Elimination method of annealing white spots on the edge of cold-rolled aluminum

An annealing and aluminum coil technology, applied in the field of aluminum alloy heat treatment, can solve problems such as white spot defects in aluminum coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

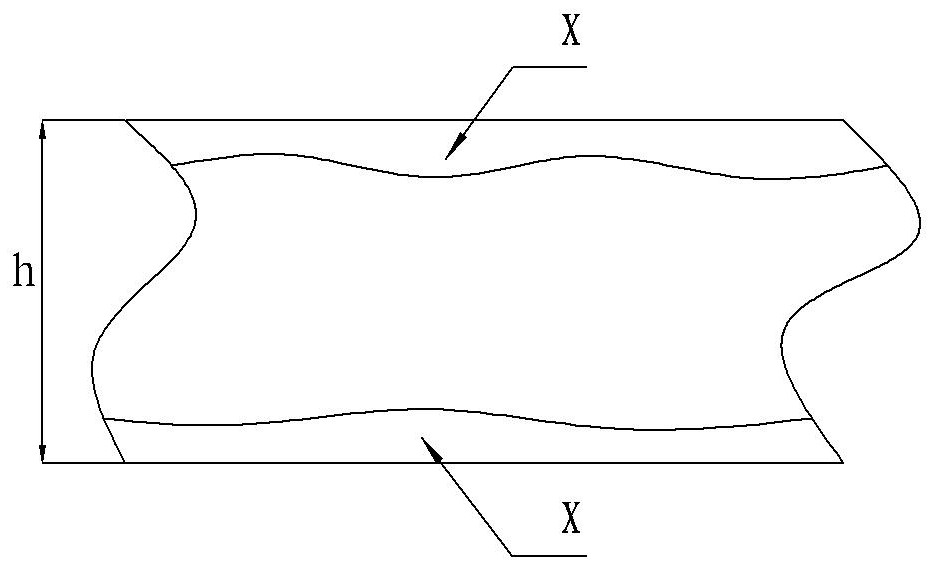

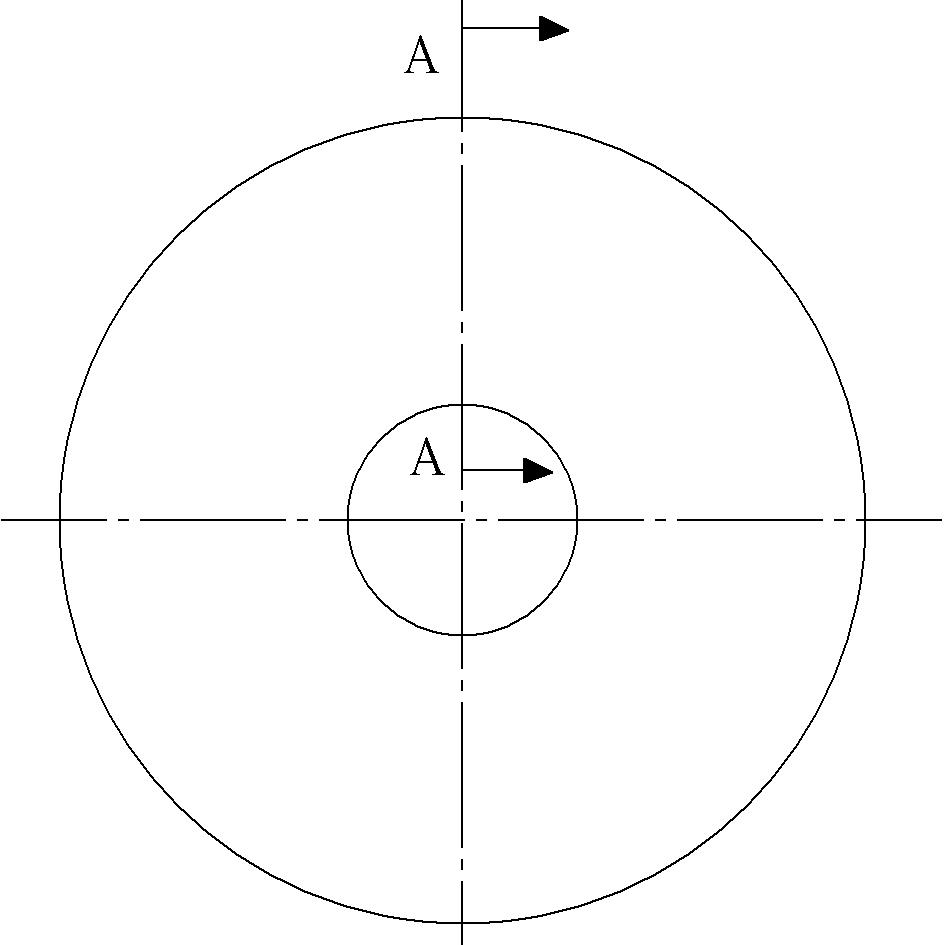

[0022] The method for eliminating the annealed white spots at the edge of cold-rolled aluminum coils deals with aluminum coil 1, alloy 1235, thickness 4.0mm, width 1350mm, and coil diameter 2000mm, including the following steps:

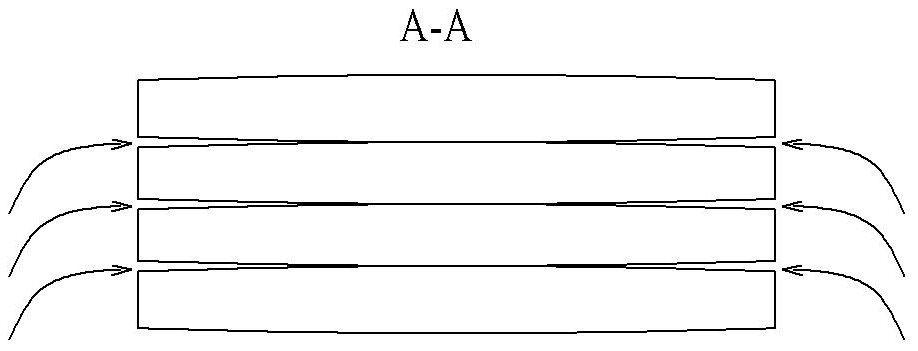

[0023] A. When fully annealed, after pushing the aluminum coil into the annealing furnace, fill the annealing furnace with high-purity argon gas, and the argon concentration reaches 90%;

[0024] B. Annealing begins to heat up. When the material temperature rises to 200°C, keep it warm for 6 hours, and control the coiling tensile stress before annealing at 25MPa;

[0025] C. After the heat preservation is over, continue to fill with high-purity argon until the argon concentration in the furnace reaches 98.0%;

[0026] D. Continue to heat up to a material temperature of 500°C, keep it warm for 5 hours, and then cool it to a material temperature of 150°C with the furnace and then release it from the furnace. After unpacking inspection, there is no ann...

Embodiment 2

[0028] The method for eliminating the annealed white spots on the edge of cold-rolled aluminum coils deals with aluminum coil 2, alloy 5052, with a thickness of 1.17mm, a width of 2600mm, and a coil diameter of 2500mm, including the following steps:

[0029] A. When fully annealed, after the aluminum coil is pushed into the annealing furnace, the annealing furnace is filled with high-purity argon gas, and the argon concentration reaches 98%;

[0030] B. Annealing begins to heat up. When the material temperature rises to 240°C, keep it warm for 15 hours, and control the coiling tensile stress before annealing at 50MPa;

[0031] C. After the heat preservation is over, continue to fill with high-purity argon until the argon concentration in the furnace reaches 100%;

[0032] D. Continue to heat up to a material temperature of 320°C, keep it warm for 8 hours, and cool down to a material temperature of 200°C with the furnace before it is released from the furnace. After unpacking ...

Embodiment 3

[0034] The method for eliminating the annealed white spots on the edge of cold-rolled aluminum coils deals with aluminum coil 2, alloy 5052, with a thickness of 1.17mm, a width of 2600mm, and a coil diameter of 2500mm, including the following steps:

[0035] A. When fully annealed, push the aluminum coil into the annealing furnace, and fill the annealing furnace with high-purity neon gas, and the neon gas concentration reaches 91%;

[0036] B. Annealing begins to heat up. When the material temperature rises to 220°C, keep it warm for 8 hours, and control the coiling tensile stress before annealing at 35MPa;

[0037] C. After the heat preservation is over, continue to fill high-purity neon gas until the concentration of neon gas in the furnace reaches 99.5%;

[0038] D. Continue to heat up to a material temperature of 400°C, keep it warm for 7 hours, and cool it to a material temperature of 190°C with the furnace before it is released from the furnace. After unpacking inspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com