Induction heater for unwinding motor stators

A technology of induction heaters and motors, applied in induction heating, induction heating control, induction heating devices, etc., can solve the problems of difficult temperature control, pollution of the environment, uneven heating, etc., and achieve controllable heating time and heating environment. Safe and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

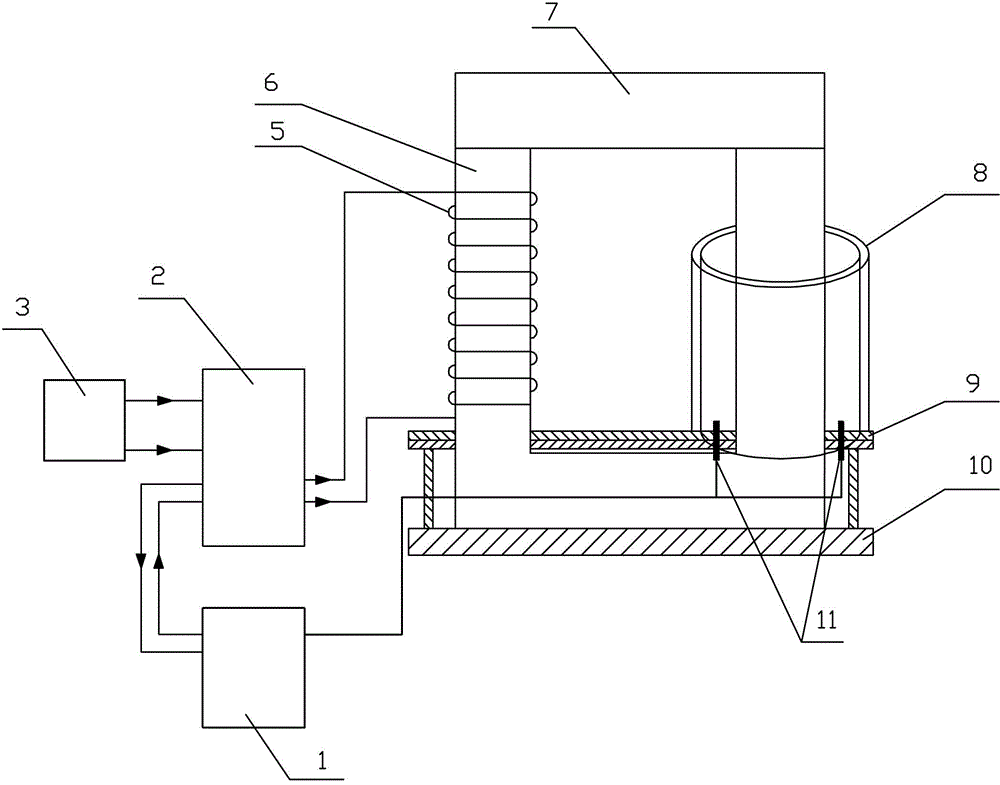

[0012] Embodiment: the induction heater of a kind of electric motor stator dismantling of the present embodiment is used, as figure 1 As shown, it includes a heating control device 1. The heating control device 1 is connected to a high-frequency power generator 2. The high-frequency power generator 2 is connected to a commercial frequency power supply 3. The induction coil 5 on the silicon steel core 6 is connected, and the insulating material is lined between the induction coil 5 and the fixed silicon steel core 6, and the movable silicon steel core 7 is placed on the two-column fixed silicon steel core 6, and the fixed silicon steel core 6 is placed below There is an equipment seat 10 with a support surface 9 on the equipment seat 10. The support surface 9 is formed by stacking two open-loop iron plates. The open loop is inlaid with a heat-resistant insulating material. There is a temperature measuring element 11 on the side, and the temperature measuring element 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com