An anti-tangle winder for heat dissipation of electric wires and its processing technology

A processing technology and wire winder technology, which is applied in the field of anti-winding wire winder and its processing technology, can solve the problems of wire entanglement, magnetic field generation, desktop clutter, etc., to slow down high temperature oxidation, improve stability, and facilitate storage and the effect of rounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

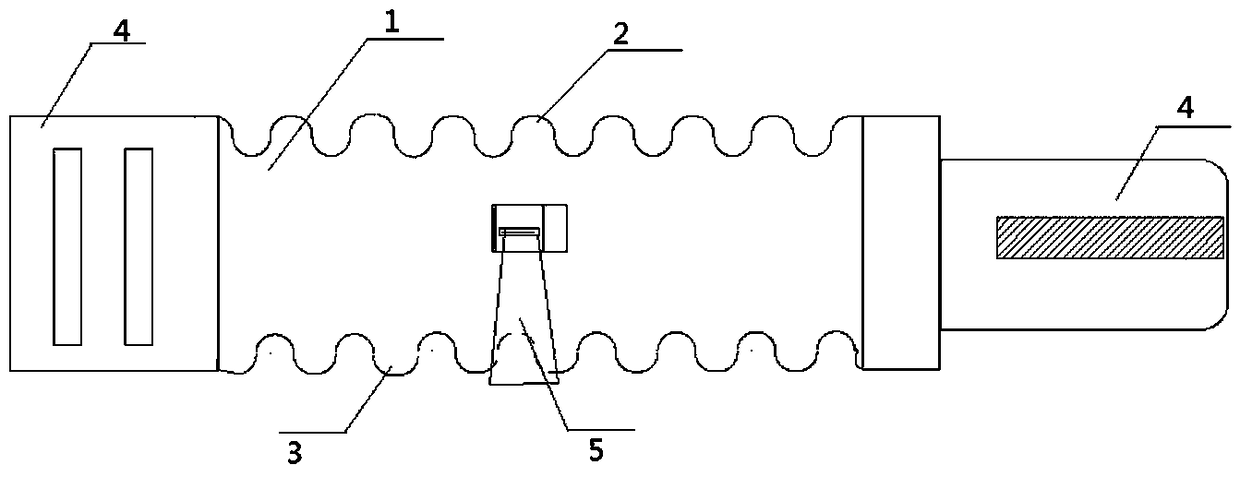

[0035] like figure 1 An anti-tangle wire winder for heat dissipation of wires is shown, comprising: a wire winder body 1, the upper and lower sides of the wire winder body 1 are respectively provided with first teeth 2 and second teeth 3, Moreover, the two ends of the cable winder body 1 are provided with locking devices 4, the first teeth 2 and the second teeth 3 are arranged in a misaligned position, and the inner side of the cable winder body 1 is provided with The supporting base 5 is rotatably connected to the main body 1 of the winding device through the connecting piece.

[0036] In this embodiment, the grooves between the first teeth 2 and the second teeth 3 are arc-shaped.

[0037] The locking device 4 described in this embodiment is composed of a mounting buckle and a clamping strip, and the mounting buckle and the clamping strip are respectively arranged at both ends of the winding body 1, and the described mounting buckle and the clamping strip are connected to ea...

Embodiment 2

[0040] The structure of the wire winder in the processing technology of an anti-tangle wire winder for heat dissipation of electric wires described in this embodiment is the same as that in Embodiment 1.

[0041] like figure 1 An anti-tangle wire winder for heat dissipation of wires is shown, comprising: a wire winder body 1, the upper and lower sides of the wire winder body 1 are respectively provided with first teeth 2 and second teeth 3, Moreover, the two ends of the cable winder body 1 are provided with locking devices 4, the first teeth 2 and the second teeth 3 are arranged in a misaligned position, and the inner side of the cable winder body 1 is provided with The supporting base 5 is rotatably connected to the main body 1 of the winding device through the connecting piece.

[0042] In this embodiment, the grooves between the first teeth 2 and the second teeth 3 are arc-shaped.

[0043] The locking device 4 described in this embodiment is composed of a mounting buckle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com