Pass-type rotor heating furnace for piston compressor

A rotor heating and compressor technology, which is applied in the field of rotor heating furnaces, can solve the problems of uneven heating, stuck heating furnace, easy damage of heating, etc., and achieve the effect of uniform and sufficient rotor heating, prolonging the heating time, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

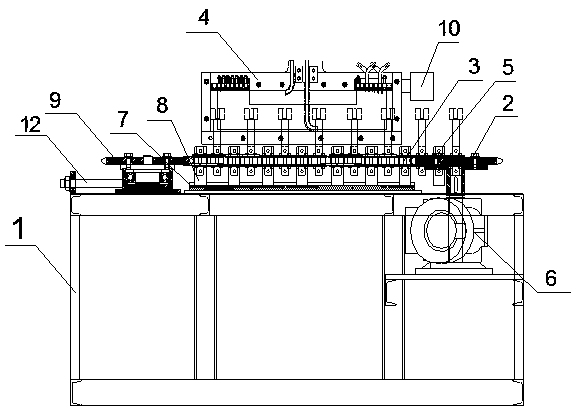

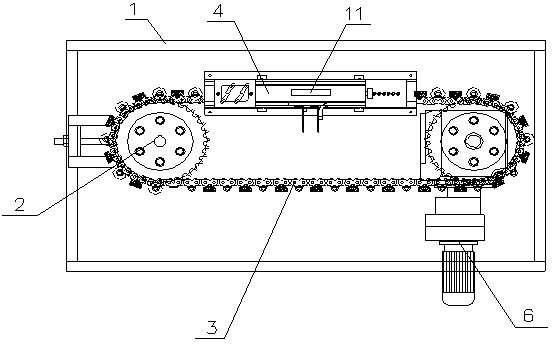

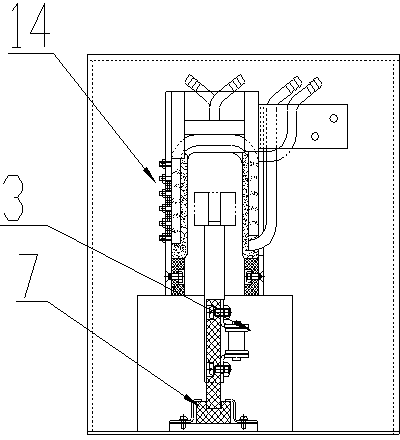

[0018] Such as figure 1 , 2 , 3, 4, and 5, the present embodiment provides a piston compressor through-type rotor heating furnace, including a frame 1, and two left and right sprockets 2 are installed on the frame 1, and the sprocket 2 The frame 1 is provided with an induction heating furnace 14, and a protective cover 4 is installed above the induction heating furnace 14; the frame 1 is provided with a guide rail 7, and the guide rail 7 is provided with a support Block 8, the bent plate chain 3 is fixed on the support block 8 by threaded connection, and the support block 8 is provided with a tooling fixture 5; the bottom of the sprocket 2 on the right side of the frame 1 is provided with a motor 6, and the motor 6 drives the sprocket 2 to rotate , the sprocket 2 drives the support block 8 fixed on the chain 3 to move on the guide rail 7, and the fixture 5 is tightly connected with the support block 8 through threads. The left side of the frame 1 is provided with a chain te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com