Method for treating solid waste through rotary hearth furnace

A rotary hearth furnace and flue gas waste heat technology, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of high pulverization rate of metallized pellets, low grade of zinc oxide powder, waste heat utilization, etc., and achieve simplified process , Reduce production cost, improve production capacity and life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

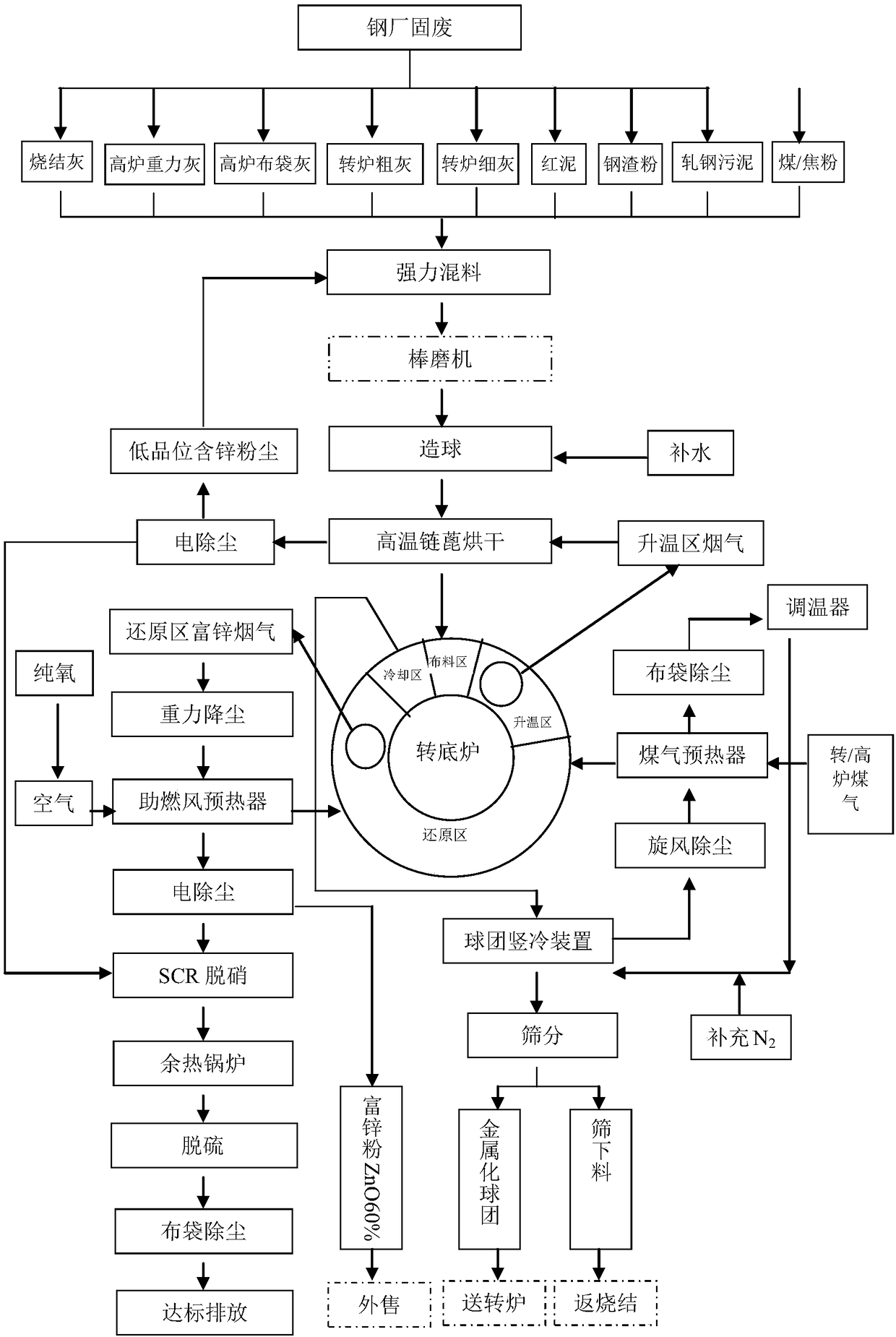

Method used

Image

Examples

Embodiment 1

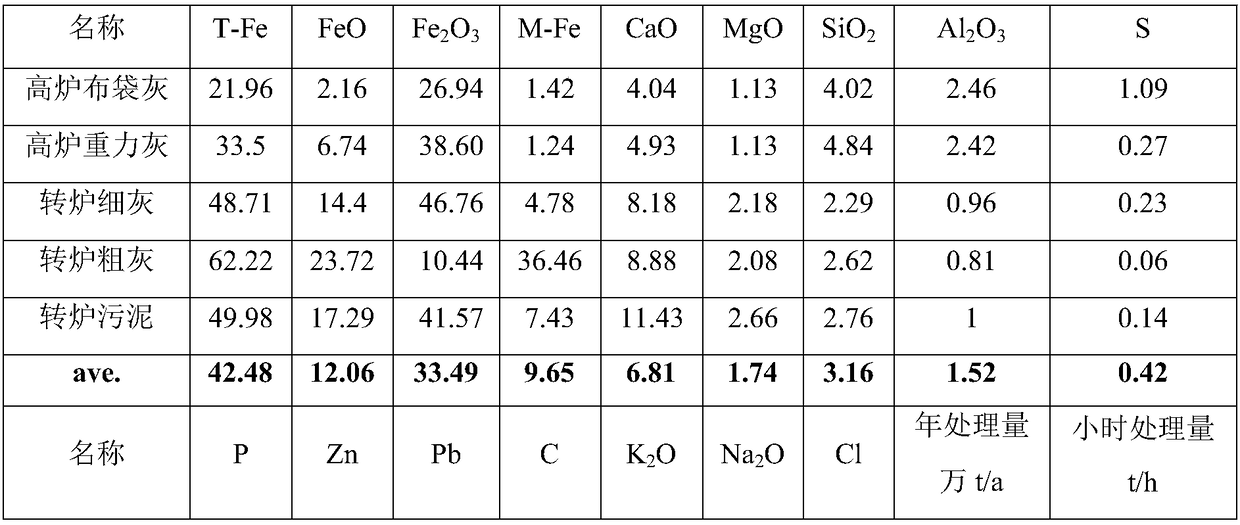

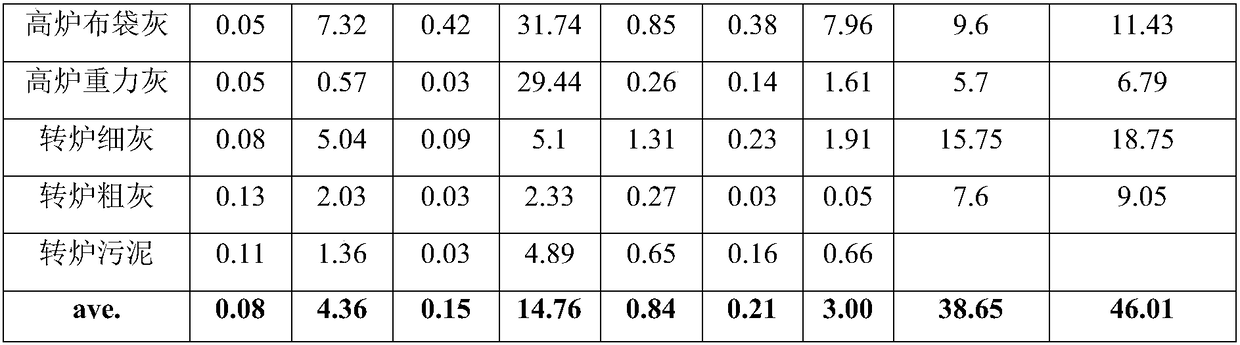

[0059] The solid waste materials processed by the method for treating solid waste in the rotary hearth furnace of the present invention include: blast furnace ashes, converter ashes and sintering dust removal ash, etc.; blast furnace dust includes blast furnace bag ash, blast furnace gravity ash; converter dust includes converter fine ash, converter coarse Ash and converter sludge etc. According to the actual situation, add some binders, such as bentonite, bentonite, etc. The following is an example of a rotary hearth furnace production line with an annual processing capacity of 386,500 tons. The composition and content of various solid waste materials are shown in Table 1. The rotary hearth furnace production line can process 96,000 tons of blast furnace bag ash and 57,000 tons of blast furnace gravity ash / a, converter fine ash 157,500 t / a, converter coarse ash 76,000 t / a.

[0060] According to the production requirements, the above-mentioned materials are mixed in appropri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com