Method for reducing tetravalent tin content in stannous sulfate

A technology of stannous sulfate and tetravalent tin, which is applied in the direction of electrolytic components and electrolytic processes, can solve the problems of affecting the storage validity period and product appearance, not being suitable for large-scale continuous production, and difficult and precise control of current density, so as to improve the international Competitiveness, low cost, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

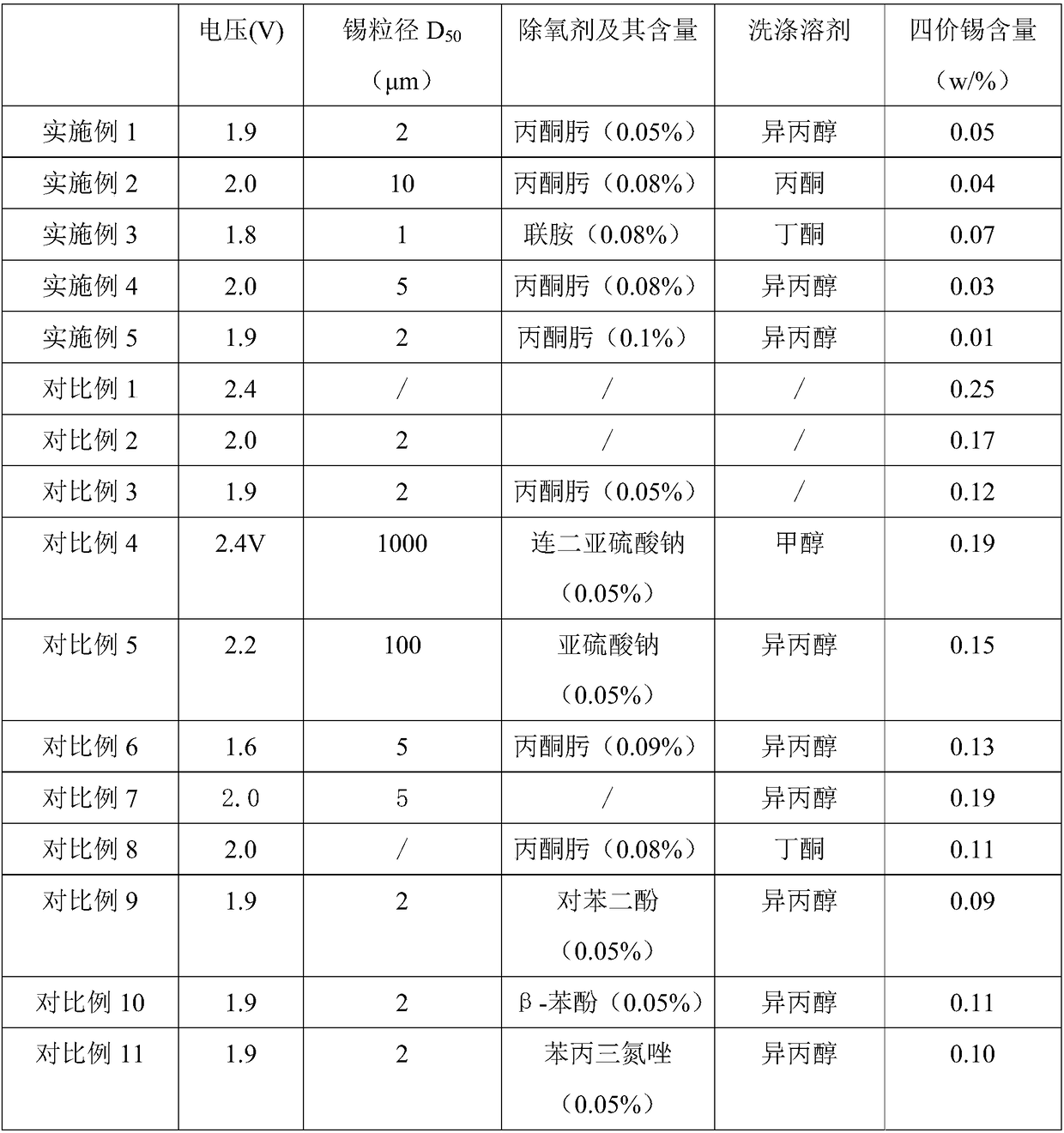

Embodiment 1

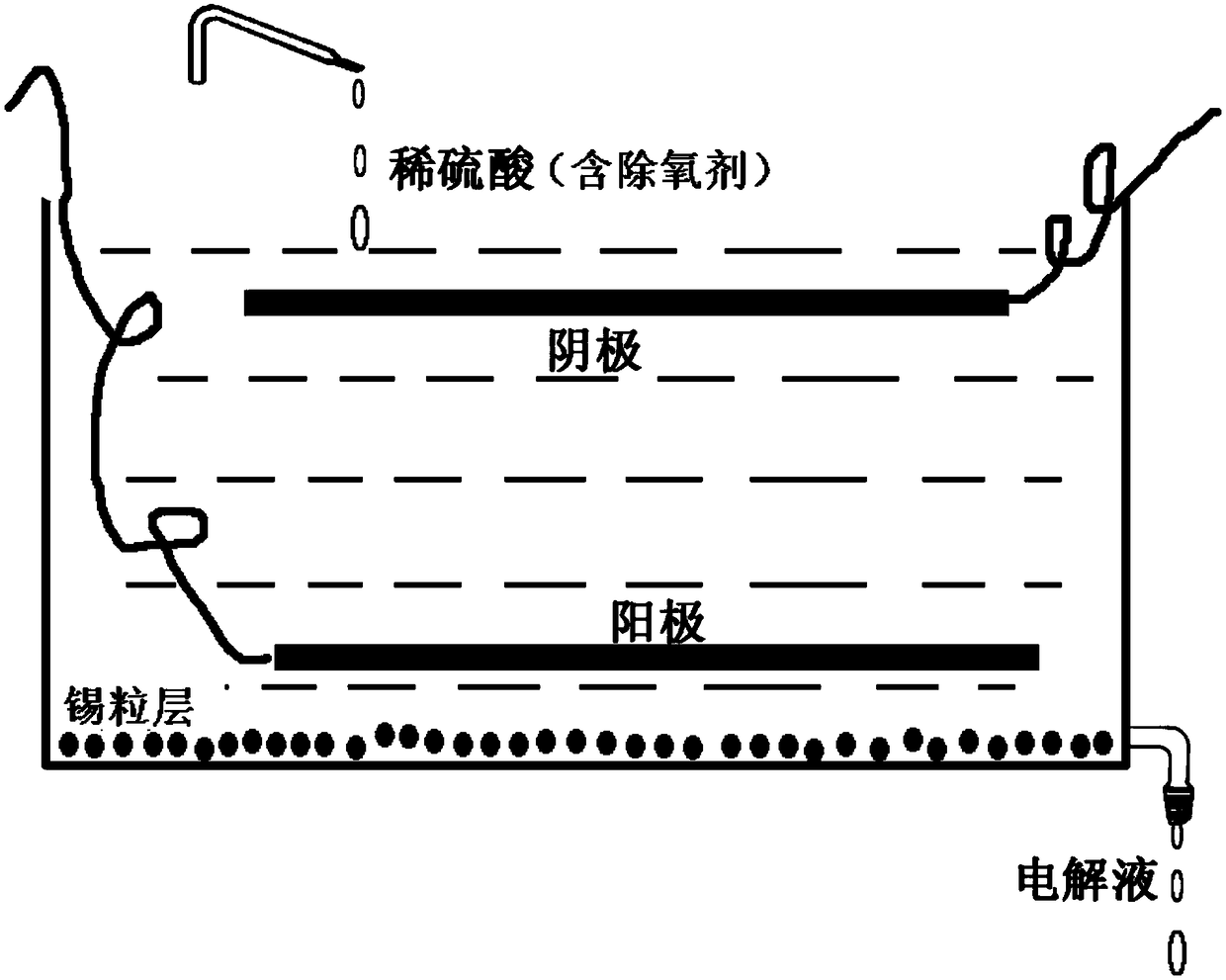

[0040] Embodiment 1, a kind of method that reduces tetravalent tin content in stannous sulfate production process comprises the steps:

[0041] 1), at the bottom of the stannous sulfate electrolytic cell, laying a layer of tin particle layer (particle size D) with a thickness of 2cm 50 is 2 μm);

[0042] 2), add acetone oxime as oxygen scavenger in dilute sulfuric acid, obtain the dilute sulfuric acid after treatment; The consumption ratio of dilute sulfuric acid and oxygen scavenger is 100ml / 0.05g;

[0043] Described dilute sulfuric acid is the sulfuric acid solution that concentration is 1mol / L;

[0044] 3) Add treated dilute sulfuric acid to the stannous sulfate electrolytic cell until the liquid level of the treated dilute sulfuric acid is below the cathode by 2 to 4 cm, and control the voltage of the electrolytic cell to 1.9V;

[0045] 4) When the tin ion content in the electrolyte at the bottom of the stannous sulfate electrolytic cell is ≥ 85g / L, discharge the electro...

Embodiment 2

[0049] Embodiment 2, a kind of method that reduces tetravalent tin content in stannous sulfate production process:

[0050] The particle size of tin particles D 50 10μm;

[0051] Add acetone oxime as oxygen scavenger in dilute sulfuric acid to obtain dilute sulfuric acid after treatment; the consumption ratio of dilute sulfuric acid and oxygen scavenger is 100ml / 0.08g;

[0052] Control the electrolyzer voltage to 2.0V;

[0053] Use acetone as a rinse agent;

[0054] The rest are equal to Example 1.

[0055] The content of tetravalent tin in the obtained stannous sulfate is 0.04%.

Embodiment 3

[0056] Embodiment 3, a kind of method that reduces tetravalent tin content in stannous sulfate production process:

[0057] The particle size of tin particles D 50 1 μm;

[0058] Add hydrazine as oxygen scavenger in dilute sulfuric acid to obtain dilute sulfuric acid after treatment; the consumption ratio of dilute sulfuric acid and oxygen scavenger is 100ml / 0.08g;

[0059] Control the electrolyzer voltage to 1.8V;

[0060] Use methyl ethyl ketone as eluent;

[0061] The rest are equal to Example 1.

[0062] The content of tetravalent tin in the obtained stannous sulfate is 0.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com