Patents

Literature

106results about How to "Heated evenly and fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

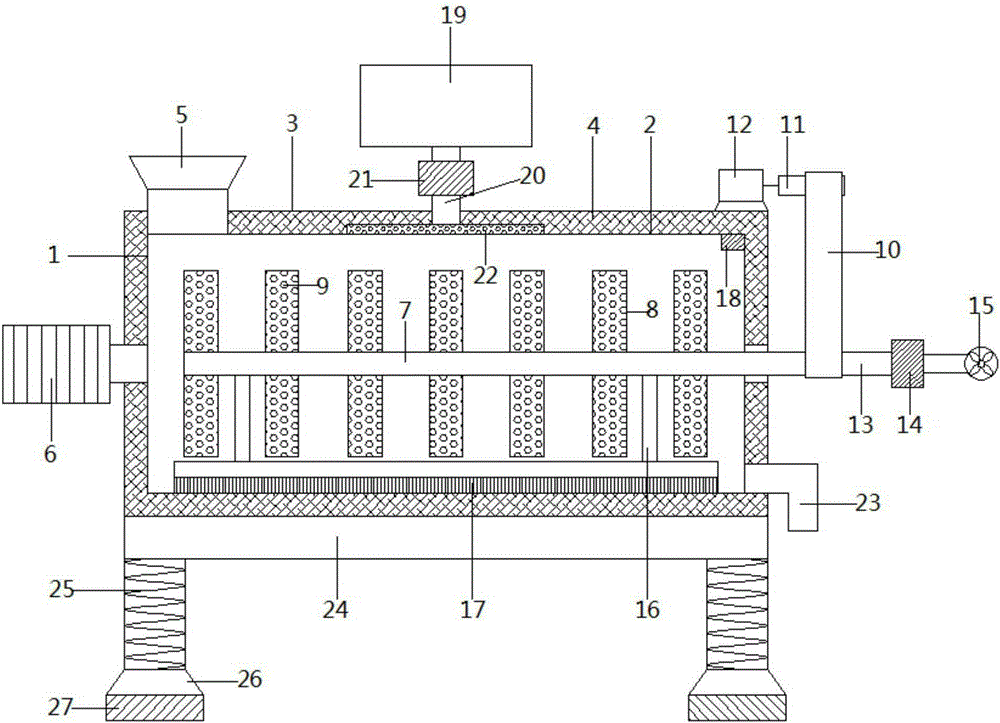

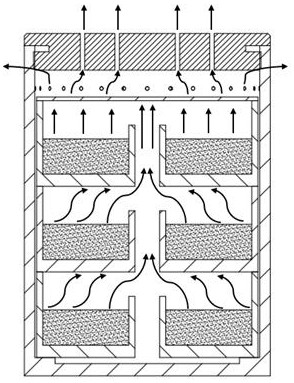

Efficient tea leaf de-enzyming machine with humidifying device

InactiveCN105192119AFully heatedImprove the killing effect and efficiencyPre-extraction tea treatmentDrive motorEnzyme

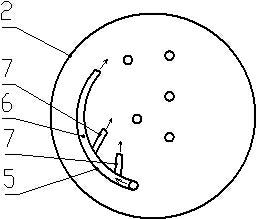

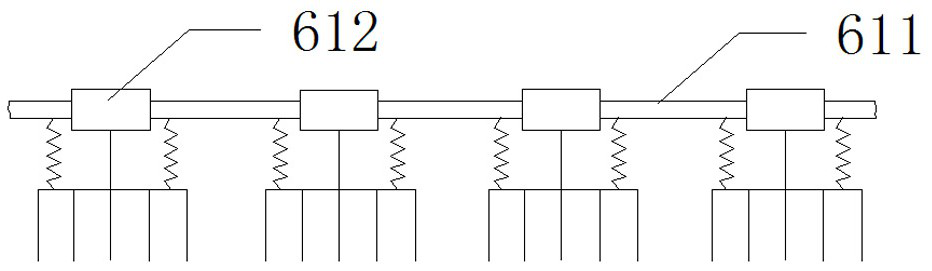

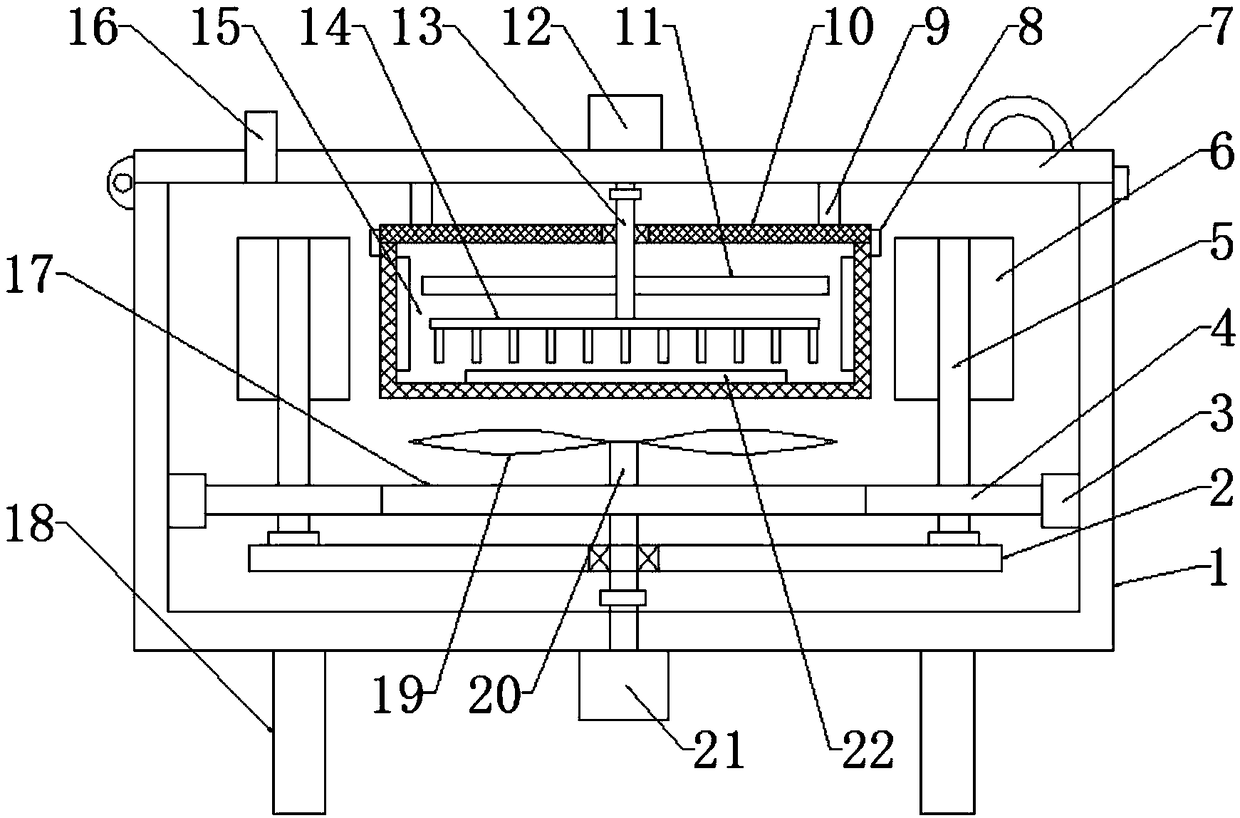

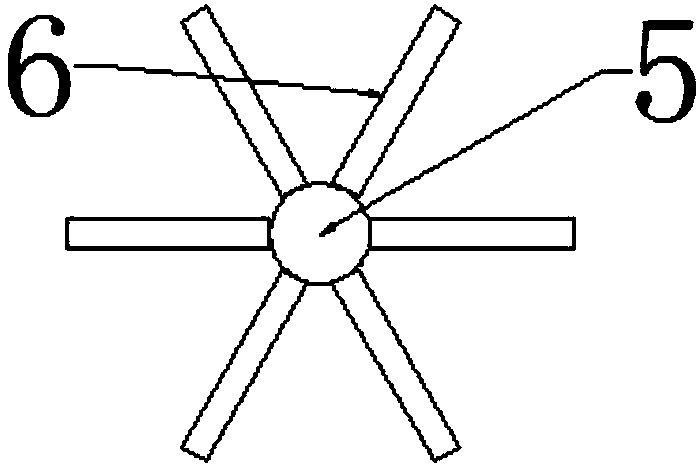

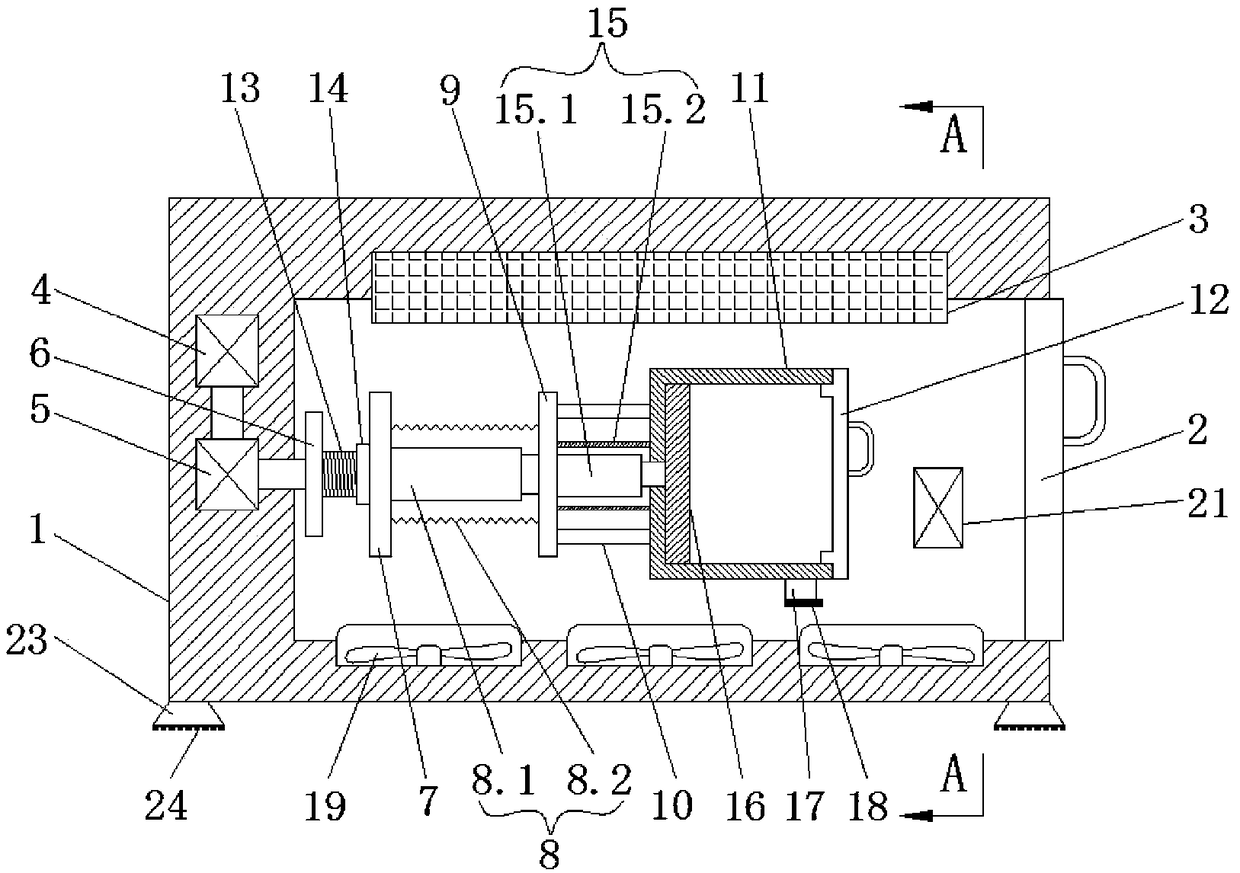

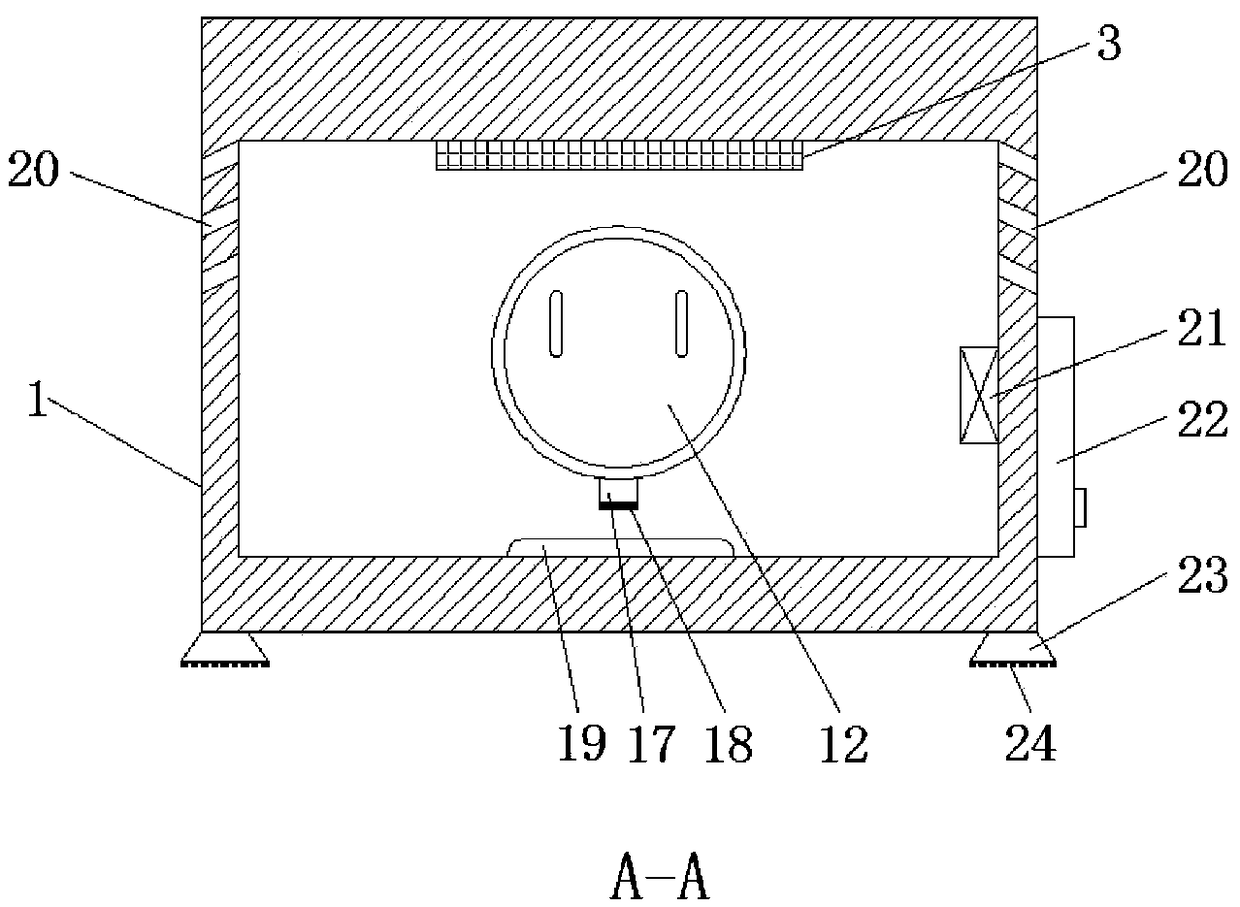

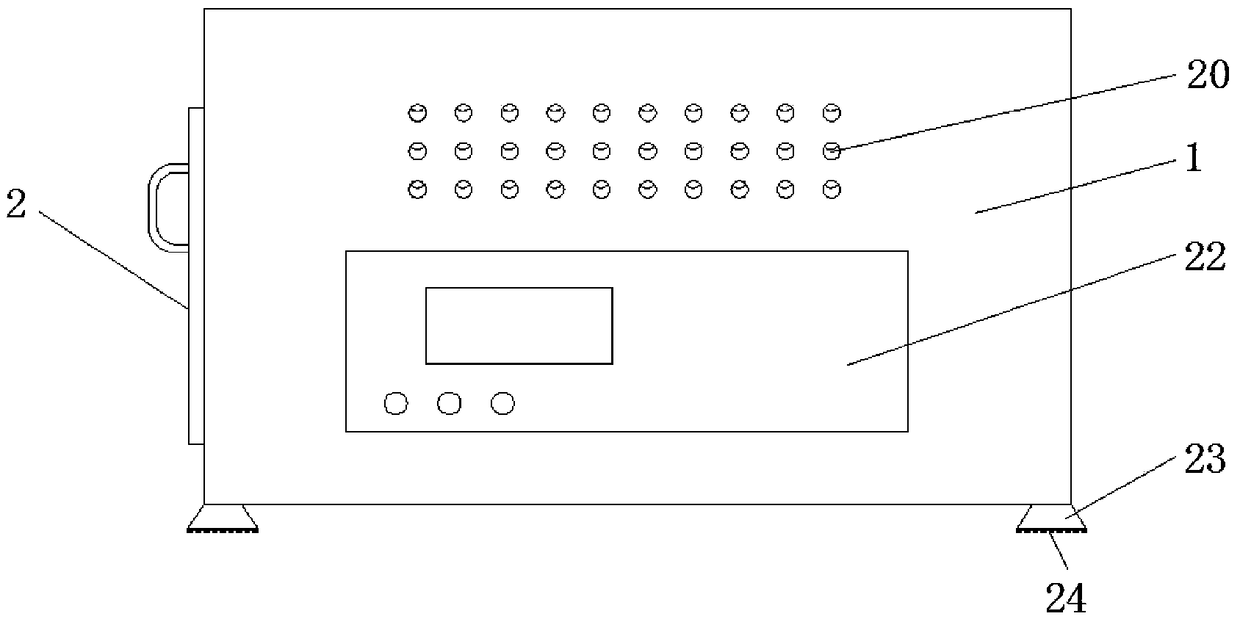

The invention discloses an efficient tea leaf de-enzyming machine with a humidifying device. The de-enzyming machine comprises a de-enzyming cylinder, an inner cylinder and an outer cylinder. The de-enzyming cylinder is of a double-layer structure and comprises the inner cylinder and the outer cylinder. The inner cylinder and the outer cylinder are coaxially arranged, an electric heating layer is arranged between the inner cylinder and the outer cylinder, a feeding hopper is connected with the left end of the upper side of the inner cylinder, the left end of the inner cylinder is connected with a drive motor through a rotary shaft, and the rotary shaft is horizontally arranged in the center of the interior of the inner cylinder. According to the efficient tea leaf de-enzyming machine with the humidifying device, the inner cylinder and the rotary shaft rotate in opposite directions, and tea leaves in the inner cylinder are stirred and overturned. Meanwhile, the electric heating layer and hot air are matched to de-enzyme the tea leaves, the tea leaves are fully and evenly heated, the de-enzyming effect is good, efficiency is high, the tea leaves attached to the inner wall of the inner cylinder can be scraped off, and waste of raw materials is avoided. Besides, the tea leaves can be humidified, the situation that quality is affected because the tea leaves are excessively dehydrated is avoided, effective shock absorption can be achieved through a shock-absorbing spring and a shock-absorbing pad, noise is lowered, and the service life of the de-enzyming machine is also prolonged.

Owner:成都米戈科技有限公司

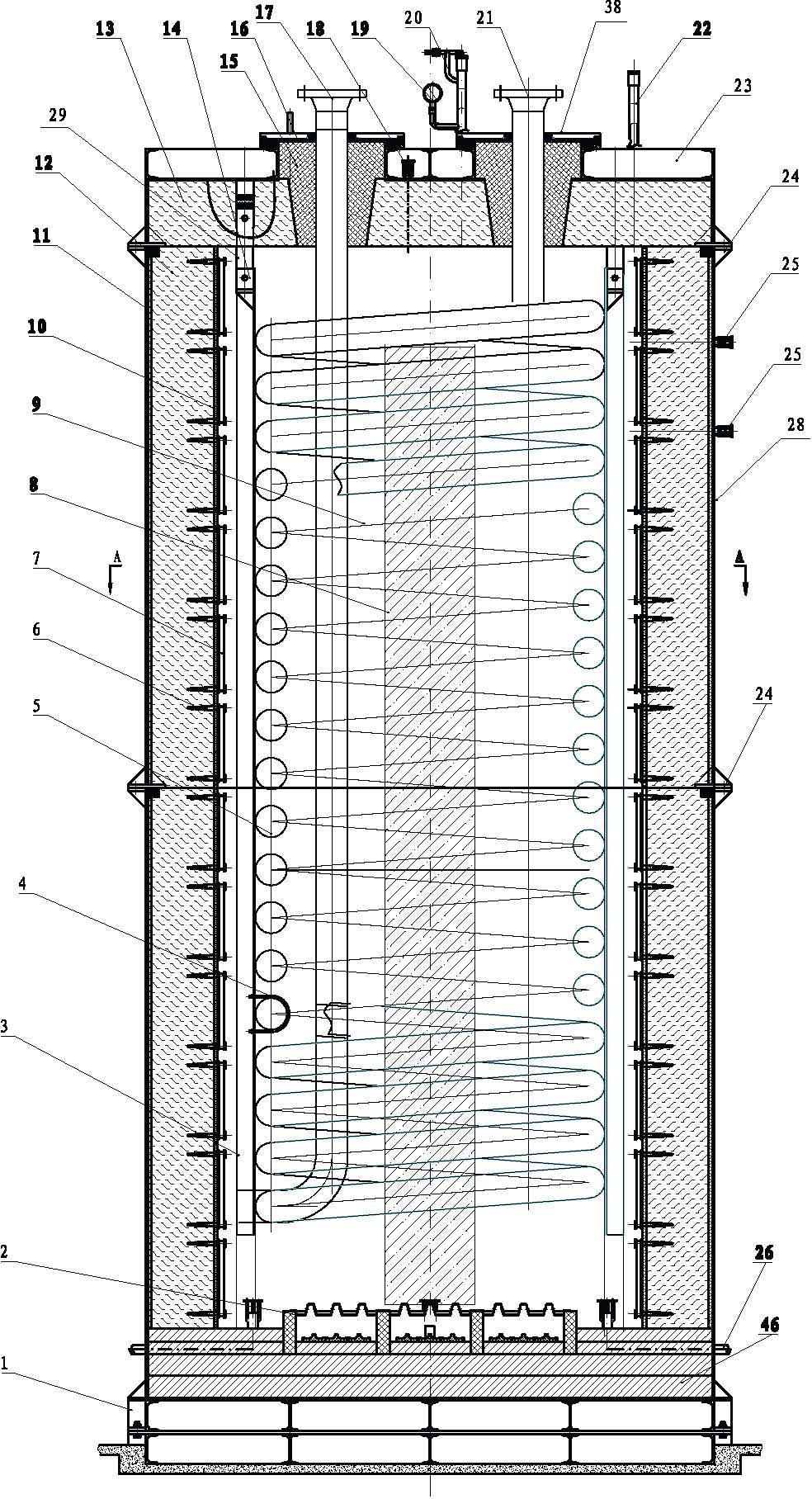

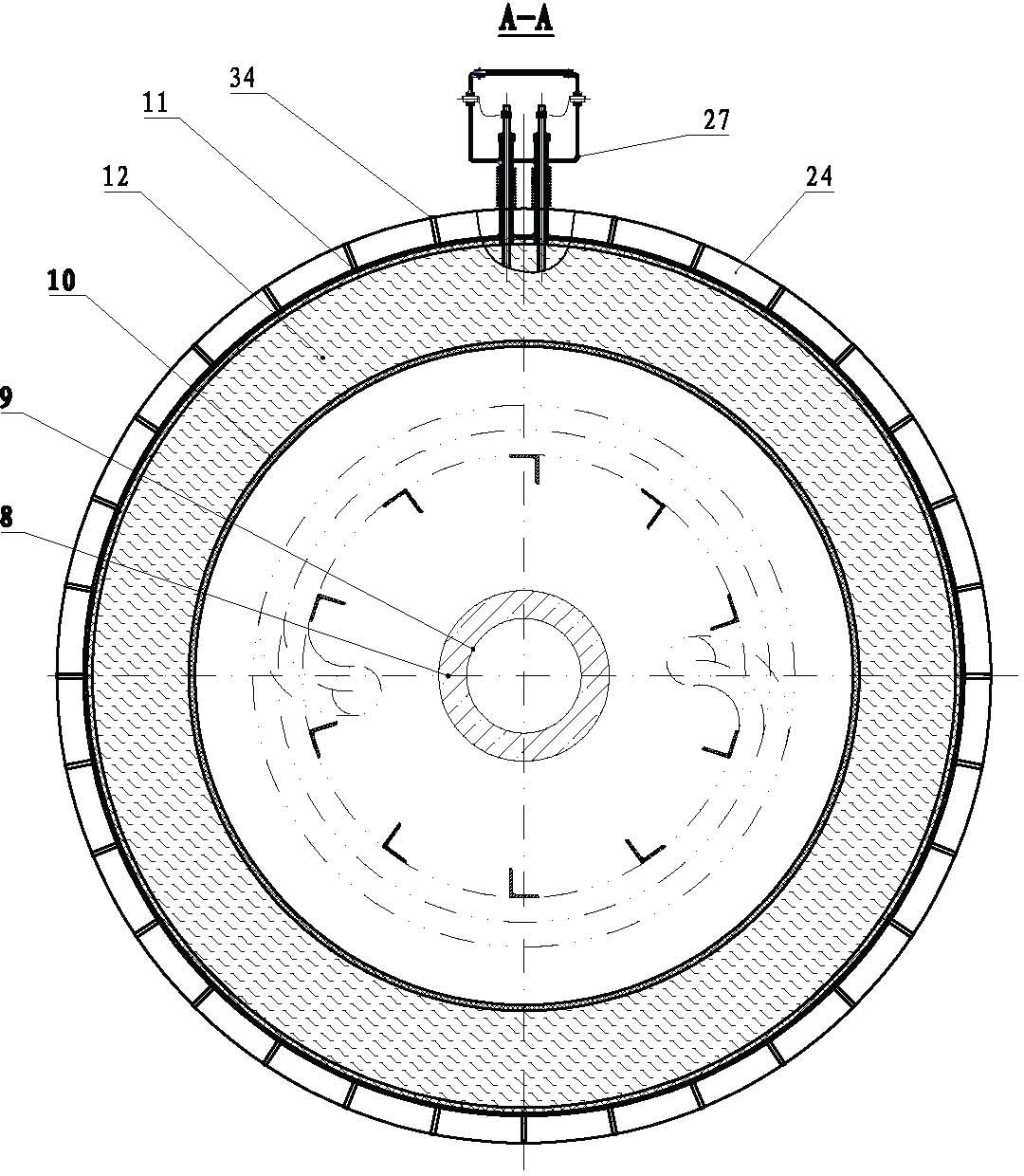

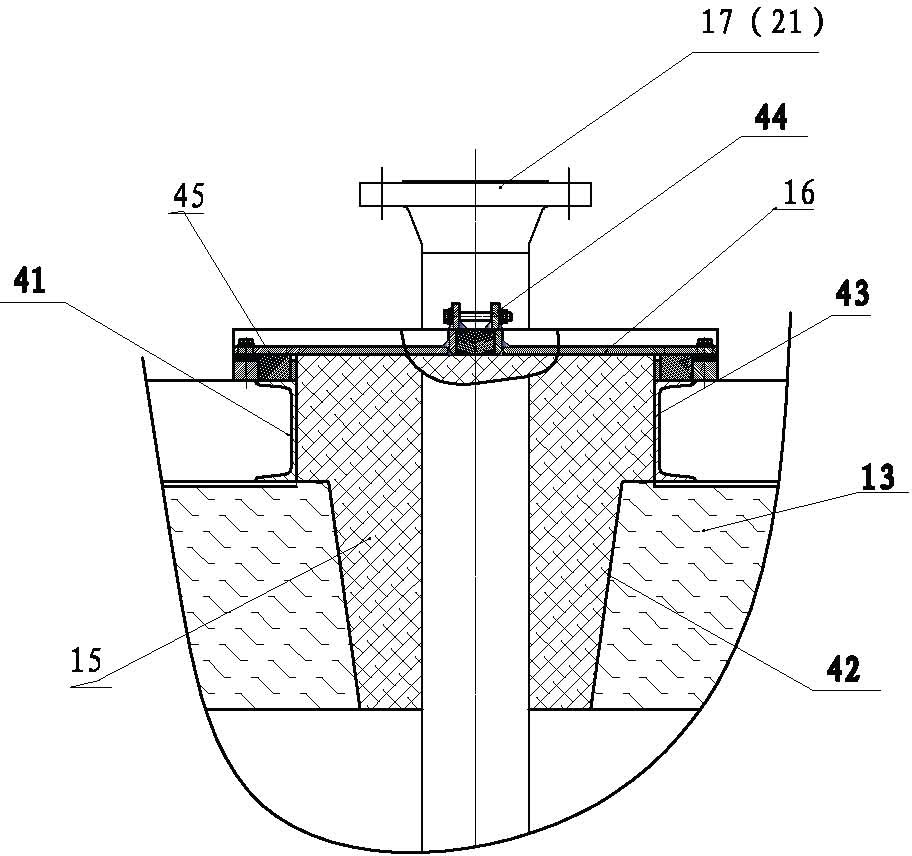

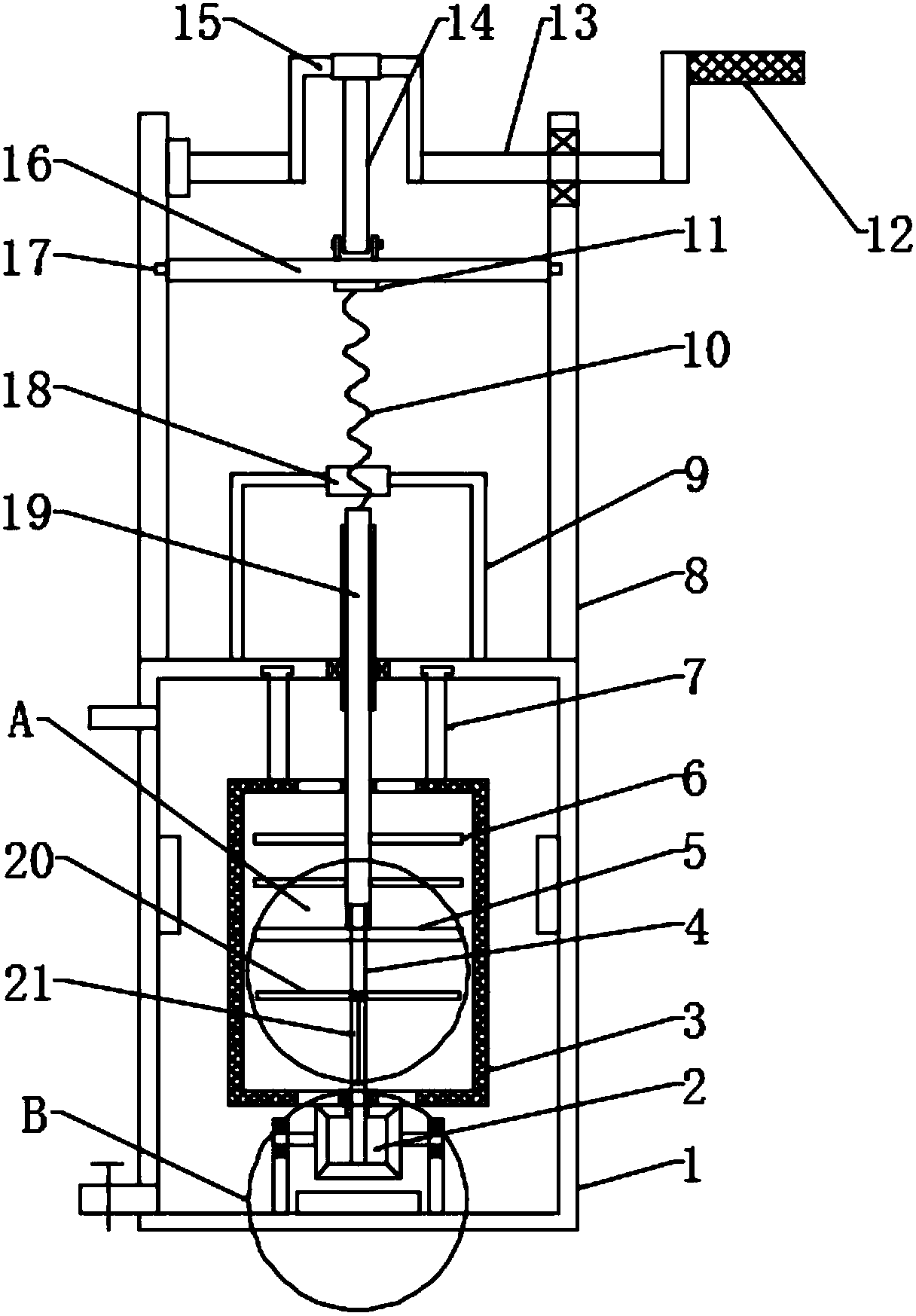

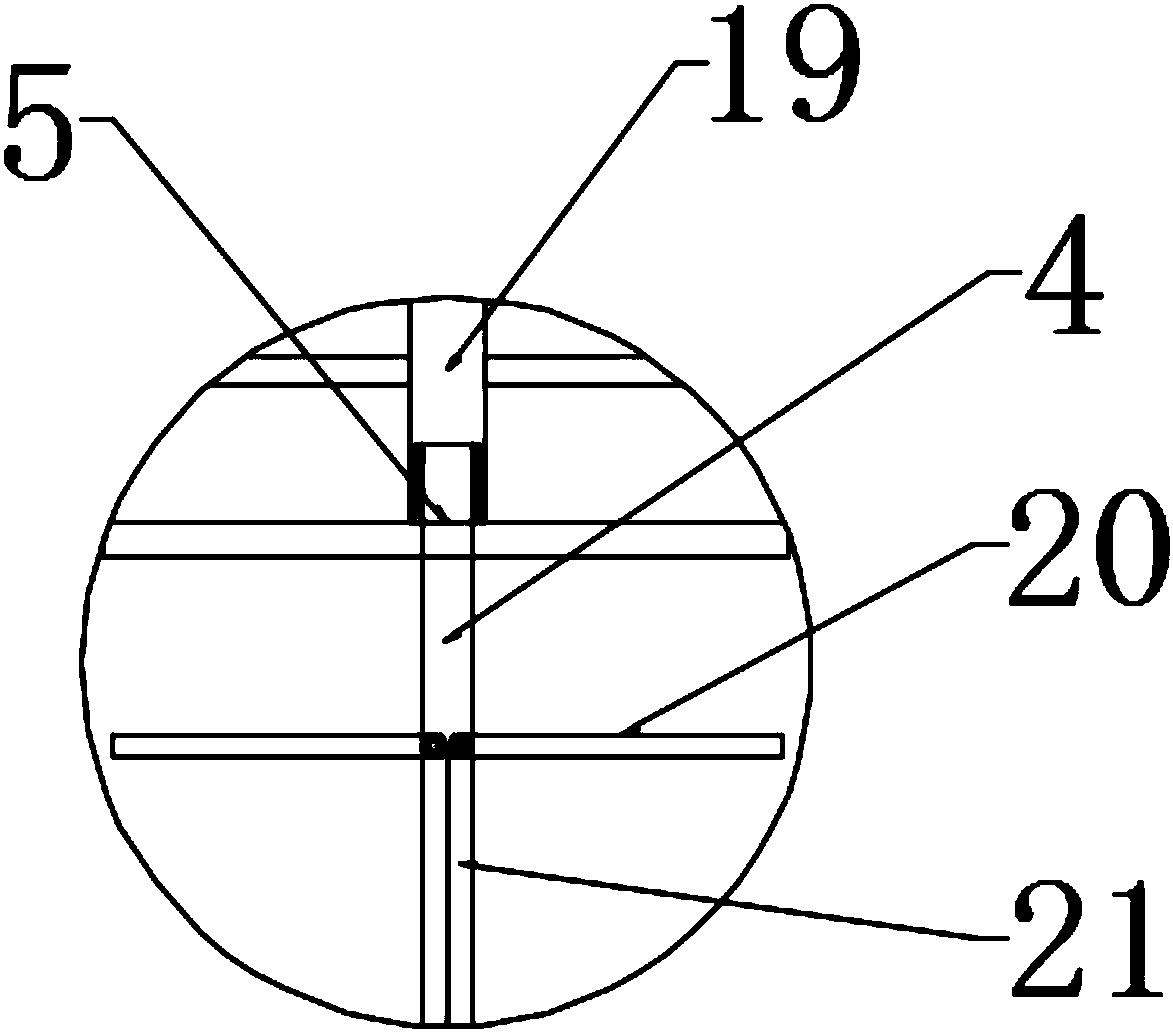

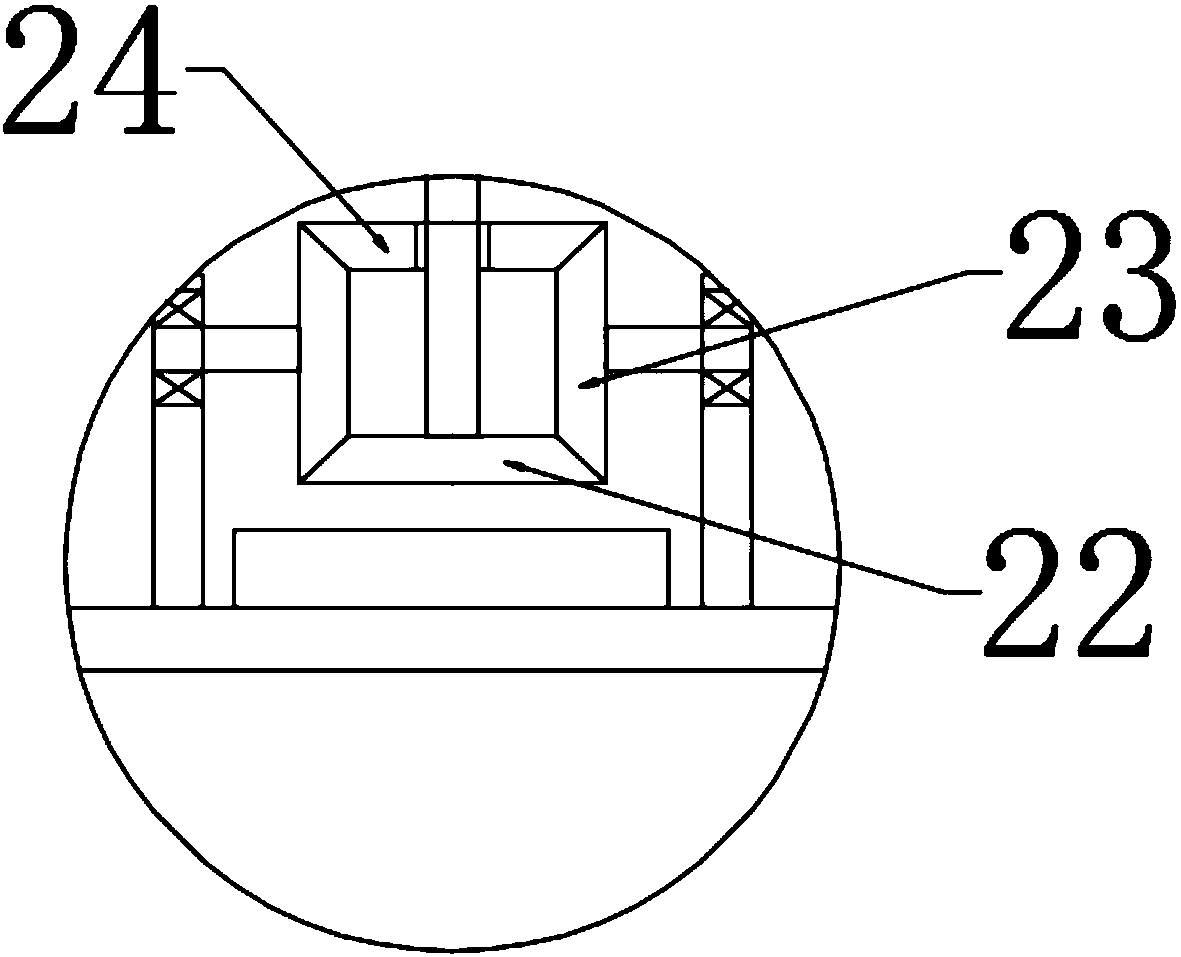

Uniform temperature type efficient electric heating furnace

ActiveCN102432015AEasy to make and take outStable performanceSiliconChemical industryElectric heatingEngineering

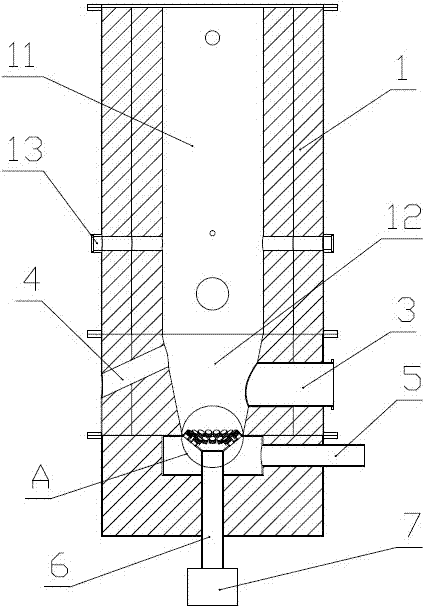

The invention relates to a uniform temperature type efficient electric heating furnace, which comprises a support seat (1), a furnace inner tube (11), a furnace outer tube (11) and a tube body (28), wherein heat insulation materials (12) are filled between the furnace inner tube (10) and the furnace outer tube (11), the tube body (28) is fixedly arranged on the support seat (1) arranged at the bottom of the tube body, and the upper part of the tube body (28) is connected with a furnace cover (23). The uniform temperature type efficient electric heating furnace is characterized in that a resistance belt heating element (7) is arranged on the inner wall of the furnace inner tube (10), a bottom heating element (2) is arranged at the bottom of the tube body (28) and on the support seat (1), acolumn-shaped heating element (8) is arranged in the center of the tube body (28), a heated medium pipe (5) is spirally arranged around the column-shaped heating element (8) and is positioned in an inner cavity of the tube body (28) through a fixing element (4) and a support rod (3), the fixing rod (4) is connected with the lower end of a hanging rod (29) through a connecting element (14), the hanging rod (29) is fixedly arranged in the furnace cover (23), the inlet end (17) and the outlet end (21) of the heated medium pipe (5) respectively pass through the furnace cover (23), a protection gas inlet pipe (26) passes through the bottom (46) of the tube body to be communicated with the inner cavity of the tube body (28), and a protection gas outlet pipe passes through the furnace cover (23)to be communicated with the inner cavity of the tube body (28). The uniform temperature type efficient electric heating furnace has the advantages that the uniform temperature performance in the furnace is good, and the manufacture, the hanging and the maintenance of a furnace pipe are convenient.

Owner:江苏中圣压力容器装备制造有限公司

Method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas

ActiveCN104725634AAvoid it happening againProcess environmental protectionHydrolysisSodium hydroxide

The invention relates to a method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas. The method comprises the following steps: performing substitution reaction of molten maleic anhydride and ammonia gas in a closed reactor and absorbing the residual gas after the completion of the substitution reaction; adding sodium hydrate solution into the reacted maleic anhydride and ammonia gas to perform neutrallzation reaction, so as to obtain a mixture of maleamic acid sodium and maleamic acid ammonium; directly heating the product in the closed reactor and performing condensation polymerization by stirring; steaming and drying the moisture after the completion of the condensation polymerization, so as to obtain the polysuccinimide solid; adding water in another reaction kettle and starting stirring; then adding the polysuccinimide solid into the reaction kettle and slowly adding sodium hydrate solution and heating to perform hydrolysis reaction, so as to obtain the polyaspartic acid solution. According to the method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas, the production process is simplified and the polyaspartic acid prepared according to the method has a weight-average molecular weight of 2000-15000 and a molecular weight distribution index of 1.5-1.65, so that molecular weight requirements of various application domains are met and environment-friendly production process is realized.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

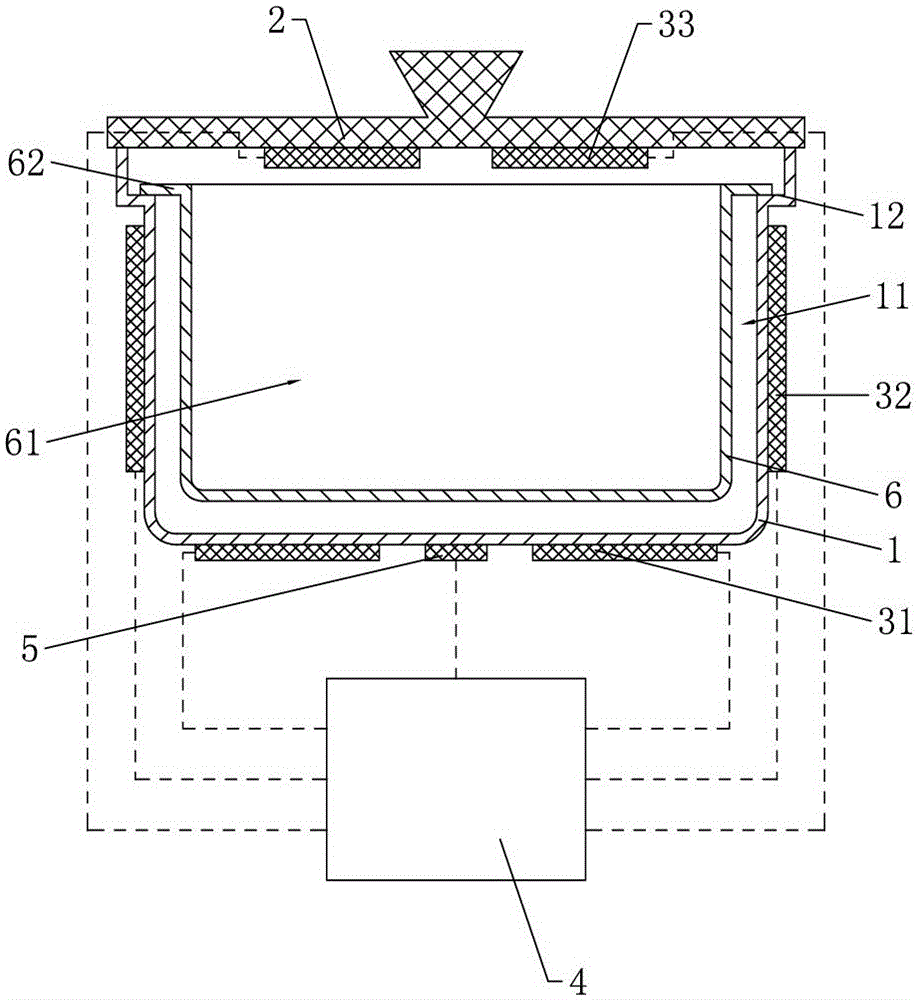

Convection conduction type electrical heating device for electric cooker

InactiveCN106388625AHeating fully and evenlyHeated evenly and fullyCooking-vessel materialsWarming devicesHeating effectEngineering

The invention discloses a convection conduction type electrical heating device for an electric cooker. A heating inner container is embedded into an outer container containing cavity of a metal heating outer container, the upper side end of the metal heating outer container is provided with a movable cover body at an opening of the upper end of the outer container containing cavity, a bottom surface thick film heating element is printed on the lower surface of the metal heating outer container, a side wall thick film heating element is printed on the outer surface of the side wall of the metal heating outer container, and a cover body thick film heating element is printed at a middle position of the lower surface of the movable cover body; the novel electric cooker electrical heating device also comprises a controller, and a temperature sensor is arranged on the lower surface of the metal heating outer container; and a food heating chamber is moulded inside the heating inner container, the heating inner container is suspended in the outer container containing cavity, and the outer surface of the heating inner container and the inner wall of the outer container containing cavity are arranged at intervals. The convection conduction type electrical heating device for the electric cooker has the advantages that a safe and nonradiative surround three-dimensional thick film heating way is adopted for heating and cooking food, and the food can be effectively, fully and uniformly heated. Therefore, the convection conduction type electrical heating device for the electric cooker has the advantages of novel structural design, high security and good heating effect.

Owner:DONGGUAN ZUOYOU ELECTRONICS TECH CO LTD

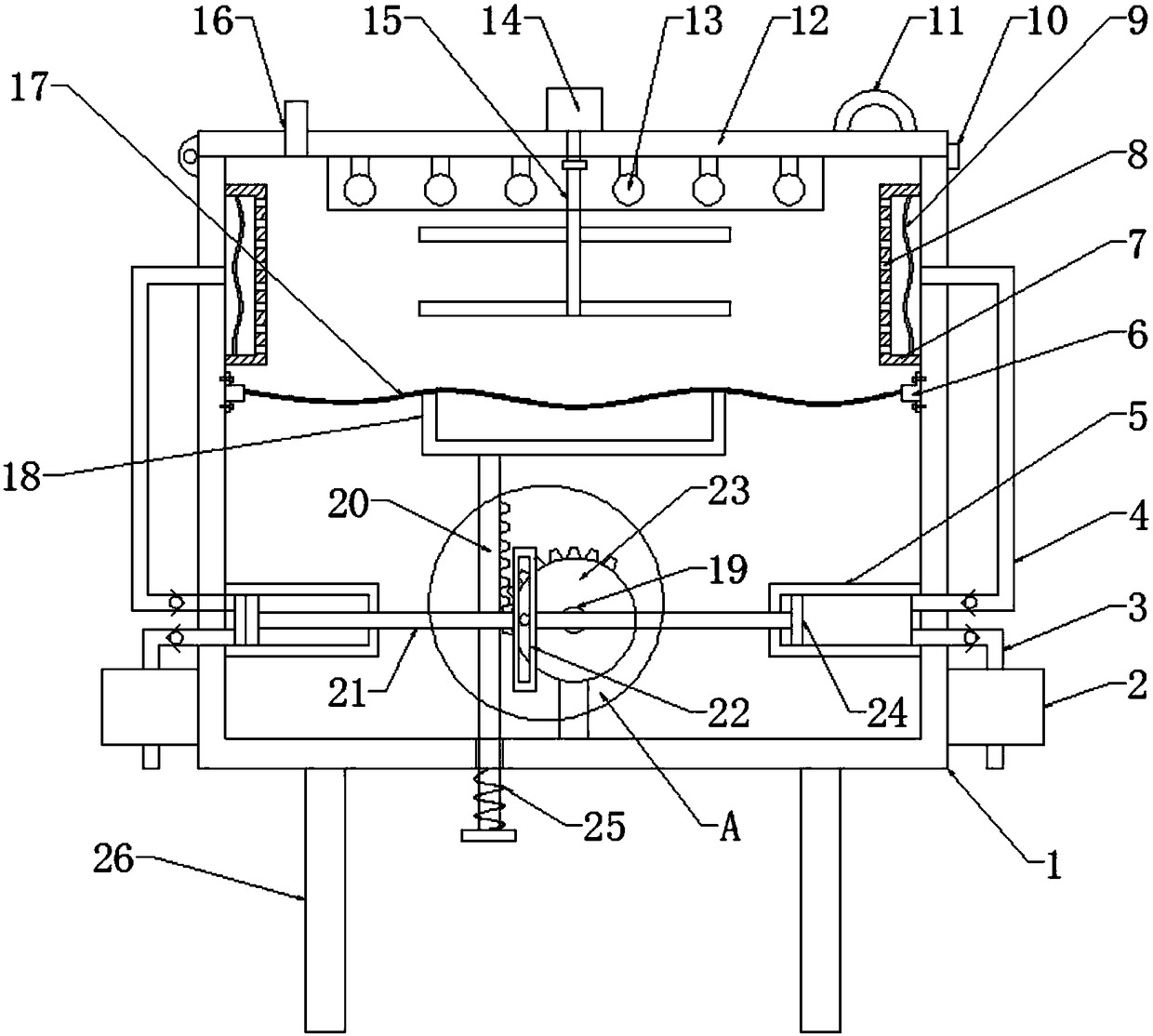

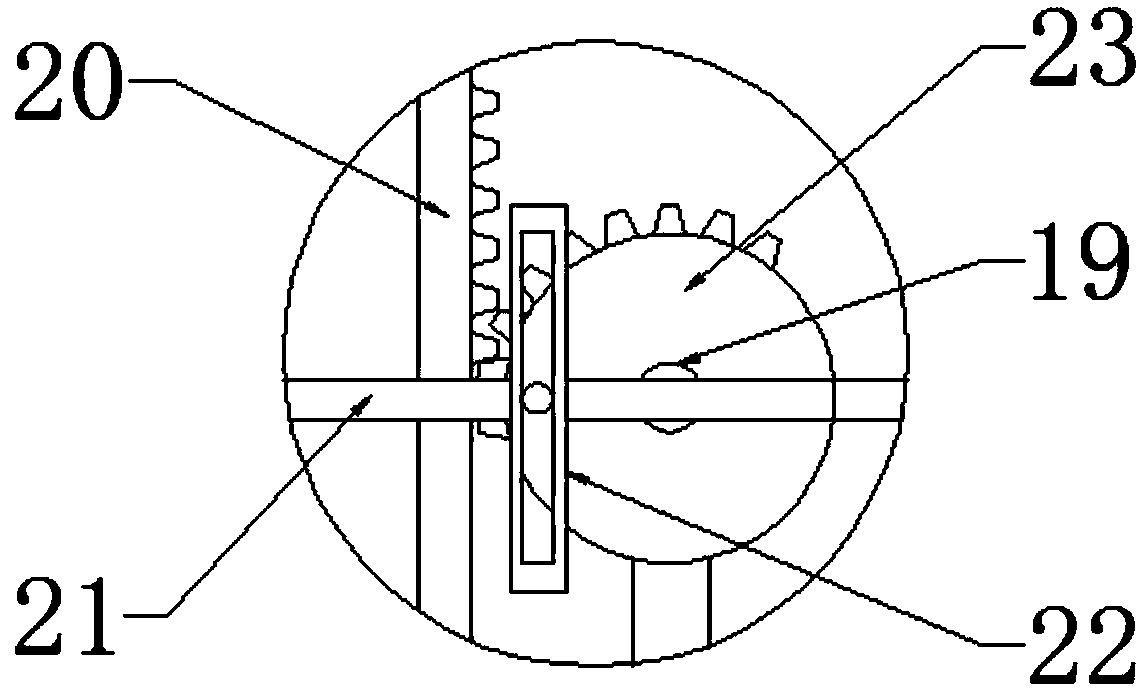

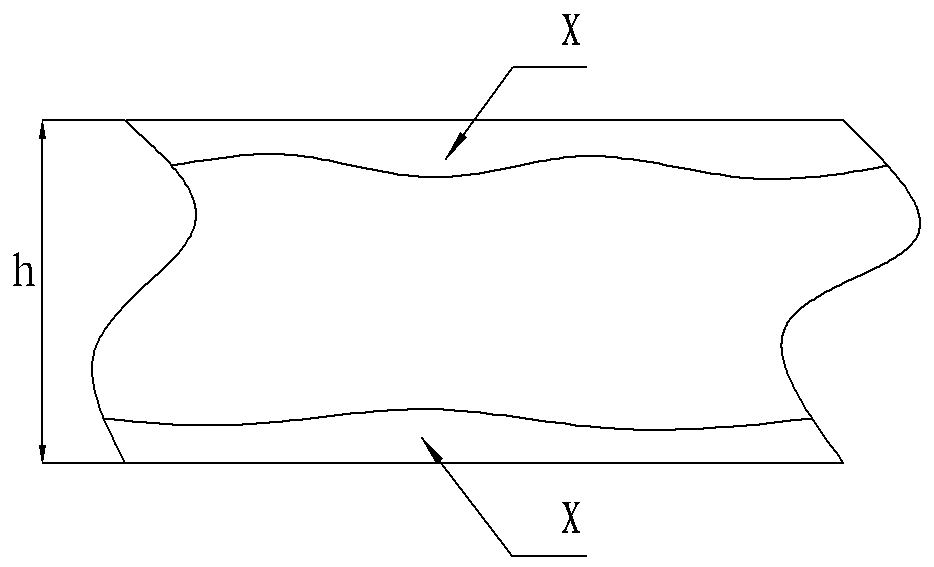

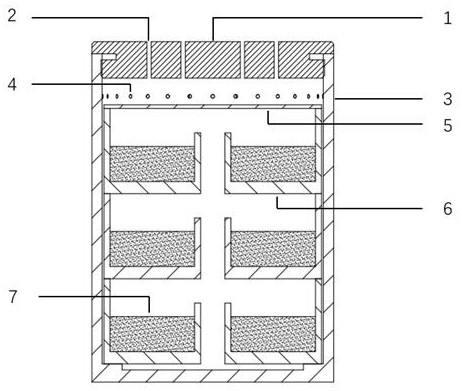

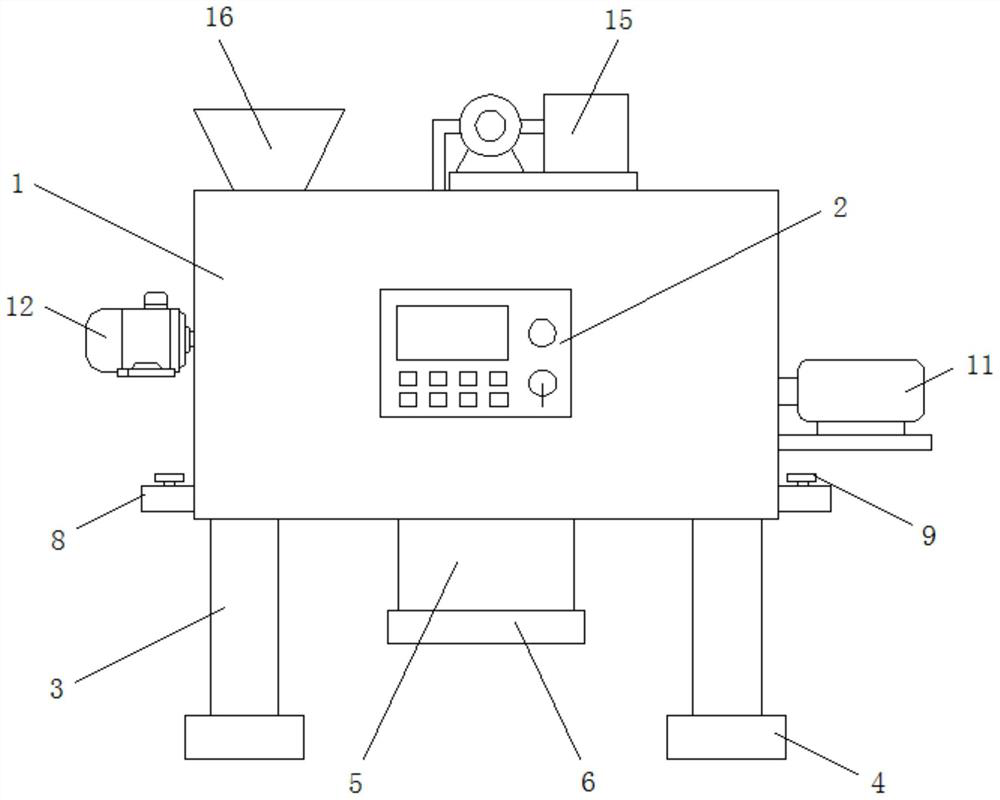

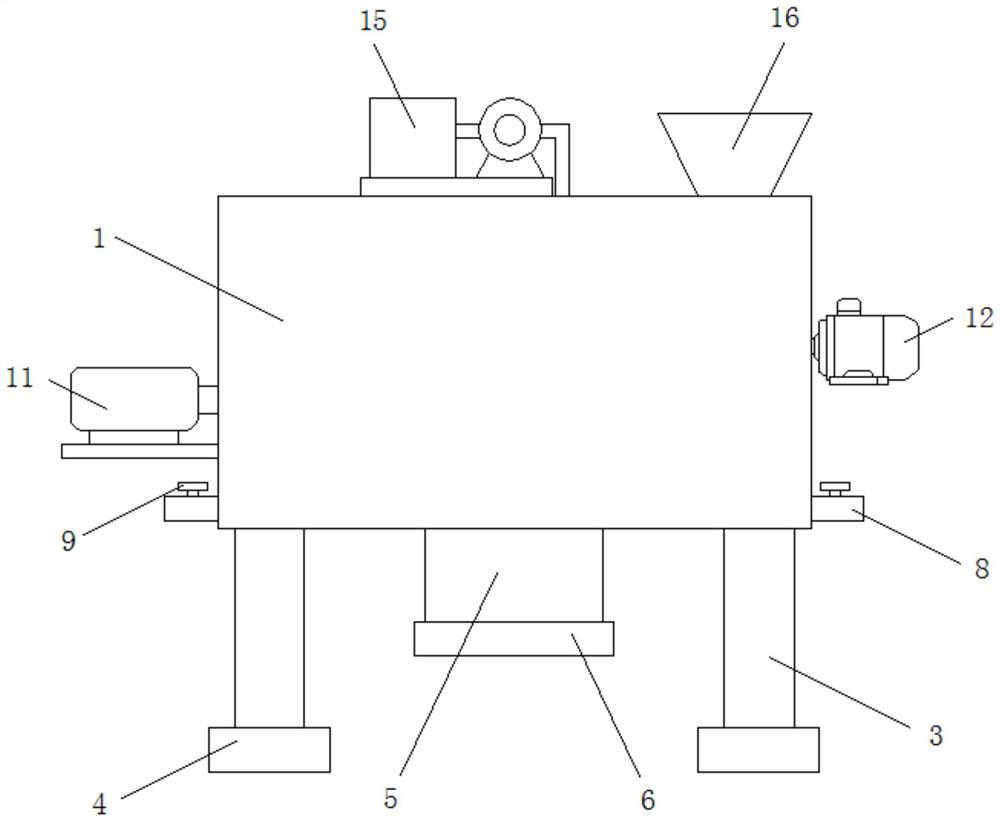

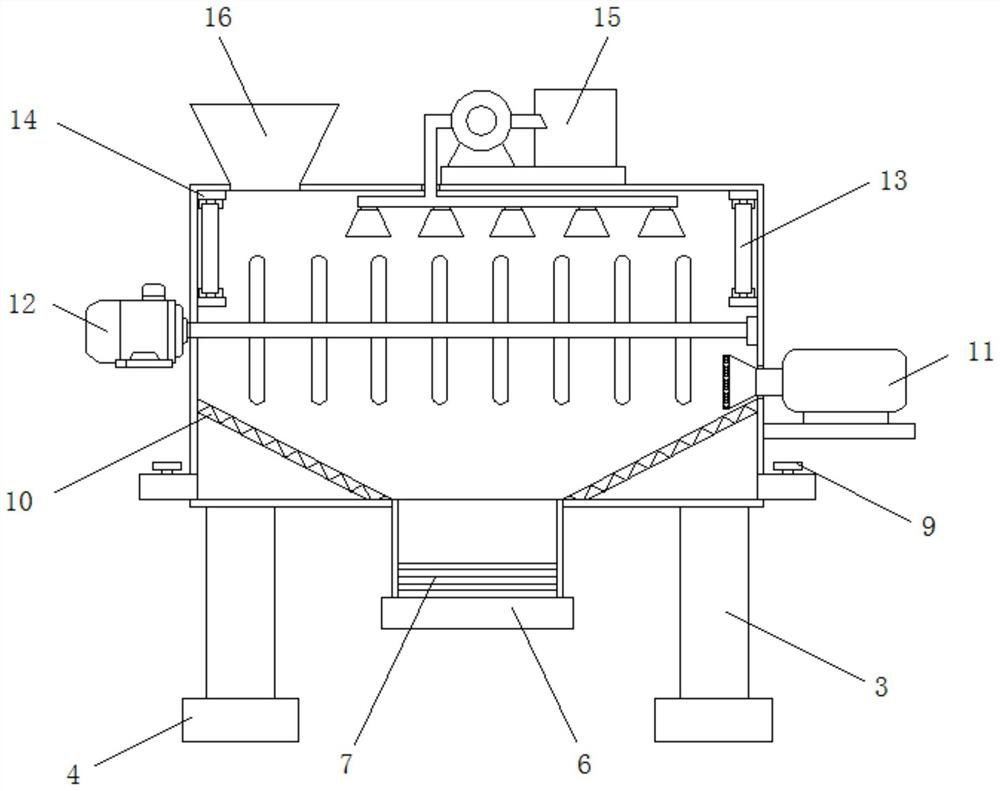

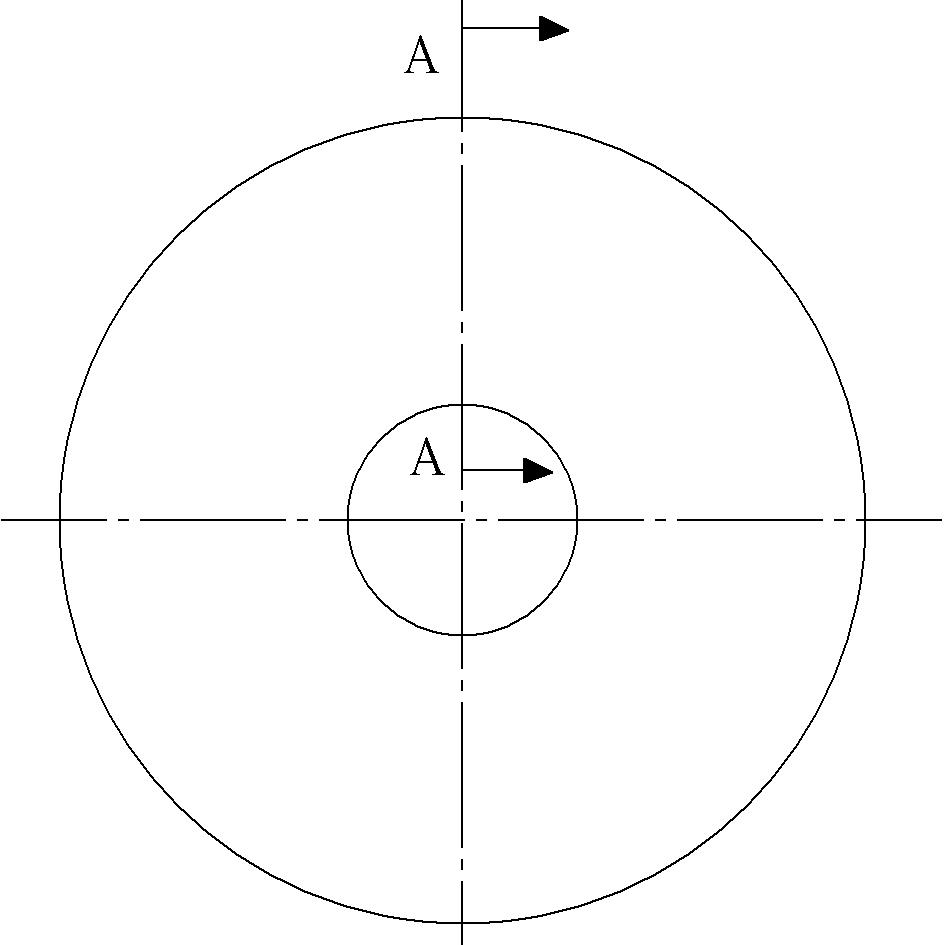

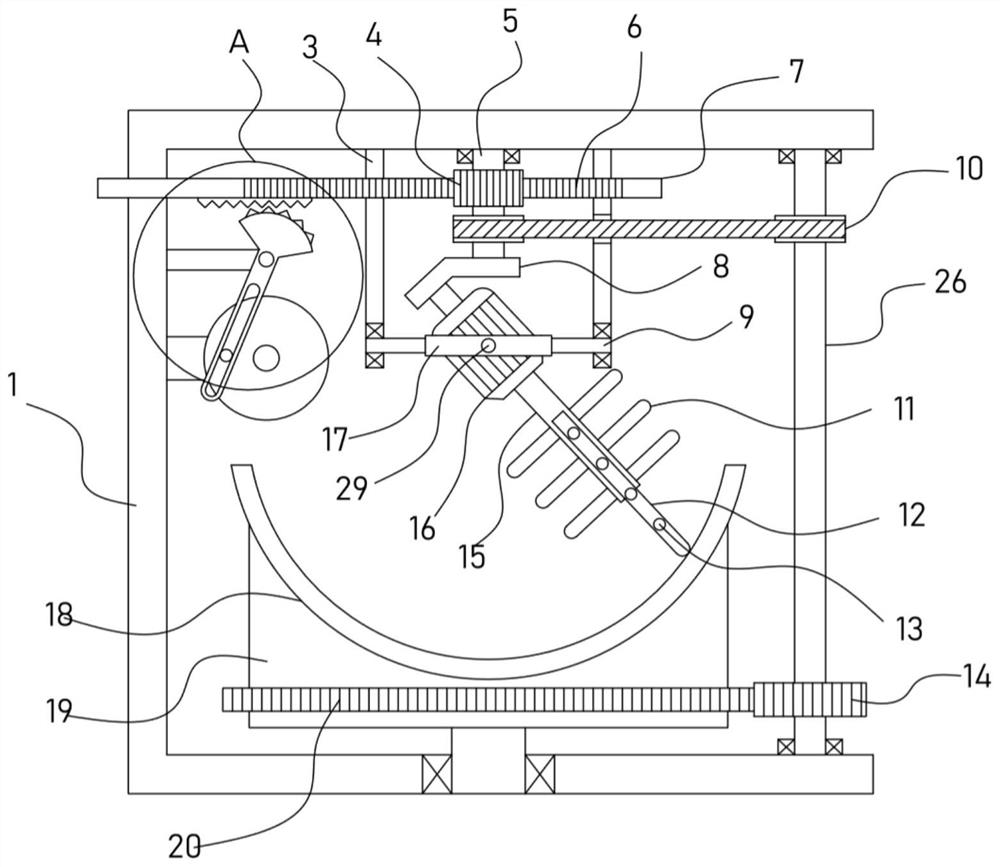

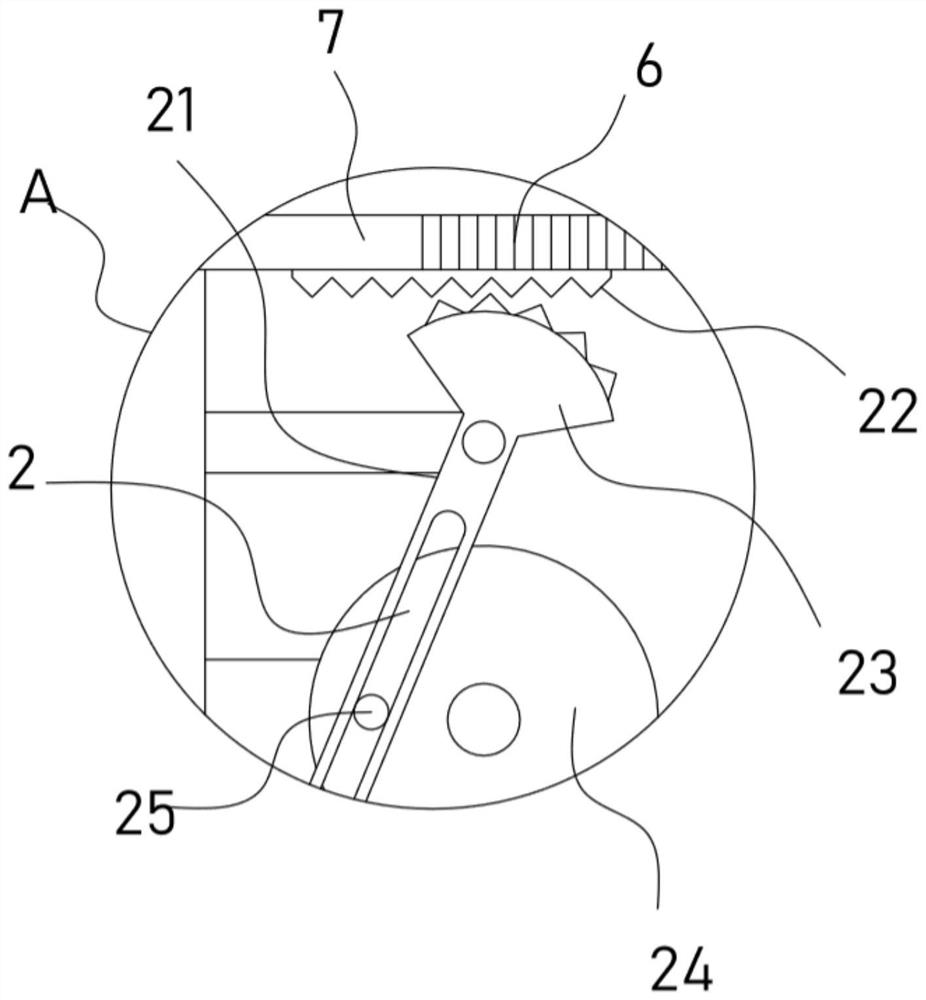

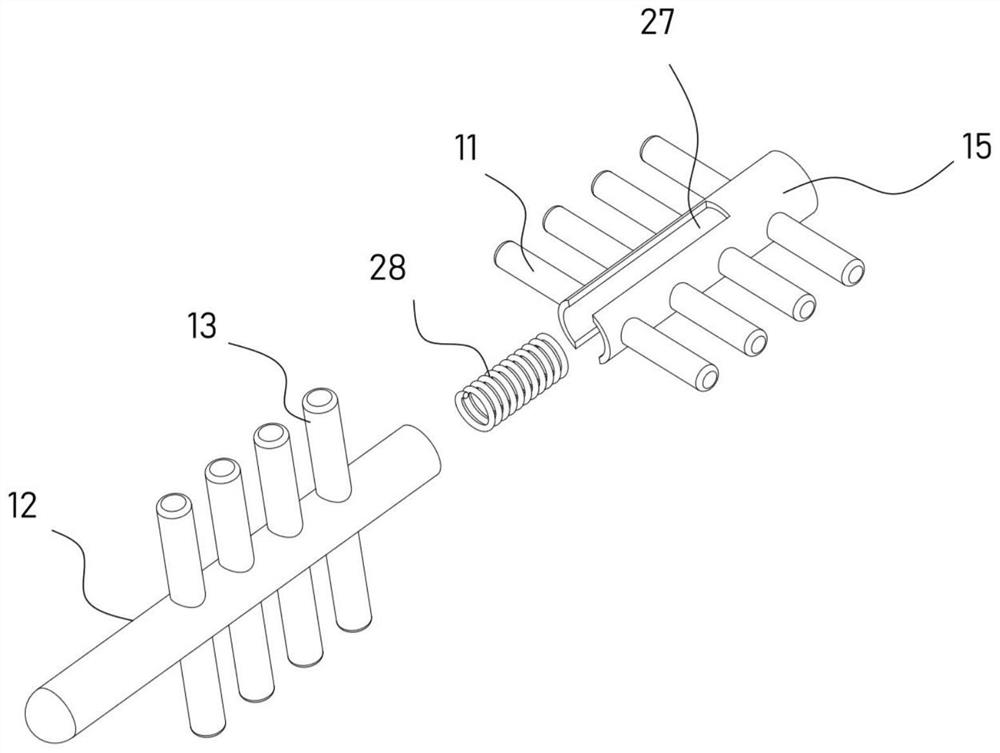

Impact traditional Chinese medicine efficient drying equipment

InactiveCN108302917AAvoid accumulationHeated evenly and fullyDrying solid materials with heatDrying gas arrangementsElectric heatingElectricity

The invention discloses impact traditional Chinese medicine efficient drying equipment. The equipment comprises a box body, a box cover, support cloth, a first motor, a stirring shaft, a stirring rod,a drying lamp, a box, an electric heating wire, a second motor, an incomplete gear, a rack, a spring, a U-shaped rod, a movable rod, a piston rod, a cylinder block and a piston. The equipment is provided with the first motor, the stirring shaft and the stirring rod for preventing accumulation of traditional Chinese medicines to fully and uniformly heat the traditional Chinese medicines, and is provided with the second motor, the incomplete gear, the rack, the spring and the support cloth for cooperatively driving the U-shaped rod to quickly impact on the support cloth; under impact force, thetraditional Chinese medicines on the support cloth are thrown up for scattering, so that water vapor in the traditional Chinese medicines is dissipated, the traditional Chinese medicines are heated more fully and uniformly, and the drying efficiency is improved; and the equipment is provided with the movable rod, the piston rod, the piston, the cylinder block, the box and the electric heating wire for continuously spraying out hot air from the two sides to dry the traditional Chinese medicines, so that the drying speed is high, and the drying efficiency is further improved.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

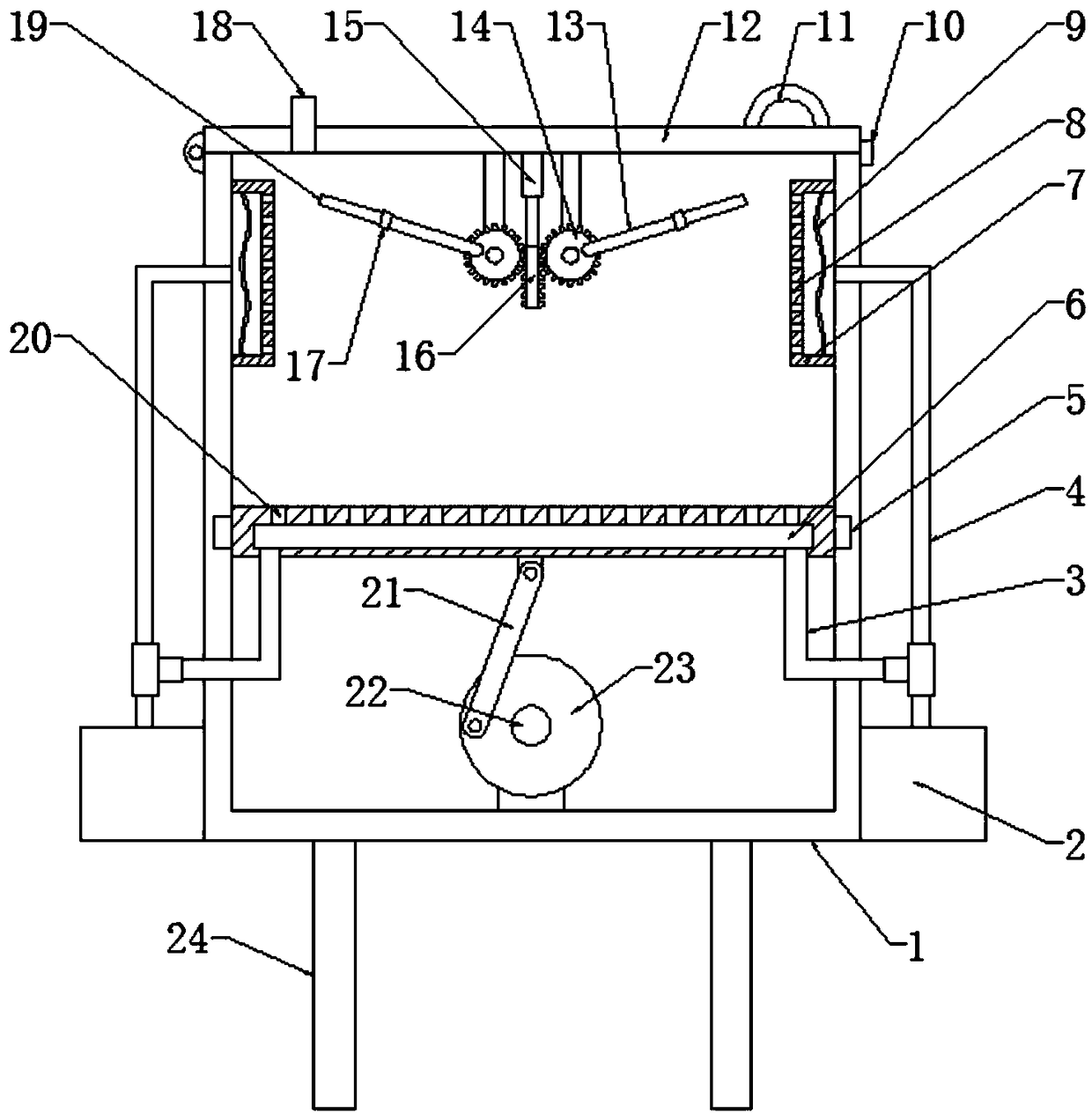

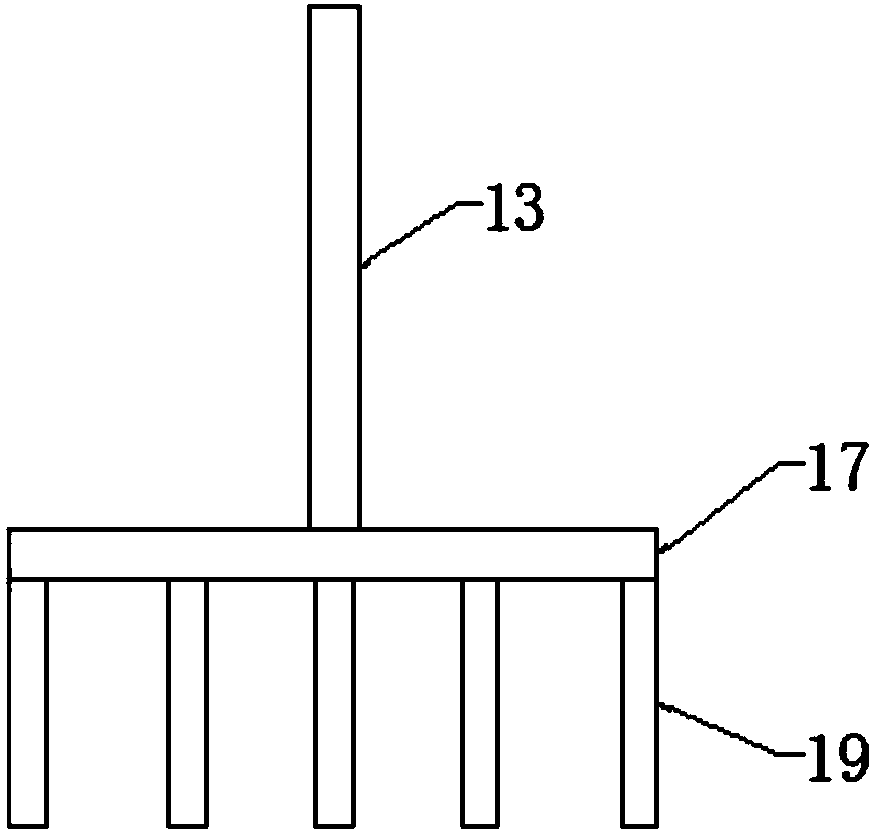

Traditional Chinese medicine drying device simulating hand turning-over

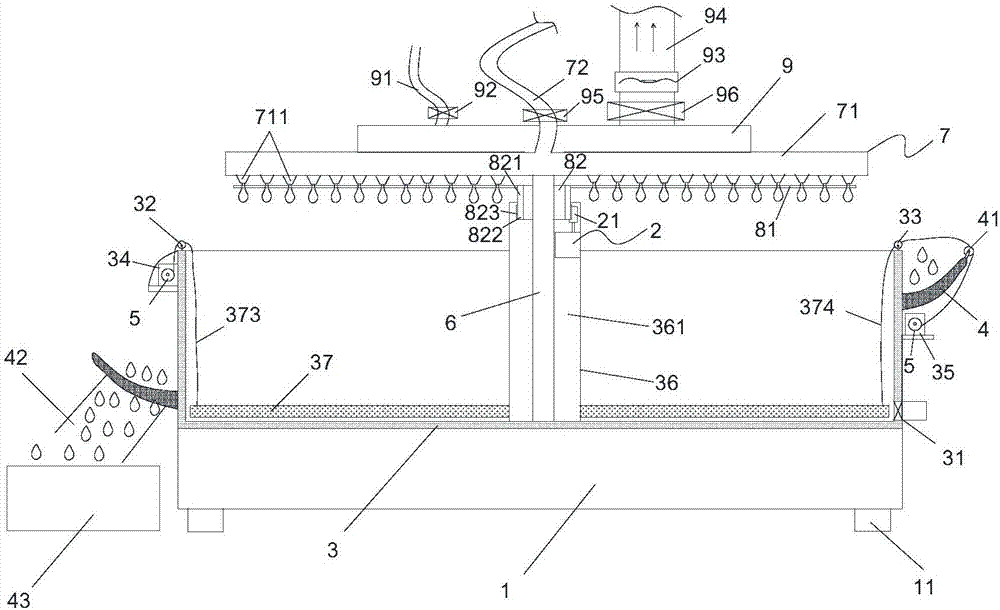

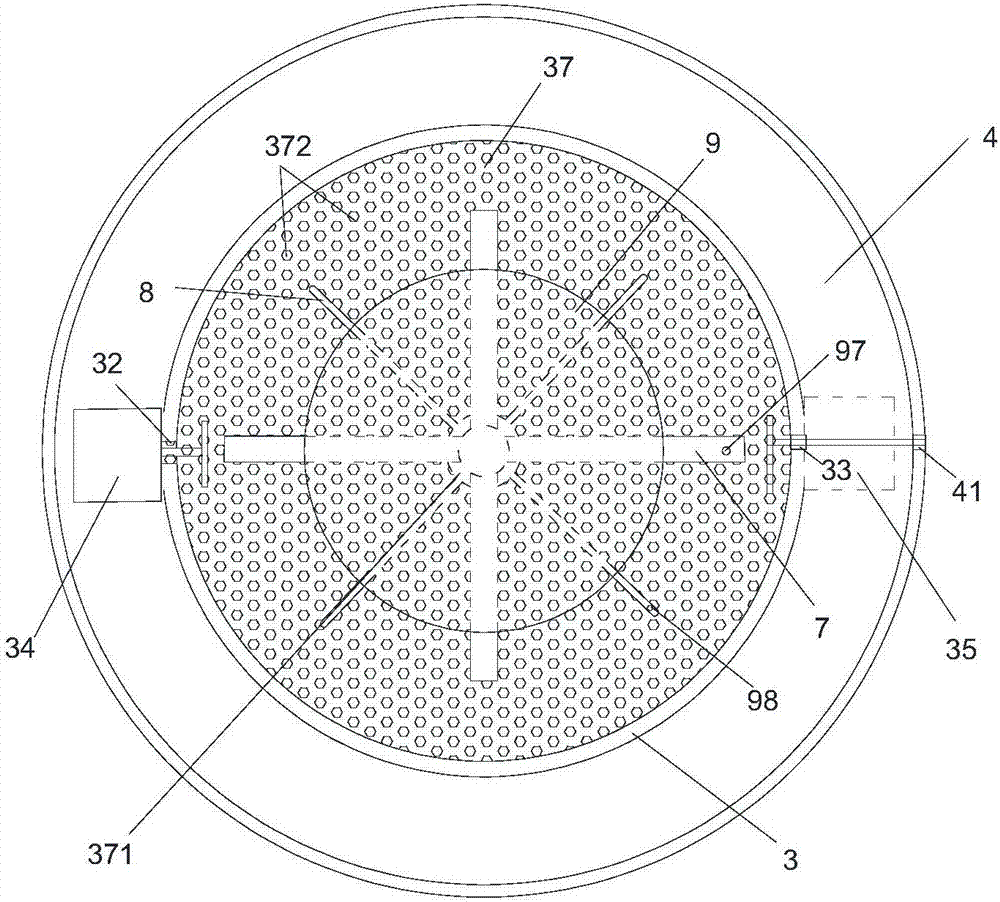

InactiveCN108253751AFully heatedHeated evenly and fullyDrying gas arrangementsDrying solid materialsCircular discElectricity

The invention discloses a traditional Chinese medicine drying device simulating hand turning-over. The traditional Chinese medicine drying device comprises a case body, a case cover, an electric pushrod, a rack, a gear, connecting rods, mounting rods, turning-over rods, box bodies, electric heating wires, a movable plate, a motor, a disc, a connecting rod, air heaters, first hoses and second hoses. The traditional Chinese medicine drying device is provided with the air heaters, the box bodies, the electric heating wires, the first hoses, the second hoses and the movable plate, traditional Chinese medicine is dried multi-directionally and heated more fully, and thus the drying efficiency is improved; the electric pushing rod, the rack, the gear, the mounting rods and the turning-over rodsare arranged, the turning rods swing continuously through cooperation and synchronously act like the two hands of people to turn over the traditional Chinese medicine, thus accumulation of the traditional Chinese medicine is avoided, moisture volatilizing is accelerated, and the drying efficiency is improved; and the motor, the disc and the connecting rod are arranged, the traditional Chinese medicine is thrown in air through cooperation, and hot air fully makes contact with the traditional Chinese medicine, so that the traditional Chinese medicine is heated more fully and more evenly, moisture volatizing is faster, and the drying efficiency is further improved.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

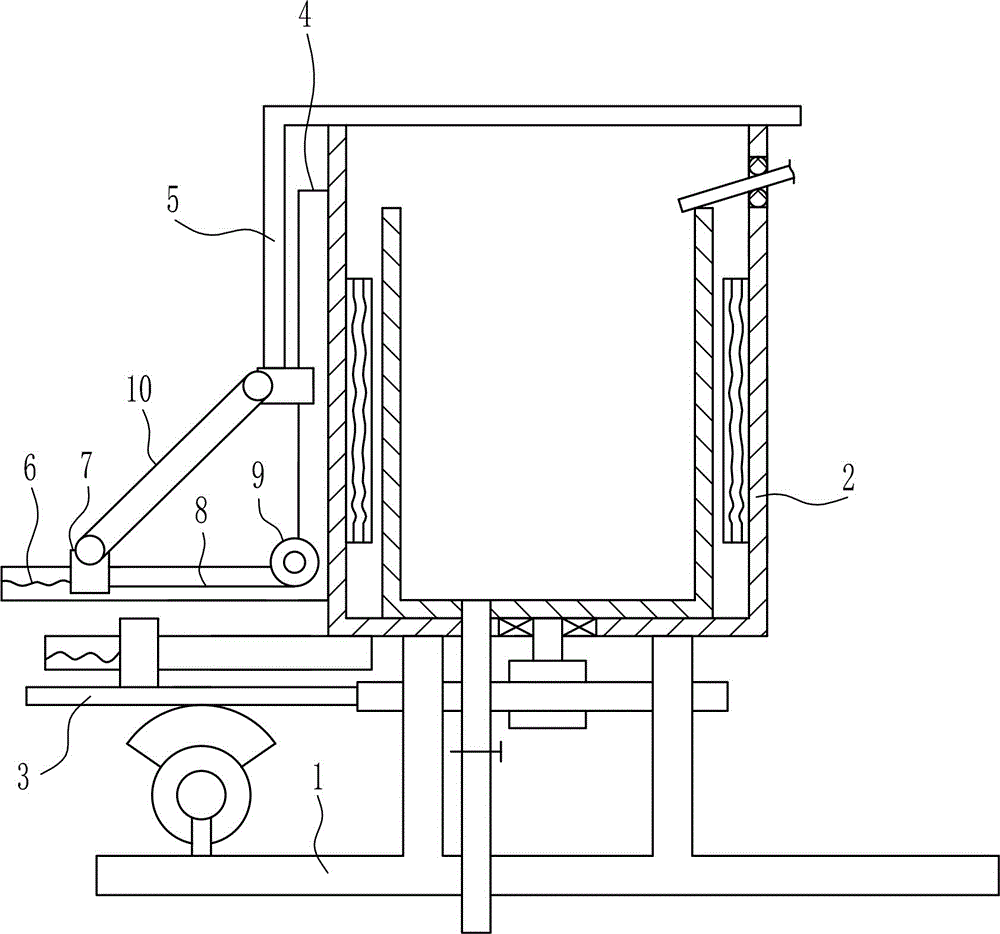

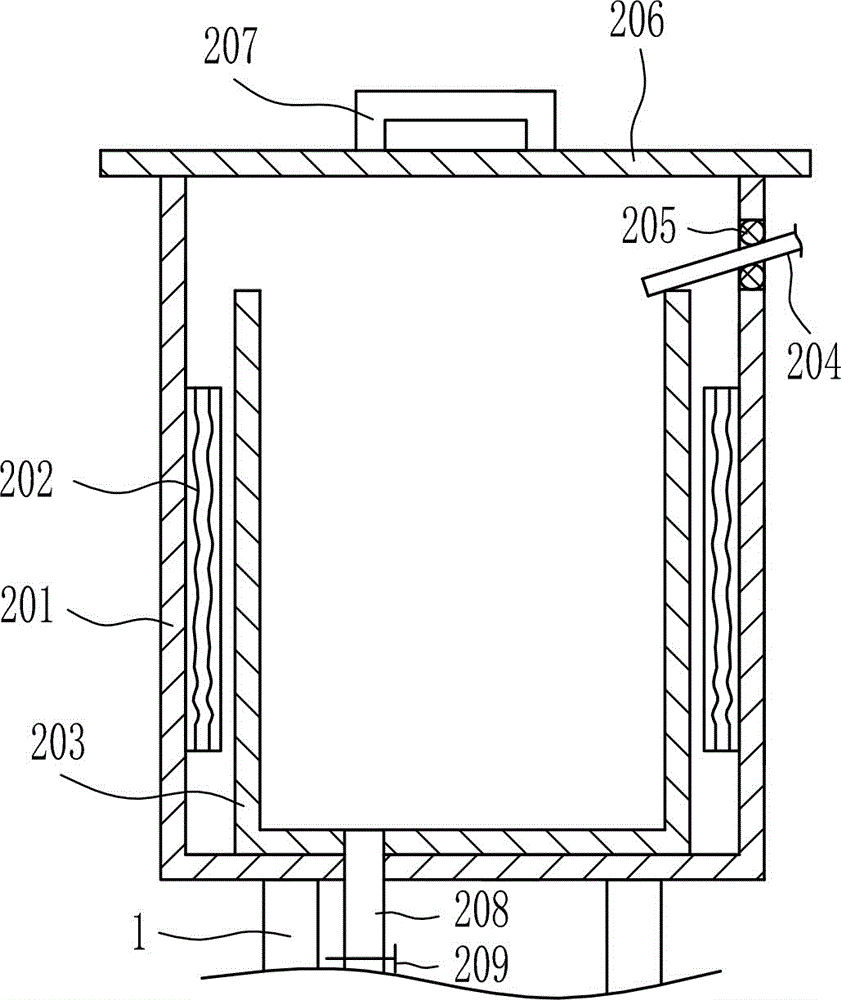

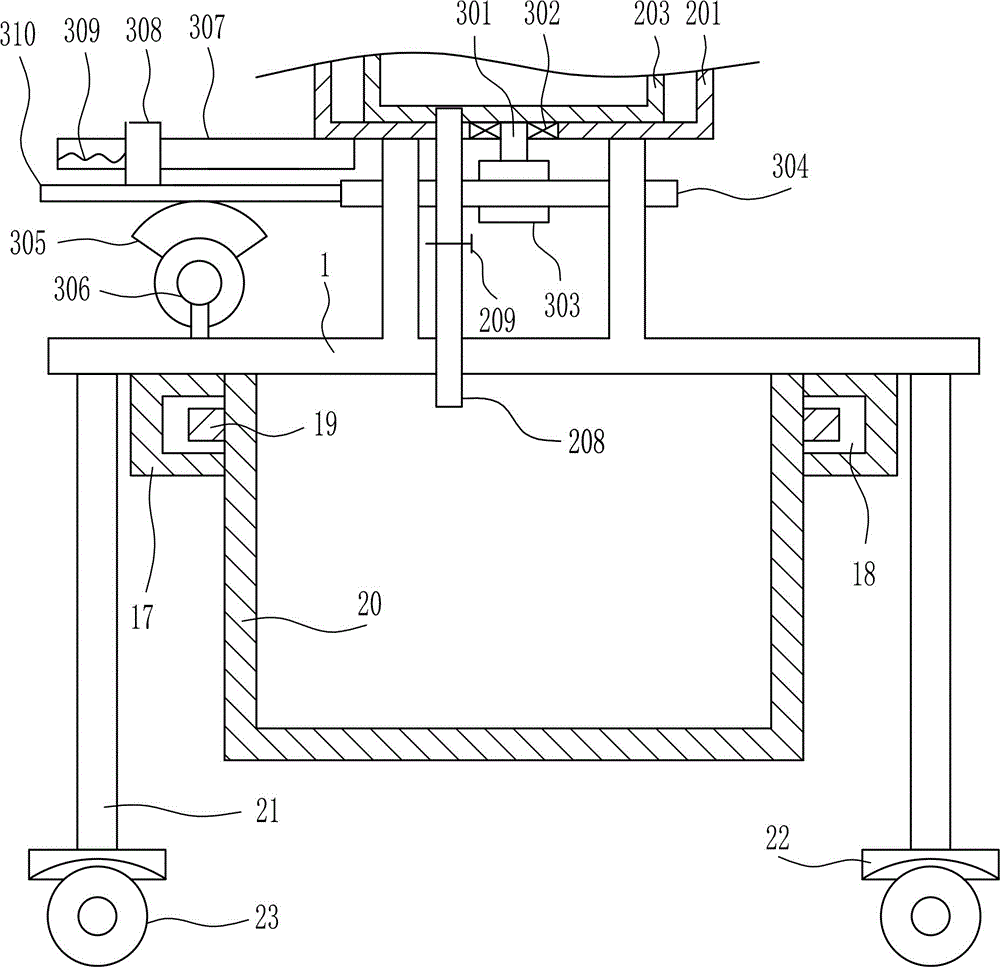

Melting equipment for petroleum asphalt

ActiveCN107523322AMelt evenly and fullyMelt stableWorking-up pitch/asphalt/bitumen by meltingAsphaltPetroleum

The invention relates to melting equipment, in particular to melting equipment for petroleum asphalt. The invention aims at providing the melting equipment for the petroleum asphalt, which can replace manual stirring, enables the petroleum asphalt to be uniformly and sufficiently melt and avoids the conditions that wastes are caused and splashed liquid threatens the safety of workers due to the fact that the petroleum asphalt is not uniformly melt and further is boiled for splashing. For solving the technical problem, the invention provides the melting equipment for the petroleum asphalt. The melting equipment comprises a base plate and the like, wherein a melting device is connected to the top end of the base plate; a driving mechanism is connected to the bottom of the melting device. The invention provides the melting equipment for the petroleum asphalt; the melting device is arranged for quickly melting the petroleum asphalt and preventing the petroleum asphalt from splashing out of the melting device; the driving mechanism is arranged for uniformly and sufficiently heating the petroleum asphalt in a rotating tank and stably melting the petroleum asphalt.

Owner:天津领先正华能源科技发展有限公司

Method for eliminating annealing white spots on edge of cold-rolled aluminum coil

The invention discloses a method for eliminating annealing white spots on the edge of a cold-rolled aluminum coil, and relates to the technical field of aluminum alloy heat treatment. The method comprises the steps: A, when complete annealing is about to be carried out, after the aluminum coil is pushed into an annealing furnace, filling the annealing furnace with high-purity inert gas, wherein the concentration of the inert gas reaches 90-98%; B, during annealing, increasing the temperature to 200 to 240 DEG C, preserving the temperature for 6 to 15 hours, and controlling the coiling tensilestress before annealing to be 25 MPa or more; C, after the heat preservation is finished, filling the annealing furnace with high-purity argon until the concentration of the inert gas in the furnace reaches 98-100%; and D, increasing the temperature to the target temperature for complete annealing, preserving the temperature, cooling to 200 DEG C or below along with the furnace, and discharging. Compared with the prior art, the method can solve the problem that the edge of an existing aluminum coil has white spot defects in the process of complete annealing.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

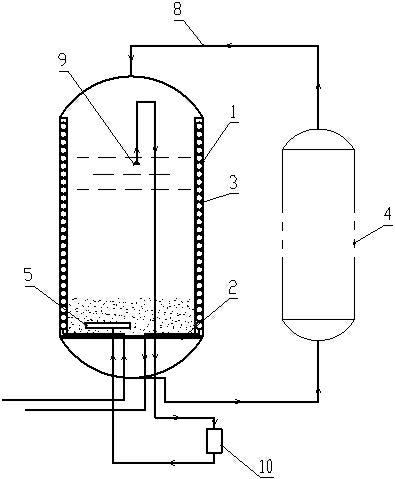

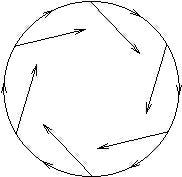

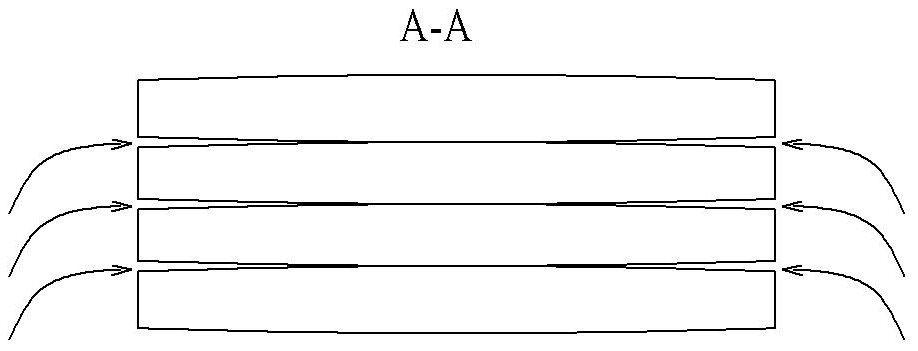

Forced reflux extraction tank and forced reflux extraction process

The invention discloses a forced reflux extraction tank, which comprises a tank body, wherein a grate is arranged on the bottom part in the tank body; the tank body is provided with a cyclone system; the cyclone system comprises a fluid suction port, a pump and a cyclone which are connected through a pipeline; the fluid suction port is arranged on the upper part in the tank body; the cyclone comprises a main cyclone tube and sub cyclone tubes connected onto the main cyclone tube; the main cyclone tube is in an arc shape; one end of each sub cyclone tube is connected with the inner side of the arc shape, and the other end of each sub cyclone tube is provided with an opening; and the sub cyclone tube are inclined towards the opening direction of the main cyclone tube. According to the reflux extraction tank, the cyclone system is adopted, the trash pump is used for sucking liquid medicine on the top part in the tank body from the fluid suction port and pumping into the cyclone, and then the liquid medicine is respectively sprayed out through the main cyclone tube and the sub cyclone tubes, so that medicinal materials deposited on the grate is rotated and turned accordingly, the accumulation of the medicinal materials is effectively avoided, the mixing of the medicinal materials is more uniform, and the heating is also more uniform.

Owner:HENAN SOAR VETERINARY PHARMA

Deposition method of SiOx passive film and LED (light emitting diode) chip with passive film

InactiveCN102569564AHeated evenly and fullyElicit activitySemiconductor devicesPlasma activationNitrogen atmosphere

The present invention provides a deposition method of a SiOx passive film and an LED (light emitting diode) chip with the passive film. The deposition method of the SiOx passive film comprises the following steps: obtaining a preheated wafer by a preheating step; depositing a SiOx passive film on the surface of the preheated wafer after processing the preheated wafer by multiple plasma activation steps and SiOx passive film pre-deposition steps in turn and repeating the plasma activation step and the SiOx passive film pre-deposition step in turn for 4-6 times, wherein the preheating step is performed under the nitrogen atmosphere. The deposition is performed repeatedly for many times and after each deposition, the plasma is used to bomb the passive film, thus the Si atom of the passive film is completely oxidized, the quality of the SiOx film is improved and the compactness of the passive film is increased, therefore the passive effect is increased.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Medicine decocting device for traditional Chinese medicine

ActiveCN107789193AImprove stirring efficiencyHeated evenly and fullyPharmaceutical product form changeDomestic articlesAdditive ingredientTraditional medicine

The invention discloses a medicine decocting device for traditional Chinese medicine. The device comprises a box body, a medicine placement cylinder, crankshafts, rod journals, a sleeve, a connectionrod, a spiral rod, a spiral sleeve, a first stirring shaft, a press plate, first stirring rods, a second stirring shaft, a second stirring rod and a transmission mechanism. The transmission mechanismcomprises a first inclined gear, a second inclined gear and a third inclined gear. The medicine decocting device is provided with the crankshaft, the spiral rod, the spiral sleeve, the first stirringshaft, the second stirring shaft, the first stirring rod and the second stirring rod, the first stirring rods are driven to move up and down and rotate forward and reversely through cooperation at thesame time, so that the medicine decocting efficiency is improved, and the traditional Chinese medicine is heated more sufficiently and evenly; the transmission mechanism is arranged and drives the medicine placement cylinder to rotate through cooperation, and the rotating direction of the medicine placement cylinder is opposite to the rotating directions of the first stirring shaft and the secondstirring shaft, so that the medicine decocting efficiency is further improved; the press plate is arranged, can sufficiently squeeze effective ingredients in the traditional Chinese medicine in medicine decocting, and meanwhile squeezes out residual medicine liquid in medicine residues and waste is avoided.

Owner:安徽济人药业股份有限公司

Method for synthesizing low-nitrogen high-purity silicon carbide powder

The invention discloses a method for synthesizing low-nitrogen high-purity silicon carbide powder, and relates to the technical field of silicon carbide synthesis. The method comprises the steps of filling the raw material powder into a crucible with an exhaust hole, putting the crucible into a furnace, vacuumizing a furnace chamber, and heating; then injecting high-purity H2 into the furnace chamber to 750-850 mbar, and then vacuumizing the furnace chamber to 4.5*10<-6>-5.5*10<-6>mbar; and repeating for multiple times, heating the furnace chamber, injecting high-purity Ar and H2 into the furnace chamber according to the flow ratio of (9-10.5): 1, carrying out synthetic reaction and conversion synthetic reaction, and cooling to room temperature under the protection of Ar and H2 after the reaction is finished. The nitrogen concentration in the powder synthesis process can be effectively reduced, and the powder purity is improved; and the mixed raw materials are effectively prevented from escaping from the crucible in the powder synthesis process, and the reaction efficiency of the powder is improved.

Owner:SHANXI SEMICORE CRYSTAL CO LTD

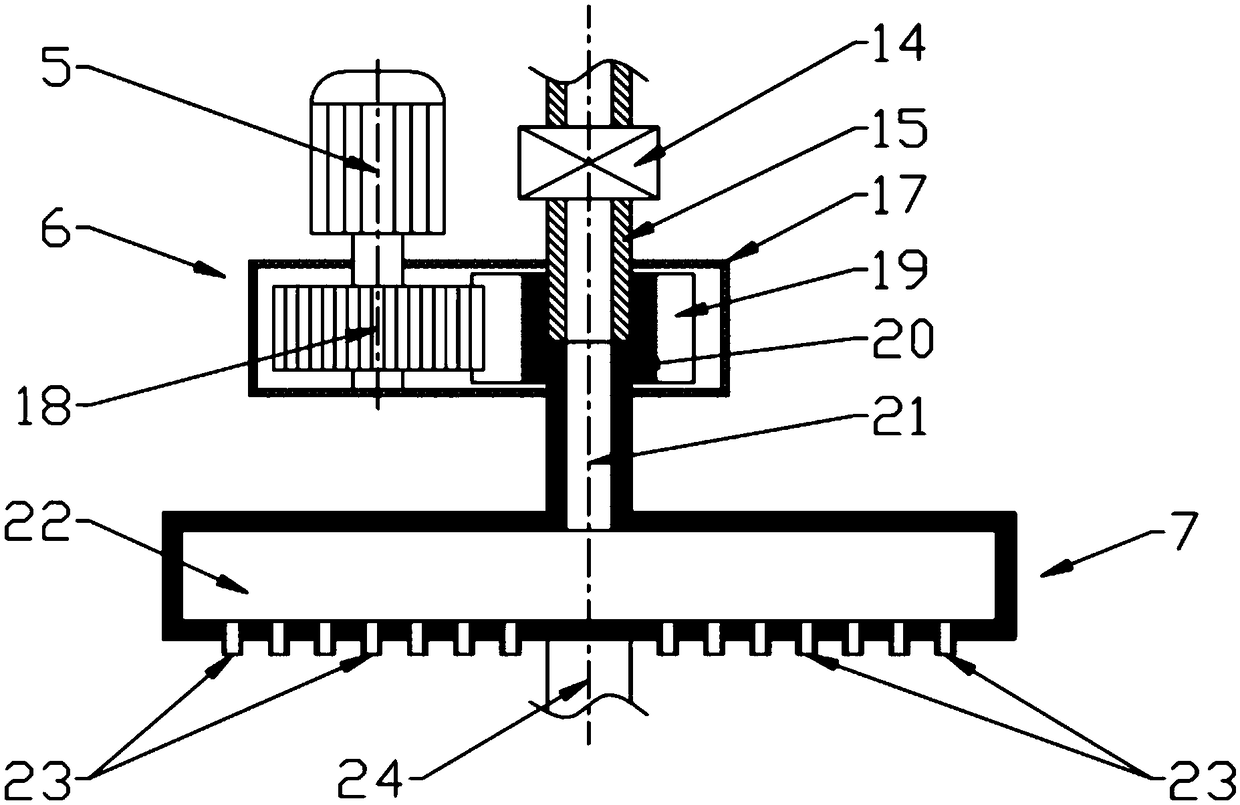

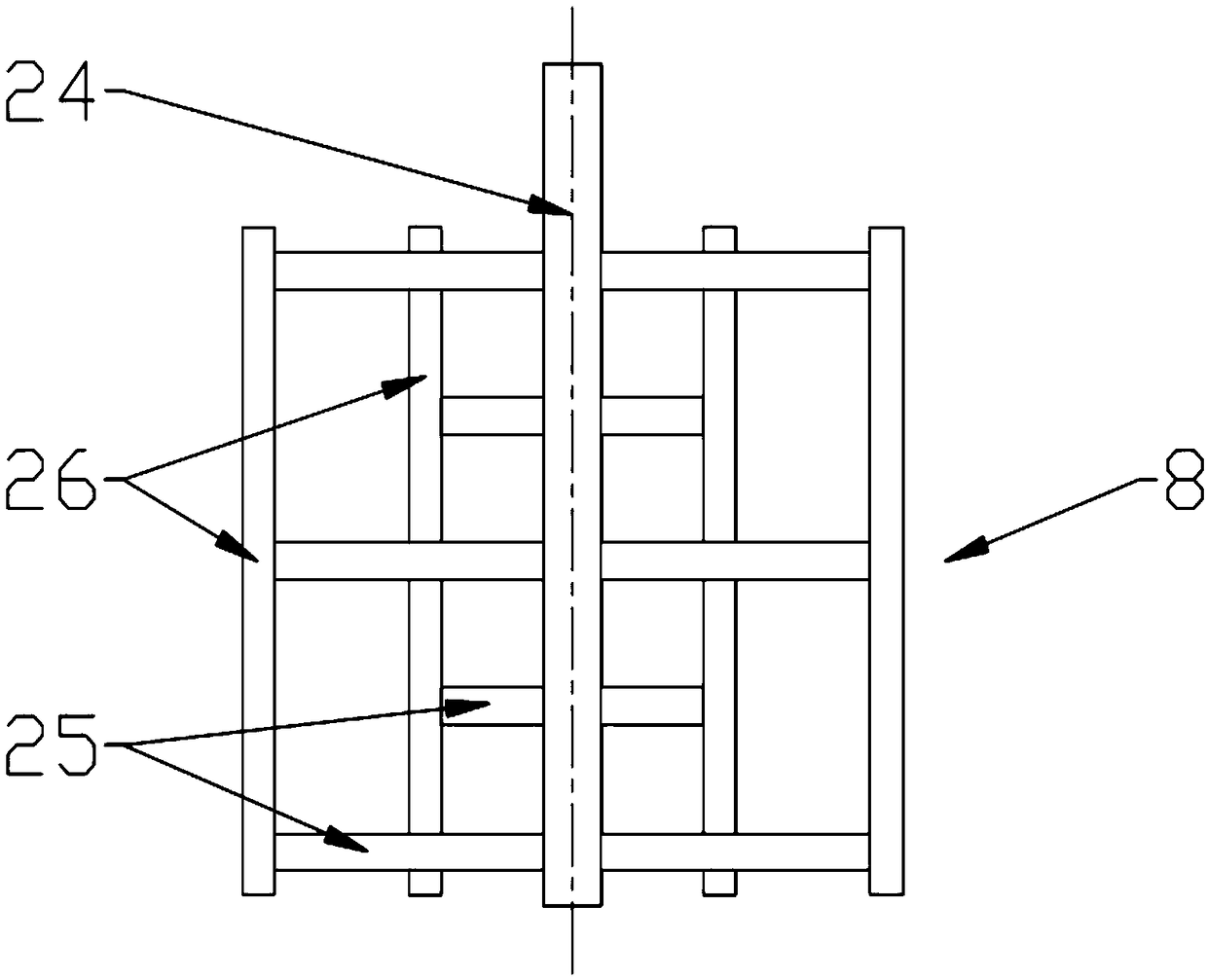

Pipeline supporting and repairing device and pipeline repairing method

PendingCN112856096AReasonable designSimplify repair operationsPipe elementsElectric machineryEngineering

Owner:四川兴辉腾集团有限公司

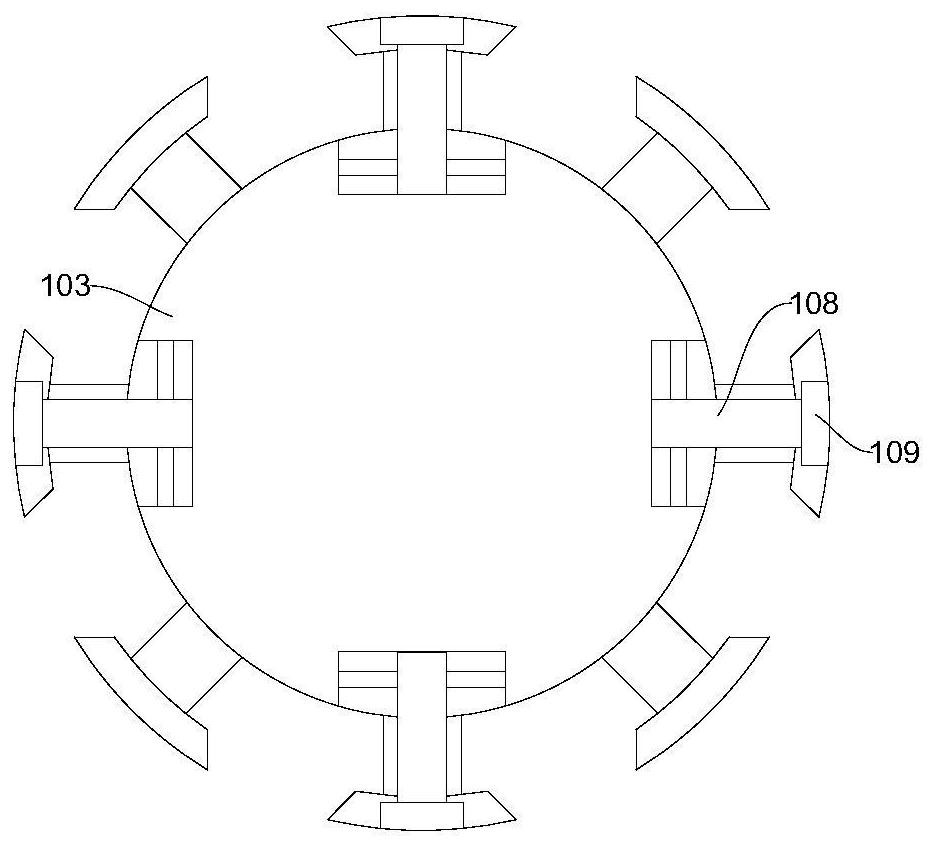

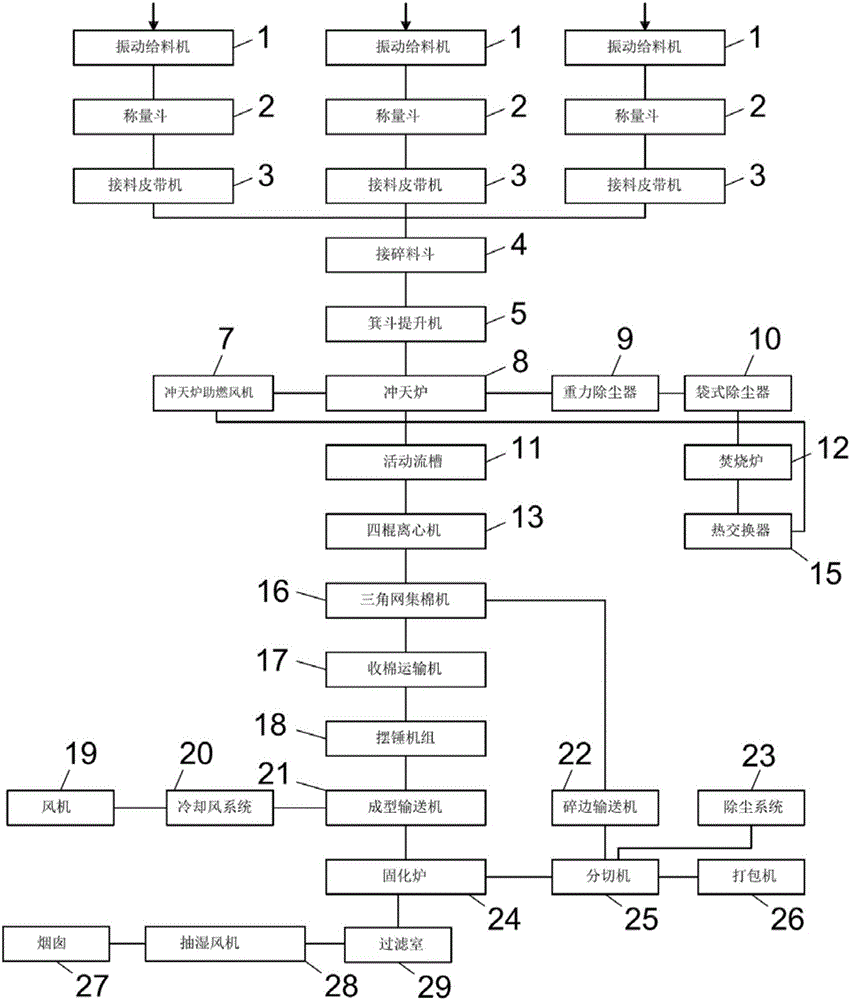

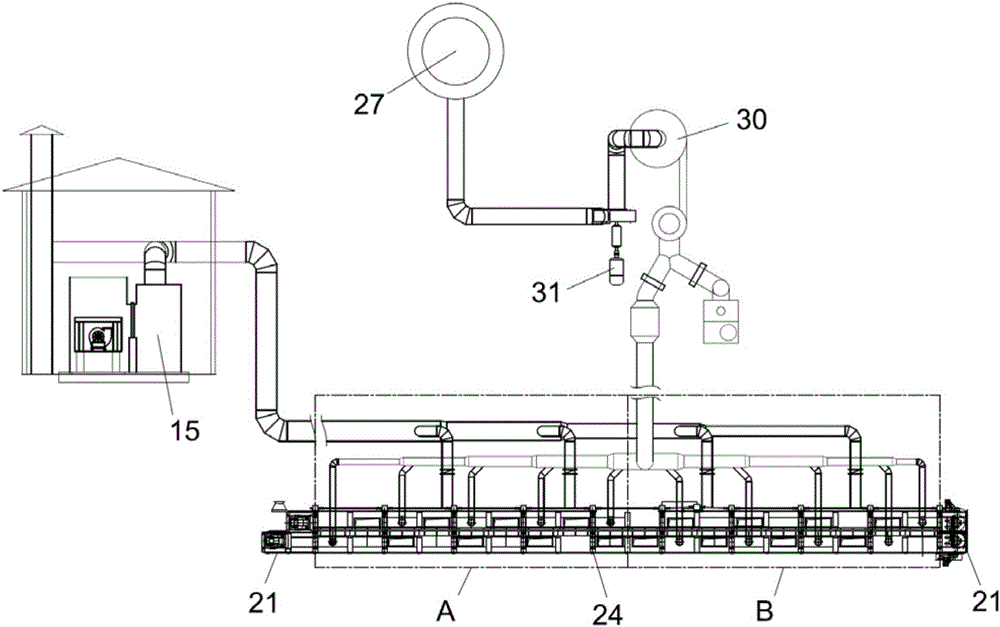

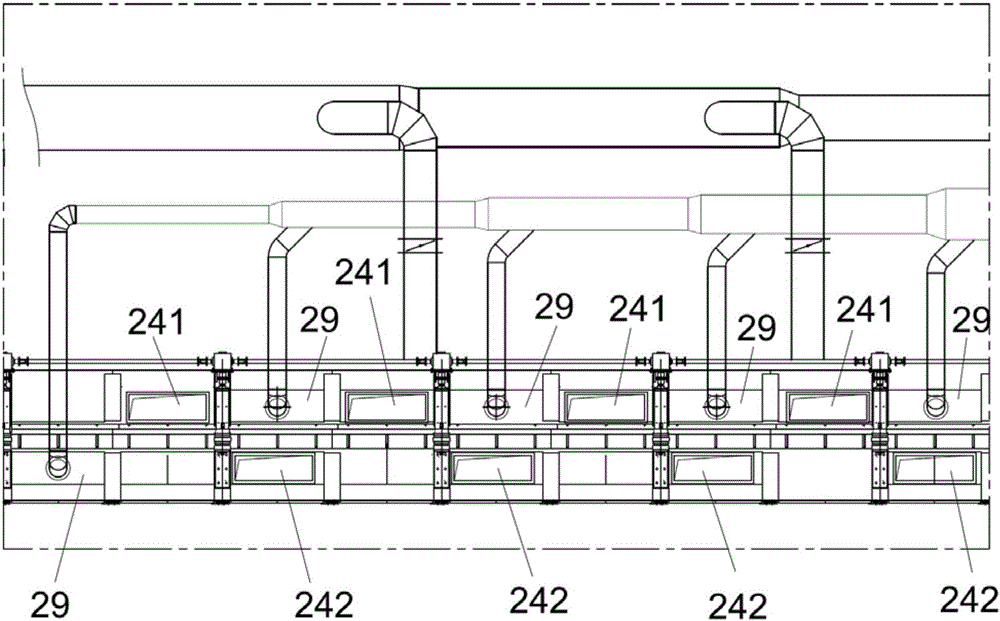

Energy-saving and high-yielding rock wool production line

ActiveCN106116133AImprove curing effectHigh cotton efficiencyGlass making apparatusEngineeringCupola furnace

The invention discloses an energy-saving and high-yielding rock wool production line. The energy-saving and high-yielding rock wool production line comprises at least three charging mechanisms, a scrappy material receiving hopper, a blast furnace, a four-roller centrifuge, a triangular-mesh wool collecting machine, a pendulum bob unit, a curing furnace, a slitting mechanism and a packing machine; each charging mechanism comprises a vibratory feeder, a weigh hopper and a receiving belt conveyor, the receiving belt conveyors of all the charging mechanisms are separately connected to the scrappy material receiving hopper, and a skip hoist which is used for conveying a scrappy material in the scrappy material receiving hopper into the blast furnace is arranged between the scrappy material receiving hopper and the blast furnace; the blast furnace is connected with a gravity dust collector, the gravity dust collector is connected with a bag type dust collector, the bag type dust collector is connected with an incinerator, the incinerator is connected with a heat exchanger, the heat exchanger is connected with a combustion-supporting fan, and the combustion-supporting fan is then connected with the blast furnace; and a movable chute is arranged between the blast furnace and the four-roller centrifuge, and a collected wool conveyor is arranged between the triangular-mesh wool collecting machine and the pendulum bob unit. According to the rock wool production line disclosed by the invention, the production efficiency is high, and energy is saved.

Owner:SICHUAN PAWOKE MINERAL FIBER PROD CO LTD

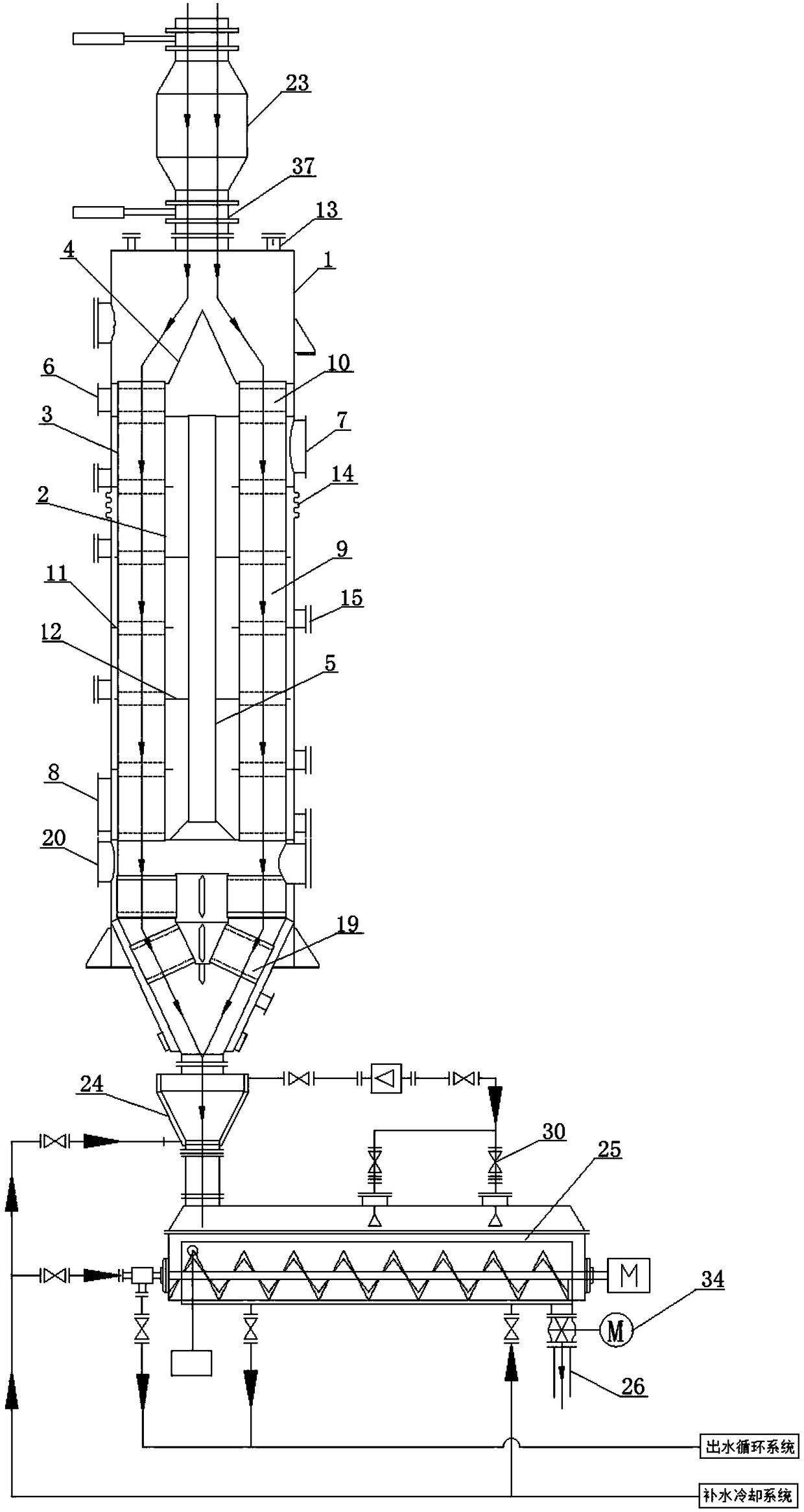

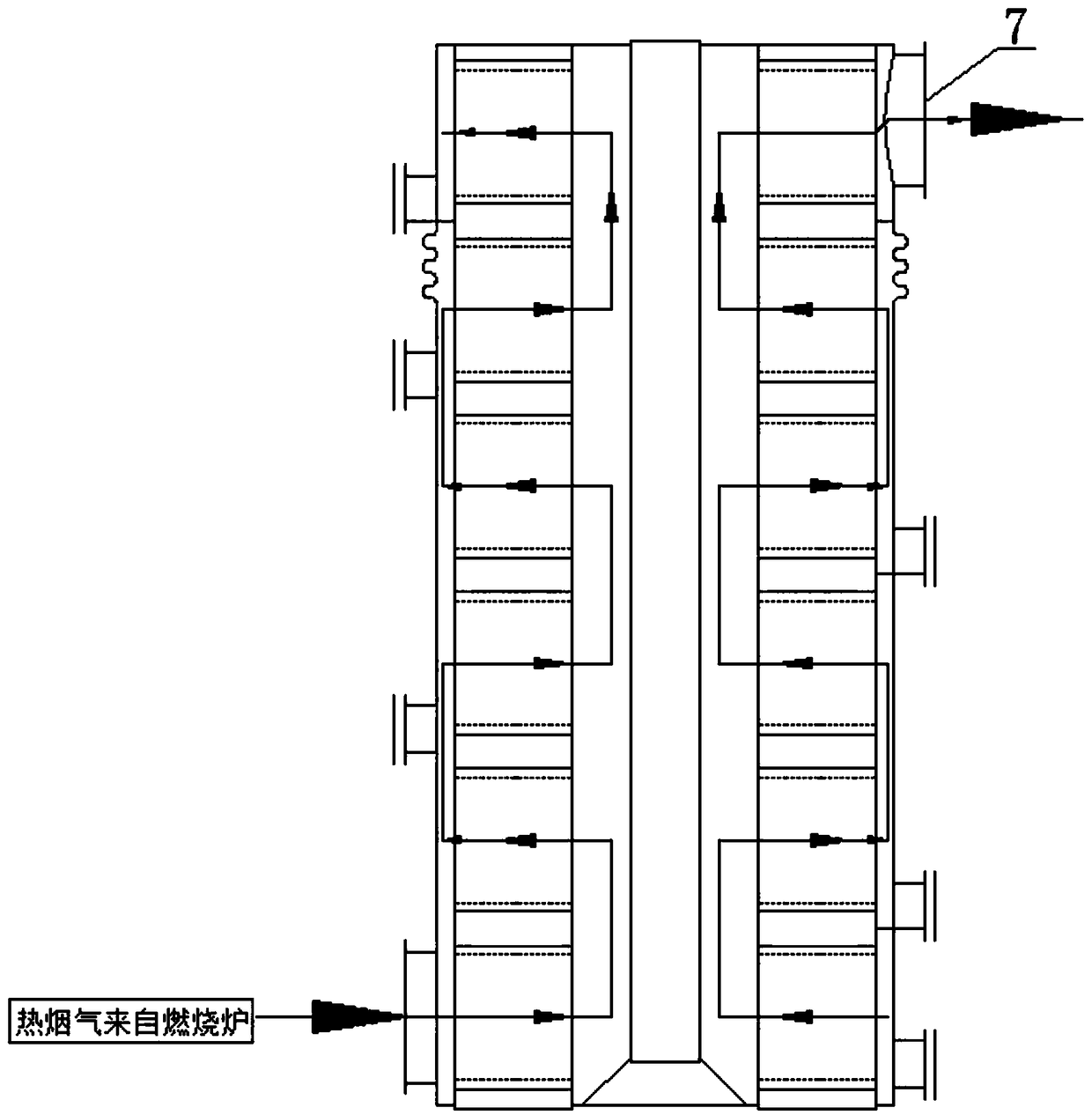

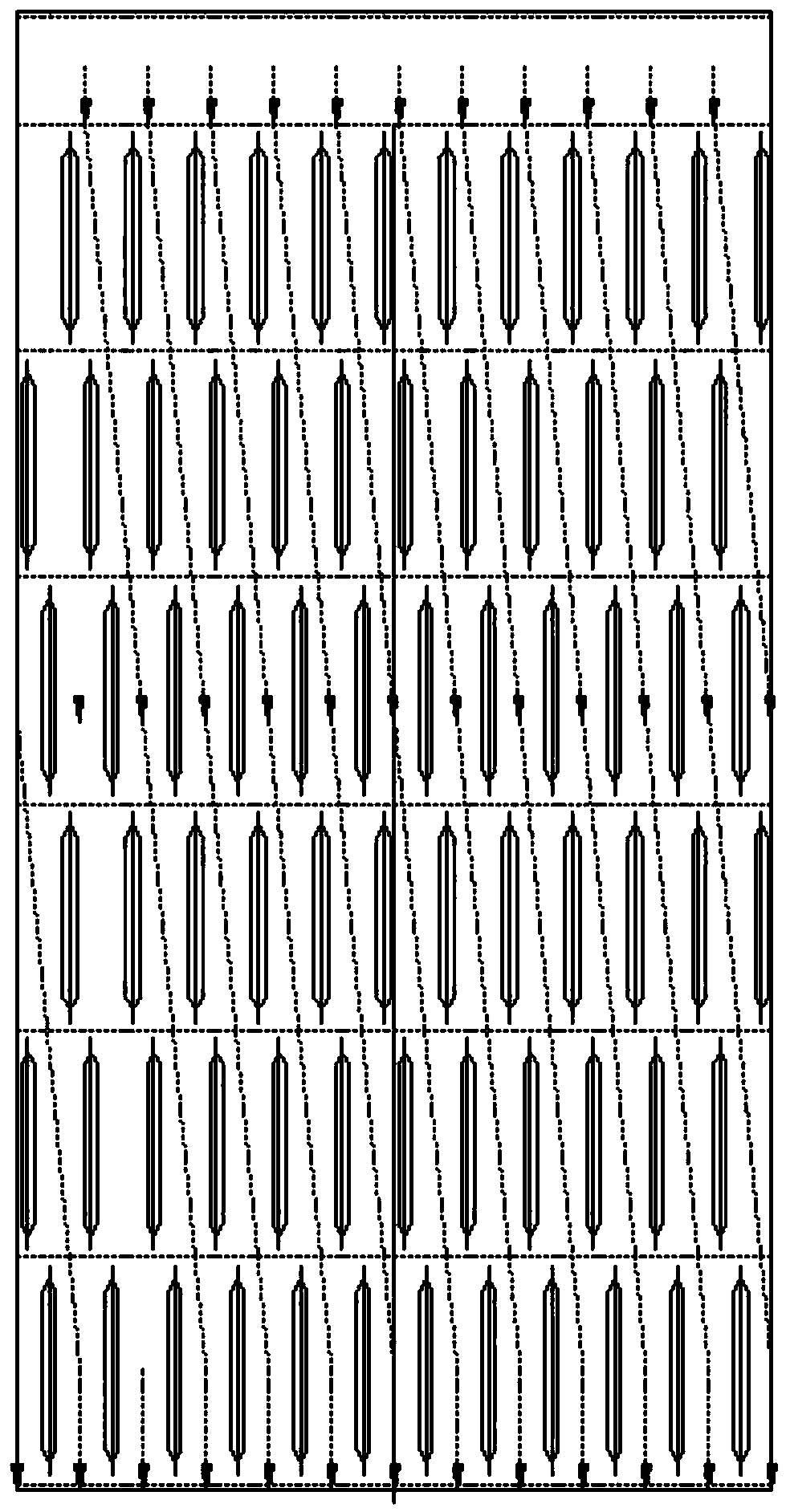

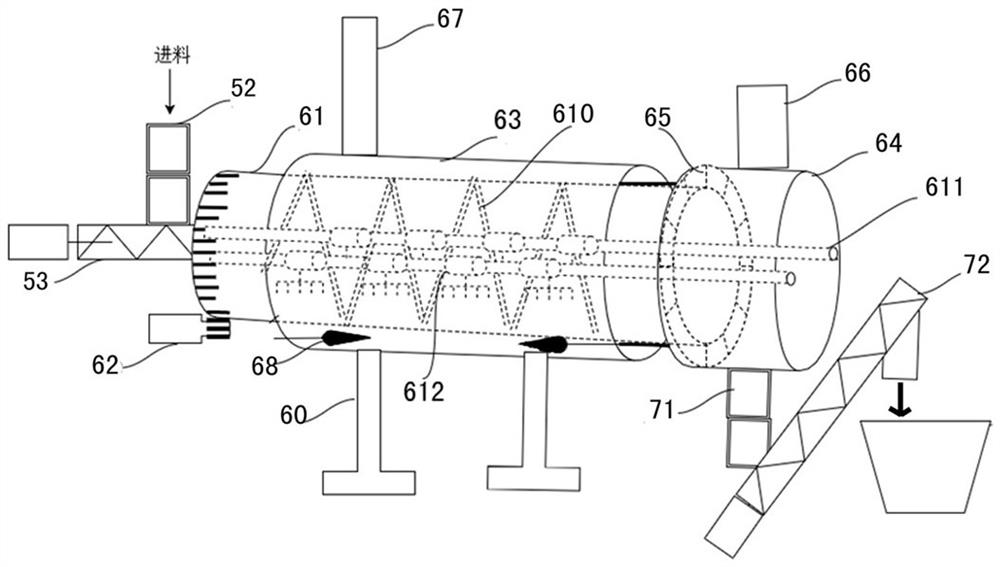

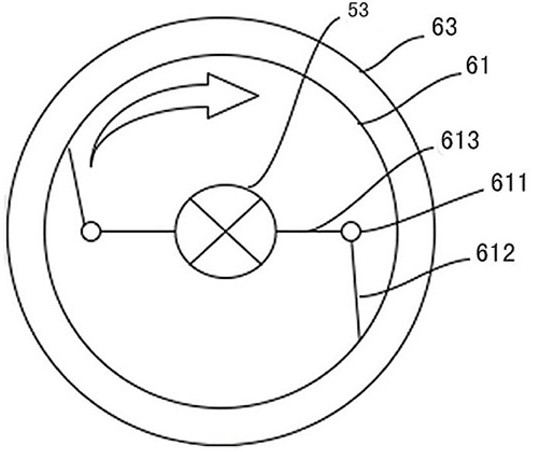

Efficient and energy-saving self-weight spiral progressive biomass pyrolysis system

PendingCN109161389AIncrease the heat exchange areaShorten pyrolysis timeBiofuelsSpecial form destructive distillationBiomassProcess engineering

The invention discloses an efficient and energy-saving self-weight spiral progressive biomass pyrolysis system which comprises a pyrolysis furnace, a material distribution tank (23), an air cooler anda water cooling system, wherein an outlet of the material distribution tank (23) communicates with the material feeding hole of the pyrolysis furnace; a biomass charcoal outlet in the bottom of the pyrolysis furnace communicates with a material inlet in the upper part of the air cooler; a material outlet in the lower part of the air cooler communicates with the material feeding hole of the watercooling system; an inner cylinder (2) and an outer cylinder (3) are arranged in the middle inside the furnace body (1) of the pyrolysis furnace; a conical material distributor (4) is arranged at the top, corresponding to the material feeding hole of the furnace body (1), of the inner cylinder (2); a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2); the outlet of thepyrolysis gas secondary pyrolysis tube (5) communicates with a pyrolysis gas outlet (6); both a flue gas outlet (7) and a hot flue gas inlet (8) communicate with an inner cavity of the inner cylinder(2). Mutual actions of heat conduction are achieved, high heat utilization efficiency is achieved, and gradient utilization of energy is achieved.

Owner:HUBEI NORMAL UNIV +1

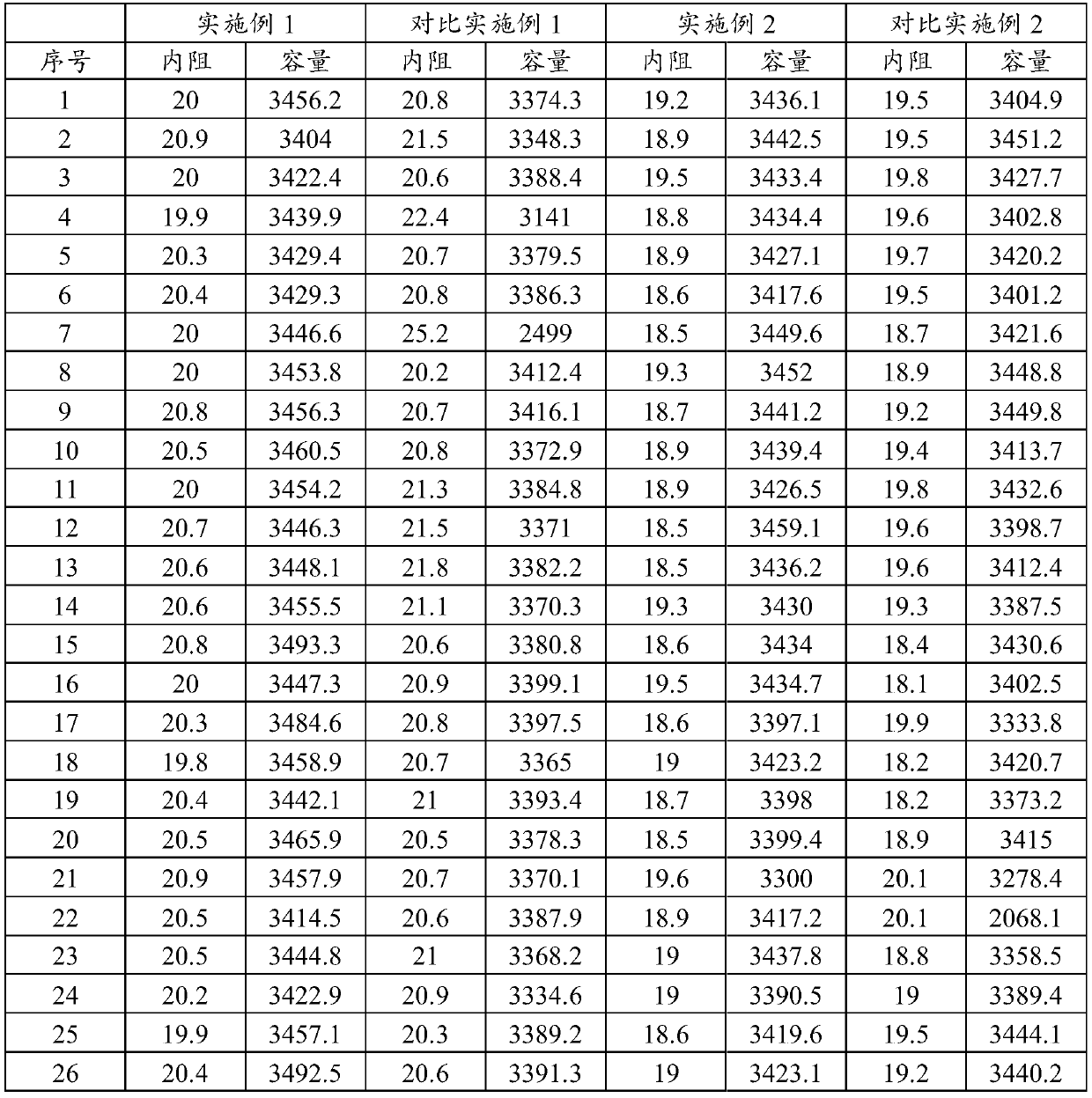

High-performance lithium battery and preparation method thereof

InactiveCN110707362AHigh component yieldImprove consistencyFinal product manufactureSecondary cells manufactureThermal adhesiveLithium-ion battery

The invention discloses a preparation method of a high-performance lithium battery, which comprises the following steps of placing a thermal adhesive diaphragm between a positive plate and a negativeplate, and preparing a battery cell, the thermal adhesive diaphragm being a diaphragm having an adhesion effect on an electrode material at a preset temperature or pressure; carrying out preheating and / or flat pressing treatment on the battery cell, wherein the temperature of the preheating treatment is greater than or equal to the softening temperature of the thermal adhesive material and is lessthan the melting temperature of the thermal adhesive material, the pressure intensity of the flat pressing treatment is greater than or equal to the yield limit of the hot viscous material; carryingout shaping treatment on the preheated and / or flattened battery cell; and carrying out post-treatment on the shaped battery cell to obtain the lithium ion battery. Correspondingly, the invention alsoprovides the lithium battery prepared by the method. By adopting the method, the energy consumption reduction, process condition simplification, equipment simplification and raw material simplification can be realized at the same time, and the battery is high in appearance size consistency and stability and high in performance consistency and stability.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL +1

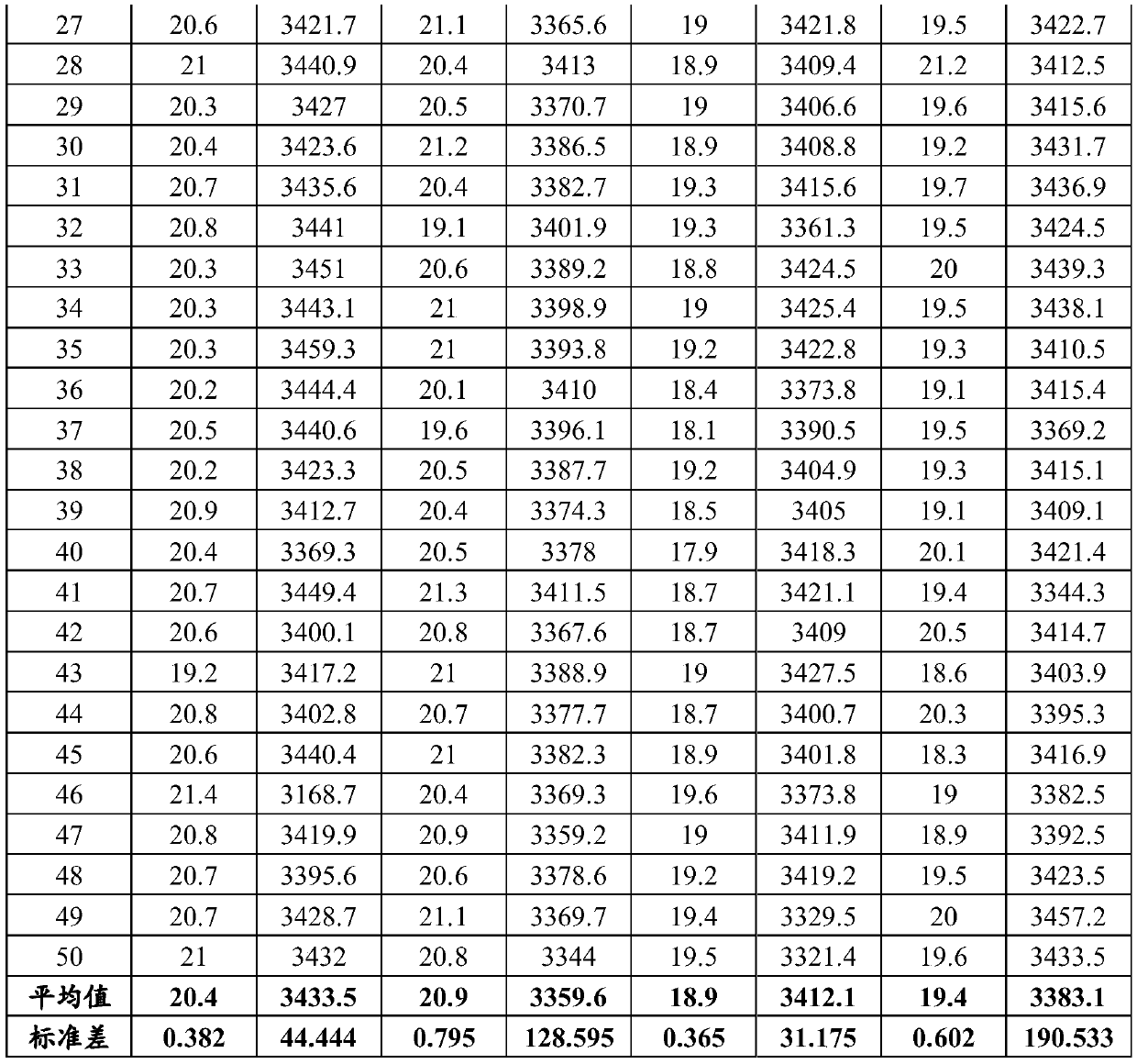

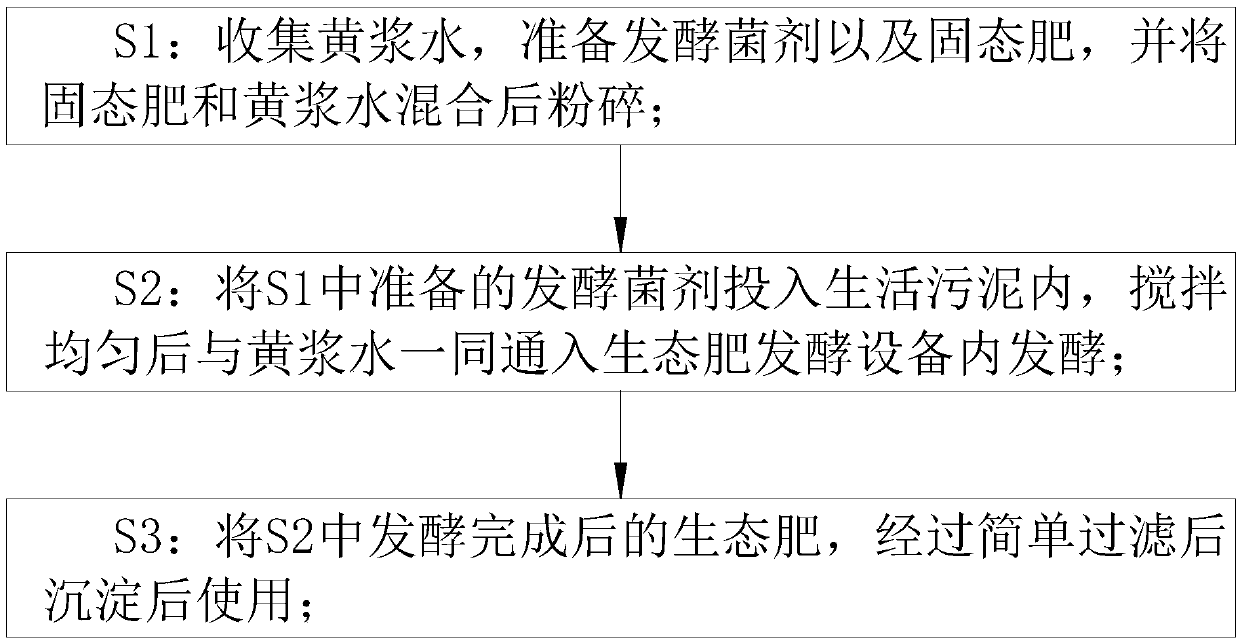

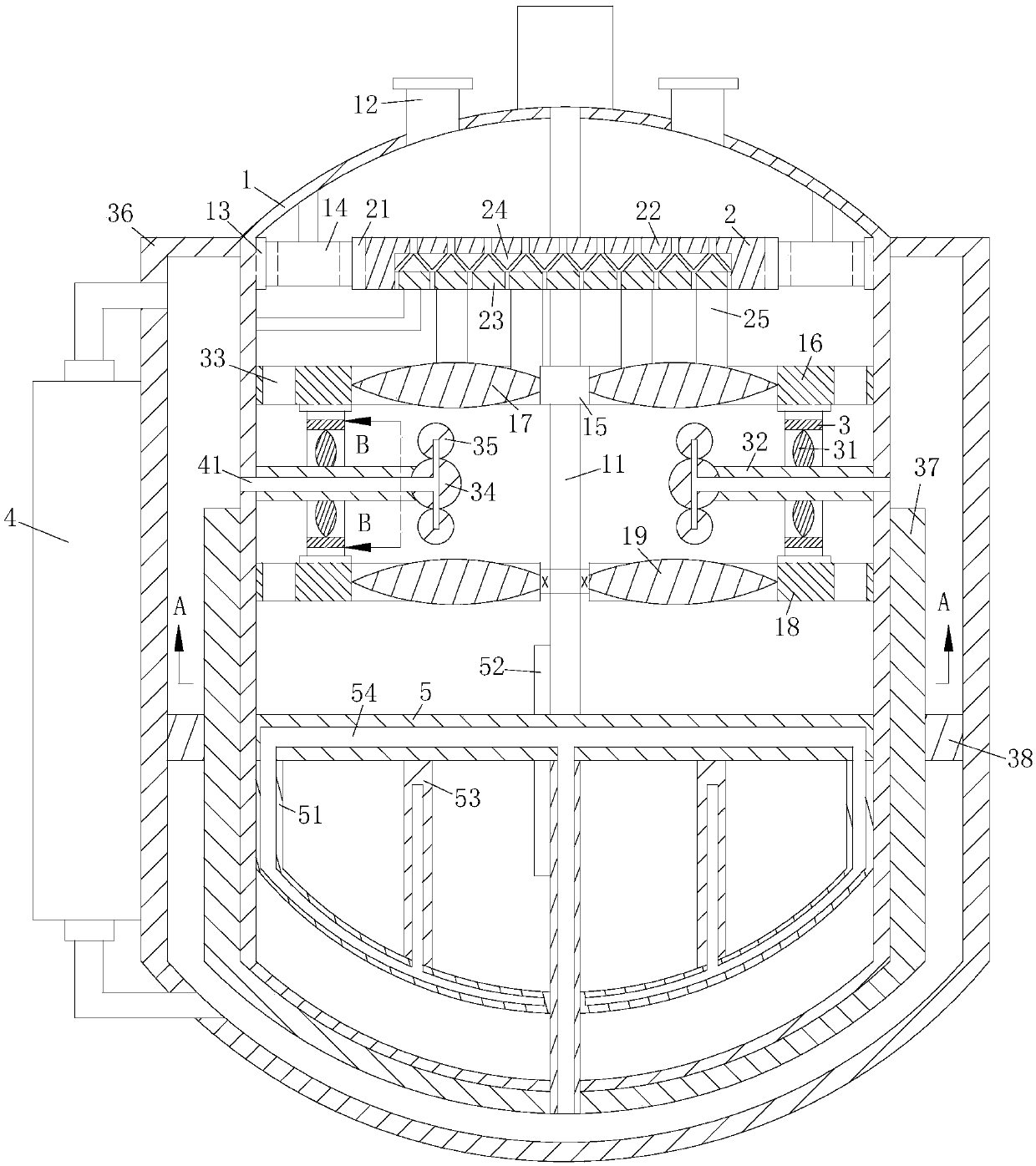

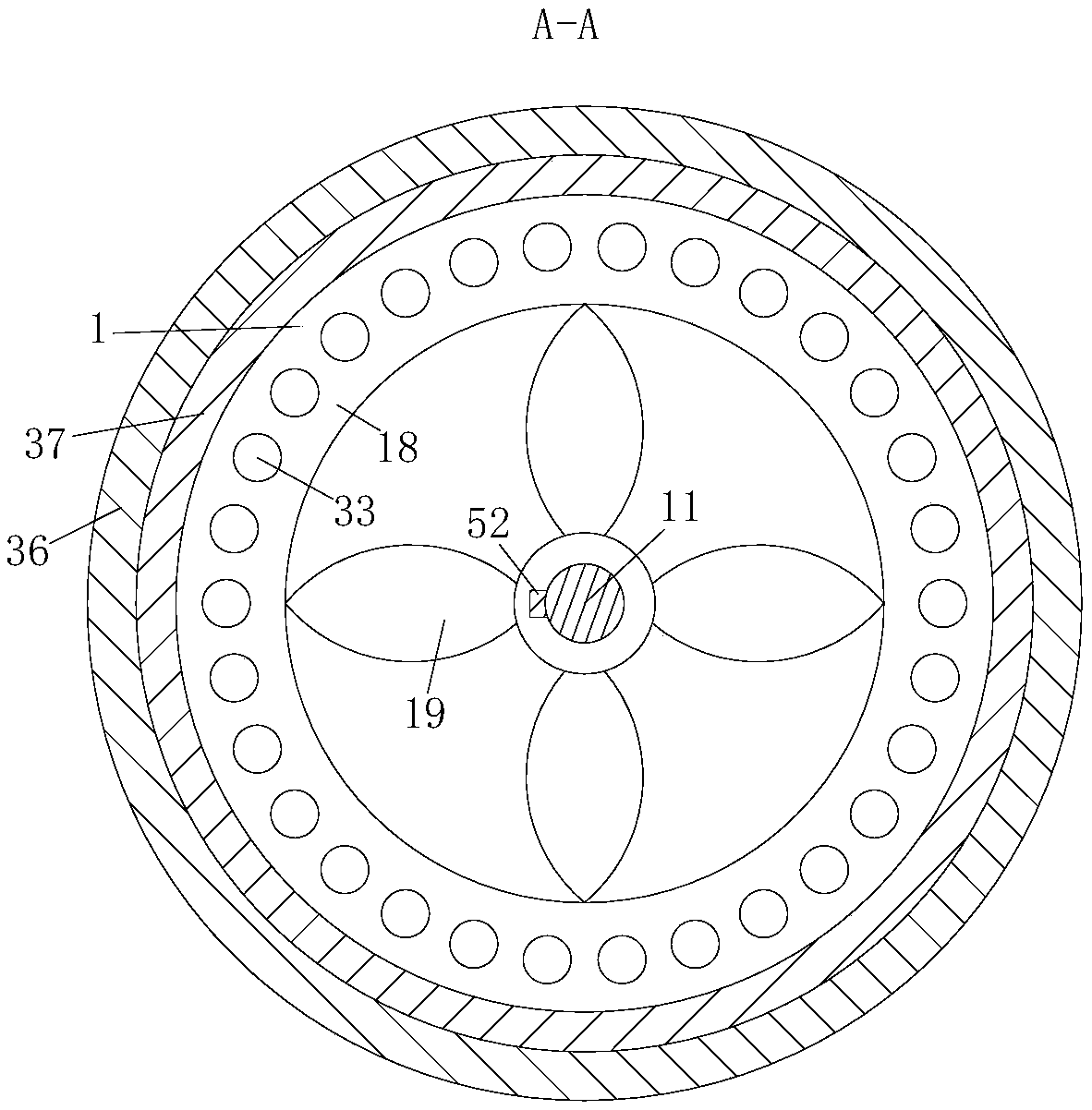

Ecological fertilizer fermentation process

ActiveCN109516848AMultiply fastWell mixedBio-organic fraction processingMicroorganism based treatmentSludgeFermentation

The invention belongs to the technical field of agricultural waste materials, and particularly relates to an ecological fertilizer fermentation process. Solid fertilizers and yellow serofluid are mixed and are then crushed, so that the mixing of the solid fertilizers and yellow serofluid is sufficient; the ecological fertilizer production through fermentation is facilitated. Fermentation bacterialagents are fed into domestic sludge to be uniformly stirred; the domestic sludge can provide proper adhesion points for bacteria, so that the breeding of bacteria is faster; the fermentation speed isaccelerated; used ecological fertilizer fermentation equipment comprises a frame body and a controller; one end, near a rotating shaft, of a second fixing rod is fixedly connected with a first aeration ball; the upper and lower ends of the first aeration ball are fixedly connected with second aeration balls; a heat insulation cabin is arranged outside the frame body. A heater is arranged on the outer surface of the frame body. A fourth stirring rod is made of magnetic materials. The ecological fertilizer fermentation process has the characteristics that the structure is simple; the operationis convenient; the stirring is uniform and thorough; the fermentation speed is high.

Owner:黑龙江信谷农业发展有限公司

High temperature refining furnace used for metallurgy worker and provided with internal protection structure

InactiveCN109000480ASpread evenlyEfficient heat transferStirring devicesCharge treatment typeHeat flowEngineering

The invention discloses a high temperature refining furnace used for a metallurgy worker and provided with an internal protection structure. The high temperature refining furnace comprises an outer protection plate and a heat relaying furnace, a middle transition plate is fixed to the inner wall of the outer protection plate, an interior lining panel is arranged on the inner side of the middle transition plate, a controller box is installed above the interior of the heat relaying furnace, and the heat relaying furnace is located on the inner side of the interior lining panel. According to thehigh temperature refining furnace used for the metallurgy worker and provided with the internal protection structure, a circulation pipe and the interior lining panel are arranged, temperature insideequipment can be stored and used in a circulated manner, it is guaranteed that the temperature inside the equipment is in the relatively-constant state, hot airflow is led into the circulation pipe, auxiliary heating is carried out on the interior of the equipment, hot flow inside the circulation pipe can be heat generated by refining metal by the equipment, after primary refining is finished, theheat can spirally flow through the circulation pipe, constant-temperature protection on the interior of the equipment is carried out, a metal heat transferring plate can achieve effective heat transferring, constant-heating cotton layers enable the heat to be emitted more evenly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

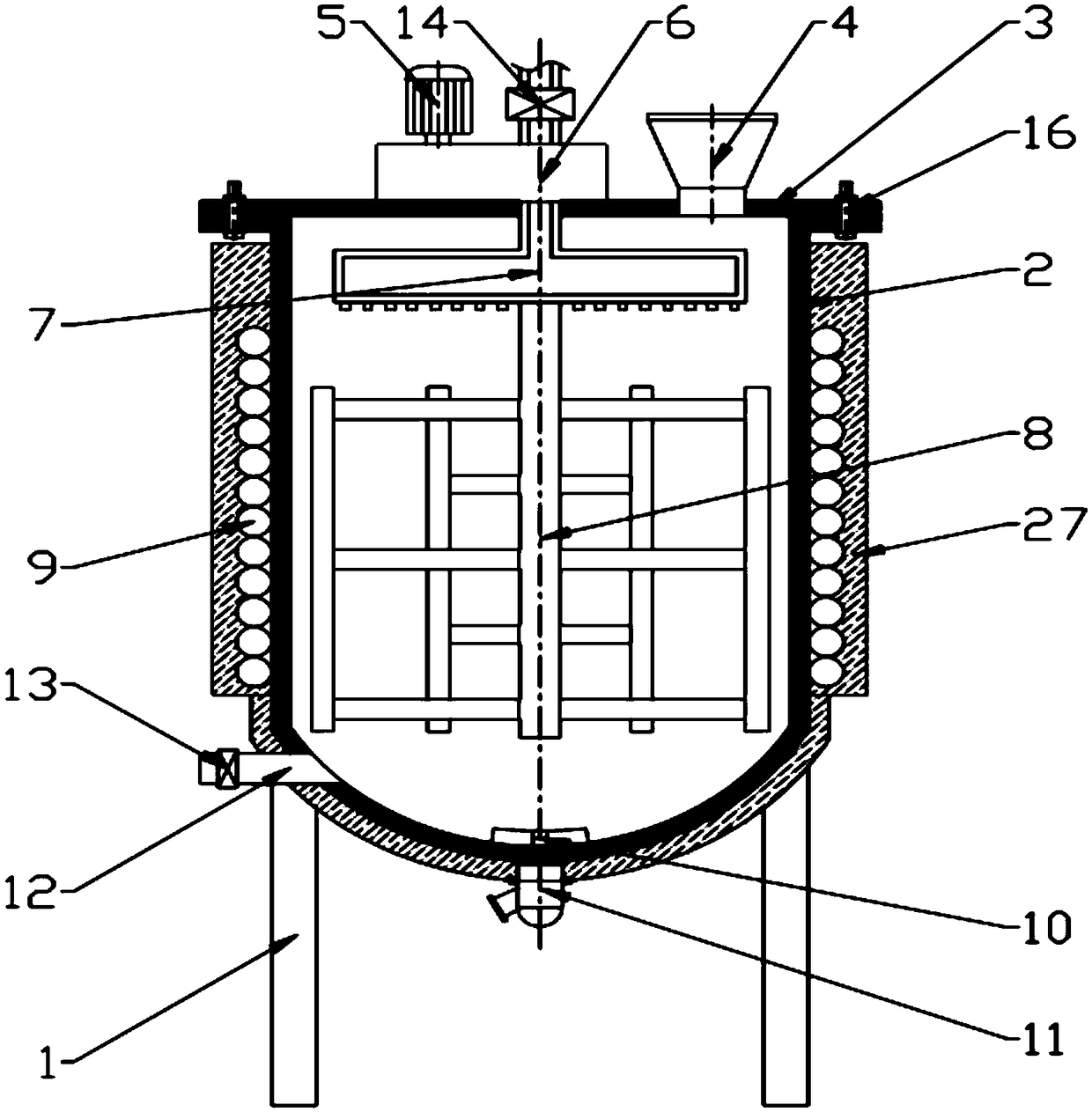

Fermentation device for biotechnology

InactiveCN109294876APrevent heat lossReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsWater pipeCentral line placement

The invention provides a fermentation device for biotechnology, and belongs to the biotechnology field, wherein the fermentation device includes a cylinder body; support legs are arranged below the cylinder body, a cover plate is arranged on the cylinder body, and the periphery of the cylinder body are wrapped with heaters; a speed reducer is arranged above the cover plate; a stirring motor is connected above the speed reducer, and a cleaning device is connected below the speed reducer; a water inlet pipe is connected above the cleaning device, and a stirring device is arranged below the cleaning device; a booster pump is mounted on the water intake pipe, a turbulent flow plate is mounted on the inner wall of the central line position of the bottom of the cylinder body, and a discharge valve is mounted on the outer wall; an insulating layer is wrapped on the outer side of the cylinder body. A fermentation material in the cylinder body is heated by arrangement of the heater, so that microorganisms reach the optimum active state, a material is stirred by the stirring device, and the material is guaranteed to be uniformly heated and is fully mixed and fermented; the insulating layer prevents heat loss and reduces energy consumption. The cleaning device rotates and cleans the cylinder body after each time of material fermentation is completed, can effectively prevent the material from hardening and sticking, and ensures the cleaning effect.

Owner:郑州韦尔特生物科技有限公司

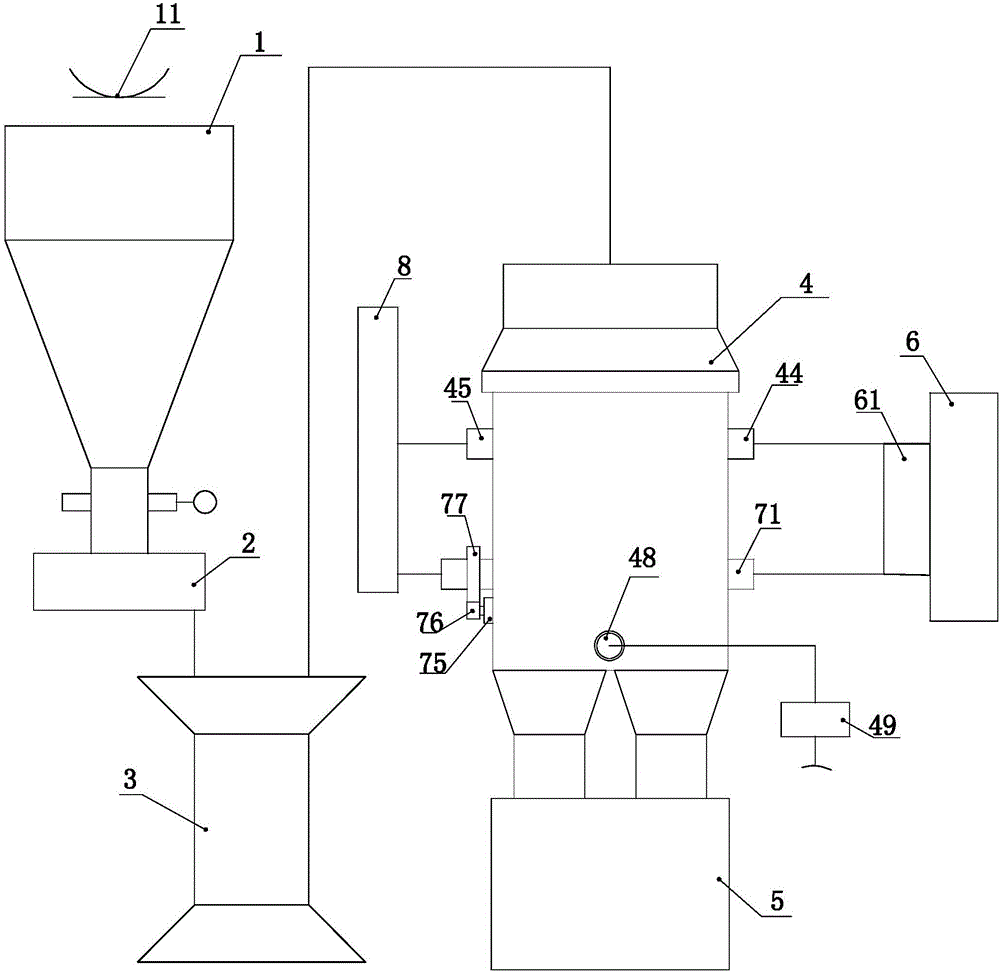

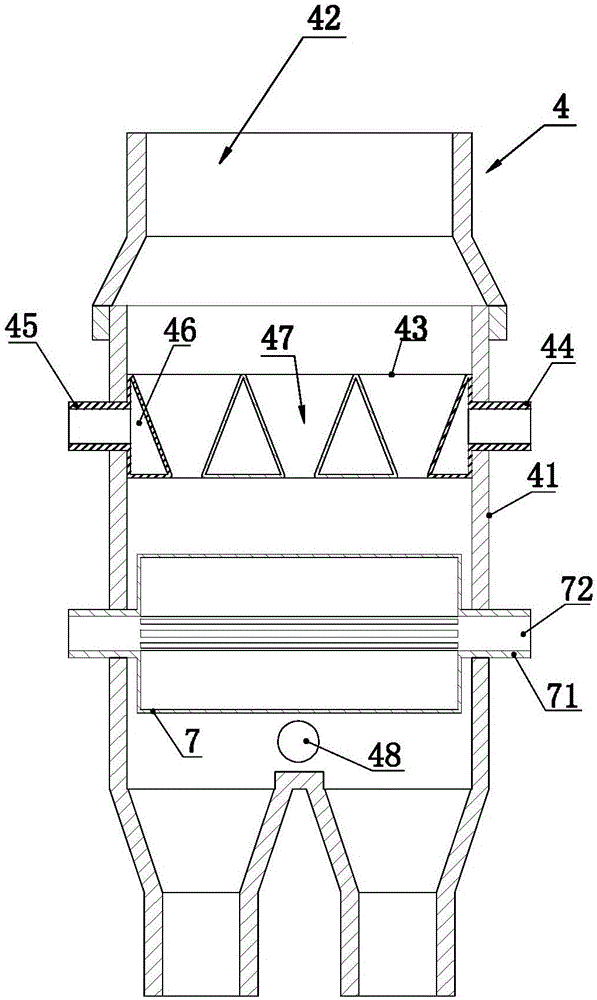

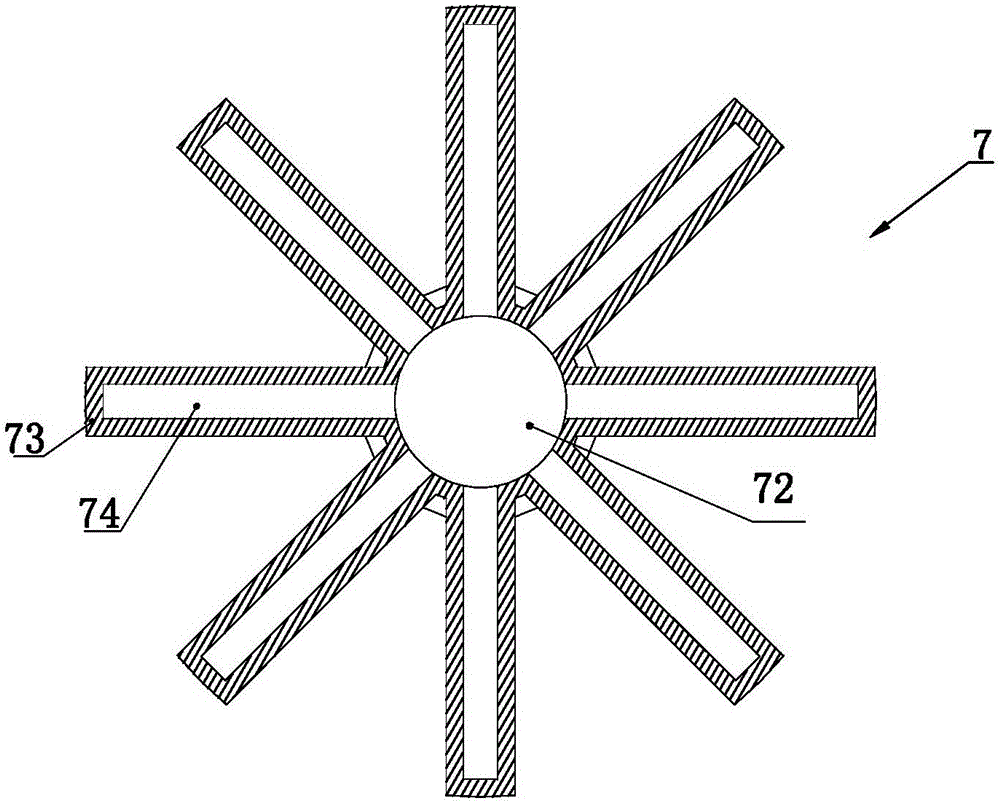

Production method and production system for extracting oil in oil sludge

ActiveCN111875208ARealize continuous industrial productionSuitable for harmless treatmentSludge treatment by pyrolysisByproduct vaporizationThermodynamicsCoke

The invention discloses a production method and a production system for extracting oil in oil sludge. An oil sludge pyrolysis device comprises a rotary drum, wherein the open end of the rotary drum iscommunicated with a fixed cylindrical discharge end socket, and the rotary drum is in rotary sealing fit with the discharge end socket; a spiral guide plate is fixedly arranged on the inner wall of the rotary drum, the rotary drum rotates, and the spiral guide plate pushes and throws oil sludge; oil steam and residues after pyrolysis are discharged from the discharging seal head; a decoking and crushing device in the rotary drum comprises a fixed shaft parallel to the axis of the rotary drum, a plurality of decoking tooth claws are arranged on the fixed shaft at intervals in the axial direction, the handle ends of the decoking tooth claws are rotatably arranged on the fixed shaft in a sleeving mode, the claw ends elastically press and contact the inner wall of the rotary drum through springs, and the rotating direction of the claw ends is opposite to that of the rotary drum under the action of the springs; the decoking tooth claws grab and dig the inner wall of the rotary drum along with the rotation of the rotary drum to remove inner wall cokes and crush oil sludge blocks. The method realizes continuous industrial production of extracting the oil in the oil sludge, and is high inpyrolysis efficiency, thorough in harmless treatment of the oil sludge and high in oil recovery rate.

Owner:舟山麦哲伦环保科技有限公司

Negative-pressure pulverized coal preparing system

InactiveCN106196133AQuality improvementIncrease profitSolid fuel pretreatmentLump/pulverulent fuel feeder/distributionCentrifugal fanMechanical engineering

The invention relates to the technical field of fuel preparing, in particular to a negative-pressure pulverized coal preparing system used for improving the pulverized coal drying efficiency and increasing the energy utilization rate. The negative-pressure pulverized coal preparing system is characterized by comprising a conveying belt, a raw coal bin, a coal feeder, a coal mill, a dryer, a powder collecting bin and a coal-fired furnace; a discharging port of the coal mill communicates with the dryer; the dryer comprises a case, a pulverized coal inlet is formed in the upper end of the case and communicates with the discharging port of the coal mill, and a platy drying device is fixedly connected in the case; and a scattering device is rotationally connected in the case, the case is provided with an extraction opening, the extraction opening is located below the scattering device and connected with a centrifugal fan, and the bottom of the case communicates with the powder collecting bin. The negative-pressure pulverized coal preparing system has the beneficial effects that the pulverized coal can be prevented from being gathered into small particles, and the pulverized coal drying efficiency and quality are improved.

Owner:SHANDONG HUANNENG DESIGN INST

Planet wheel type drying equipment for traditional Chinese medicine

InactiveCN108106364AAvoid accumulationHeated evenly and fullyDrying gas arrangementsDrying machines with non-progressive movementsMotor driveElectric machinery

Owner:周兰芝

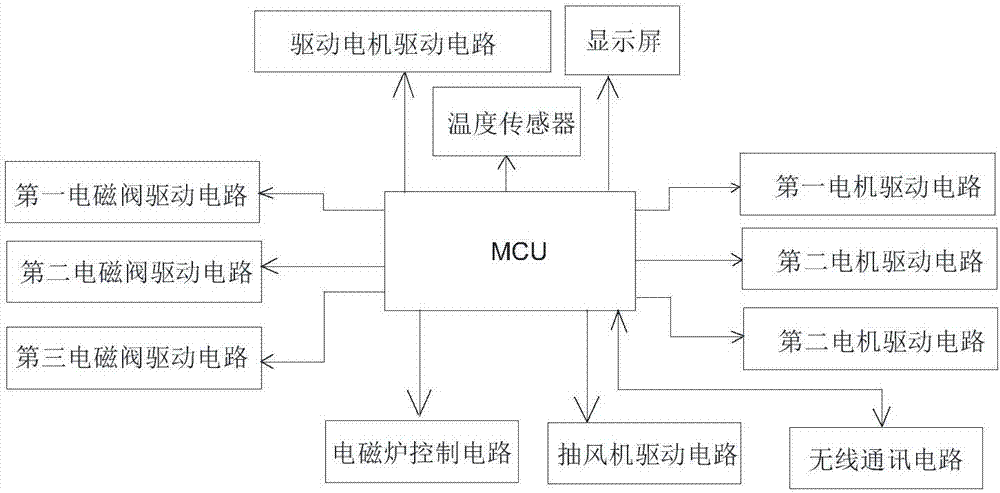

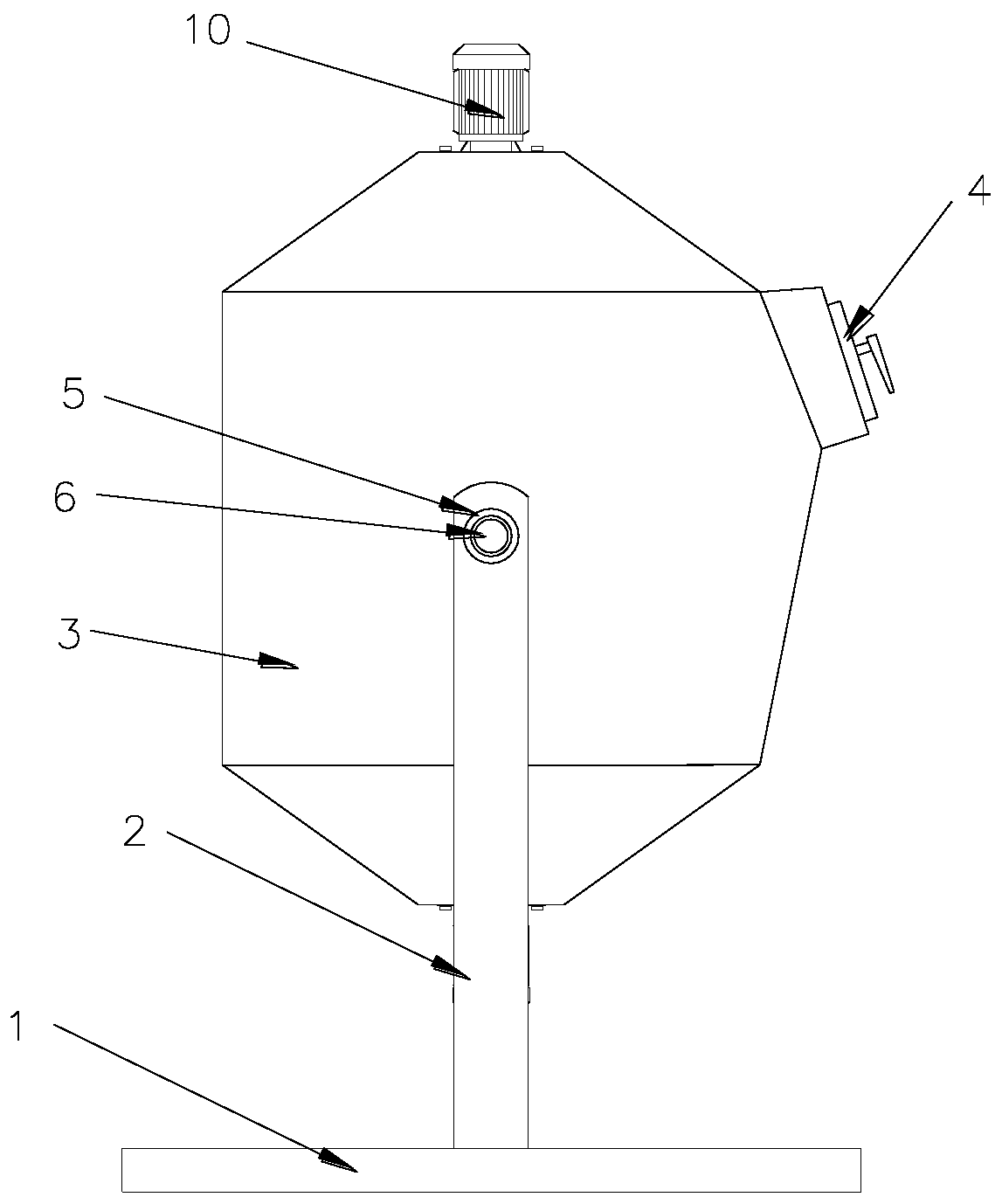

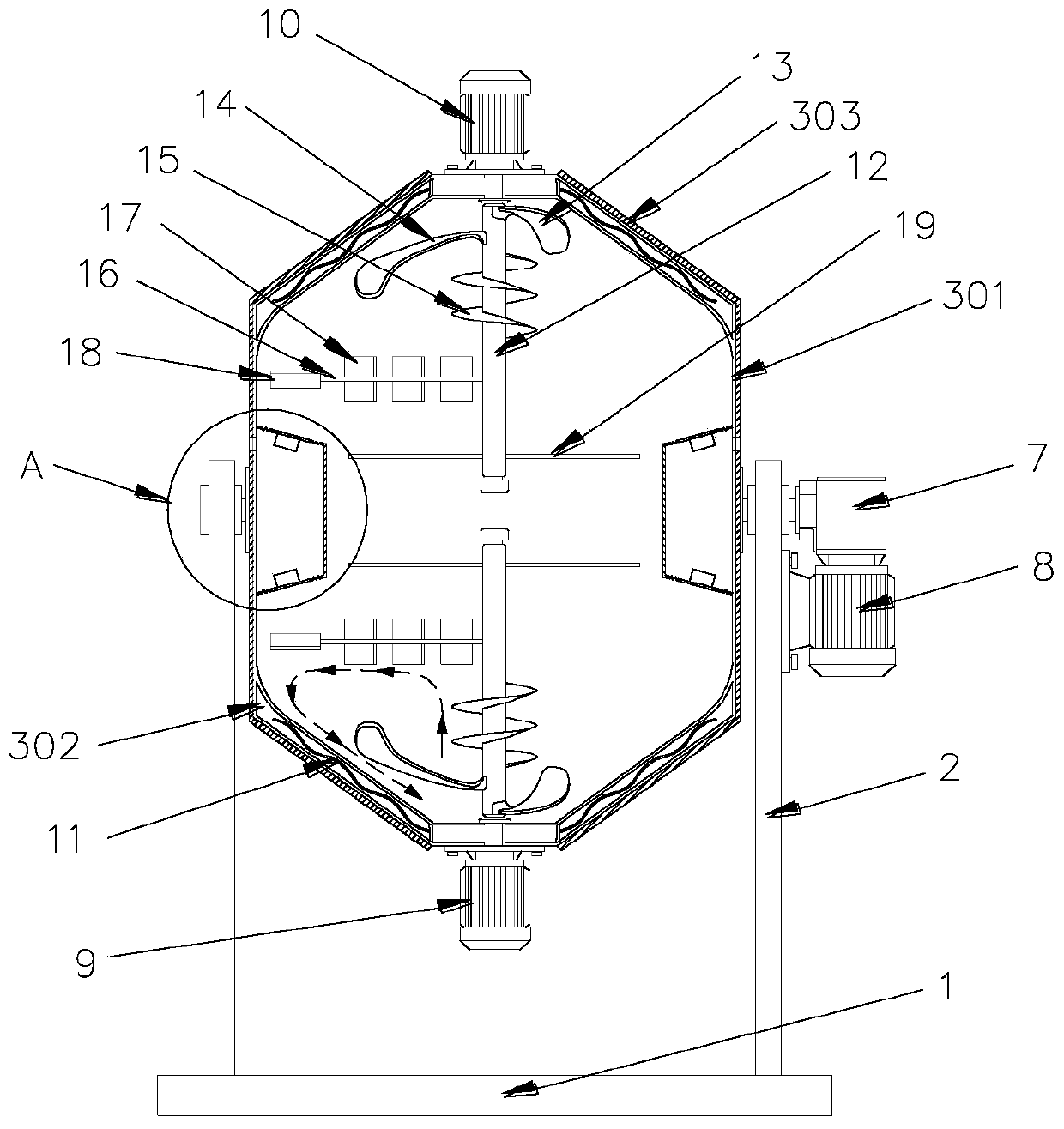

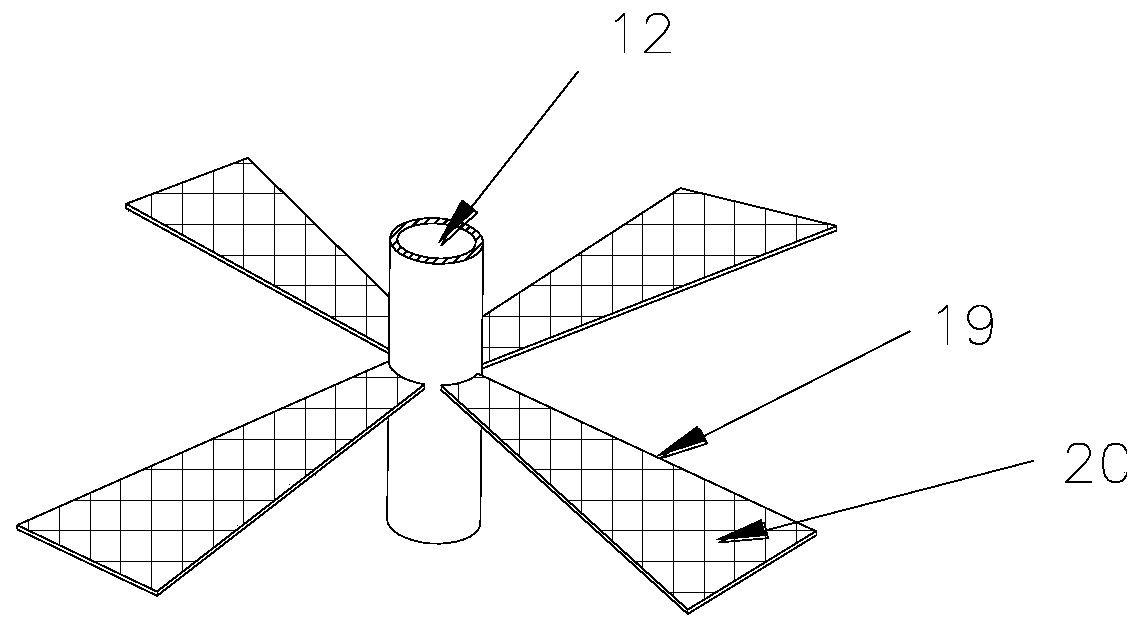

Industrial pill water boiling device

ActiveCN106923143AReduce churnHeated evenly and fullyFood processingFood shapingElectric machineryEngineering

The present invention relates to an industrial pill water boiling device. The device comprises an electromagnetic oven bottom seat and a motor drive mechanism, a ceramic pot is arranged on the electromagnetic oven bottom seat, and a helical material receiving trough surrounds the peripheral side wall of the ceramic pot; a lifting mechanism is arranged on the peripheral side wall of the ceramic pot, a cylindrical tube is vertically fixed in the middle part of the ceramic pot and has a hollow cavity body, and an iron tray is arranged within the ceramic pot and can conduct vertical lifting driven by the lifting mechanism; a support column is arranged at the middle part of the hollow cavity body, a pill material extruding mechanism is arranged on the support column and comprises a cross-shaped material extruding pipe and a material inlet pipe, and a plurality of material extruding heads are arranged on the bottom part of the cross-shaped material extruding pipe; and a cutting assembly is arranged at the top part of the cylindrical tube and can cut pills extruded from the material extruding pipe. The device can intelligently conduct extruding and molding of the pills, then conduct boiling and automatic taking from water, and can improve production efficiency. The manufactured pills are clean and good in mouthfeel.

Owner:邱秀娟

Production device and production process of fresh and crisp melon seeds

The invention discloses a production device and a production process of fresh and crisp melon seeds. The production device adopts an up-and-down turnover roller type structure, electric heating devices and stirring mechanisms are arranged on the top end and the bottom end of a roller, stirring blades of the stirring mechanisms also comprise long blades and short blades, and the long blades and theshort blades are connected with the electric heating device, melon seeds in the center and the edge of the roller bottom can be effectively turned over, so that the melon seeds in the roller body integrally, uniformly and quickly flow along with a stirring shaft; besides, the roller is turned over once every a period of time, so that the melon seeds in the roller are raised and fall back to the bottom of the roller, the melon seeds in the roller can be turned over and flow, the melon seeds can be more uniformly and fully heated in combination with the baking of an electric heating wire, and the probability of insufficient baking or excessive baking of the melon seeds is reduced; the overall quality of finished melon seeds is remarkably improved, and the obtained melon seeds are fresh, crispy and delicious; and the stir-frying mode of matching up-and-down rolling and stirring can enable the melon seeds to be stir-fried more quickly, so that the stir-frying time is shortened.

Owner:福州翁财记食品有限公司

Drying device with dust collecting effect for cotton processing

PendingCN114061285ANo contactImprove practicalityDrying gas arrangementsDrying chambers/containersDust controlEnvironmental engineering

The invention discloses a drying device with a dust collecting effect for cotton processing. The drying device comprises a drying box, a discharge port, a drainage pipe, a filter screen plate and an ultraviolet germicidal lamp, a control panel is embedded in one face of the drying box, the bottom of the drying box is fixedly connected with the supporting legs in a welding mode, and the discharge port is formed in the middle of the bottom end of the drying box. The discharge port is connected with a sealing cover by screwing. Water drainage pipes are symmetrically arranged on the two sides of the drying box, water drainage valves are installed above the water drainage pipes, the filter screen plate is arranged in the drying box, a drying mechanism is arranged on one side of the drying box, meanwhile, a stirring mechanism is arranged on the other side of the drying box, and the ultraviolet sterilization lamp is installed in the drying box through a lamp holder. And a dust removal mechanism is arranged above the drying box. According to the drying device with the dust collecting effect for cotton processing, the stirring mechanism and the drying mechanism are arranged, cotton can be conveniently and evenly stirred through the stirring mechanism, the phenomenon of uneven heating is avoided, and the cotton can be conveniently dried through the drying mechanism.

Owner:建湖县星宇纺织有限公司

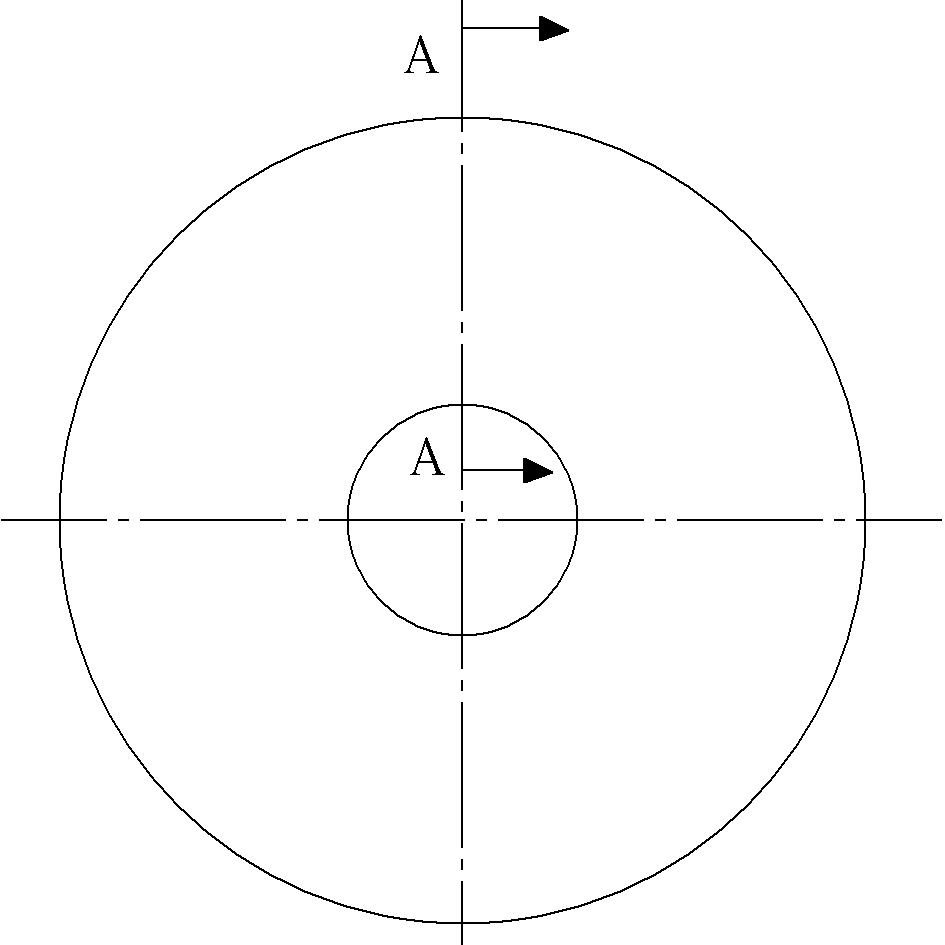

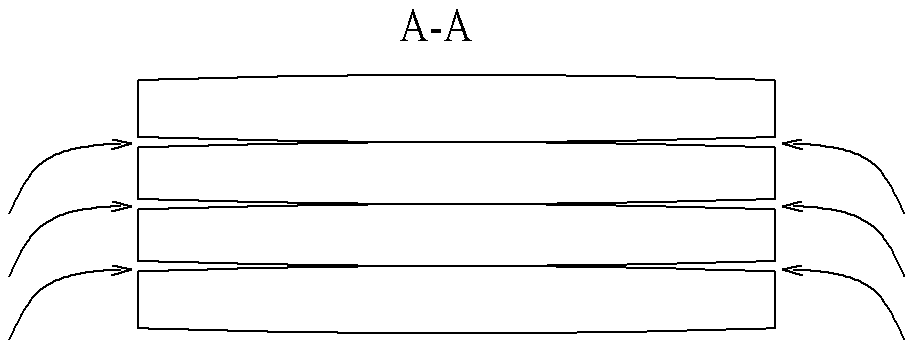

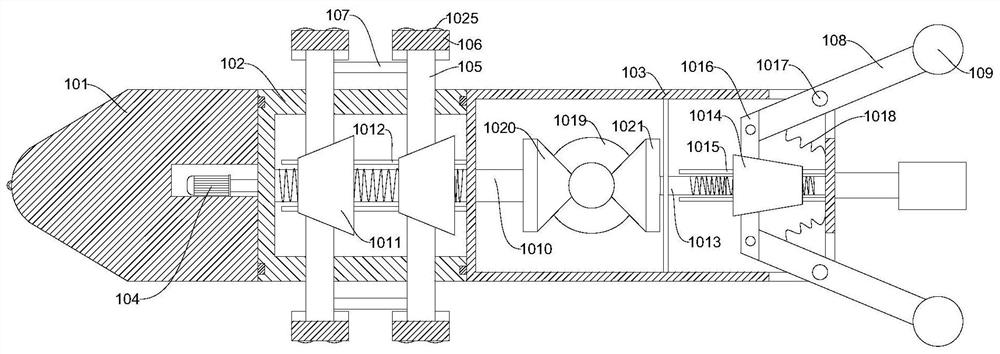

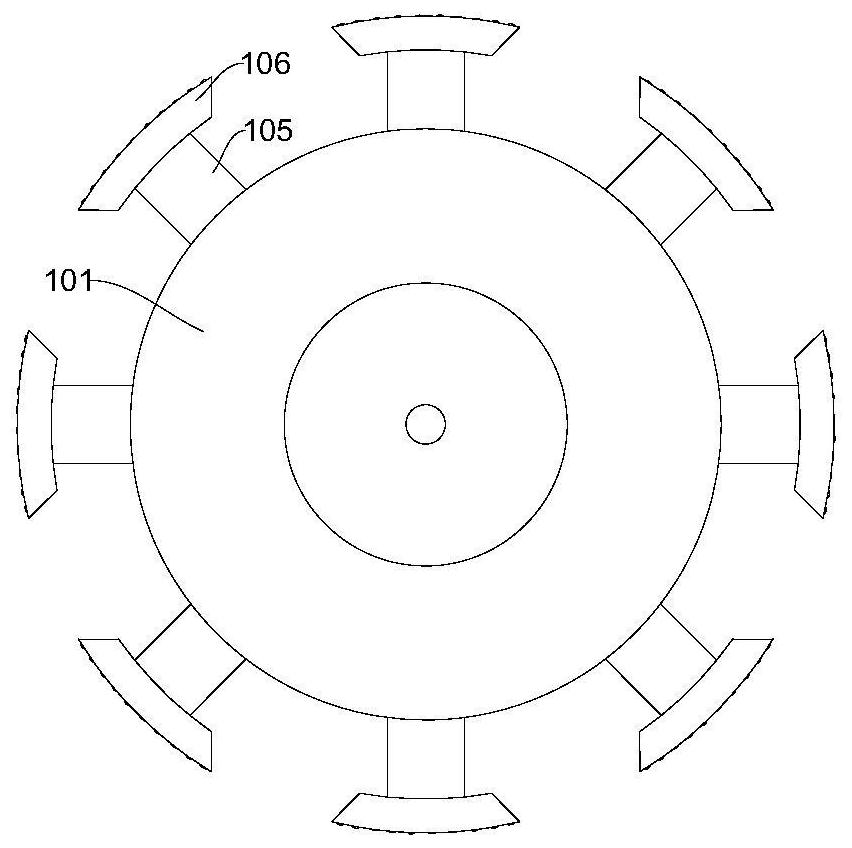

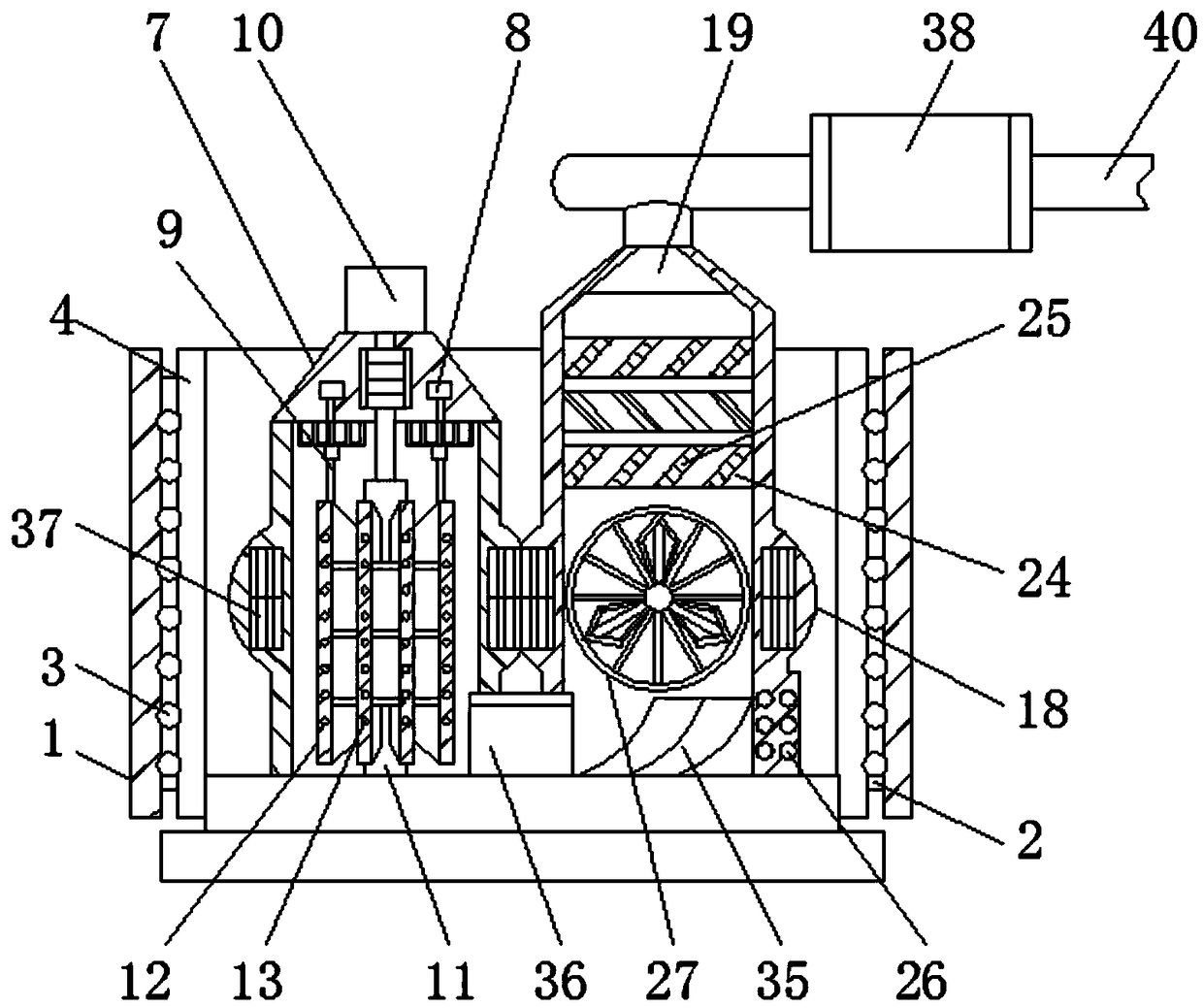

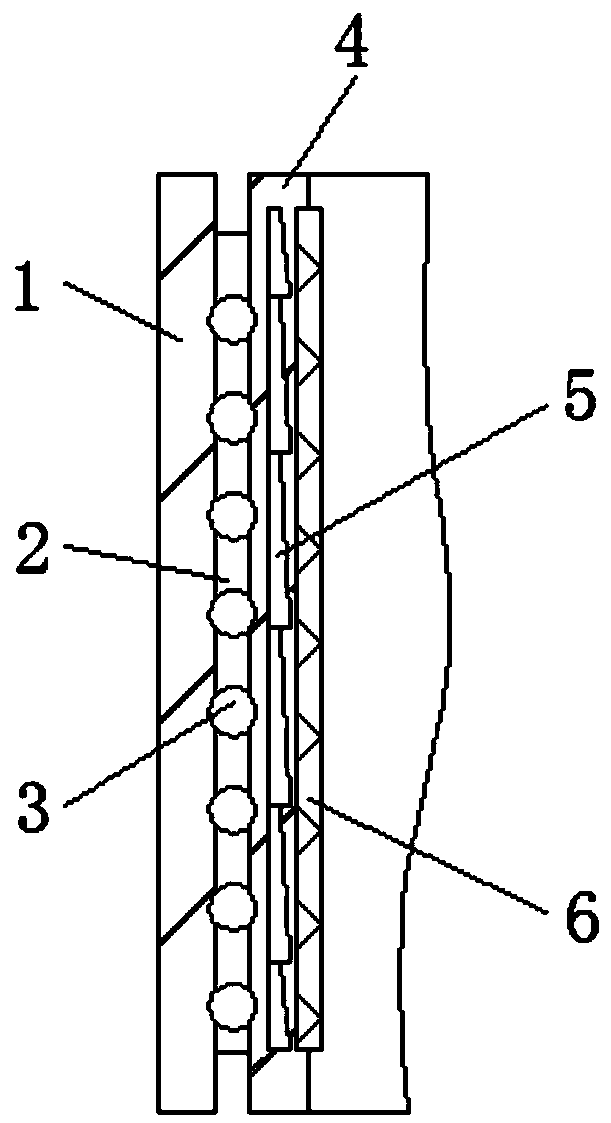

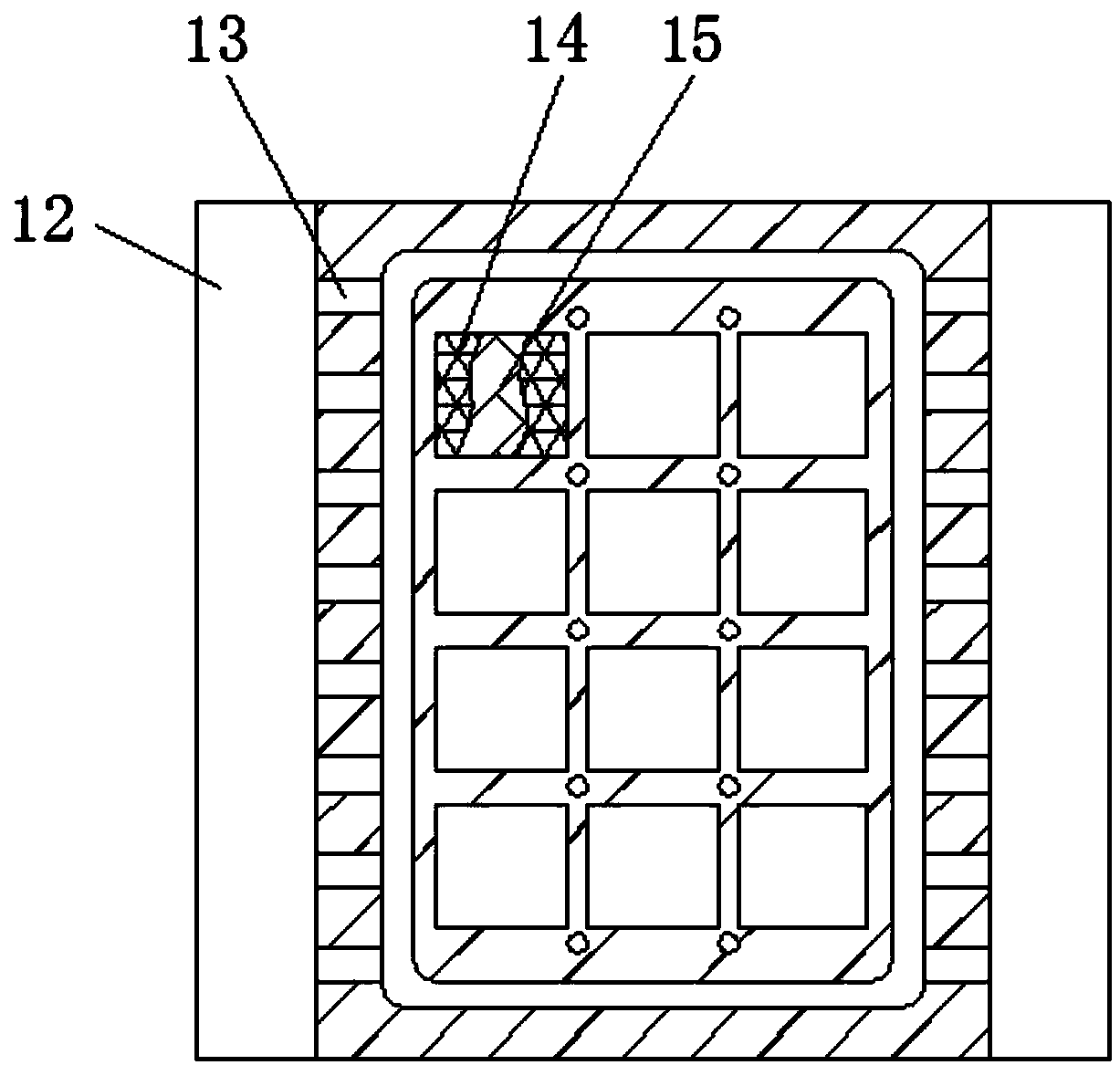

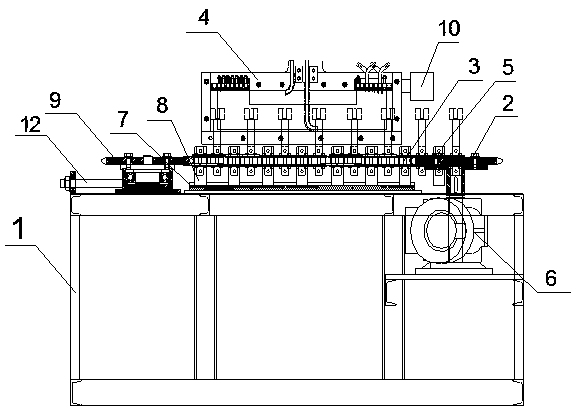

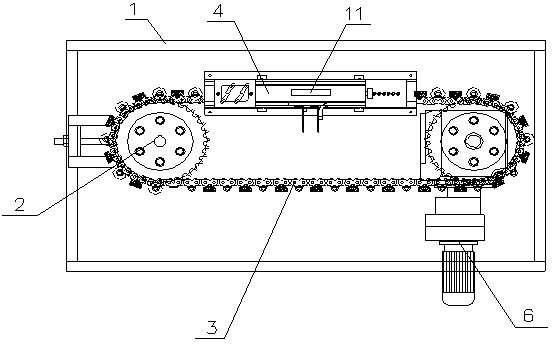

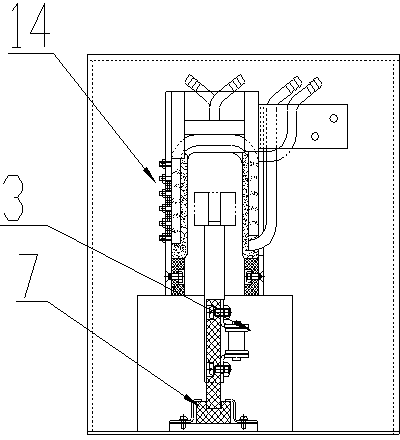

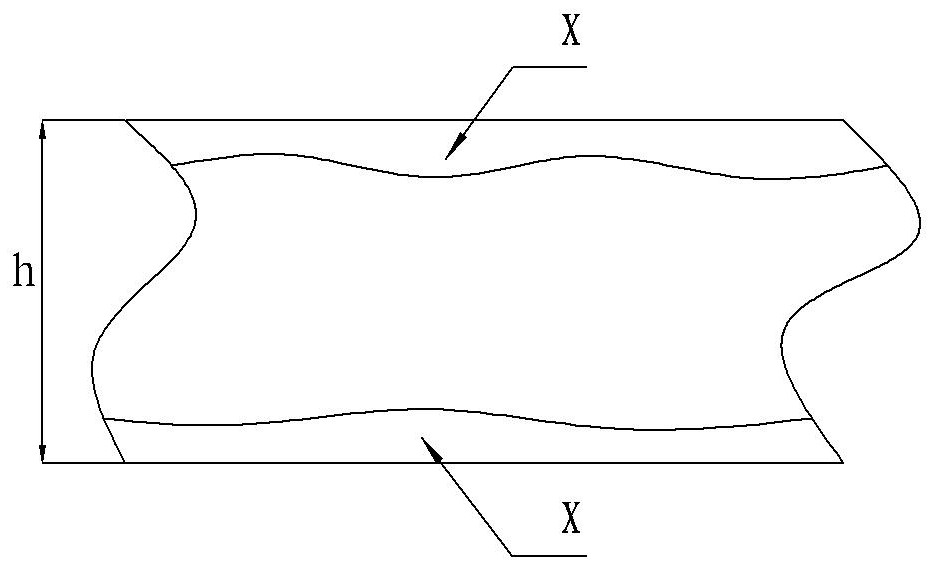

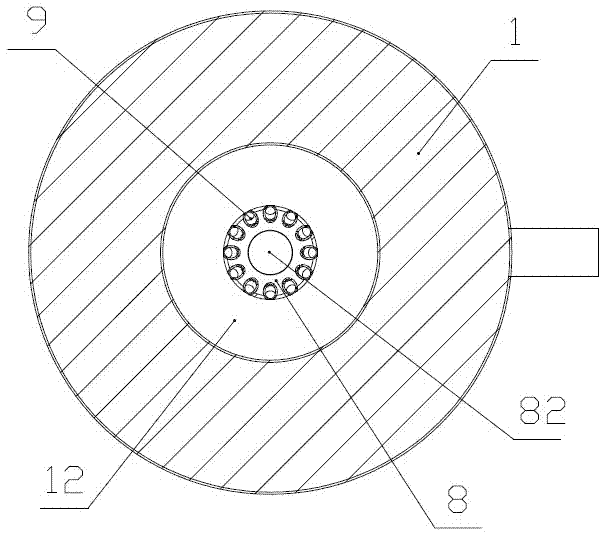

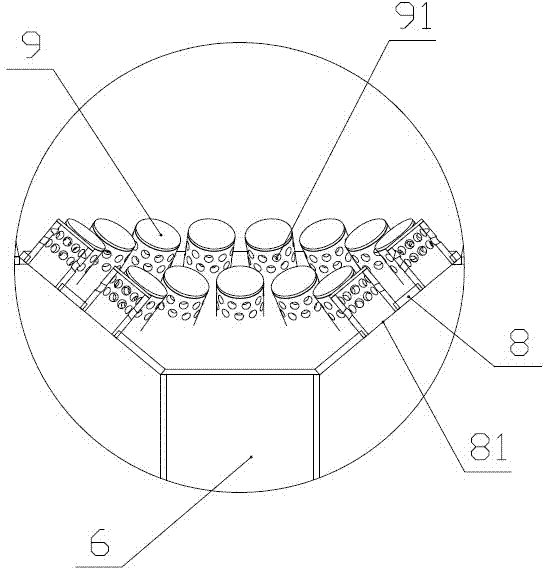

Pass-type rotor heating furnace for piston compressor

ActiveCN103540733AControllable heating timeImprove appearance qualityCharge manipulationFurnace typesHeating timeEngineering

The purpose of the invention is to provide a pass-type rotor heating furnace, comprising a rack, wherein at least two chain wheels are mounted on the rack and connected through a bent plate chain; an induction heating furnace is arranged on the rack; the bent plate chain passes through the interior of the induction heating furnace; a work fixture is arranged on the bent plate chain; and a motor is arranged below the chain wheel on the right side and drives the chain wheels to rotate. A rotor is heated through the induction heating furnace arranged on the rack and is placed on the work fixture on the bent plate chain, the chain is driven by the chain wheels to rotate, the heating time of the rotor in the induction heating furnace is further controlled; moreover, a temperature detector is arranged, the motor and a chain expansion mechanism are controlled so that the heating time of the rotor which is not completely heated is prolonged; therefore, the work efficiency is improved, the work time is reduced and the work intensity is reduced.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

Elimination method of annealing white spots on the edge of cold-rolled aluminum

The invention discloses a method for eliminating annealing white spots on the edge of a cold-rolled aluminum coil, and relates to the technical field of aluminum alloy heat treatment. The method comprises the steps: A, when complete annealing is about to be carried out, after the aluminum coil is pushed into an annealing furnace, filling the annealing furnace with high-purity inert gas, wherein the concentration of the inert gas reaches 90-98%; B, during annealing, increasing the temperature to 200 to 240 DEG C, preserving the temperature for 6 to 15 hours, and controlling the coiling tensilestress before annealing to be 25 MPa or more; C, after the heat preservation is finished, filling the annealing furnace with high-purity argon until the concentration of the inert gas in the furnace reaches 98-100%; and D, increasing the temperature to the target temperature for complete annealing, preserving the temperature, cooling to 200 DEG C or below along with the furnace, and discharging. Compared with the prior art, the method can solve the problem that the edge of an existing aluminum coil has white spot defects in the process of complete annealing.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

Nut stir-frying device for food processing

InactiveCN112056589ARealize stir-fryingFacilitates a thorough stir-fryFood treatmentDrive shaftElectric machinery

The invention discloses a nut stir-frying device for food processing, and relates to the technical field of food processing. The nut stir-frying device comprises a fixing frame, wherein a hanging bracket is fixed on the fixing frame, a stirring motor is in driving connection to a driving shaft through a driving mechanism, a stir-frying mechanism extending into a stir-frying pot is in driving connection with the stirring motor, and a rotating disc is rotatably mounted on the fixing frame; and a reversing mechanism for driving a driving shaft to alternately rotate forwards and backwards is in transmission connection with the rotating disc, and a rotating mechanism used for driving a heating base to rotate is in transmission connection with the driving shaft. Stir-frying of nuts is achieved through the arranged stir-frying mechanism, the arranged driving mechanism can drive the angle of the stirring motor to be continuously adjusted, the position of the stir-frying mechanism is continuously changed, comprehensive stir-frying of nuts is promoted, a sliding column in the stir-frying mechanism can achieve adaptive stretching and retracting relative to a rotating sleeve, the full stir-frying effect on the nuts in different areas of the stir-frying pot is achieved, the nuts are heated more evenly and fully, and the stir-frying efficiency is remarkably improved.

Owner:盐池县荣桂昌食品科技有限公司

Asphalt softening microwave heating box

PendingCN108770108AHeated evenly and fullyImprove heating efficiencyWorking-up pitch/asphalt/bitumenMicrowave heatingDrive motorHeating efficiency

The invention discloses an asphalt softening microwave heating box and relates to the technical field of asphalt heating devices. The microwave heating box comprises a box body, wherein a box door isarticulated with the side end of the box body; a heating device is arranged at the top in the box body; a driving motor is arranged on an inner wall, opposite to the box door, in the box body; the driving motor is connected with a speed reducer; an output shaft of the speed reducer is connected with a rotation disk located in the box body; the rotation disk is detachably connected with a first mounting plate; the first mounting plate is connected with a first extension mechanism; the first extension mechanism is connected with a second mounting plate; the second mounting plate is connected with a heating barrel for containing asphalt through a plurality of connecting rods; and an end cover is articulated with one side end, close to the box door, of the heating barrel. The box has the advantages that the box is convenient to operate, high in automation degree and high in heating efficiency.

Owner:SICHUAN GUOXING POLYMER RESIN CO LTD

Catalyst regenerating device

ActiveCN103894239AHeated evenly and fullyHigh catalytic efficiencyCatalyst regeneration/reactivationCombustionEngineering

The invention discloses a catalyst regenerating device. The catalyst regenerating device comprises a combustion furnace, wherein the side wall of the combustion furnace is respectively provided with an inlet and an exhaust outlet which are respectively communicated with an inner cavity of the combustion furnace; the bottom of the inner cavity of the combustion furnace is provided with an ejecting device which enables a catalyst to be rapidly heated to the required temperature and then to be output from the exhaust outlet; the ejecting device is positioned below the inlet. The ejecting device is structurally characterized in that the bottom of the inner cavity of the combustion furnace is provided with concave baffles sinking downward; the concave surfaces of the concave baffles are provided with a plurality of ejecting pipes; a plurality of ejecting holes are formed in the side walls of the ejecting pipes; the top parts of the ejecting pipes are sealed, and the concave baffles corresponding to the bottom of each ejecting pipe are respectively provided with through holes communicated with each ejecting pipe; the side wall of the combustion furnace is provided with an air inlet communicated with each through hole; the air inlet is communicated with each ejecting pipe by each through hole. The catalyst regenerating device provided by the invention is simple in structure, is low in energy consumption, and greatly improves the catalytic efficiency of the catalyst.

Owner:张家港市天源机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com