Patents

Literature

38results about How to "Reduce high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding

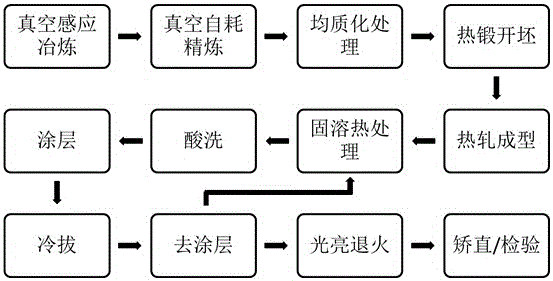

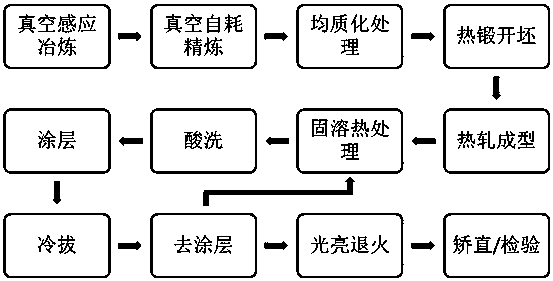

ActiveCN106181131APrecise content controlReduce lossWelding/cutting media/materialsSoldering mediaSolution treatmentVacuum arc remelting

The invention discloses a preparation method of a solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding, and belongs to the technical field of metal welding. The method includes the technological processes of vacuum smelting, vacuum arc remelting, homogenization, hot forging cogging, hot rolling, solution treatment, acid pickling, coating, cold drawing, coating removal and bright annealing. The invention further discloses the solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding. The solid cored welding wire is prepared through the method. Compared with the prior art, by the adoption of the method, high-quality solid cored welding wires of various diameters for molten-salt corrosion resistance nickel-base superalloy welding can be produced with the extremely-high rolling yield in a batch mode, and the prepared solid cored welding wire can meet the requirement for welding molten-salt reactor structural materials.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

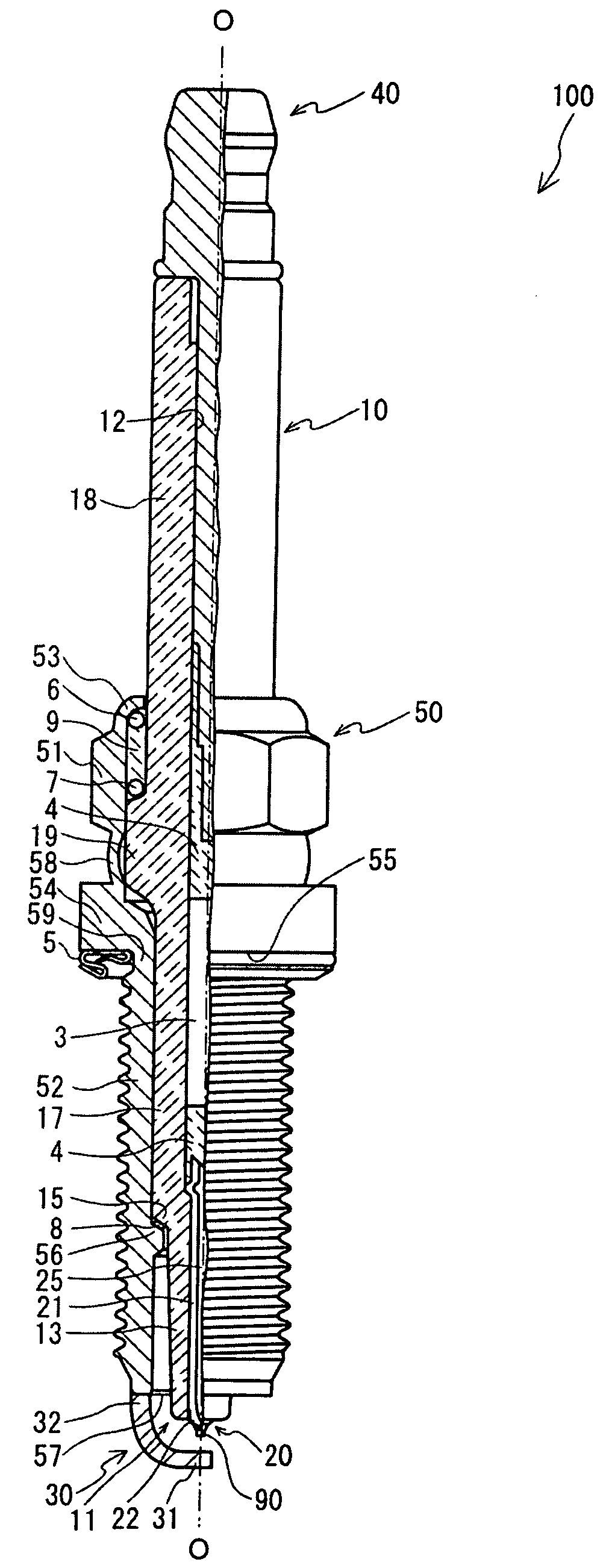

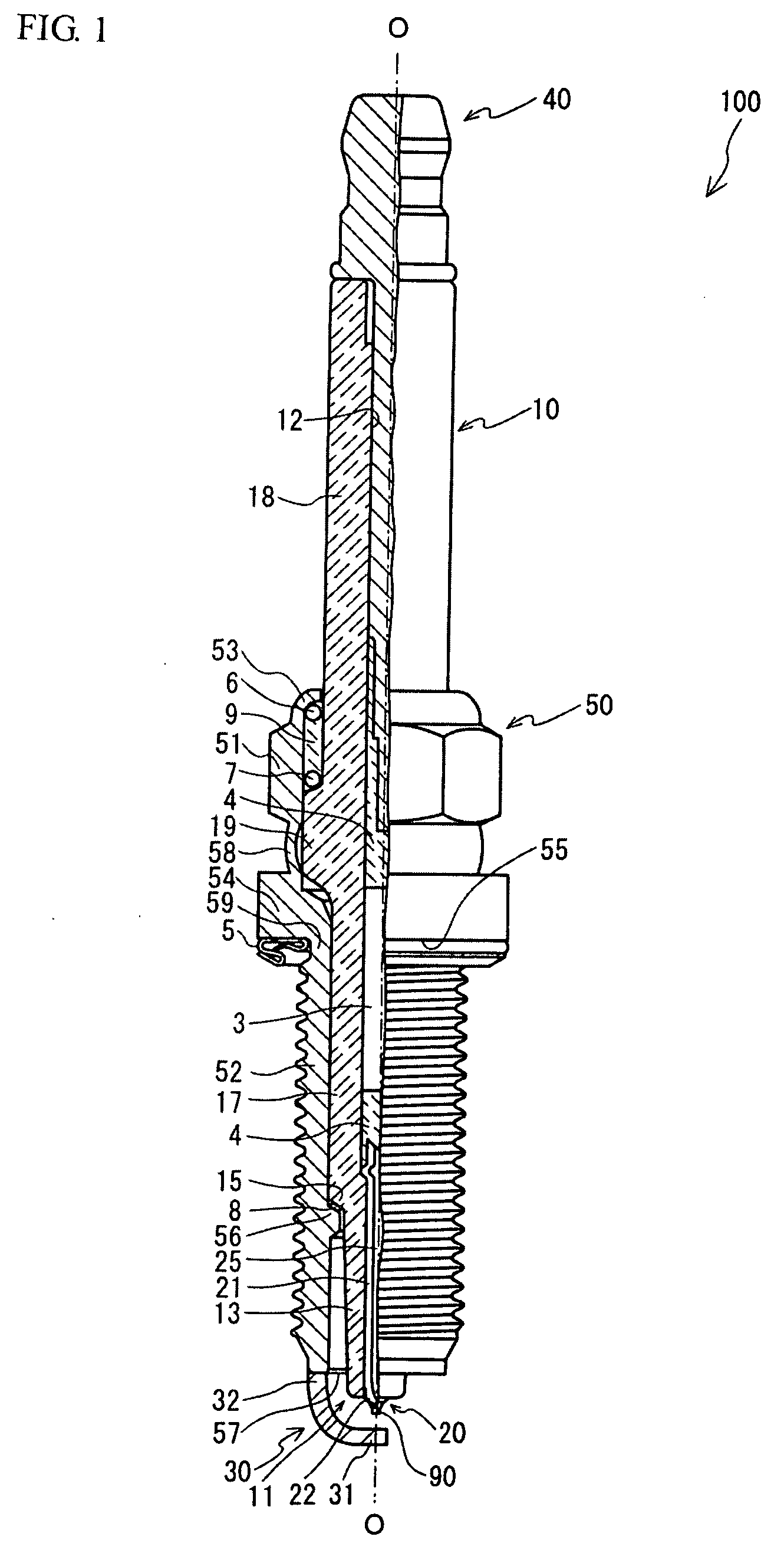

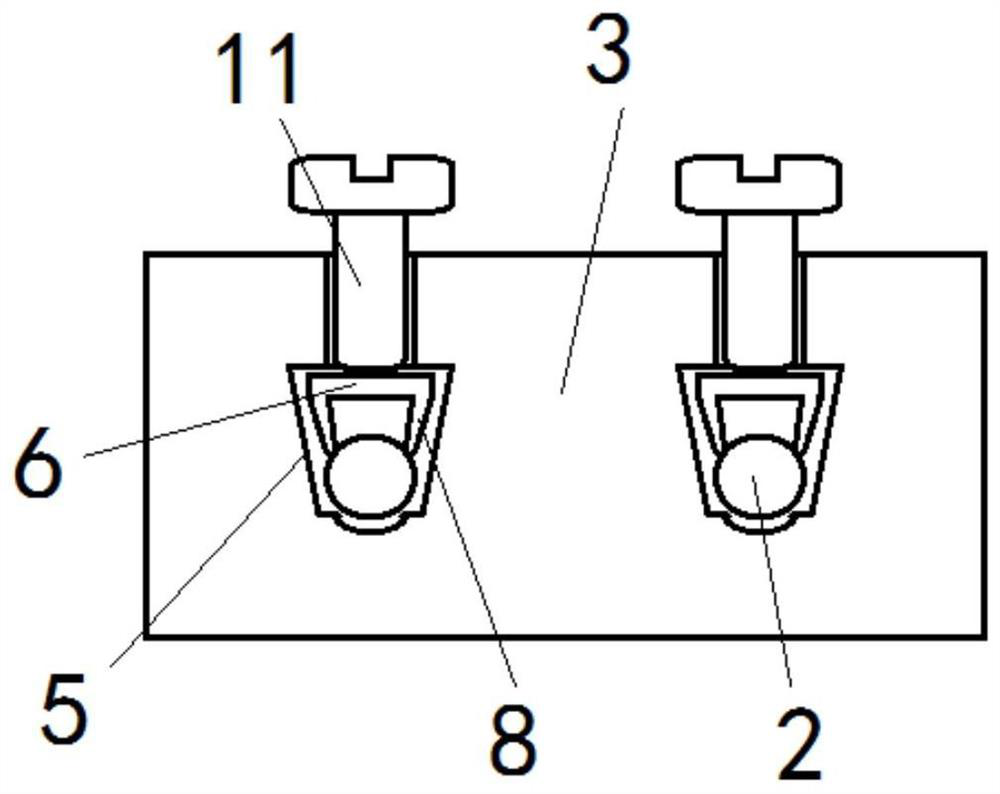

Spark plug

ActiveUS20090009048A1Improve cooling effectImproved spark wear resistanceSparking plugsFuel injection apparatusCombustion chamberEngineering

A spark plug (100) includes: a center electrode (2); and a ground electrode (30) which is to be exposed in a combustion chamber of an internal combustion engine and which forms a spark discharge gap with the center electrode (2), wherein at least one of the center electrode (20) and the ground electrode (30) contains an electrode material whose principal component is Ni and in which an intermetallic compound is precipitated at least intergranularly and intragranularly.

Owner:NGK SPARK PLUG CO LTD +1

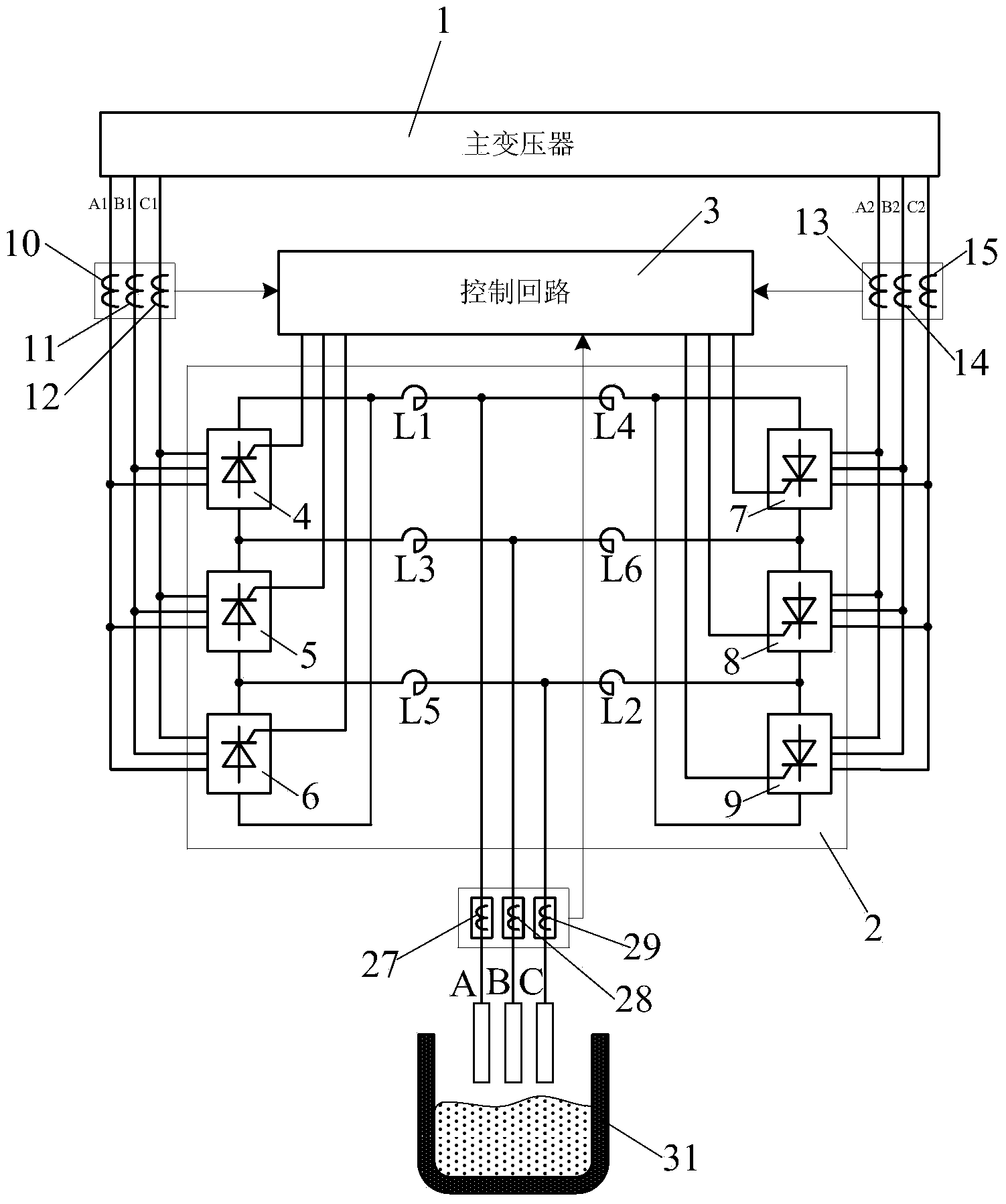

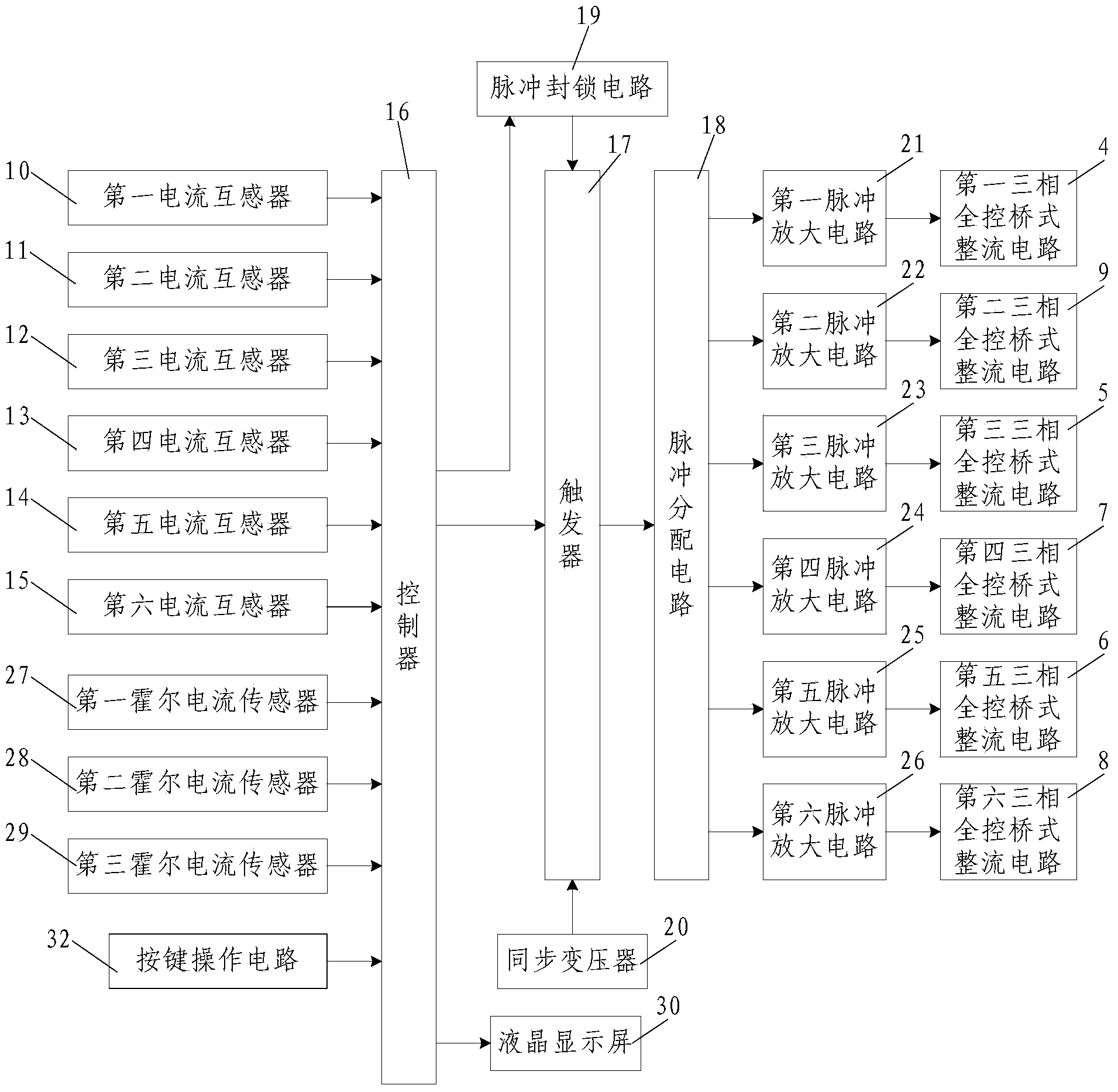

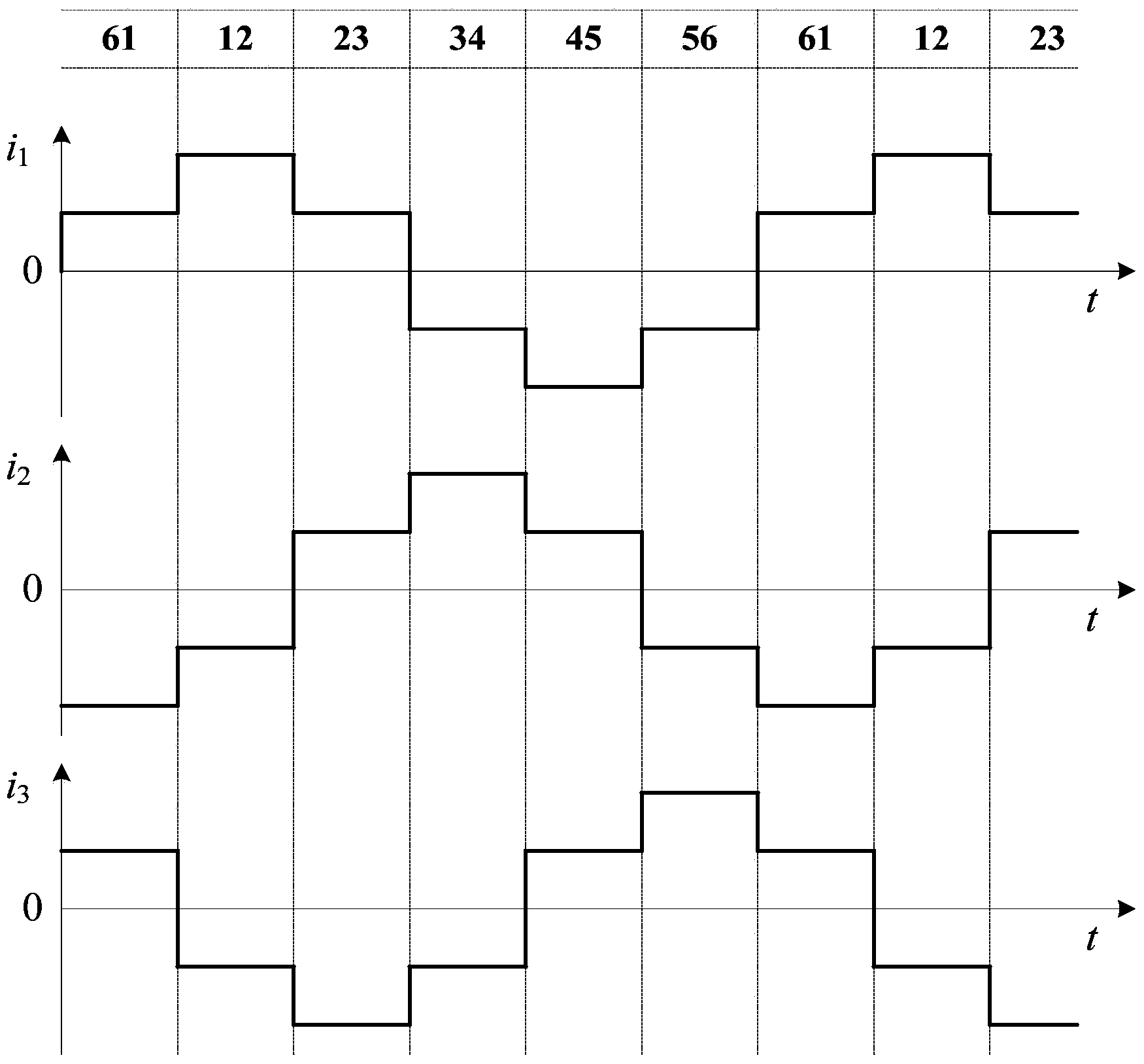

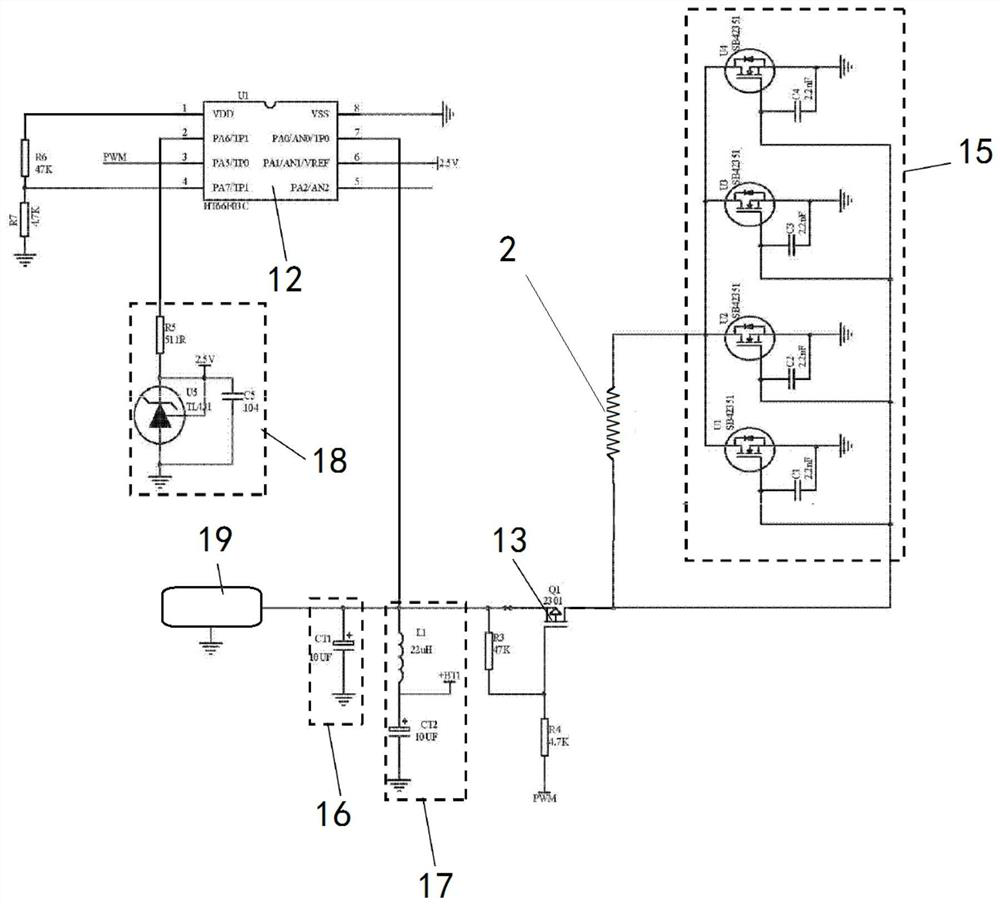

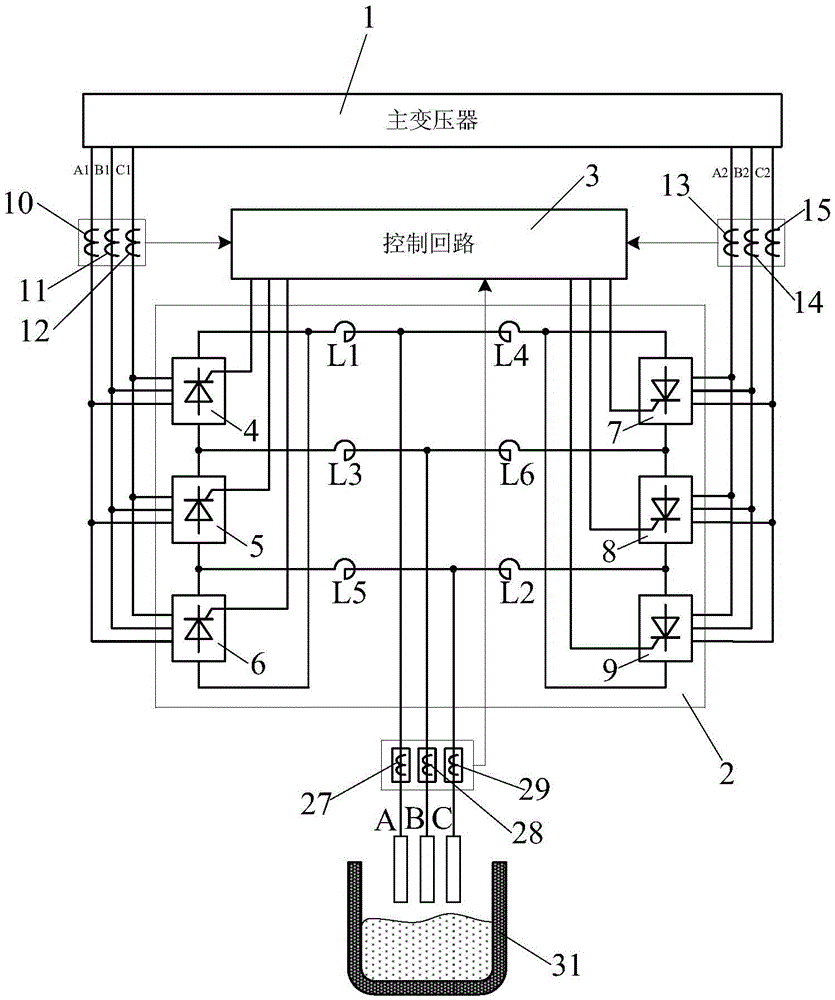

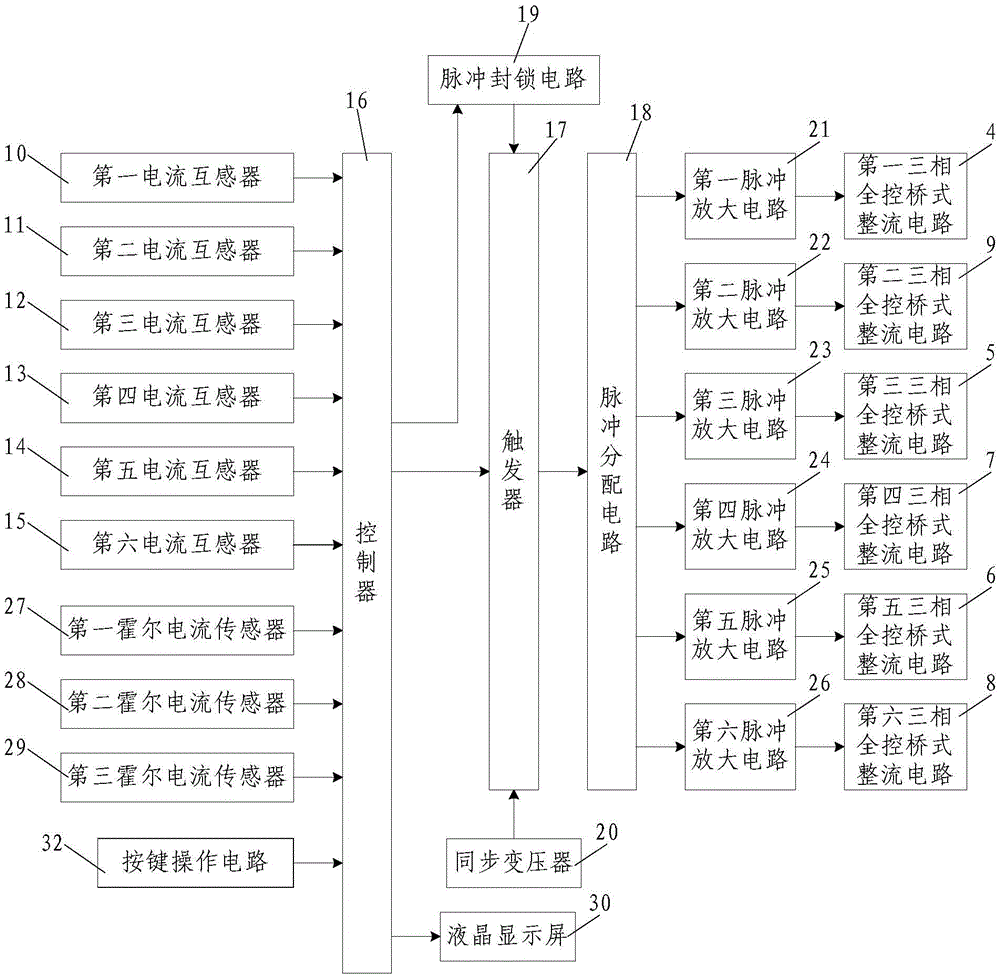

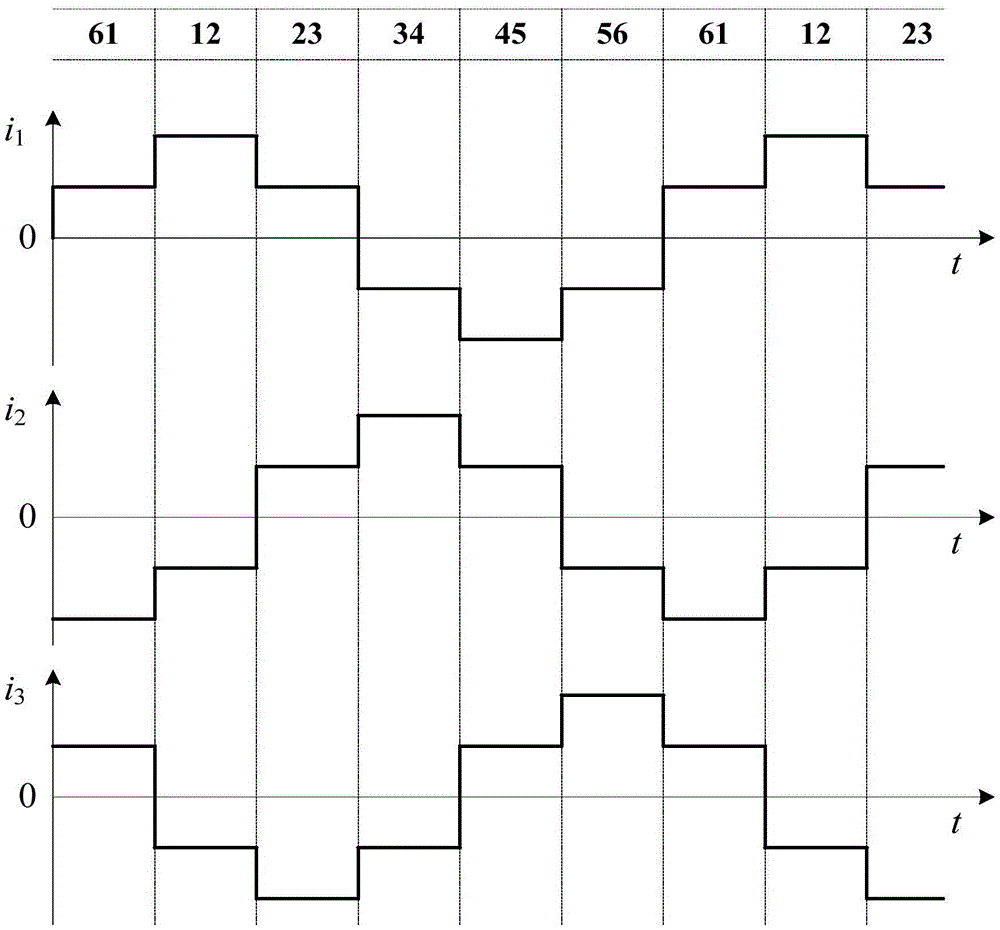

Three-phase controllable polar direct-current electric arc furnace power supply device

ActiveCN103840685ASimple structureNovel and reasonable designEfficient power electronics conversionAc-dc conversionDc arc furnaceElectrical polarity

The invention discloses a three-phase controllable polar direct-current electric arc furnace power supply device which comprises a main transformer, a main loop and a control loop. Secondary side windings of the main transformer comprise a first winding and a second winding. The main loop comprises a first three-phase fully-controlled bridge rectifier circuit, a third three-phase fully-controlled bridge rectifier circuit, a fifth three-phase fully-controlled bridge rectifier circuit, a second three-phase fully-controlled bridge rectifier circuit, a fourth three-phase fully-controlled bridge rectifier circuit and a sixth three-phase fully-controlled bridge rectifier circuit, wherein the first three-phase fully-controlled bridge rectifier circuit, the third three-phase fully-controlled bridge rectifier circuit and the fifth three-phase fully-controlled bridge rectifier circuit are connected with the first winding, and the second three-phase fully-controlled bridge rectifier circuit, the fourth three-phase fully-controlled bridge rectifier circuit and the sixth three-phase fully-controlled bridge rectifier circuit are connected with the second winding. The control loop comprises six current transformers, a trigger, a pulse distribution circuit, a pulse inhibition circuit, a synchronous transformer and six pulse amplifying circuits. The three-phase controllable polar direct-current electric arc furnace power supply device is simple in structure, convenient to use and operate and capable of accelerating the melting speed of a direct-current electric arc furnace, reduces heat shut-down, improves heat efficiency, prolongs the service life of a furnace body of the direct-current electric arc furnace, and is high in practicability and convenient to popularize and use.

Owner:高辉

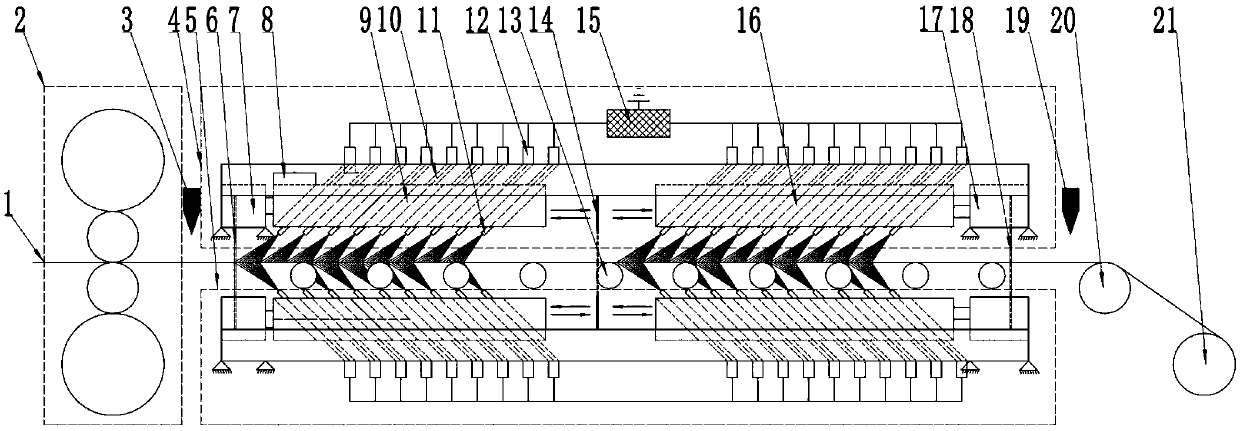

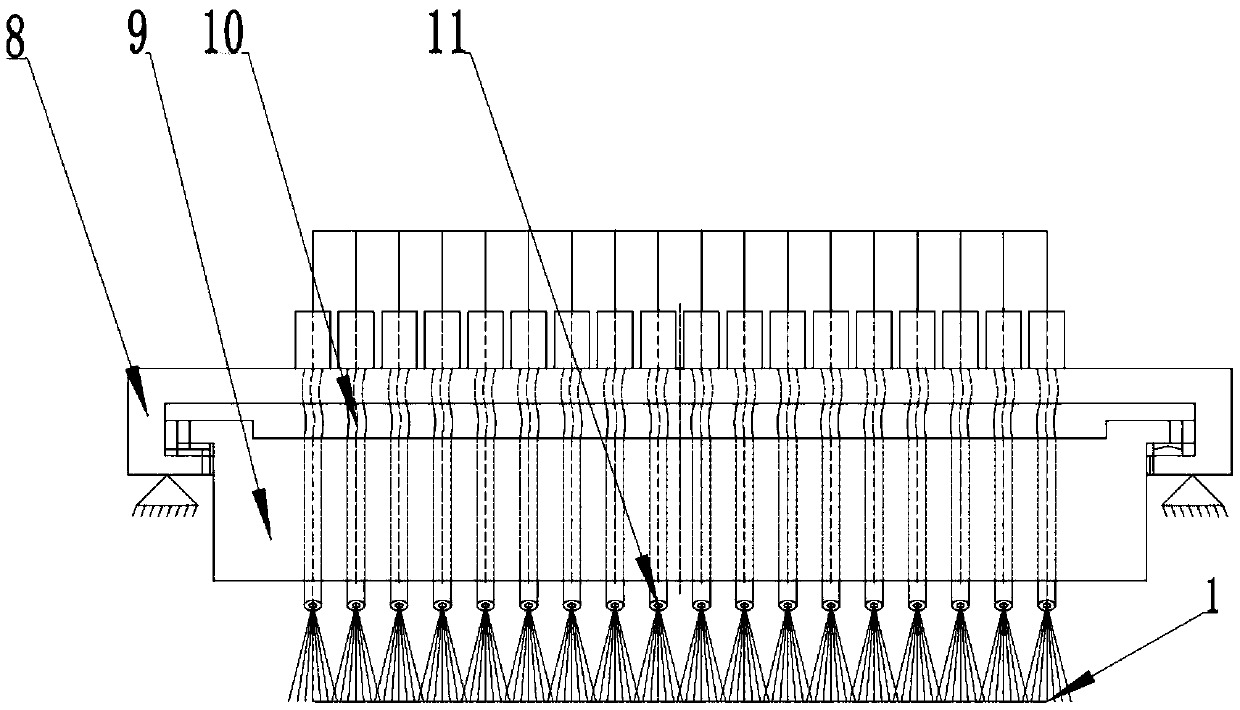

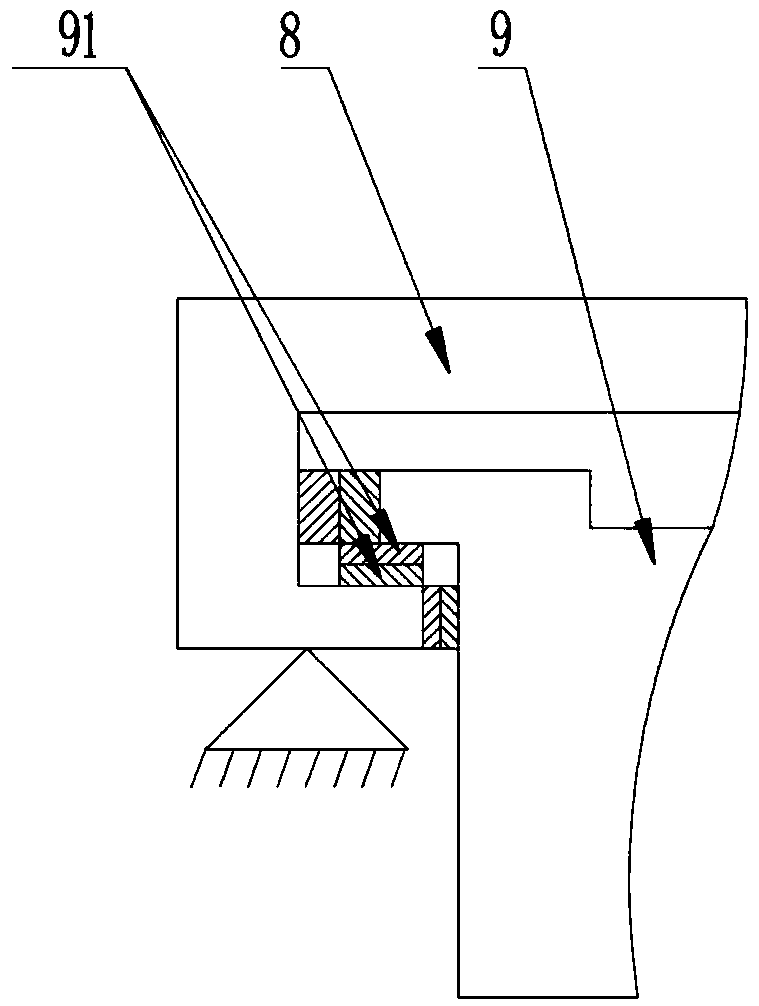

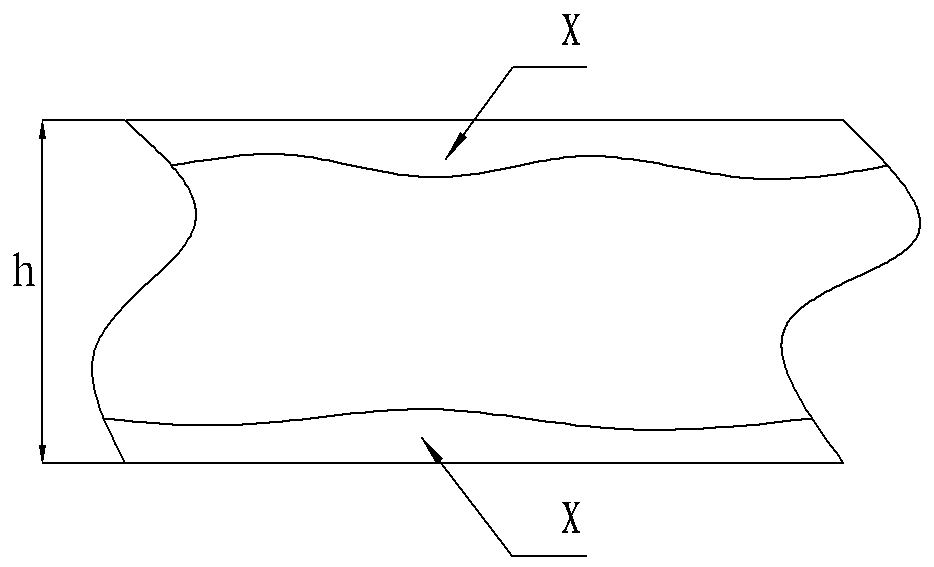

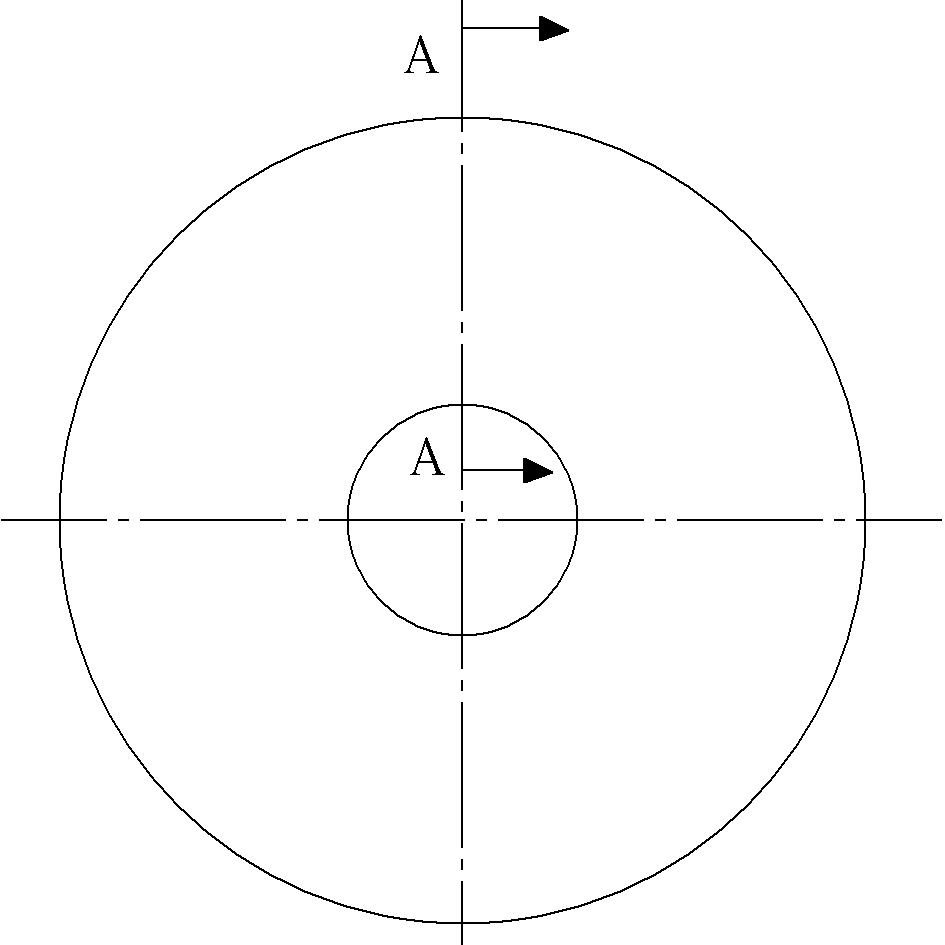

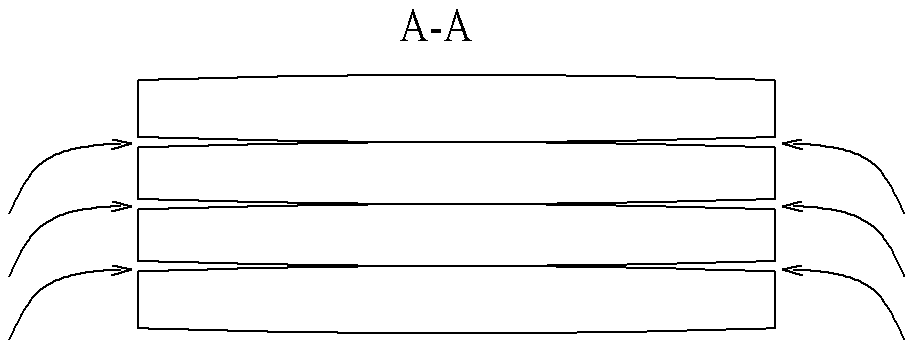

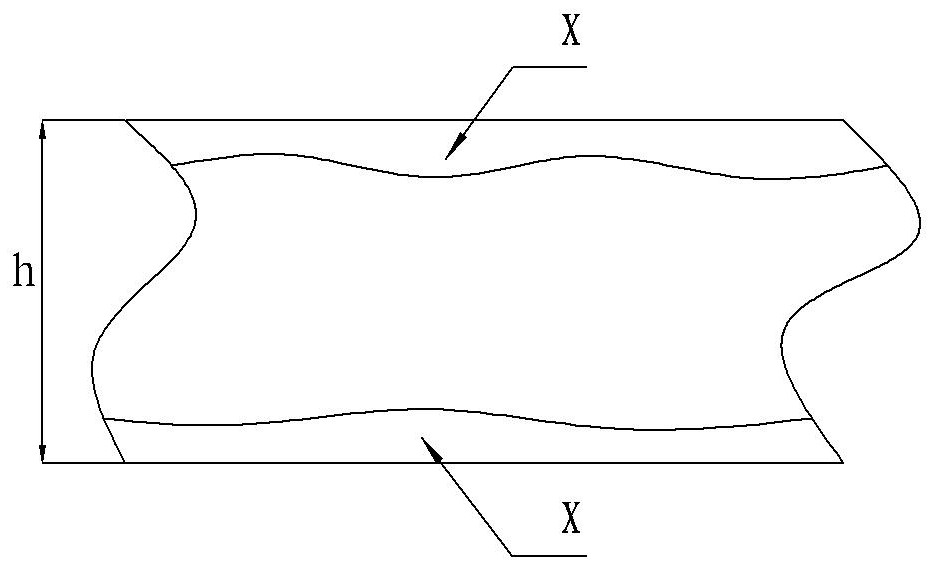

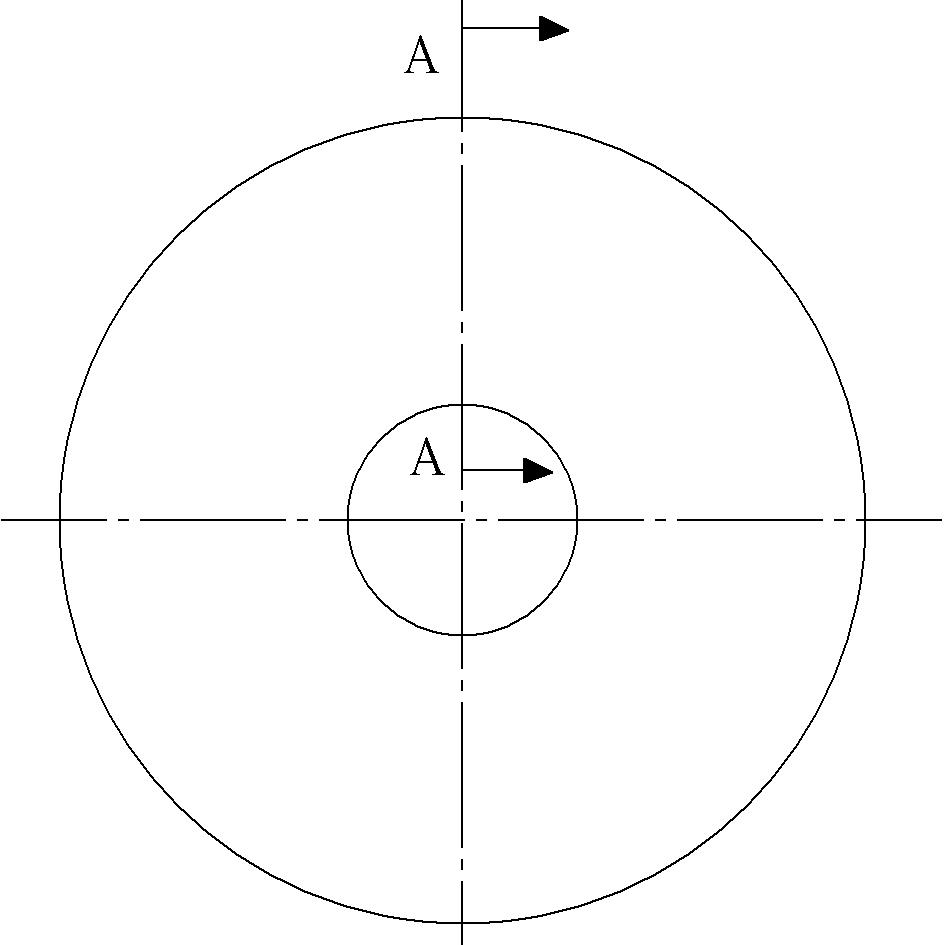

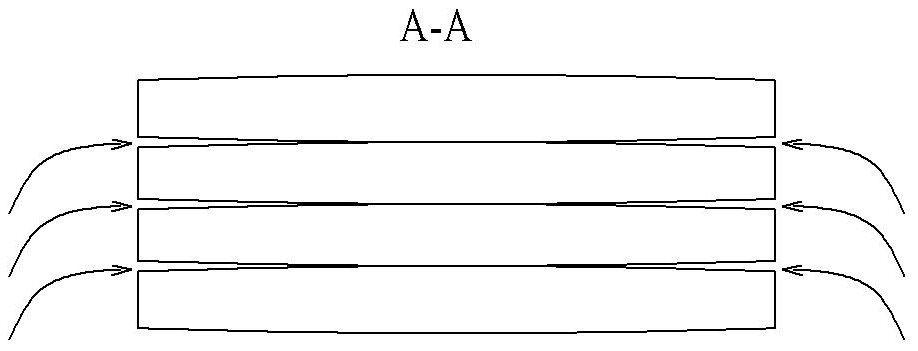

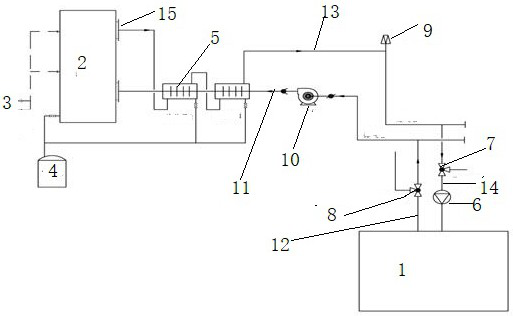

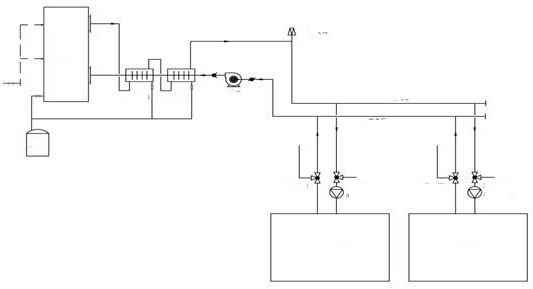

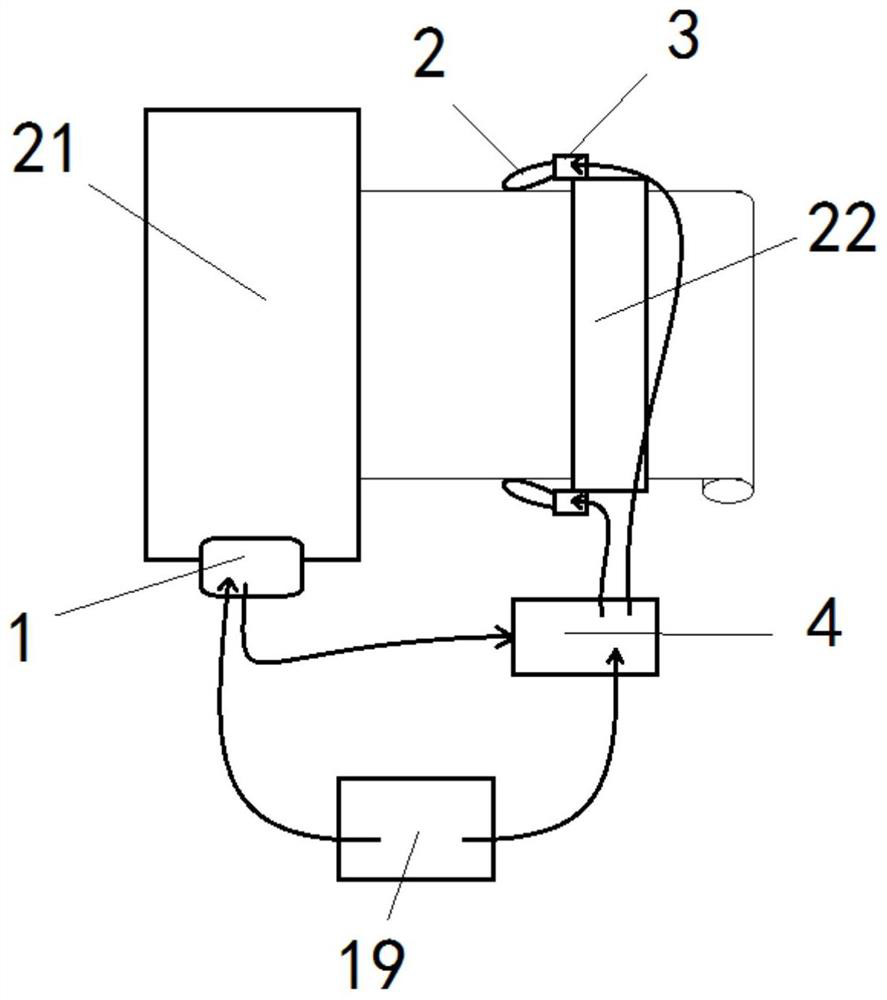

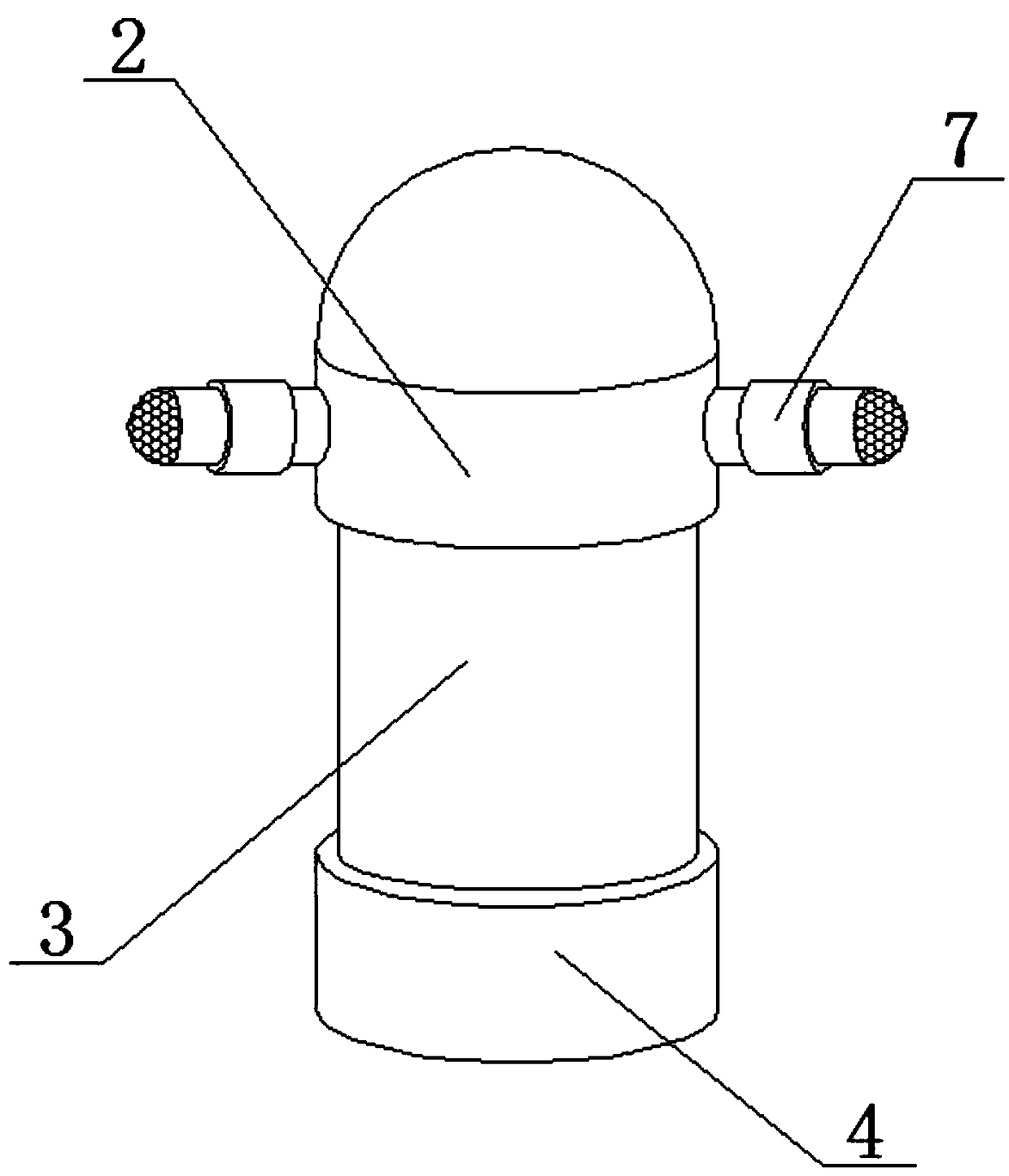

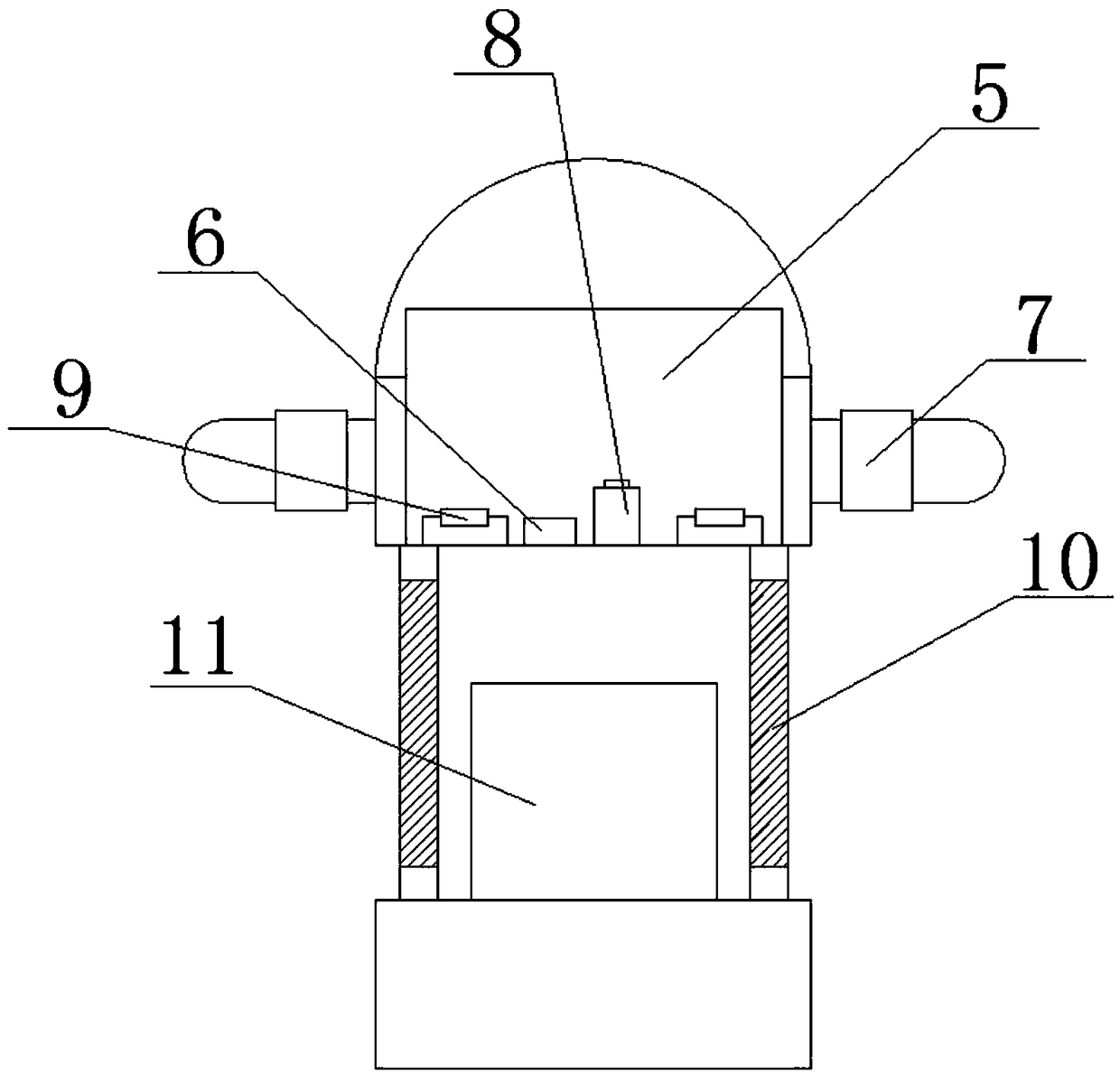

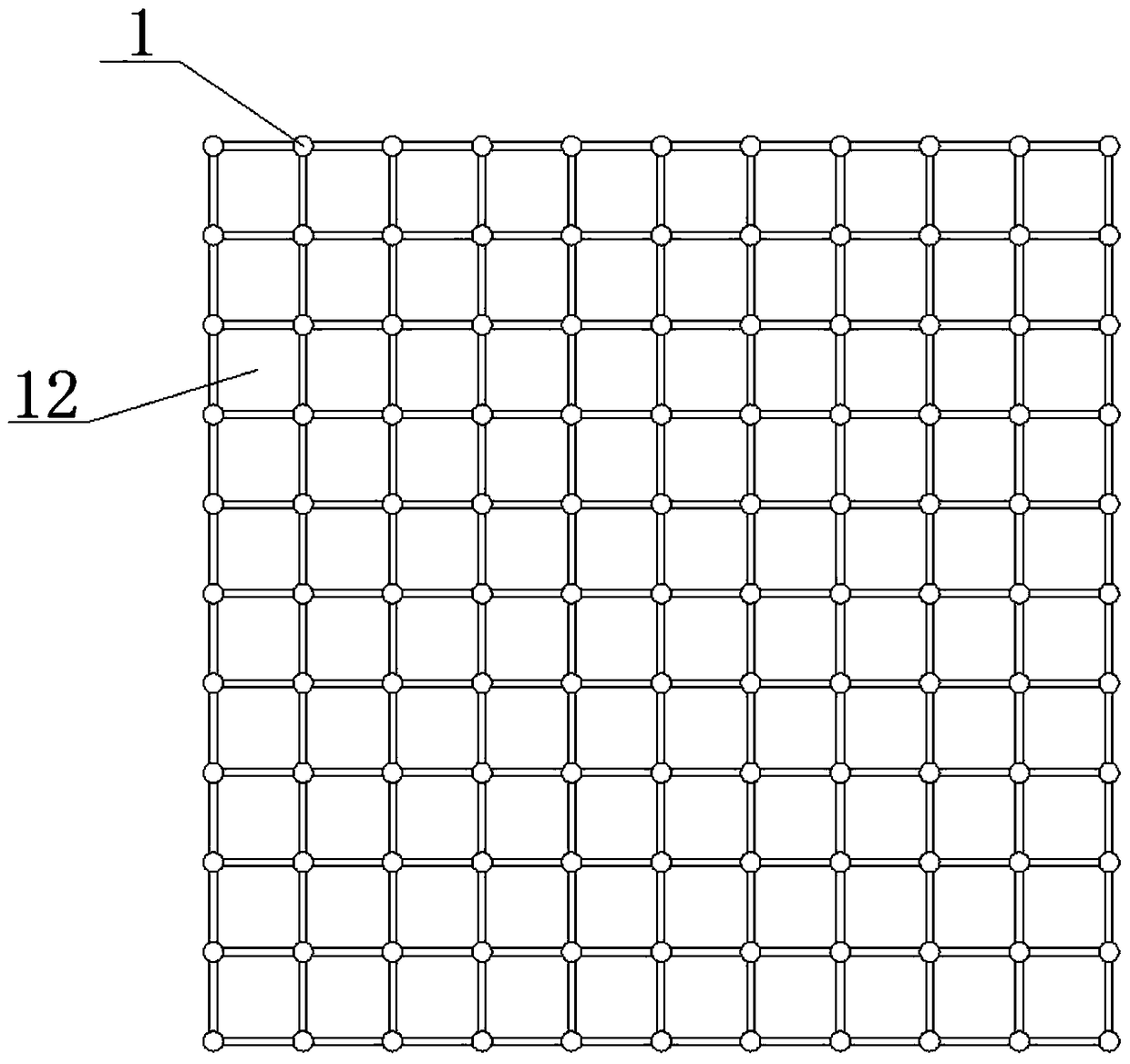

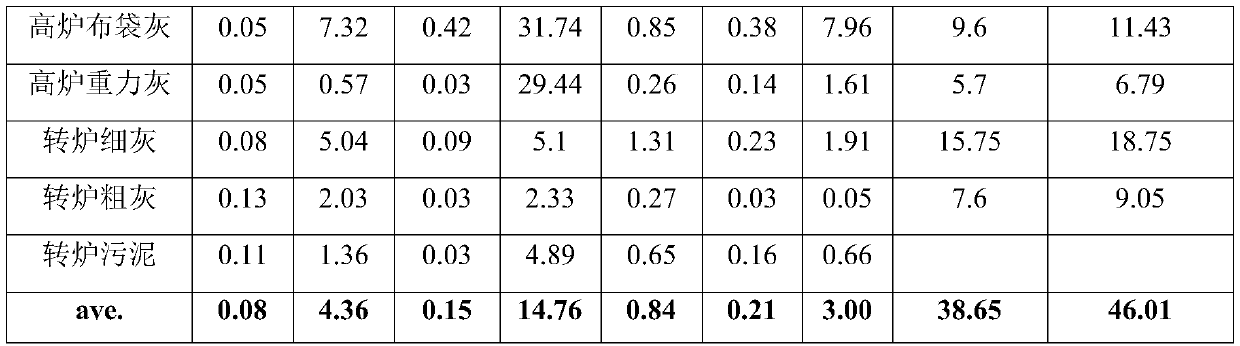

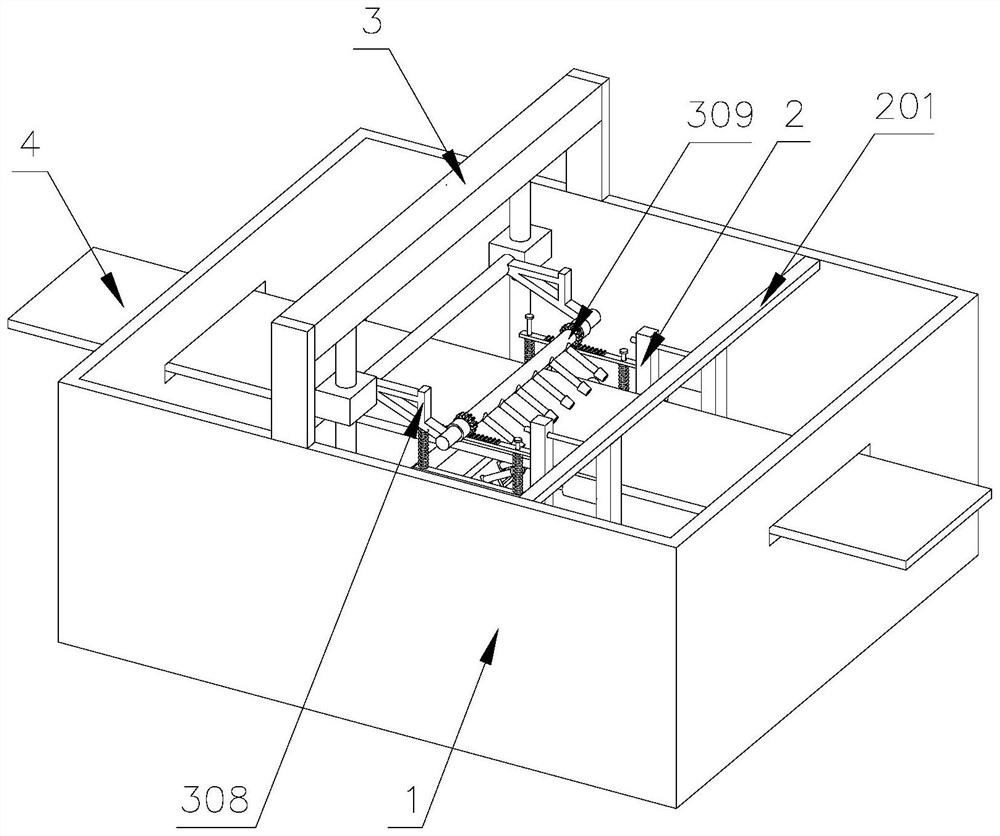

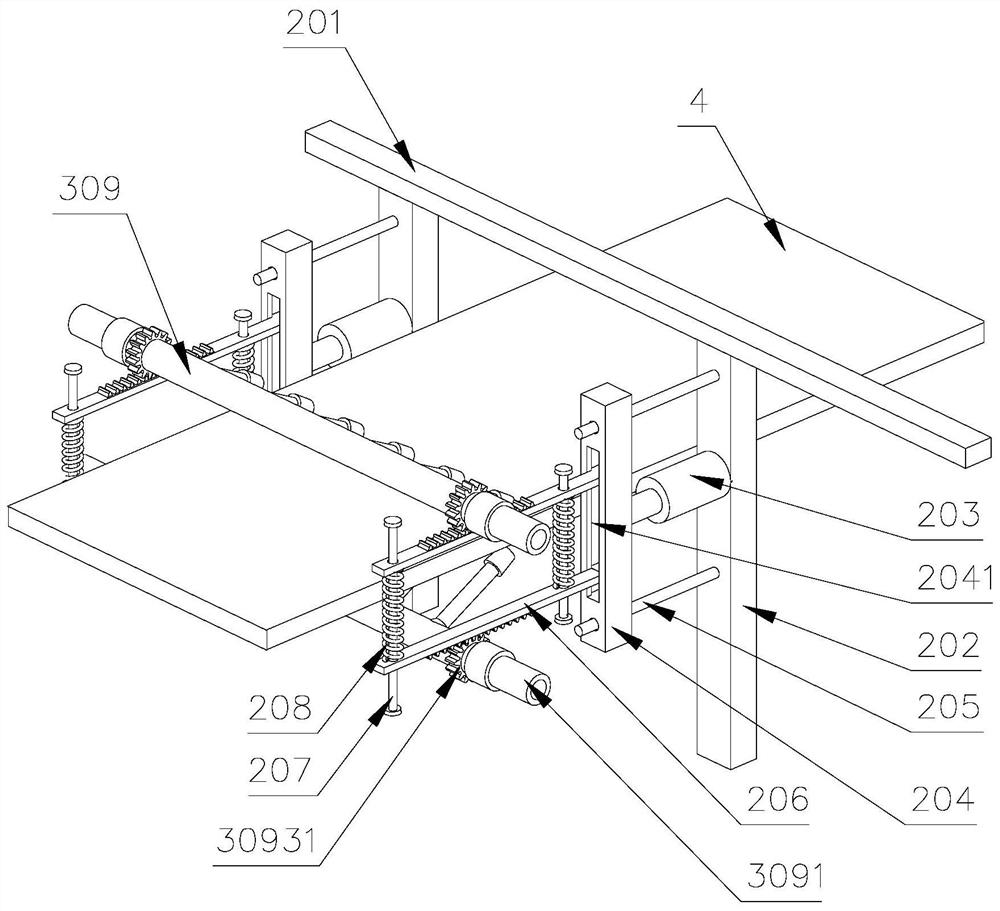

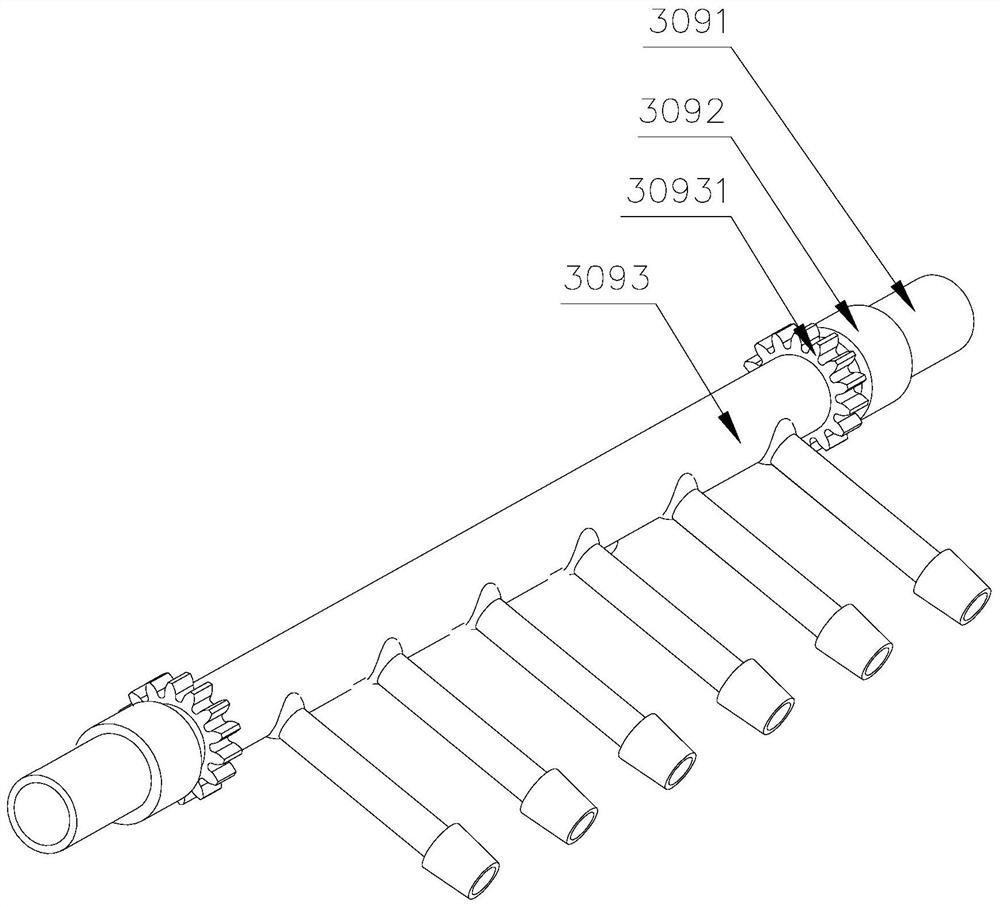

Hot rolled sheet strip liquid nitrogen ultrafast cooling device

ActiveCN109647914APrevent oxidationAvoid warmingTemperature control deviceMeasuring devicesWinding machineLiquid nitrogen container

The invention relates to a hot rolled sheet strip liquid nitrogen ultrafast cooling device. The hot rolled sheet strip liquid nitrogen ultrafast cooling device comprises thermo detectors, a controllerand a plurality of cooling sections connected between a finishing mill and a winding machine in series; the thermo detectors are located before an outlet of the finishing mill and the winding machine; each cooling section comprises an upper controlled cooling device and a lower controlled cooling device which are arranged on the two sides of a sheet strip, and the upper controlled cooling deviceand the lower controlled cooling device each comprise a controlled cooling transverse beam guide rail, a guide rail type supporting frame, slice nozzle assemblies, pressure nozzles, a displacement cylinder, a liquid nitrogen container, an infrared temperature measurement device and solenoid valves; the guide rail type supporting frames are slidably connected with the controlled cooling transversebeam guide rails and pushed by the displacement cylinders to move in the rolling direction; the multiple slice nozzle assemblies are fixed to the guide rail type supporting frames in the rolling direction, a plurality of pressure nozzles are fixed to the slice nozzle assemblies, inclined angles are formed between the nozzles and the rolling direction of the sheet strip, and the nozzles are connected with the liquid nitrogen containers through powder heat insulated pipes; the solenoid valves are arranged on the pressure nozzles and connected with the controller; and the two ends of the coolingsections are provided with the infrared temperature measurement devices.

Owner:北京秦冶众智科技有限公司

Method for eliminating annealing white spots on edge of cold-rolled aluminum coil

The invention discloses a method for eliminating annealing white spots on the edge of a cold-rolled aluminum coil, and relates to the technical field of aluminum alloy heat treatment. The method comprises the steps: A, when complete annealing is about to be carried out, after the aluminum coil is pushed into an annealing furnace, filling the annealing furnace with high-purity inert gas, wherein the concentration of the inert gas reaches 90-98%; B, during annealing, increasing the temperature to 200 to 240 DEG C, preserving the temperature for 6 to 15 hours, and controlling the coiling tensilestress before annealing to be 25 MPa or more; C, after the heat preservation is finished, filling the annealing furnace with high-purity argon until the concentration of the inert gas in the furnace reaches 98-100%; and D, increasing the temperature to the target temperature for complete annealing, preserving the temperature, cooling to 200 DEG C or below along with the furnace, and discharging. Compared with the prior art, the method can solve the problem that the edge of an existing aluminum coil has white spot defects in the process of complete annealing.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

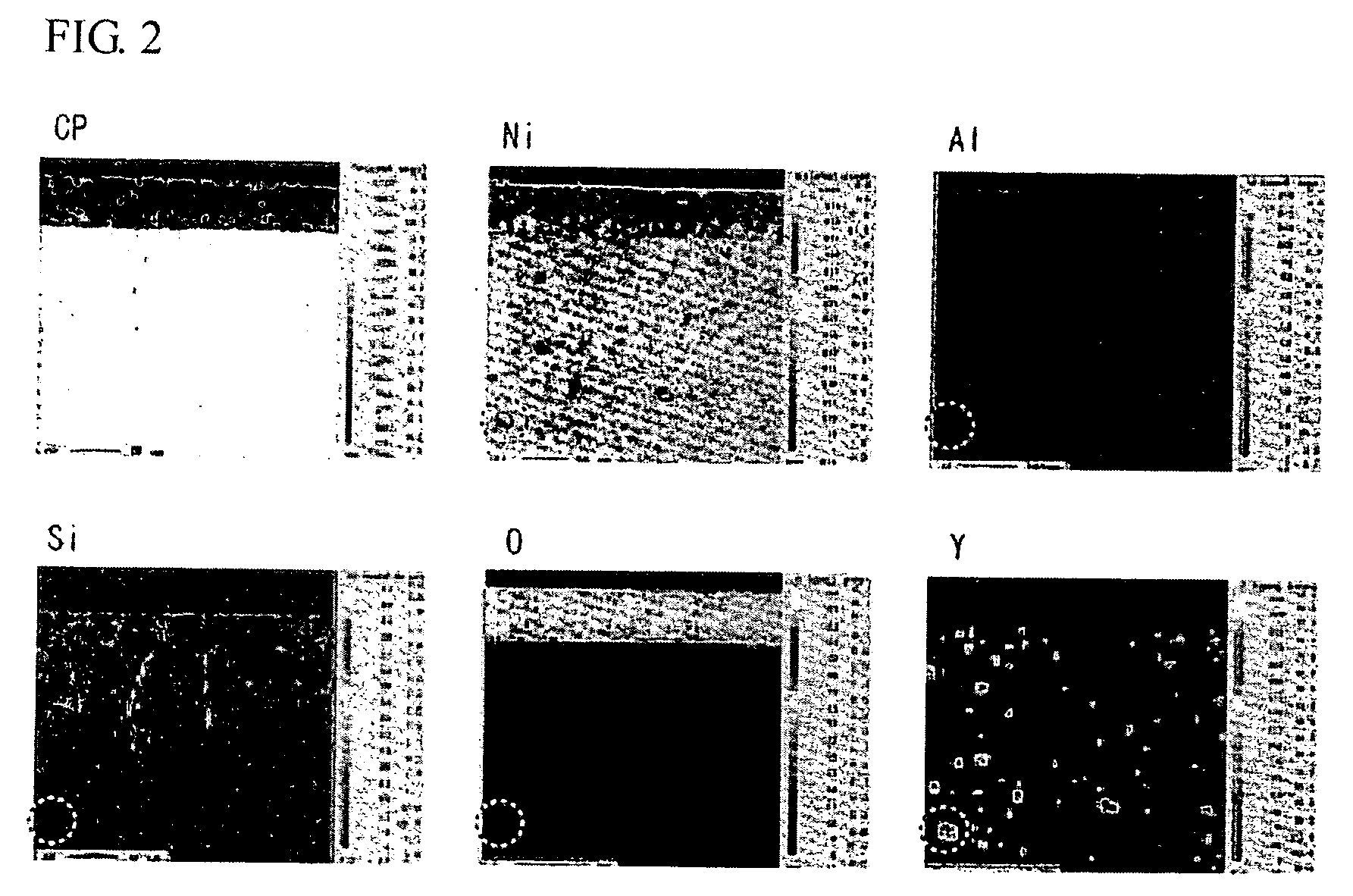

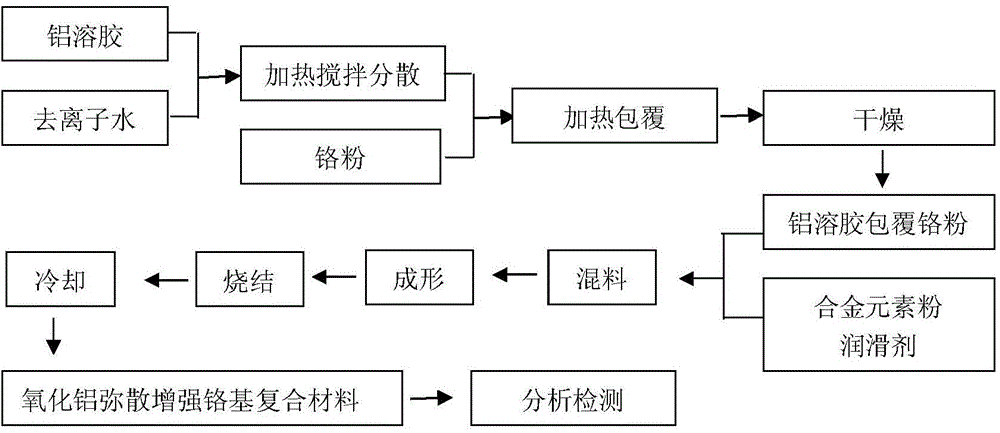

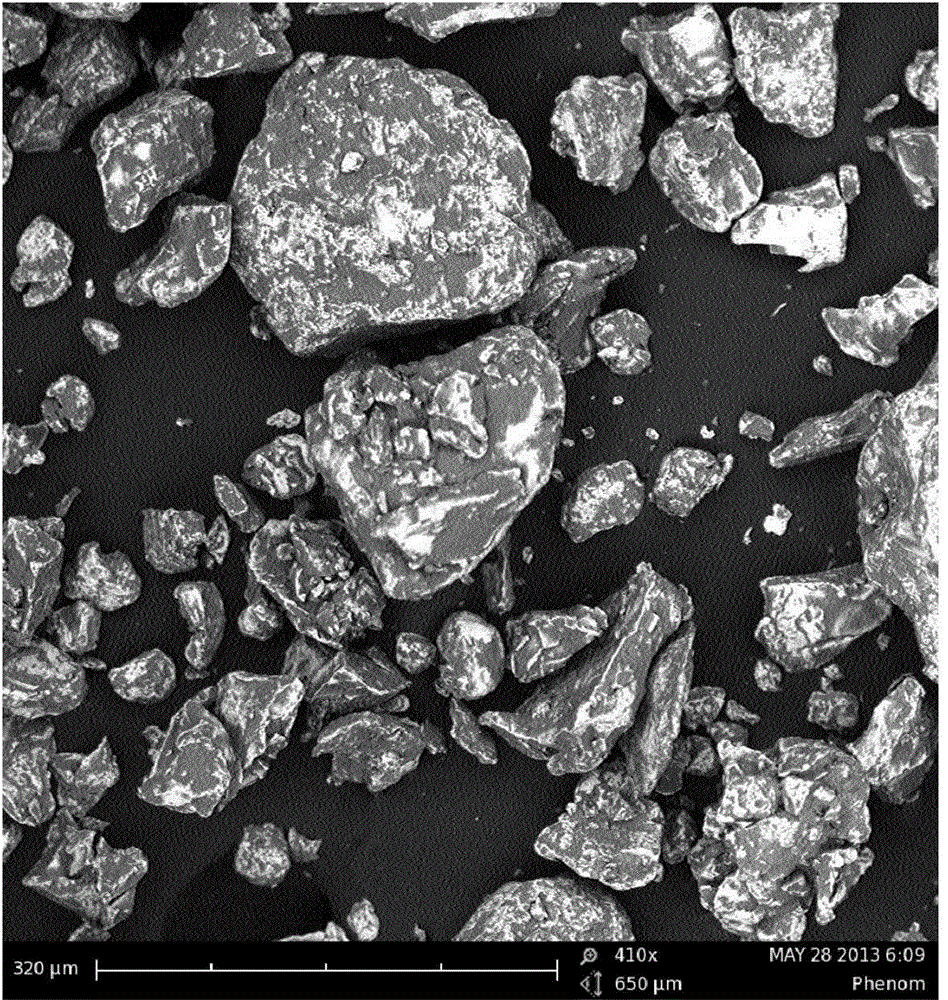

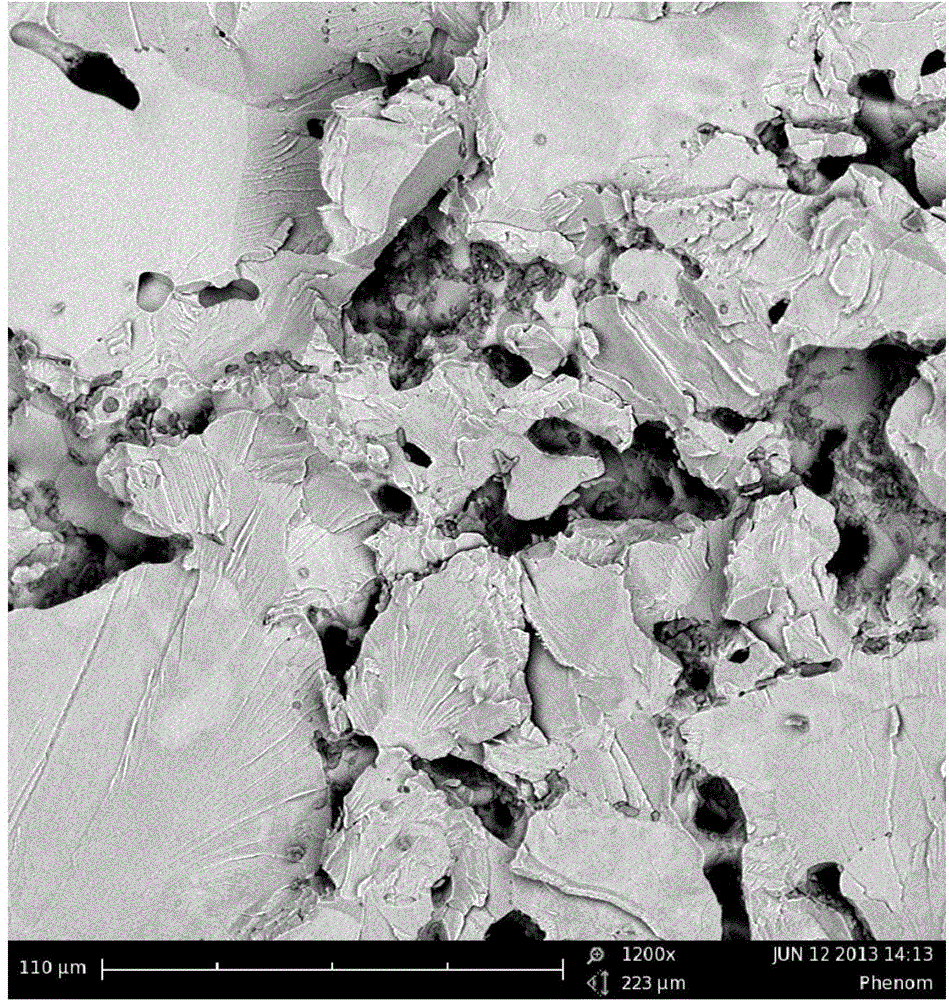

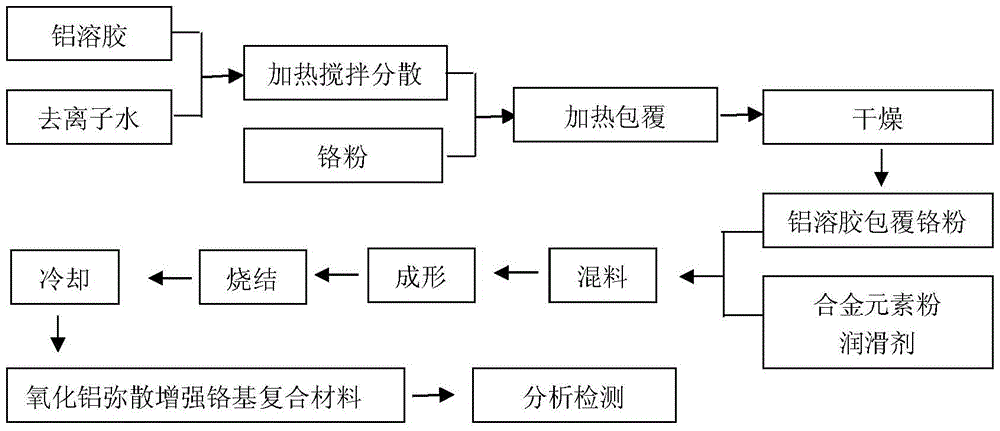

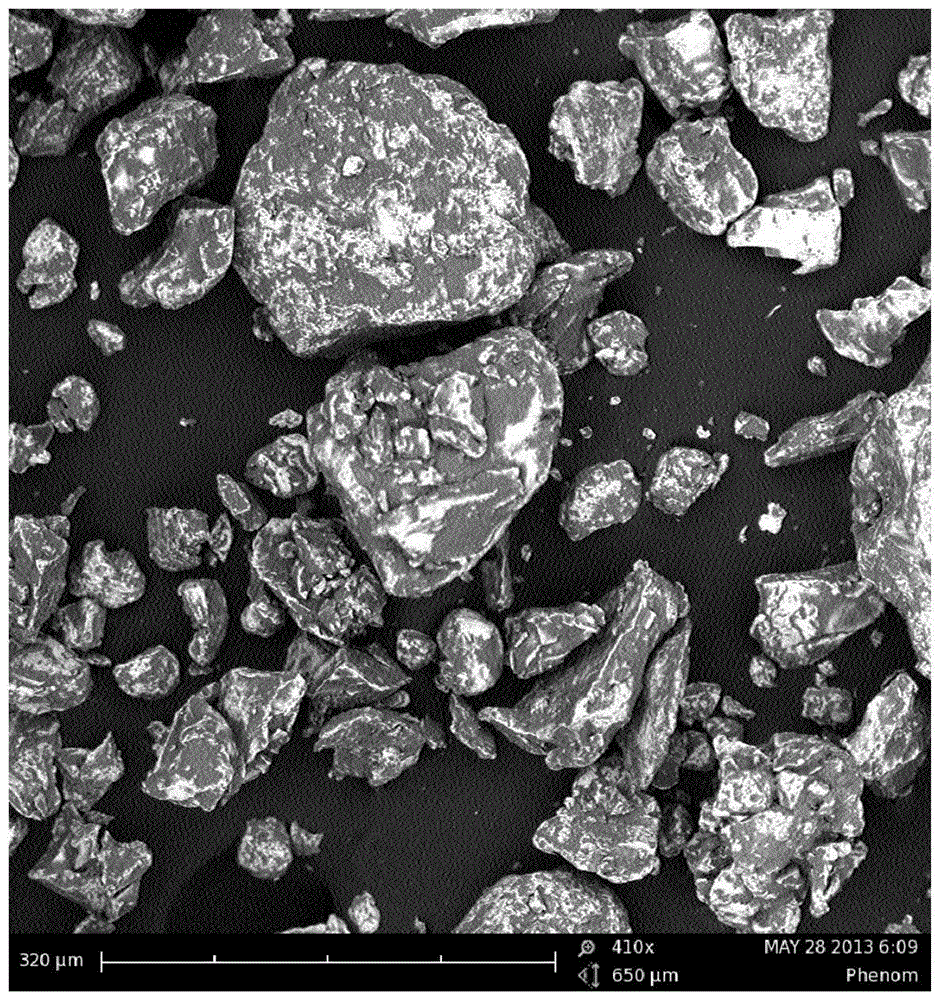

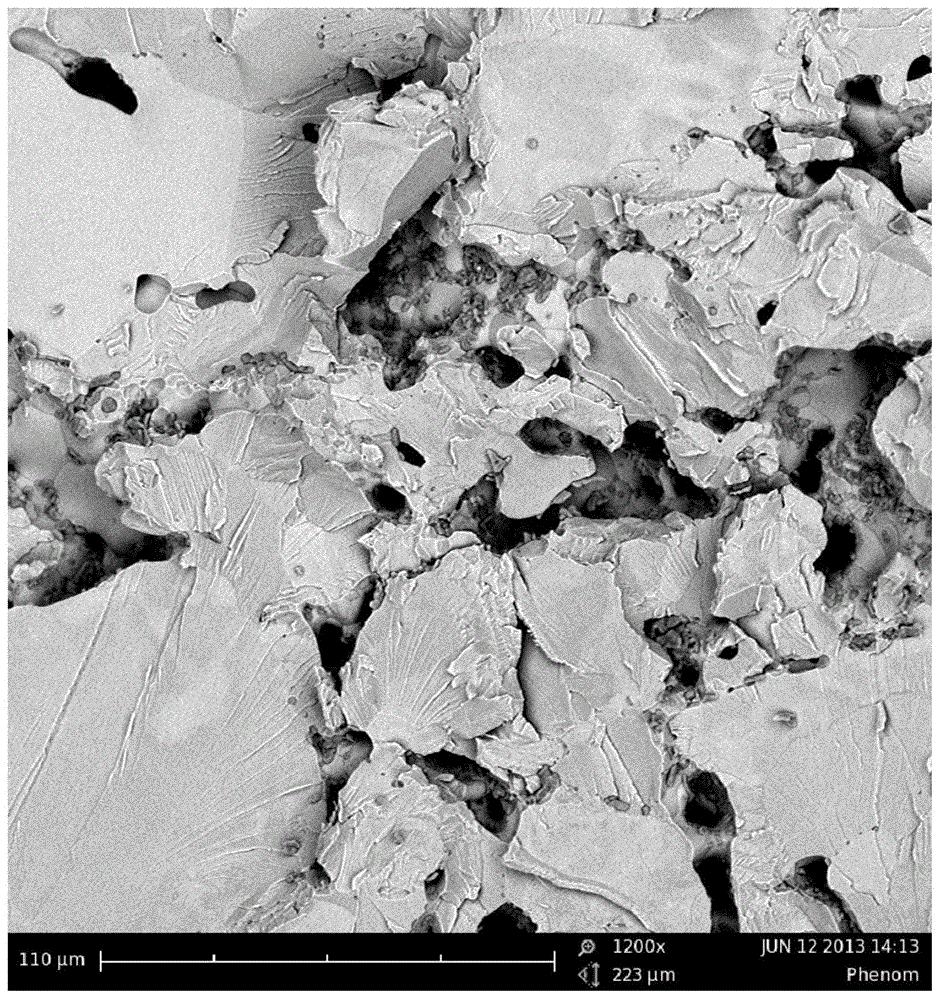

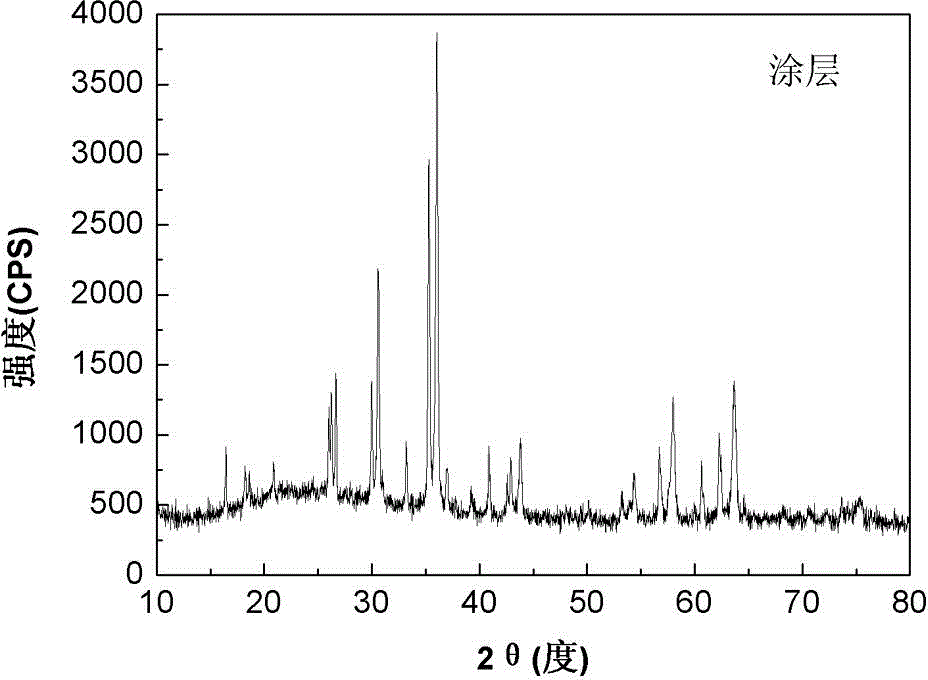

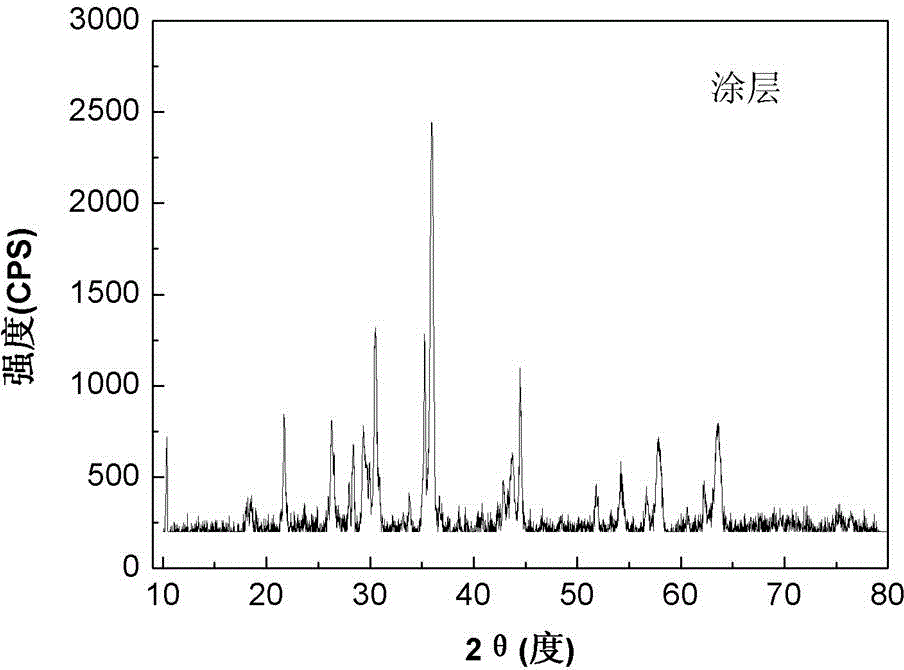

Method for preparing chromium-based composite material for connecting plate

ActiveCN104550965APrevent grain coarseningImprove high temperature resistanceCoatingsFuel cellsThermal expansion

The invention relates to a method for preparing a chromium-based composite material for a connecting plate. Aluminum oxide is adopted by the chromium-based composite material for replacing Yttrium oxide in a commercial Cr-5Fe-1Y2O3 material, the aluminum oxide in a submicron level can be uniformly and dispersedly arranged in a chromium-based body, chromium oxide crystalline grains are prevented from being thickened and enlarged, and high-temperature oxidation of chromium is slowed down. The method comprises the preparing steps of firstly, preparing aluminum sol coating chromium powder; then mixing the aluminum sol coating chromium powder with alloying elements and a lubricating agent; then, forming in a pressing way; finally, cooling after high-temperature sintering. According to the method for preparing the chromium-based composite material for the connecting plate, disclosed by the invention, the technology is simple, and the prepared chromium-based composite material has excellent high temperature-resisting performance and corrosion resistance; compared with existing commercial Cr-5Fe-1Y2O2, the cost is low, meanwhile, the thermal expansion coefficient is close to that of other components of a solid fuel cell, large influence on assembling and use cannot be generated, the chromium-based composite material can be used as a connecting plate of a fuel cell and is a feasible material for replacing the Cr-5Fe-1Y2O2, and the chromium-based composite material is suitable for being produced in a large scale.

Owner:NBTM NEW MATERIALS GRP

Hot work die steel coated with coating and preparing method of hot work die steel

InactiveCN111155083AImprove high temperature performanceReduce high temperature wearMetallic material coating processesHigh entropy alloysHot work

The invention belongs to the field of materials, and particularly discloses hot work die steel coated with a coating. A hot work die steel base body and the coating arranged on the hot work die steelbase body are included. The coating is mainly composed of TiC and a high-entropy alloy, and the high-entropy alloy is a high-entropy alloy FeMnCrNiCo. According to the hot work die steel, the high-entropy alloy serves as a basis, TiC serves as an enhancing phase, the laser cladding technology is utilized, fusion covering of FeMnCrNiCo high-entropy alloy powder and TiC is conducted on the hot workdie steel, the hot work die steel has better high-temperature performance, and high-temperature abrasion and high-temperature oxidation in the high-temperature work environment can be effectively reduced. The comprehensive performance of the hot work die steel coated with the coating is excellent, the hot work die steel can bear huge impact force during work and can bear contact with high-temperature metal, and repeated heating and cooling can be achieved.

Owner:珠海华瑞达电子科技有限公司

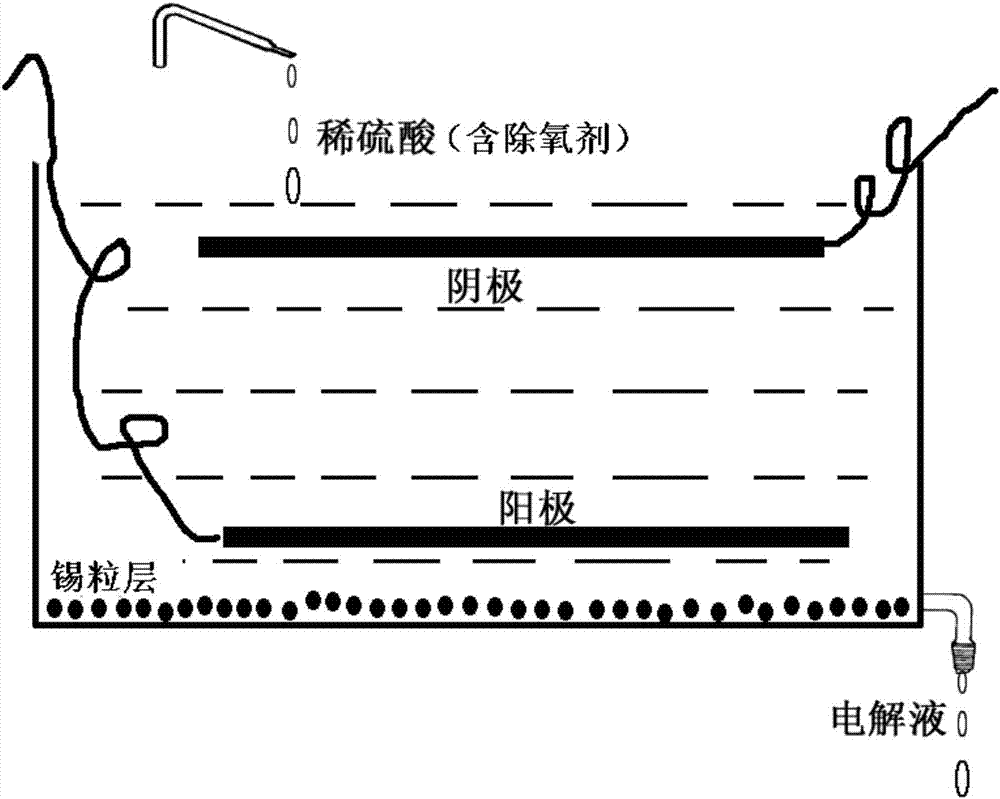

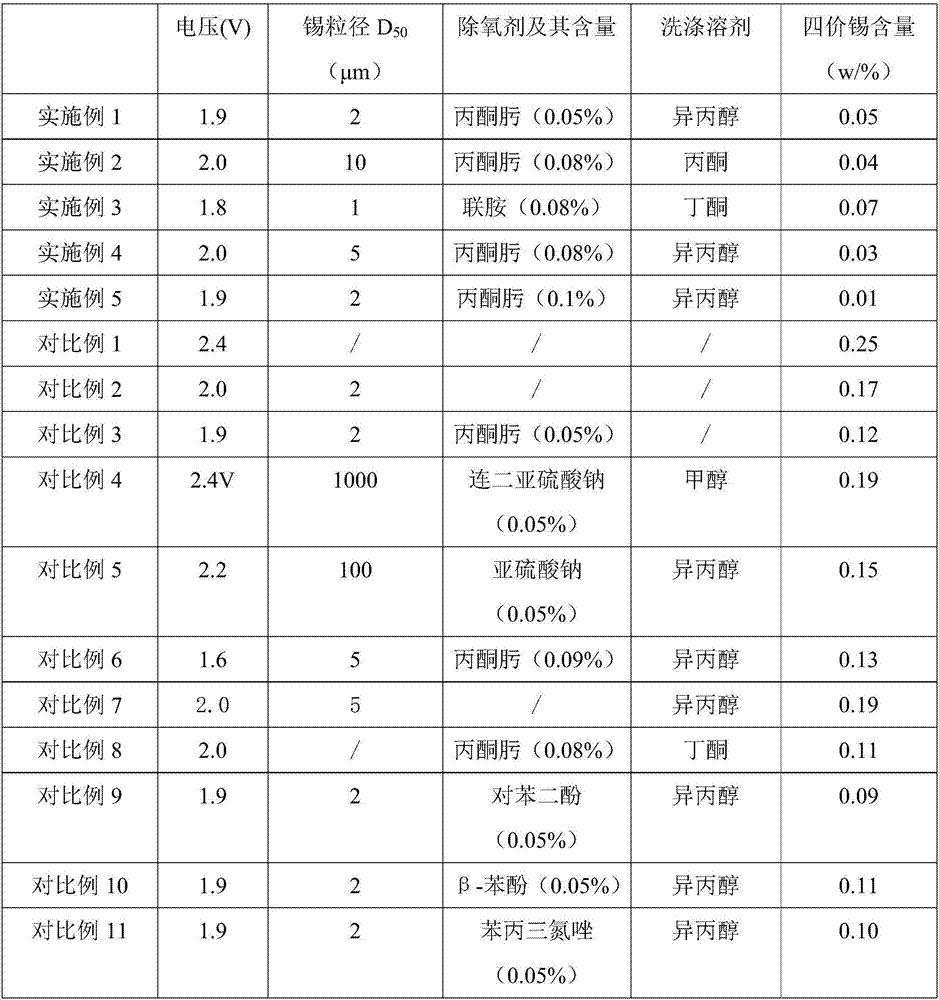

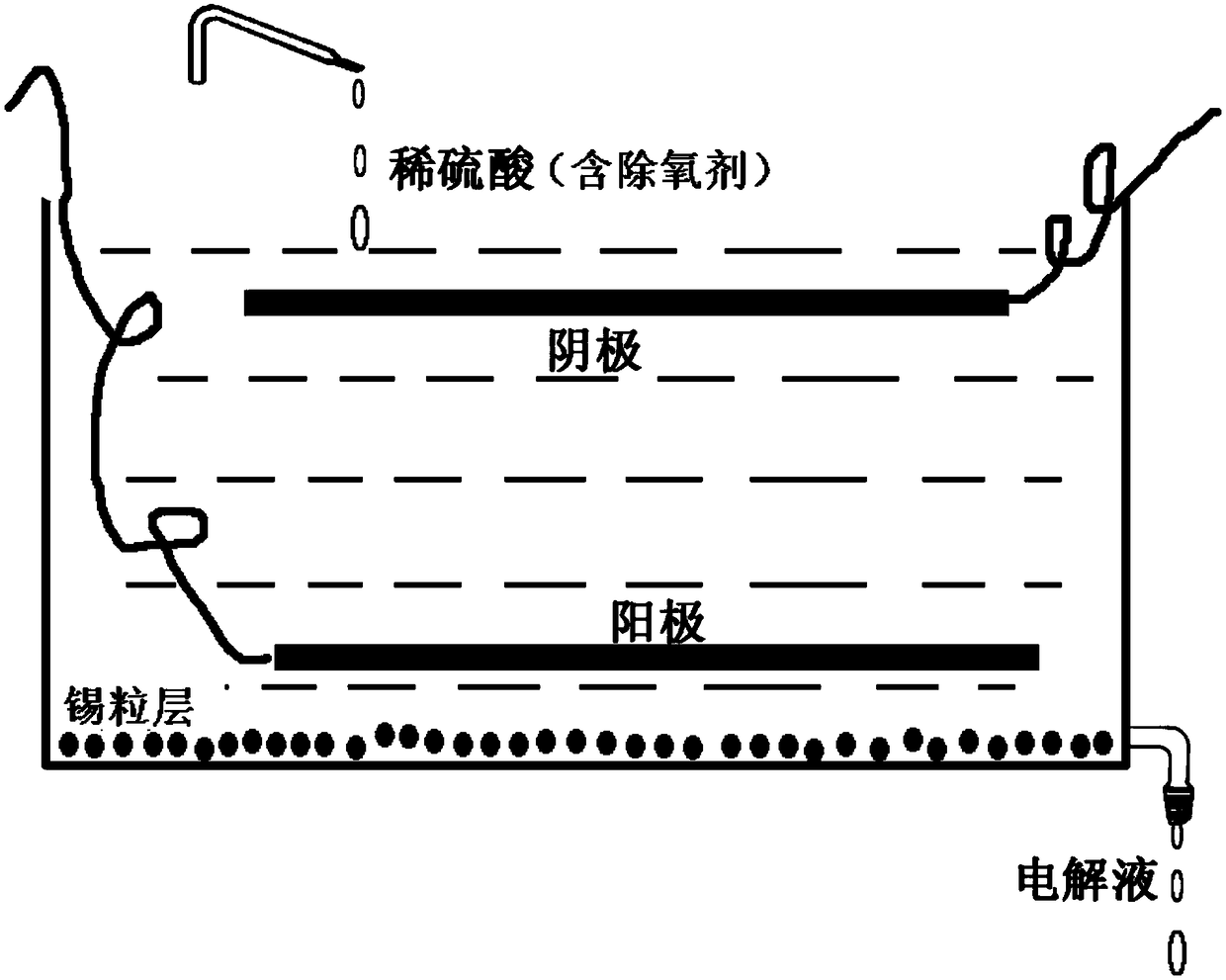

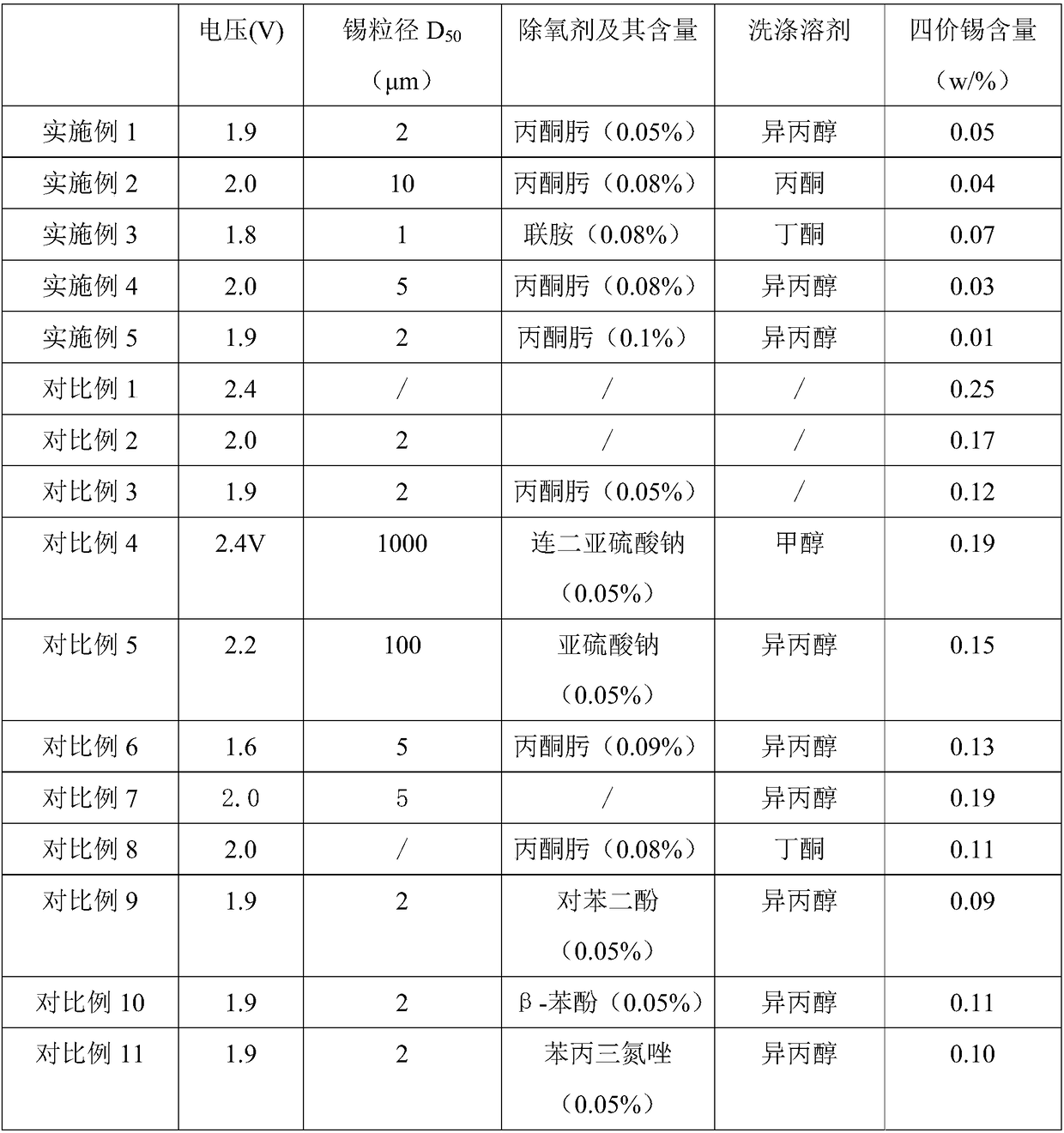

Method for reducing content of tetravalent stannum in stannous mono-sulphate

ActiveCN107385469ALarge specific surface areaImprove qualityElectrolysis componentsTinCrystallization

The invention discloses a method for reducing the content of tetravalent stannum in stannous mono-sulphate. The method for reducing the content of the tetravalent stannum in the stannous mono-sulphate comprises the following steps that a stannum granular layer is laid in the bottom of a stannous mono-sulphate electrolytic tank; a deoxidant is added into a dilute sulphuric acid, and the treated dilute sulphuric acid is obtained; the treated dilute sulphuric acid is added into the stannous mono-sulphate electrolytic tank till the liquid level of the treated dilute sulphuric acid is higher than a cathode by 2-4 cm, and the voltage of the electrolytic tank is controlled to be lower than 2.4 V; when the content of stannum ions in an electrolyte at the bottom of the stannous mono-sulphate electrolytic tank is greater than or equal to 85 g / L, the electrolyte is discharged out of the tank from an outlet, and the treated dilute sulphuric acid is supplement into the tank to maintain the liquid level of tank liquid to be an original height while the electrolyte is discharged; when the content of the stannum ions in the electrolyte at the bottom of the stannous mono-sulphate electrolytic tank is decreased to 80 g / L, discharging of the electrolyte and supplementing of the treated dilute sulphuric acid are stopped; and the electrolyte is subjected to condensation crystallization, obtained crystals are eluted by using an eluting agent and then dried, and the stannous mono-sulphate is obtained.

Owner:FINE CHEM GRP

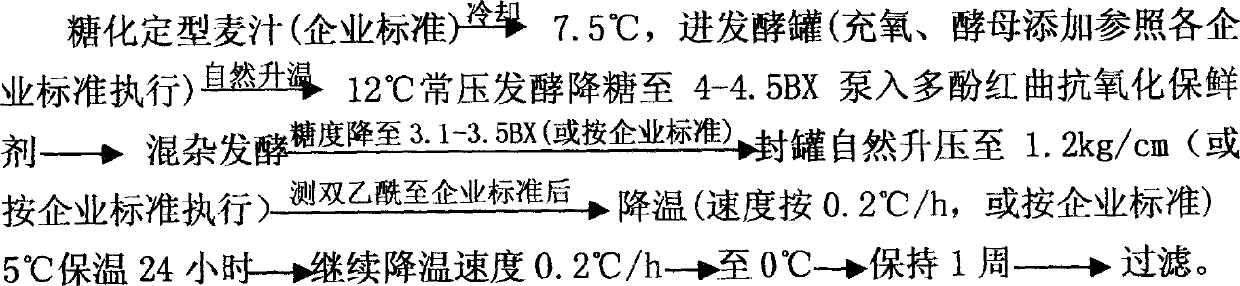

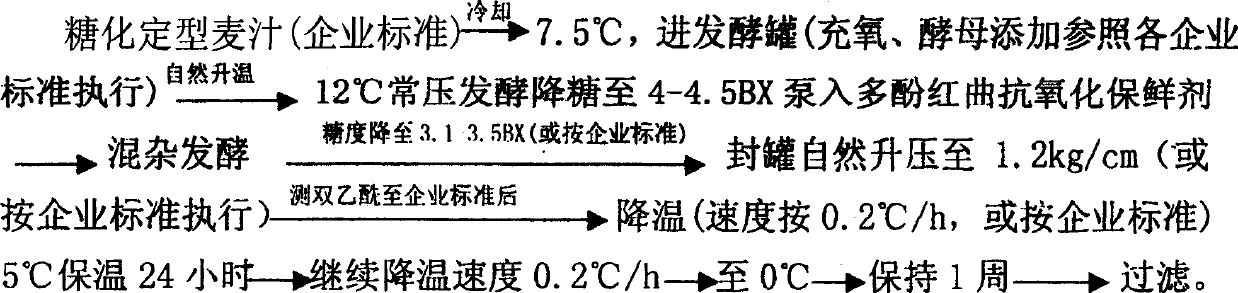

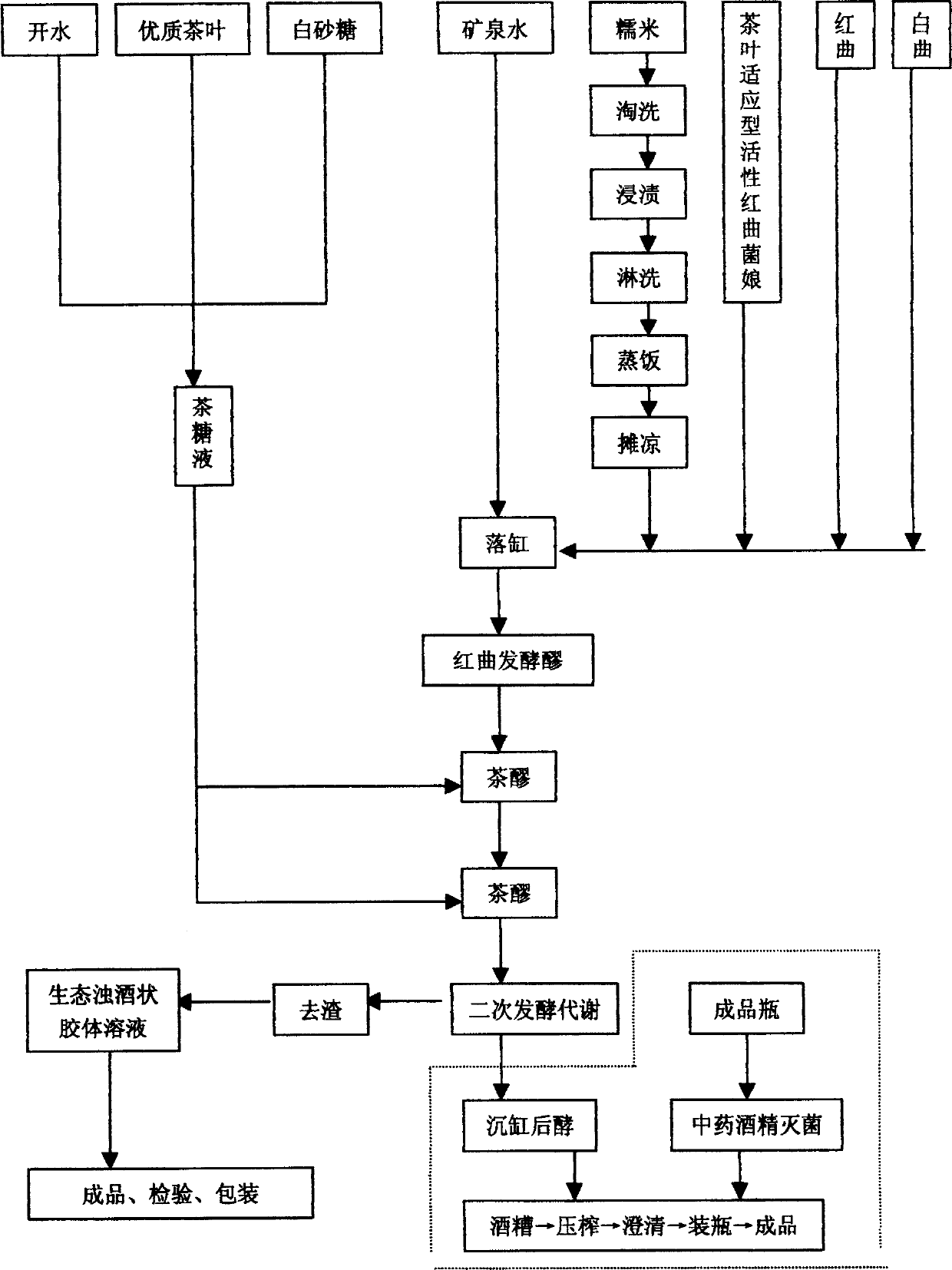

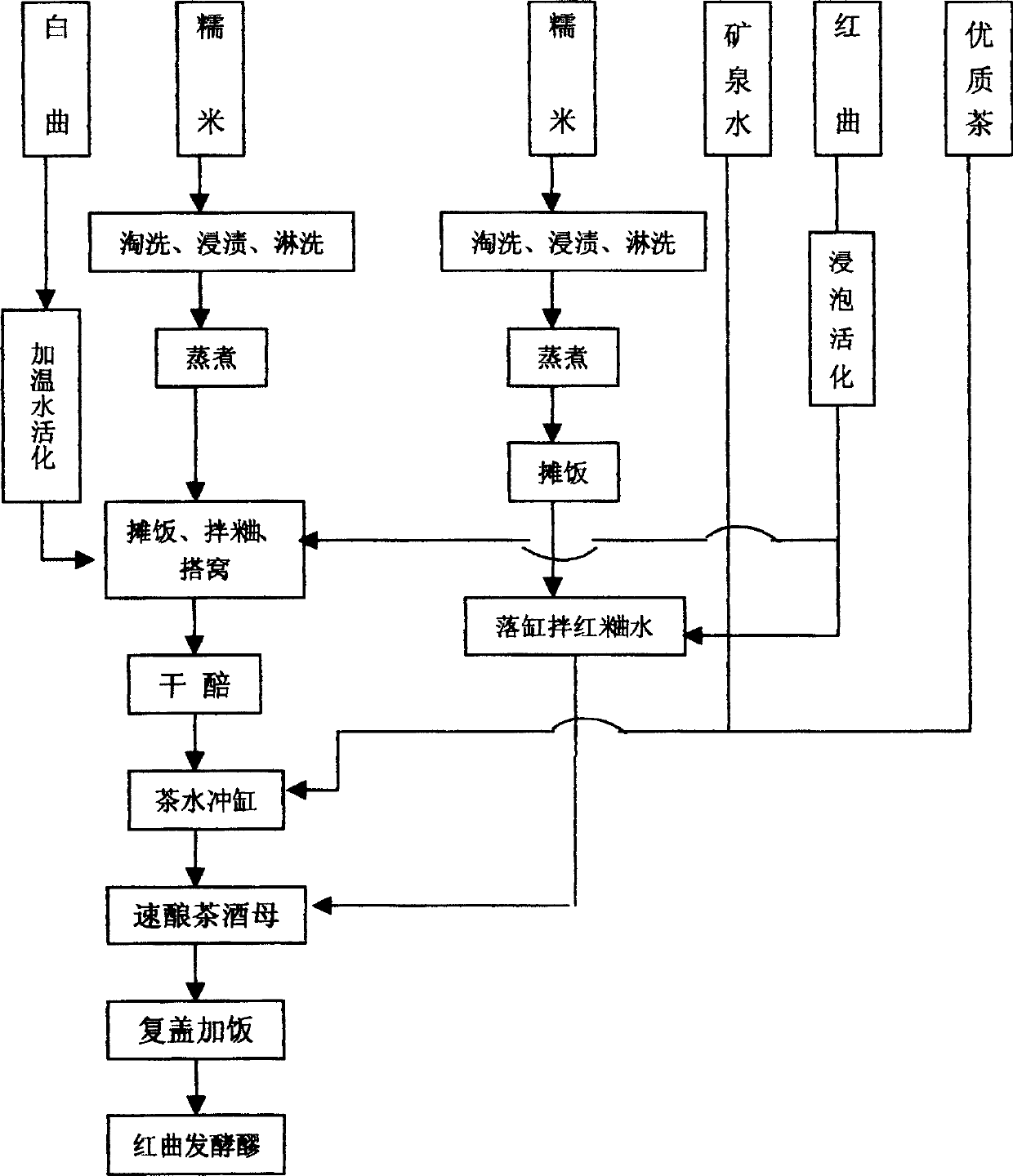

Polyphenol red koji antioxidant preservative and its application technology

InactiveCN1417321AGood for healthMaintain healthFood preservationAlcoholic beverage preparationPreservativeColloid

The present invention relates to a functional fermentation technology, especially a polyphenol red koje antioxidant preservative and its application technology. It is developed on the basis of the patent technology of ZL94115941.8. The polyphenol red koje antioxidant preservative is prepared from tea, red koje, glutinous rice, sugar, white Qu and water and through fermentation. It contains tea polyphenol, tea pigment, red koji saccharomycete and other active matters and has the functions of antioxidation, resisting free radical, inhibiting bacteria, antisepticising, etc. It may be used as additive for wine, beverage and food, especially in brewing high-quality beer.

Owner:吴卫清

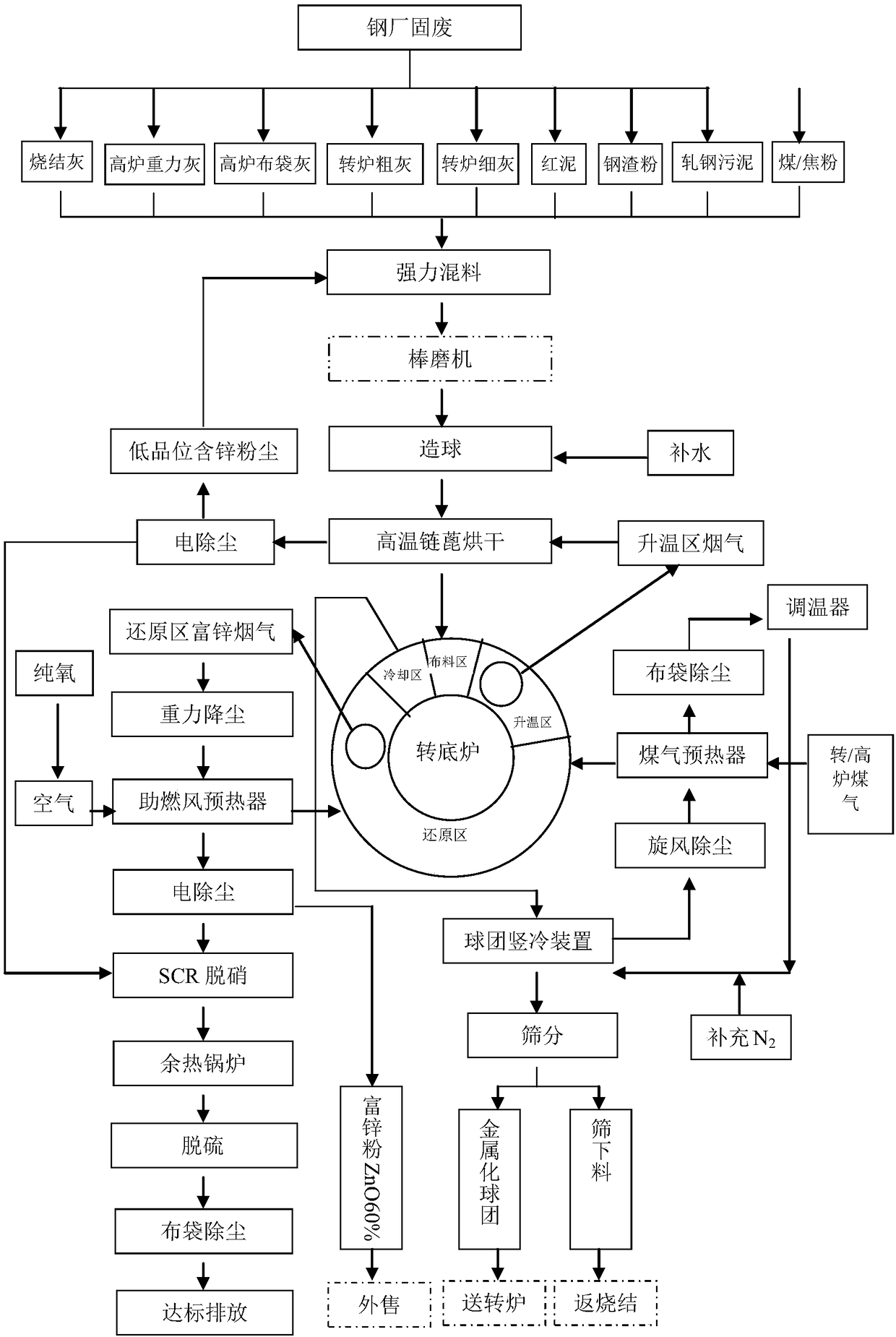

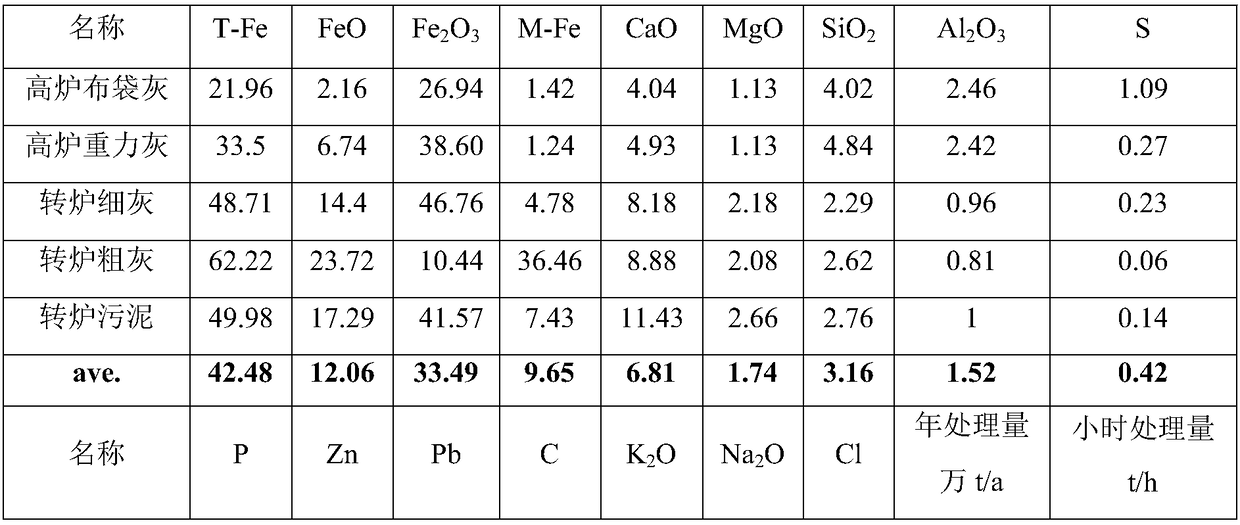

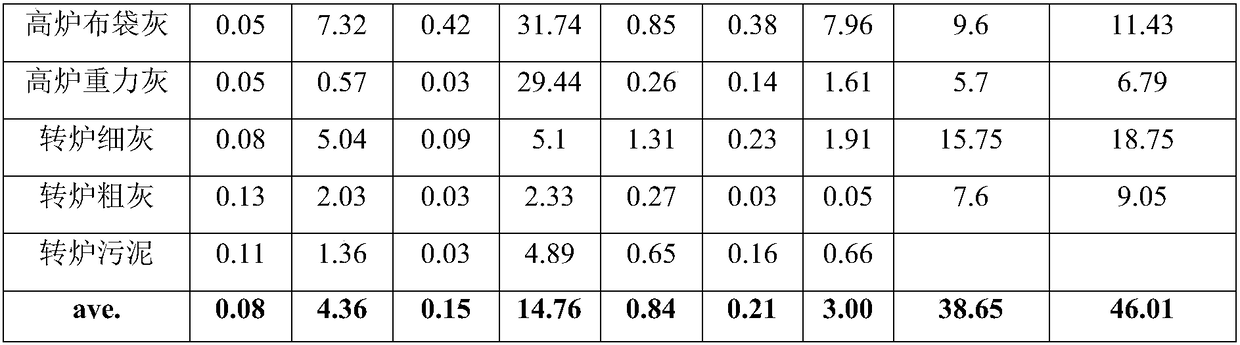

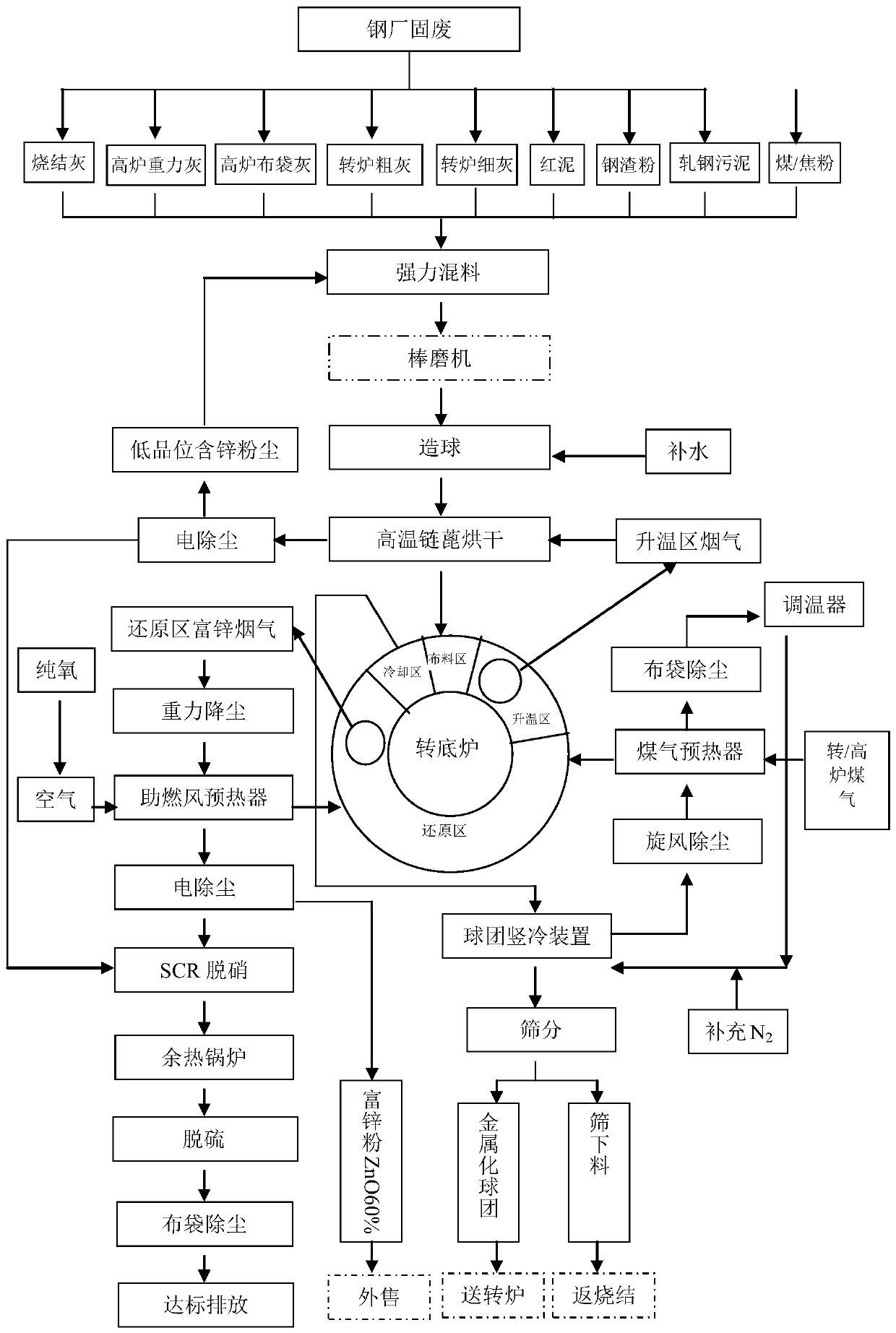

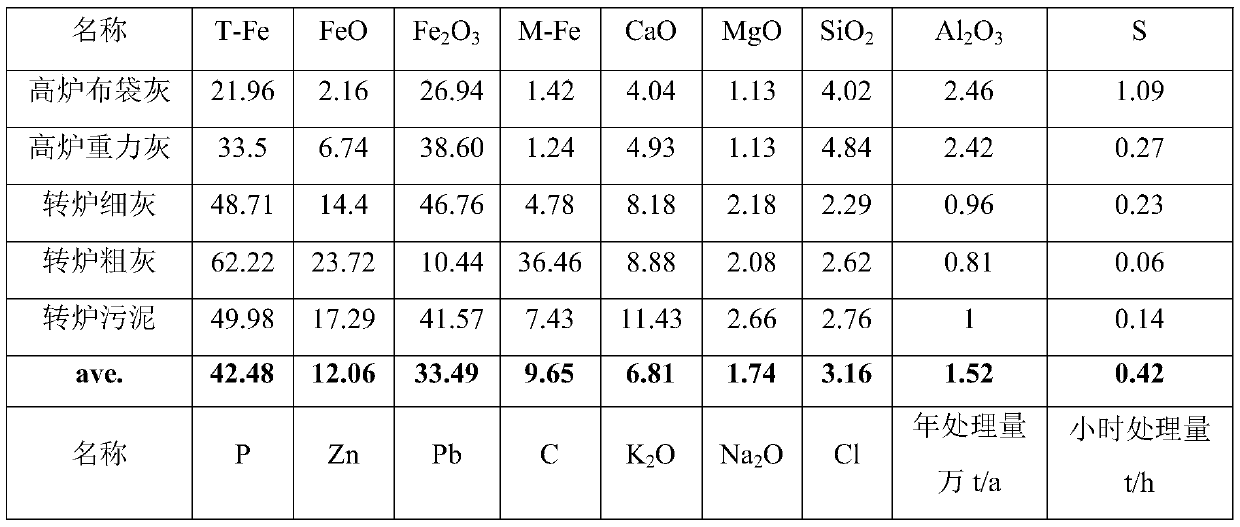

Method for treating solid waste through rotary hearth furnace

ActiveCN108611458AHigh strengthReduce pulverization rateRotary drum furnacesProcess efficiency improvementSteelmakingHearth

The invention relates to a method for treating solid waste through a rotary hearth furnace and belongs to the technical field of steel mill solid waste treatment. The problems that in the prior art, recycled zinc oxide powder is low in grade, and finished metallized pellets are high in pulverization rate are solved. The method for treating the solid waste through the rotary hearth furnace comprises the following steps of pelletizing, reduction and zinc-contained powder recycling, and a drying stage is further performed between the pelletizing and the reduction. The method for treating the solid waste through the rotary hearth furnace provided by the invention can be used for treating solid materials generated in the production processes of sintering, ironmaking and steelmaking.

Owner:钢研晟华科技股份有限公司

Elimination method of annealing white spots on the edge of cold-rolled aluminum

The invention discloses a method for eliminating annealing white spots on the edge of a cold-rolled aluminum coil, and relates to the technical field of aluminum alloy heat treatment. The method comprises the steps: A, when complete annealing is about to be carried out, after the aluminum coil is pushed into an annealing furnace, filling the annealing furnace with high-purity inert gas, wherein the concentration of the inert gas reaches 90-98%; B, during annealing, increasing the temperature to 200 to 240 DEG C, preserving the temperature for 6 to 15 hours, and controlling the coiling tensilestress before annealing to be 25 MPa or more; C, after the heat preservation is finished, filling the annealing furnace with high-purity argon until the concentration of the inert gas in the furnace reaches 98-100%; and D, increasing the temperature to the target temperature for complete annealing, preserving the temperature, cooling to 200 DEG C or below along with the furnace, and discharging. Compared with the prior art, the method can solve the problem that the edge of an existing aluminum coil has white spot defects in the process of complete annealing.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

Pretreating method for improving brazing performance of stainless steel

InactiveCN102451941AExcellent brazeabilityHigh thermal conductivitySoldering apparatusPretreatment methodStain

The invention provides a pretreating method for improving the brazing performance of stainless steel. The method comprises the following steps of: (1) removing oil: wetting one of ethylene trichloride, acetic ether, acetone and butanone with absorbent cotton for wiping, removing oil stains, and wiping with a clean cotton fabric for 2-4 times; (2) soaking and activating: soaking and activating with 300-400 parts by weight of 98 percent sulfuric acid at the temperature of 65-85 DEG C for 1-2 minutes; and (3) activating and pre-plating: activating and pre-plating with a solution which comprises 20-200 parts by weight of hexahydrate nickel dichloride and 15-60 parts by weight of 37 percent sulfuric acid at the cathode treatment current density of 0.5-10 at the normal temperature for 2-4 minutes. Due to the adoption of the pretreating method, the brazing performance of stainless steel can be improved by plating proper metals, high-temperature oxidation is relieved, the heat conductivity and electric conductivity are increased, high adhesion is ensured, the stainless steel is more glossy, attractive and resistant to rusting and wear, and the electric conductivity, lubricating property, strength, heat resistance and weather resistance are improved.

Owner:张国斌

Method for adding lutein ester during food manufacture

InactiveCN101336742AReduce high temperature oxidationReduce denaturationMilk preparationFood preparationLiquid stateFood processing

The present invention relates to a method for adding lutein esters into foods, belonging to food processing field. The method comprises the steps of adding sterile lutein esters into sterilized food base material of liquid state under aseptic condition. The present invention also relates to a method for producing a food added with lutein esters, which comprises the steps that bactericidal processing is performed for food base material of liquid state, and sterile lutein esters preparation is added into sterilized food base material of liquid state. In the present invention, the loss of lutein esters in food processing can be reduced, the loss of health function of lutein esters caused by oxidation can be prevented, and the amount of addition of lutein esters can be decreased.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Efficient enzymatic refining process of edible vegetable oil

PendingCN112251289AReduce refining lossEasy to operateFatty-oils/fats refiningVegetable oilEngineering

The invention belongs to the field of food processing, and particularly relates to an efficient enzymatic refining process of edible vegetable oil. The process mainly comprises five steps of centrifugal filtration of crude oil, enzymatic degumming, enzymatic deacidification, enzymatic decolorization and molecular distillation deodorization to finally obtain finished oil. According to the invention, the process is mainly based on an enzymic method, is beneficial to environmental protection and beneficial to operation, reduces the refining loss of oil, improves the product yield and refining efficiency, and has a relatively good popularization value.

Owner:HEZE ZHONGHEJIANYUAN BIOLOGY TECH CO LTD

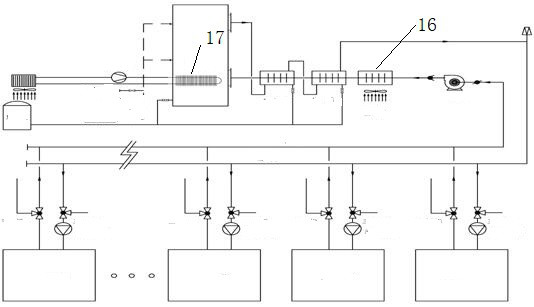

Heat treatment process oil gas recovery device and method

ActiveCN112143867AAvoid pollutionReduce security risksFurnace typesProcess efficiency improvementOil canThermodynamics

The invention provides a heat treatment process oil gas recovery device and a method. The method includes the steps that oil gas discharged by a heat treatment furnace is intensively collected througha pipeline, and the collected hot oil gas is subjected to multi-section heat exchange and cooling, so that rolling oil in the oil gas is condensed and separated out; multi-section heat exchange is carried out on the gas subjected to deep cooling and rolling oil removal again, heat exchange and temperature rise are carried out on the gas and hot oil gas exhausted by the heat treatment furnace, andthe heated gas enters into the heat treatment furnace to replace the hot oil gas; and an exhaust system and an air inlet system of the heat treatment furnace form a closed loop, inert gas is introduced into the closed loop to replace internal air, and inert gas such as liquid carbon dioxide or liquid nitrogen is introduced into the coldest end to deeply cool the oil gas. According to the heat treatment process oil gas recovery device and the method, pollution of the oil gas evaporated and discharged in the heat treatment process to the atmosphere can be eliminated, the rolling oil can be recycled, meanwhile, power consumption of the heat treatment furnace can be greatly reduced, and potential safety hazards caused by discharging of the hot oil gas are eliminated.

Owner:南京五域化工科技有限公司

Polyphenol red koji antioxidant preservative and its application technology

InactiveCN1252242CFermentation increasedGood effectFood preservationAlcoholic beverage preparationBiotechnologyPhenolic content in tea

The present invention relates to a functional fermentation technology, especially a polyphenol red koje antioxidant preservative and its application technology. It is developed on the basis of the patent technology of ZL94115941.8. The polyphenol red koje antioxidant preservative is prepared from tea, red koje, glutinous rice, sugar, white Qu and water and through fermentation. It contains tea polyphenol, tea pigment, red koji saccharomycete and other active matters and has the functions of antioxidation, resisting free radical, inhibiting bacteria, antisepticising, etc. It may be used as additive for wine, beverage and food, especially in brewing high-quality beer.

Owner:吴卫清

Preparation method of solid welding wire for welding of nickel-based superalloys resistant to molten salt corrosion

ActiveCN106181131BPrecise content controlReduce lossWelding/cutting media/materialsSoldering mediaVacuum arc remeltingCorrosion

The invention discloses a preparation method of a solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding, and belongs to the technical field of metal welding. The method includes the technological processes of vacuum smelting, vacuum arc remelting, homogenization, hot forging cogging, hot rolling, solution treatment, acid pickling, coating, cold drawing, coating removal and bright annealing. The invention further discloses the solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding. The solid cored welding wire is prepared through the method. Compared with the prior art, by the adoption of the method, high-quality solid cored welding wires of various diameters for molten-salt corrosion resistance nickel-base superalloy welding can be produced with the extremely-high rolling yield in a batch mode, and the prepared solid cored welding wire can meet the requirement for welding molten-salt reactor structural materials.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for reducing tetravalent tin content in stannous sulfate

ActiveCN107385469BLarge specific surface areaTimely removal of dissolved oxygenElectrolysis componentsTinCrystallization

The invention discloses a method for reducing the content of tetravalent stannum in stannous mono-sulphate. The method for reducing the content of the tetravalent stannum in the stannous mono-sulphate comprises the following steps that a stannum granular layer is laid in the bottom of a stannous mono-sulphate electrolytic tank; a deoxidant is added into a dilute sulphuric acid, and the treated dilute sulphuric acid is obtained; the treated dilute sulphuric acid is added into the stannous mono-sulphate electrolytic tank till the liquid level of the treated dilute sulphuric acid is higher than a cathode by 2-4 cm, and the voltage of the electrolytic tank is controlled to be lower than 2.4 V; when the content of stannum ions in an electrolyte at the bottom of the stannous mono-sulphate electrolytic tank is greater than or equal to 85 g / L, the electrolyte is discharged out of the tank from an outlet, and the treated dilute sulphuric acid is supplement into the tank to maintain the liquid level of tank liquid to be an original height while the electrolyte is discharged; when the content of the stannum ions in the electrolyte at the bottom of the stannous mono-sulphate electrolytic tank is decreased to 80 g / L, discharging of the electrolyte and supplementing of the treated dilute sulphuric acid are stopped; and the electrolyte is subjected to condensation crystallization, obtained crystals are eluted by using an eluting agent and then dried, and the stannous mono-sulphate is obtained.

Owner:FINE CHEM GRP

A preparation method of chromium-based composite material for connecting plate

ActiveCN104550965BPrevent grain coarseningImprove high temperature resistanceCoatingsFuel cellsThermal expansion

The invention relates to a method for preparing a chromium-based composite material for a connecting plate. Aluminum oxide is adopted by the chromium-based composite material for replacing Yttrium oxide in a commercial Cr-5Fe-1Y2O3 material, the aluminum oxide in a submicron level can be uniformly and dispersedly arranged in a chromium-based body, chromium oxide crystalline grains are prevented from being thickened and enlarged, and high-temperature oxidation of chromium is slowed down. The method comprises the preparing steps of firstly, preparing aluminum sol coating chromium powder; then mixing the aluminum sol coating chromium powder with alloying elements and a lubricating agent; then, forming in a pressing way; finally, cooling after high-temperature sintering. According to the method for preparing the chromium-based composite material for the connecting plate, disclosed by the invention, the technology is simple, and the prepared chromium-based composite material has excellent high temperature-resisting performance and corrosion resistance; compared with existing commercial Cr-5Fe-1Y2O2, the cost is low, meanwhile, the thermal expansion coefficient is close to that of other components of a solid fuel cell, large influence on assembling and use cannot be generated, the chromium-based composite material can be used as a connecting plate of a fuel cell and is a feasible material for replacing the Cr-5Fe-1Y2O2, and the chromium-based composite material is suitable for being produced in a large scale.

Owner:NBTM NEW MATERIALS GRP

Infrared radiation coating suitable for metal matrix and preparation method

Owner:WUHAN UNIV OF TECH

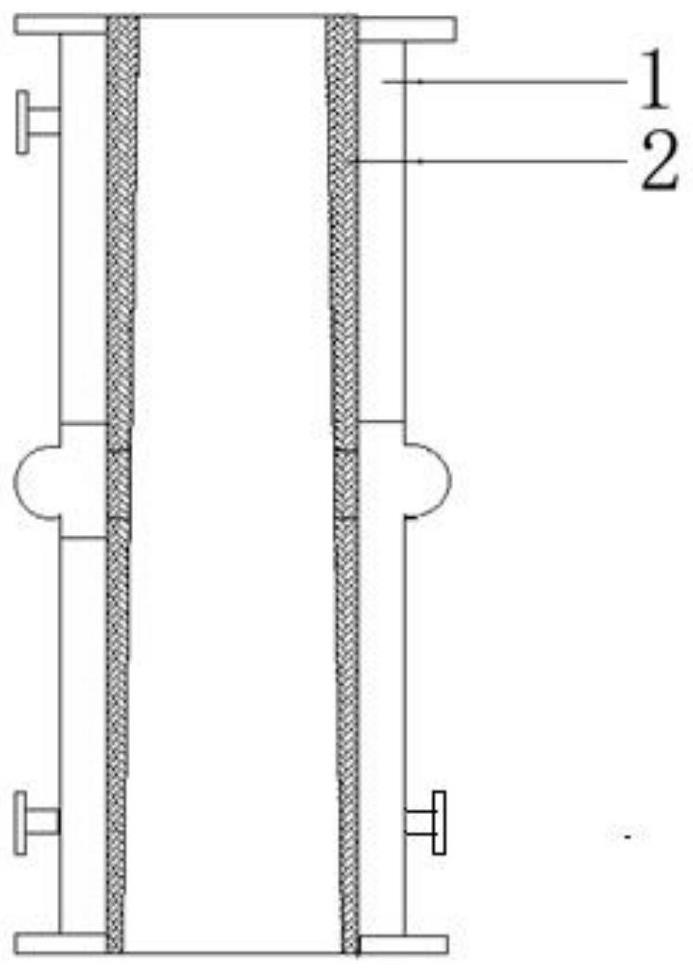

Intelligent air-jet textile machine serging device

ActiveCN111809296AEasy to replaceGuaranteed combined reliabilityTextile selvedgesAuxillary apparatusProcess engineeringMechanical engineering

The invention relates to the technical field of textile machines, in particular to an intelligent air-jet textile machine serging device which comprises a PLC used for controlling an air-jet textile machine to work, and further comprises heating heads and a power supply module, wherein the heating heads are arranged on the two sides of a discharging port of the air-jet textile machine through fixing bases, the output end of the power supply module is electrically connected with the heating heads, and the input end of the power supply module is connected with a power supply; and a communicationport of the power supply module is electrically connected with a signal output port of the PLC and is used for outputting constant current to the output end according to a signal of the PLC. The edgeof the fabric is subjected to hot melting serging through the heating heads, the serging effect is guaranteed, the serging device can adapt to the working speed of a weaving machine, and therefore the working efficiency of the weaving machine is improved.

Owner:重庆市华汇纺织有限公司

Three-phase controllable polarity DC electric arc furnace power supply device

ActiveCN103840685BSimple structureNovel and reasonable designEfficient power electronics conversionAc-dc conversionDc arc furnaceElectrical polarity

The invention discloses a three-phase controllable polar direct-current electric arc furnace power supply device which comprises a main transformer, a main loop and a control loop. Secondary side windings of the main transformer comprise a first winding and a second winding. The main loop comprises a first three-phase fully-controlled bridge rectifier circuit, a third three-phase fully-controlled bridge rectifier circuit, a fifth three-phase fully-controlled bridge rectifier circuit, a second three-phase fully-controlled bridge rectifier circuit, a fourth three-phase fully-controlled bridge rectifier circuit and a sixth three-phase fully-controlled bridge rectifier circuit, wherein the first three-phase fully-controlled bridge rectifier circuit, the third three-phase fully-controlled bridge rectifier circuit and the fifth three-phase fully-controlled bridge rectifier circuit are connected with the first winding, and the second three-phase fully-controlled bridge rectifier circuit, the fourth three-phase fully-controlled bridge rectifier circuit and the sixth three-phase fully-controlled bridge rectifier circuit are connected with the second winding. The control loop comprises six current transformers, a trigger, a pulse distribution circuit, a pulse inhibition circuit, a synchronous transformer and six pulse amplifying circuits. The three-phase controllable polar direct-current electric arc furnace power supply device is simple in structure, convenient to use and operate and capable of accelerating the melting speed of a direct-current electric arc furnace, reduces heat shut-down, improves heat efficiency, prolongs the service life of a furnace body of the direct-current electric arc furnace, and is high in practicability and convenient to popularize and use.

Owner:高辉

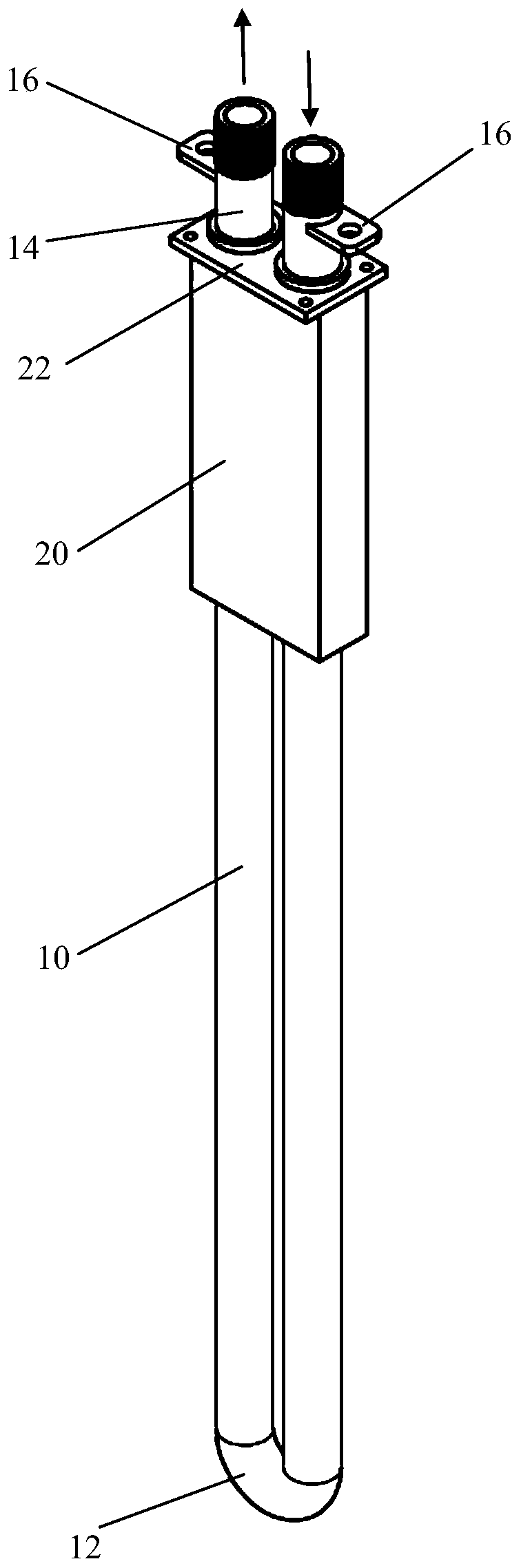

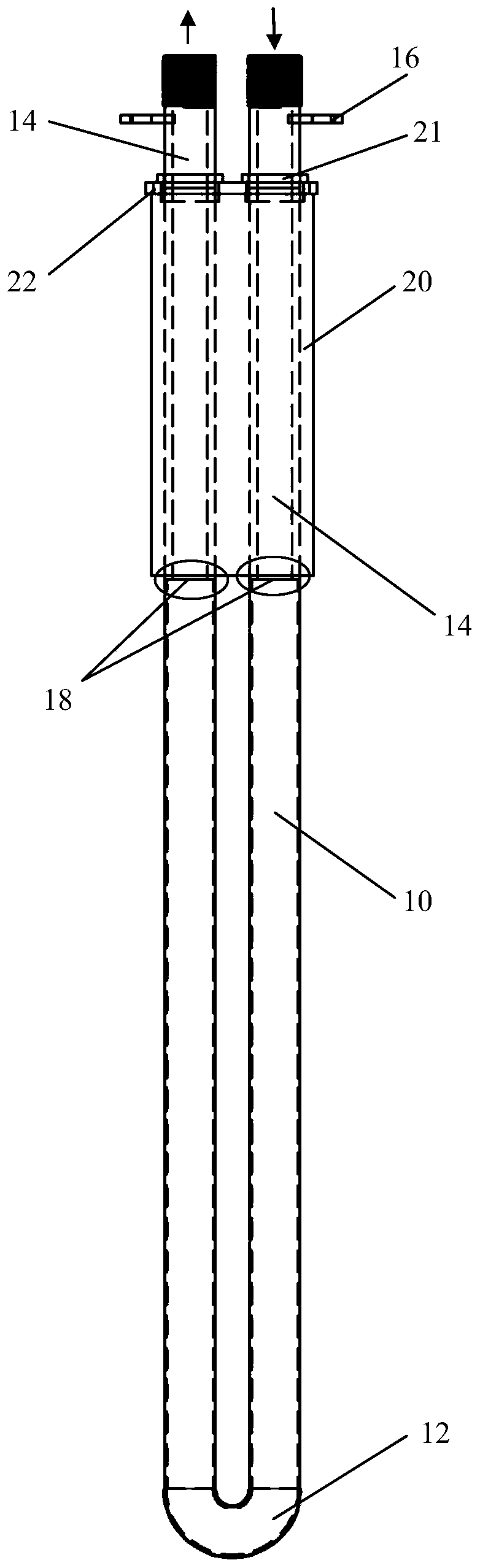

U-shaped hollow electric heating radiant tube

PendingCN109842967AExtended service lifeIncrease heating powerOhmic-resistance electrodesHeating element shapesTemperature controlThermal insulation

The invention provides a U-shaped hollow electric heating radiant tube, which comprises hollow heating tube bodies arranged in a pair, a connecting portion, connecting tubes, a thermal insulation section and a fixing plate, wherein the connecting portion connects and communicates one end portions of the tube bodies to form a U-shaped structure, the connecting tubes are connected with the other ends of the tube bodies, the thermal insulation section composed of a thermal insulation material is arranged on the peripheries of parts of the connecting tubes, and the fixing plates for fixing the heating radiant tube and a boiler are arranged at joints of the hollow heating tube bodies and the connecting tubes; the end portions of the connecting tubes are provided with threaded structures; the connecting tubes are respectively provided with electrode connecting terminals which are connected with positive and negative electrodes of a power supply; and the joints of the hollow heating tube bodies and the connecting tubes are welded and connected with joints of connecting portion and the hollow heating tube bodies by means of circumferential seam fully welding. The U-shaped hollow electric heating radiant tube directly adopts the electric heating alloy to form the hollow heating tubes, and the weight of the material is only about 20% of the original, thereby significantly reducing the material cost, and significantly reducing the energy consumption required for heating; and the temperature control precision is high, the service life is long, and the heating power is high.

Owner:江苏金达电热电器有限公司

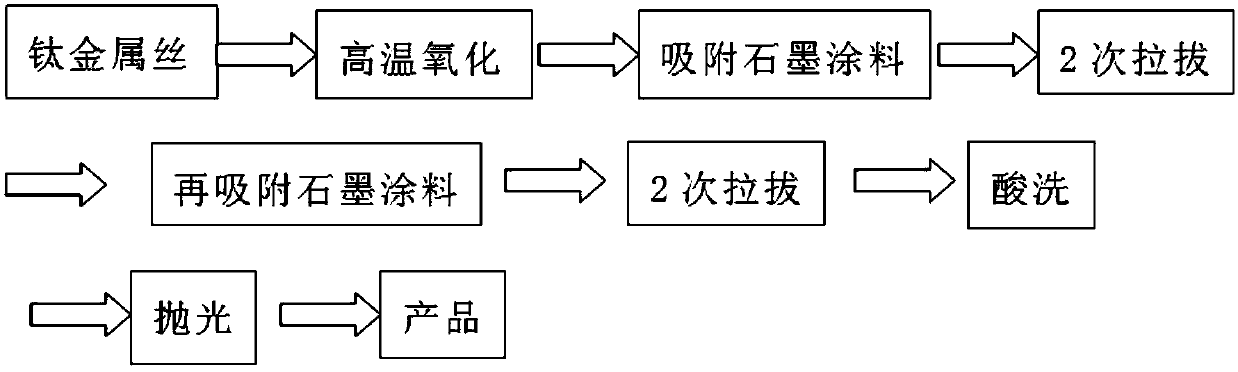

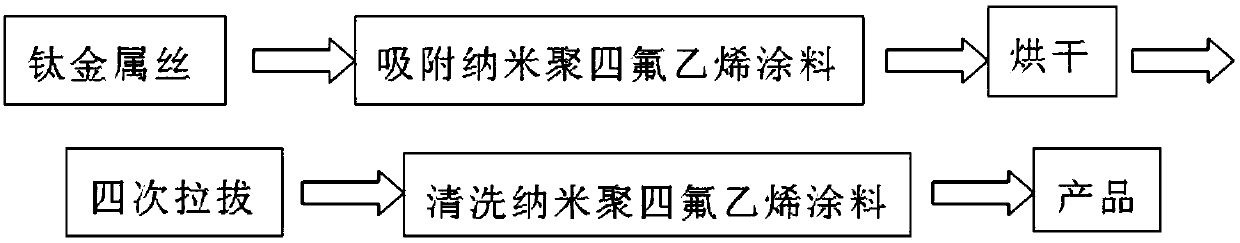

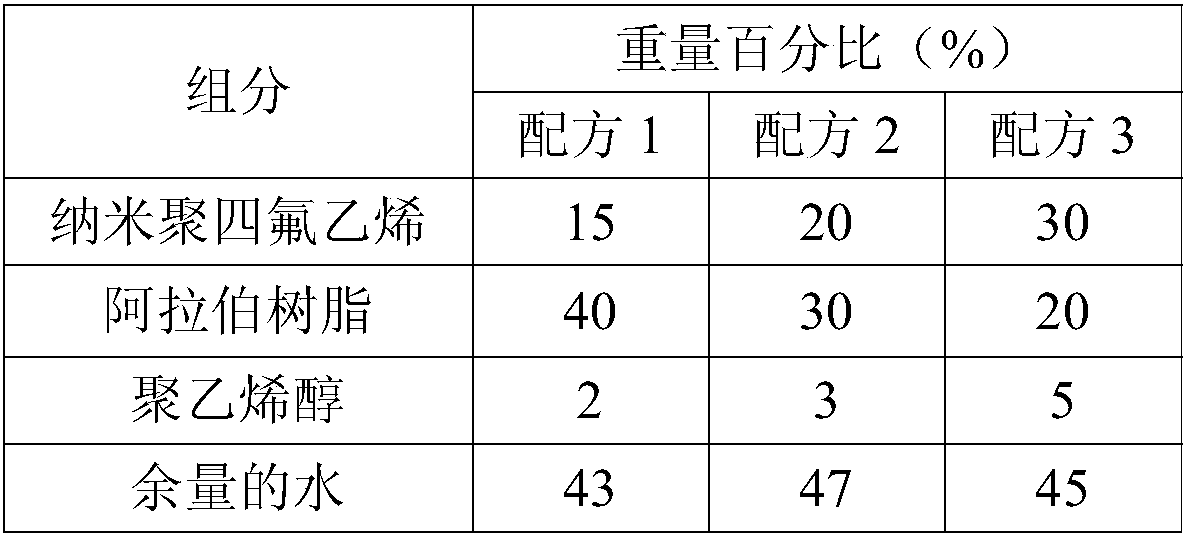

A kind of nano polytetrafluoroethylene coating and its preparation method and application

ActiveCN105886093BImprove the lubrication effectQuality improvementAdditivesTetrafluoroethylenePolyvinyl alcohol

The invention discloses a nano polytetrafluoroethylene coating. The nano polytetrafluoroethylene coating is prepared from components in percentage by weight as follows: 15%-30% of nano polytetrafluoroethylene, 20%-40% of Arabia gum, 2%-5% of polyvinyl alcohol and the balance of water. During application, a titanium metal wire is dipped in and coated with the nano polytetrafluoroethylene coating and dried, then the dried titanium metal wire is drawn, the nano polytetrafluoroethylene coating on the surface of the drawn titanium metal wire is cleaned with hot water, and the titanium metal wire is dried. The nano polytetrafluoroethylene coating has excellent lubrication performance, the smooth surface of the to-be-drawn titanium metal wire can be well dipped in and coated with the nano polytetrafluoroethylene coating, so that the drawing technology is simplified, the production cost is reduced, the quality of the titanium metal wire is improved, the service life of the titanium metal wire is prolonged, environmental pollution caused by graphite powder and health problem of operators due to the graphite powder are greatly reduced, and the coating has the broad industrial application prospect.

Owner:上海零慕纳米材料科技有限公司

Underground longitude and latitude detecting method

The invention relates to an underground longitude and latitude detecting method. A longitude and latitude monitoring device body comprises a waterproof top seat, a waterproof shell and a waterproof base, wherein the waterproof shell is arranged at the bottom of the waterproof top seat, the waterproof base is arranged at the bottom of the waterproof shell, a cavity is formed in the waterproof top seat, a Beidou positioner and a laser are arranged in the cavity, a displacement sensor is arranged at one side of the waterproof top seat, and an earthquake collector and a storage battery are arranged in the waterproof shell. The detection device is reasonable in framework, high in sensitivity, accurate in positioning, and low in manufacture cost, can be used for giving the alarm on an earthquakein advance, and determining the location of the earthquake, so as to avoid or alleviate disaster caused by the earthquake, and reduce personal casualty and property loss to a lowest degree.

Owner:惠安县金建达电子科技有限公司

A method for treating solid waste in a rotary hearth furnace

ActiveCN108611458BHigh strengthReduce pulverization rateRotary drum furnacesProcess efficiency improvementSteelmakingWaste treatment

The invention relates to a method for treating solid waste through a rotary hearth furnace and belongs to the technical field of steel mill solid waste treatment. The problems that in the prior art, recycled zinc oxide powder is low in grade, and finished metallized pellets are high in pulverization rate are solved. The method for treating the solid waste through the rotary hearth furnace comprises the following steps of pelletizing, reduction and zinc-contained powder recycling, and a drying stage is further performed between the pelletizing and the reduction. The method for treating the solid waste through the rotary hearth furnace provided by the invention can be used for treating solid materials generated in the production processes of sintering, ironmaking and steelmaking.

Owner:钢研晟华科技股份有限公司

An anti-tangle winder for heat dissipation of electric wires and its processing technology

The invention discloses an anti-twining wire winder for wire heat dissipation. The anti-twining wire winder comprises a wire winder body, wherein first teeth and second teeth are arranged on the upper side and the lower side of the wire winder body respectively, and lock catch devices are arranged at two ends of the wire winder body. According to the anti-twining wire winder for wire heat dissipation, the first teeth and the second teeth are arranged on the upper side and the lower side of the wire winder body respectively, so that a wire can be uniformly wound in grooves of the teeth and prevented from being twined together, and the wire can be well stored and arranged; and meanwhile, the problem of a circuit fault due to high temperature caused by wire twining is also well solved, so that an extremely good protection effect on the wire itself and the whole circuit is achieved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

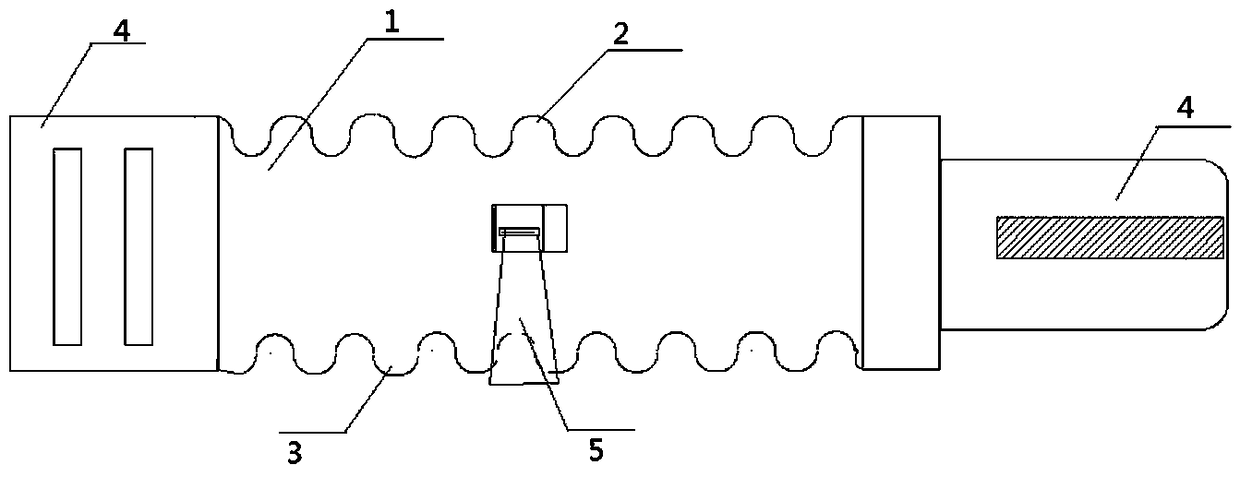

Water jacket ascension pipe heat exchanger with heat insulation and storage layer and transformation method of water jacket ascension pipe heat exchanger

PendingCN113801664AReduced wall temperature transformationReduce high temperature oxidation and high temperature creepDistillation gas withdrawalEngineeringMetallic materials

The invention discloses a water jacket ascension pipe heat exchanger with a heat insulation and storage layer and a transformation method of the water jacket ascension pipe heat exchanger. The water jacket ascension pipe heat exchanger with the heat insulation and storage layer comprises an ascension pipe heat exchanger body, and the heat insulation and storage layer is attached to the inner wall of the ascension pipe heat exchanger. The transformation method of the ascension pipe heat exchanger comprises the steps of polishing the inner wall of the ascension pipe heat exchanger, welding a fixing piece, pressing the ascension pipe heat exchanger, pouring the heat insulation and storage layer, and drying or air-drying and maintaining the heat insulation and storage layer. The problem that the inner wall of an original ascension pipe heat exchanger is coked is solved, meanwhile, the wall temperature change of the inner wall of the original ascension pipe heat exchanger is reduced, high-temperature oxidation and high-temperature creep of a pipe body metal material are reduced, and the service life of the original ascension pipe heat exchanger is prolonged by 3-5 years.

Owner:WUHAN FRONT IND EQUIP TECH

430 stainless steel and rolling method thereof

ActiveCN113584389ALimit the maximum deformation rateEasy loadingRoll force/gap control deviceSpraying apparatusSS - Stainless steelHeat conservation

The invention discloses 430 stainless steel and a rolling method thereof. The 430 stainless steel comprises, by weight, less than or equal to 0.04% of C, greater than or equal to 0.30% and less than or equal to 0.60% of Si, less than or equal to 0.45% of Mn, less than or equal to 0.030% of P, less than or equal to 0.005% of S, less than or equal to 16.50% of Cr, less than or equal to 0.045% of N, greater than or equal to 0.05% and less than or equal to 0.25% of Re, and the balance Fe and other inevitable impurities. The rolling method comprises the following specific steps of 1) heating, wherein the heating step is sequentially divided into a preheating section, a heating section I, a heating section II and a soaking section; 2) rough rolling, wherein a steel billet enters a rough rolling mechanism through a heat preservation conveying mechanism, and the rough rolling mechanism conducts primary rough rolling on the heated steel billet; 3) finish rolling, wherein after rough rolling is completed, the steel billet enters a finish rolling mechanism to be subjected to finish rolling treatment; 4) coiling; 5) uncoiling and welding; 6) annealing; 7) descaling and shot blasting; 8) acid pickling; 9) cleaning, wherein the surface of the stainless steel plate obtained after acid pickling is cleaned through a cleaning device; and 10) drying. Through the reasonable raw material ratio and rolling process, the high-quality stainless steel plate is obtained, and the surface quality of the stainless steel plate is guaranteed.

Owner:山东盛阳金属科技股份有限公司

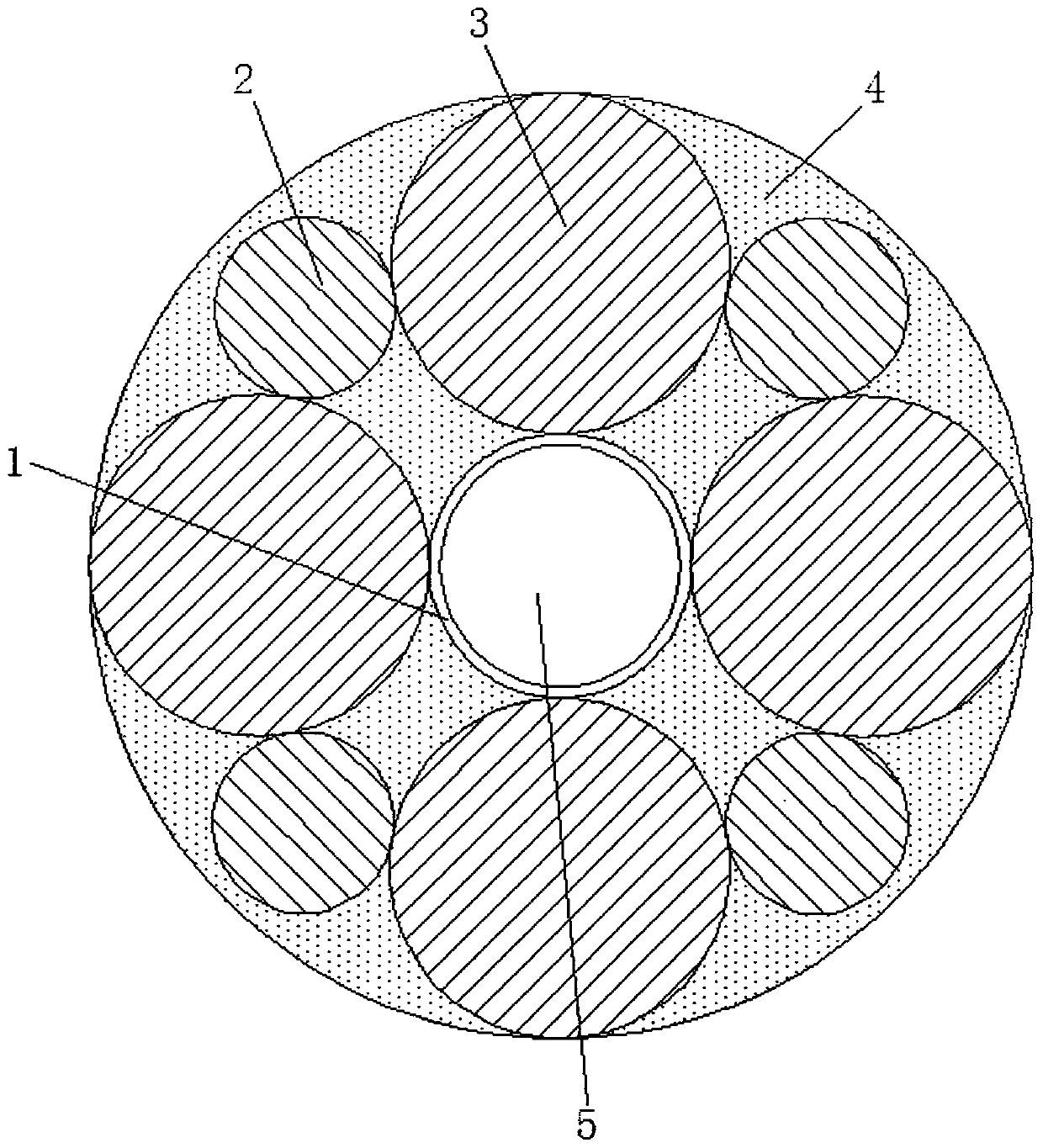

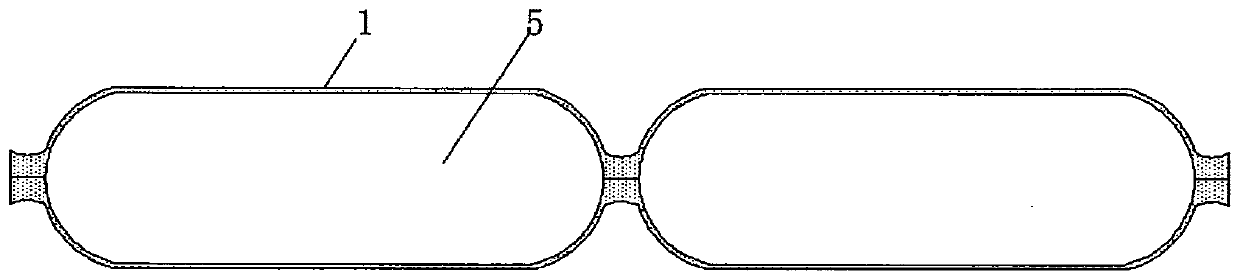

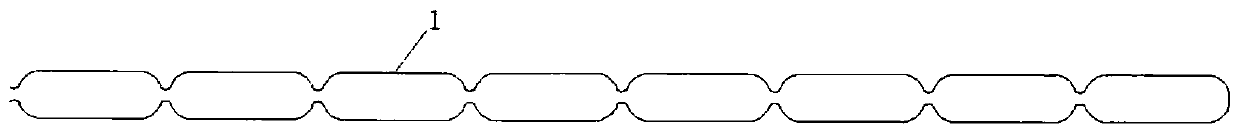

Multi-strand stranded welding wire for 3D printing wire material

InactiveCN110936049AShorten the production cycleLow costWelding/cutting media/materialsSoldering mediaCo2 storageDeposition rate

The invention relates to the technical field of welding wires, and specifically discloses a multi-strand stranded welding wire for a 3D printing wire material. The multi-strand stranded welding wire comprises a carbon dioxide storage tube, peripheral coarse wires and peripheral fixed stranded wires, wherein the number of the peripheral coarse wires is four, the number of the peripheral fixed stranded wires is four, the peripheral coarse wires are twisted on the carbon dioxide storage tube in a cross shape, the four peripheral fixed stranded wires are correspondingly positioned at gaps betweenthe peripheral coarse wires, the peripheral fixed twisted wires are stranded with the peripheral coarse wires, and the carbon dioxide storage tube is of a multi-section structure. According to the multi-strand stranded welding wire, carbon dioxide can be released during welding by adopting the carbon dioxide storage tube, so that a protection zone is formed at the welding position, high-temperature oxidation of a welding part is reduced, and the stranded stability and high deposition rate are realized by adopting the four peripheral coarse wires and the peripheral fixed stranded wires.

Owner:河北联之捷焊业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com