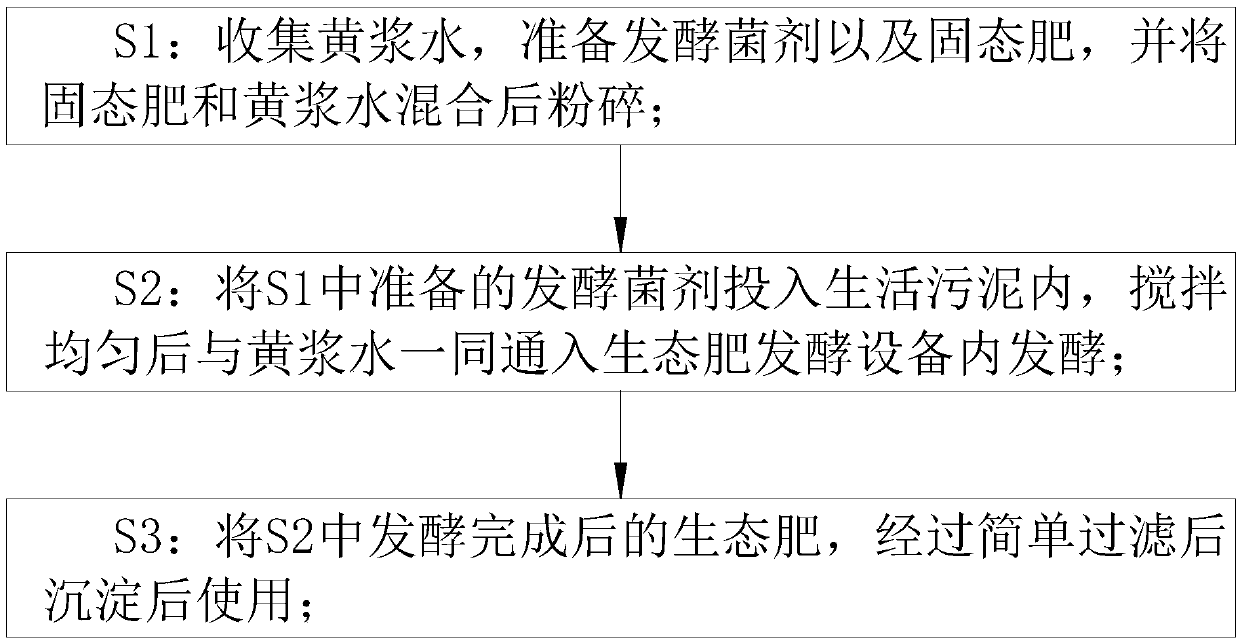

Ecological fertilizer fermentation process

A fermentation process and ecological fertilizer technology, which is applied to organic fertilizers, fertilization devices, microbial treatment, etc., can solve the problems of precipitation, decrease of fermentation rate, and difference in fungus survival temperature, so as to prevent raw material precipitation, increase fermentation rate, and strengthen The effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

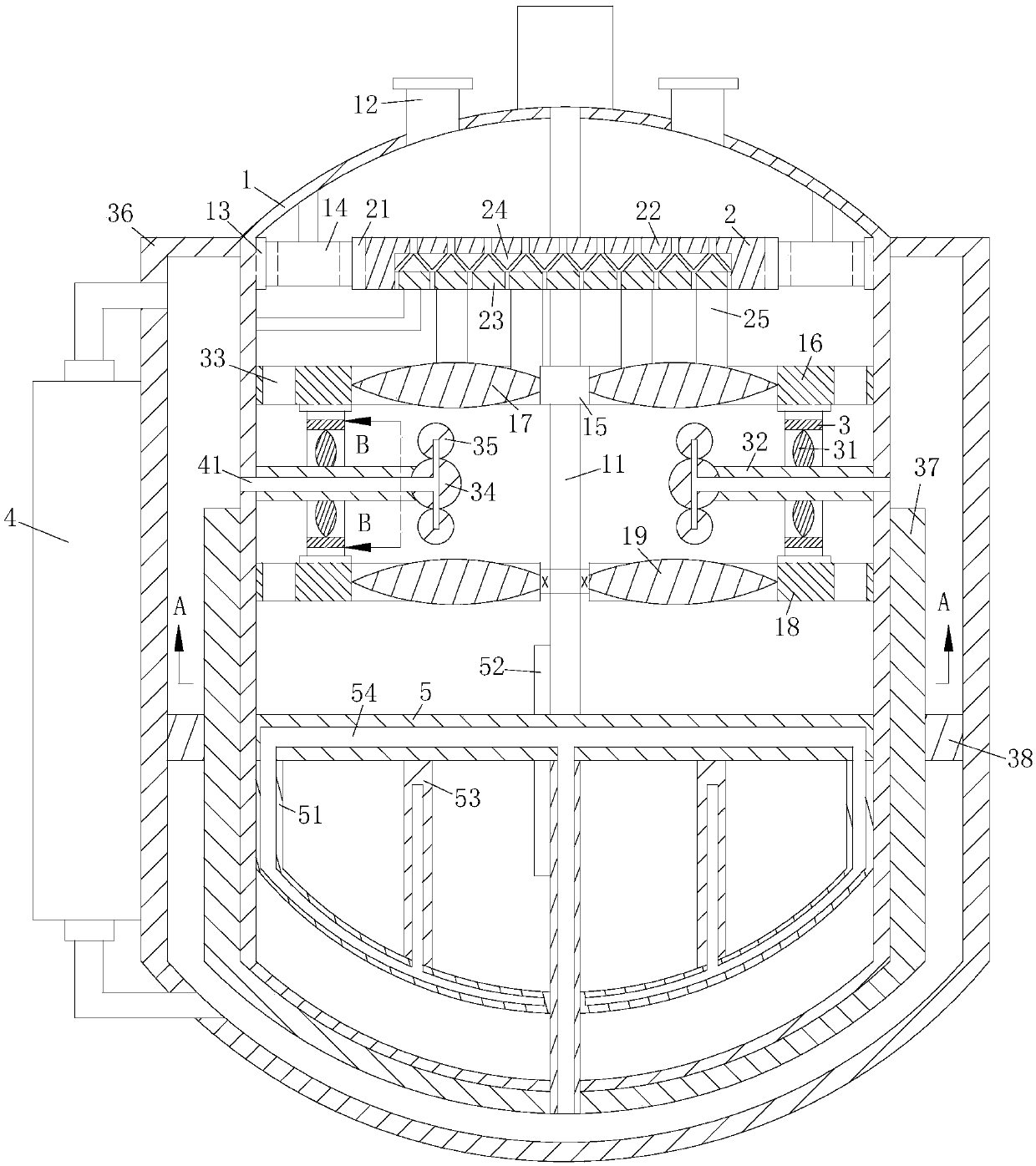

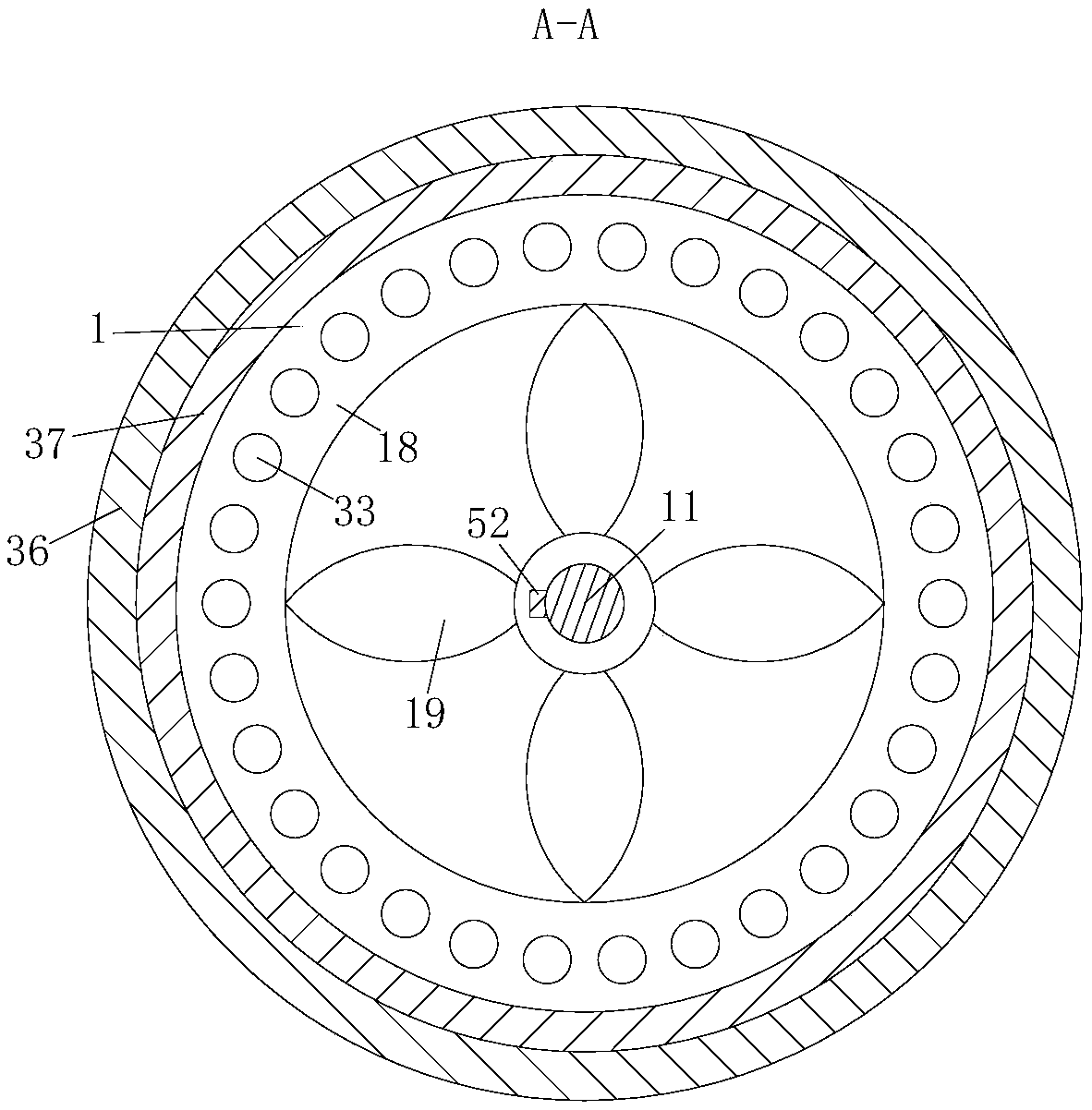

Embodiment approach

[0034] As an embodiment of the present invention, the first aeration ball 34 is fixedly connected to the end of the second fixed rod 32 close to the rotating shaft 11; the upper and lower ends of the first aeration ball 34 are fixed to the second Two aeration balls 35; the frame body 1 is provided with a thermal insulation cabin 36; the frame body 1 is located in the thermal insulation cabin 36; the outer surface of the frame body 1 is provided with a heater 37; the heater 37 "U" shaped design, and attached to the outer wall of the frame body 1, the frame body 1 is effectively heated to provide the most suitable survival temperature for fungi, and the heat preservation cabin 36 can reduce the loss of temperature; the outer wall of the heater 37 is provided with a threaded groove; The inner wall of the thermal insulation cabin 36 is slidably connected with a slider 38; the slider 38 is circular in design and slides in a threaded groove; the heater 37 is fixedly socketed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com