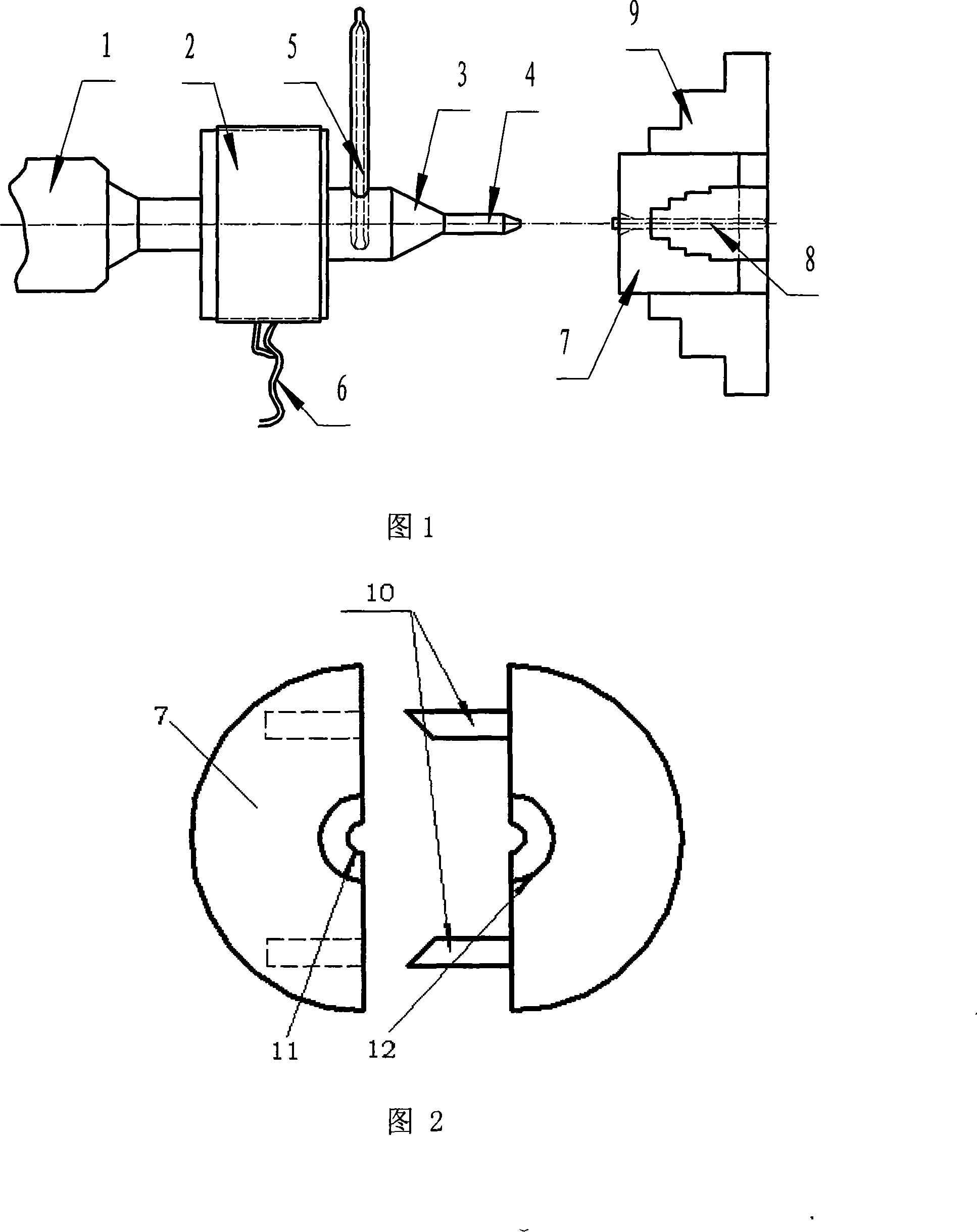

[0011] Figure 1 depicts a schematic diagram of the processing state of a thermally flared fluoroplastic tube composed of a heater, a temperature control device, and a claw plate of a machine tool. The whole system is composed of heating system, control system and mechanical system. The heating system is an electric heater, steam heater or oil heater, the control system includes a temperature sensor and a temperature control instrument, and the mechanical system is composed of a flaring fixture, a flarer and a lathe system. Its principle is: use a common lathe and a flare fixture, a new plastic flare method that rotates parts and feeds the flare to carry out plastic flare.

[0012] The punch expander and the flare die are on the same straight line, and the heater 2 is fixed on the central axis of the punch expander. The rear end of central axis cylinder is shaped on the connecting hole (not shown) of the top of suit common lathe. The heater 2 may be an electric heater, a stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com