Patents

Literature

132results about "Lanthanide oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

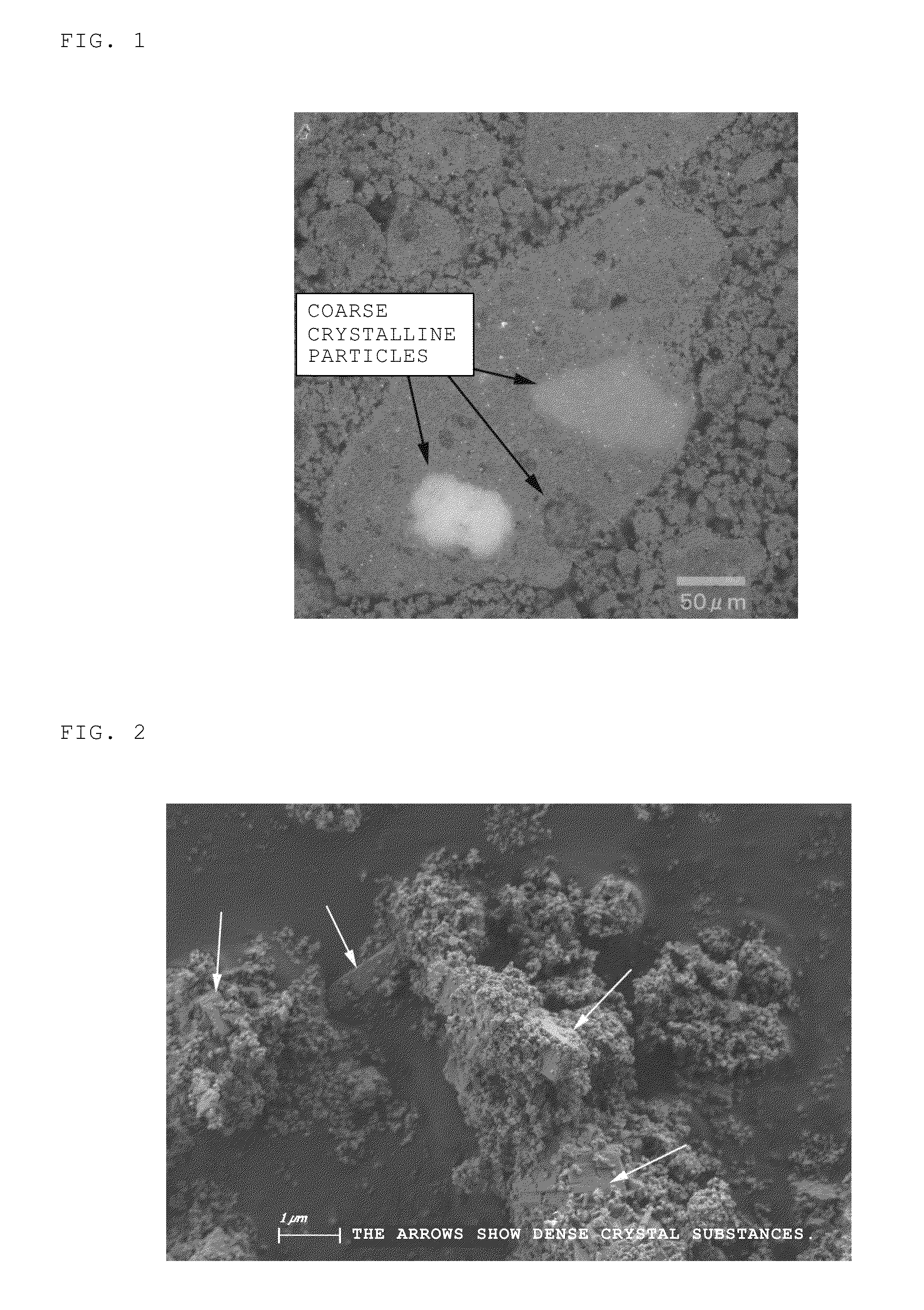

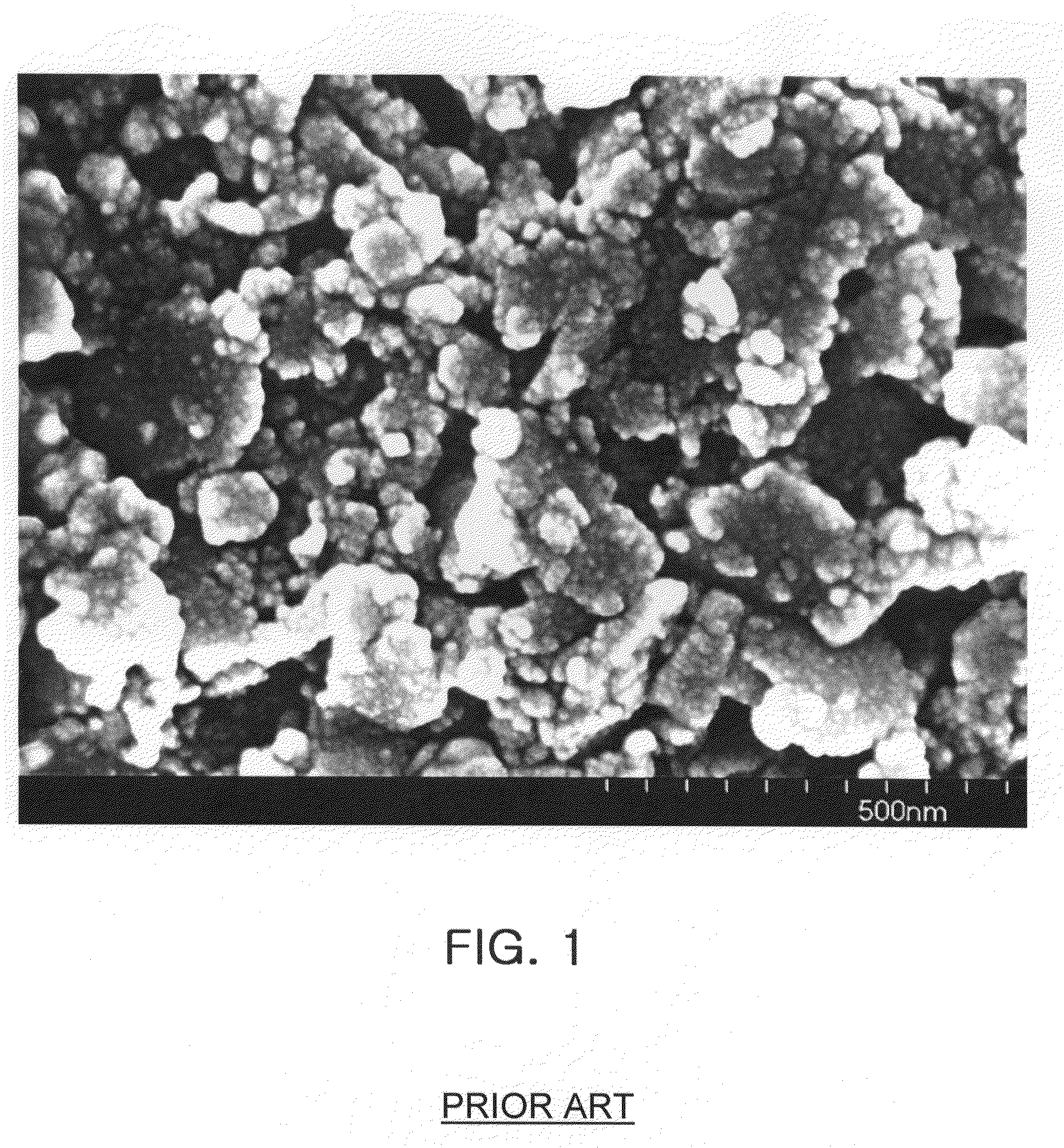

Process for the production of ultrafine particles

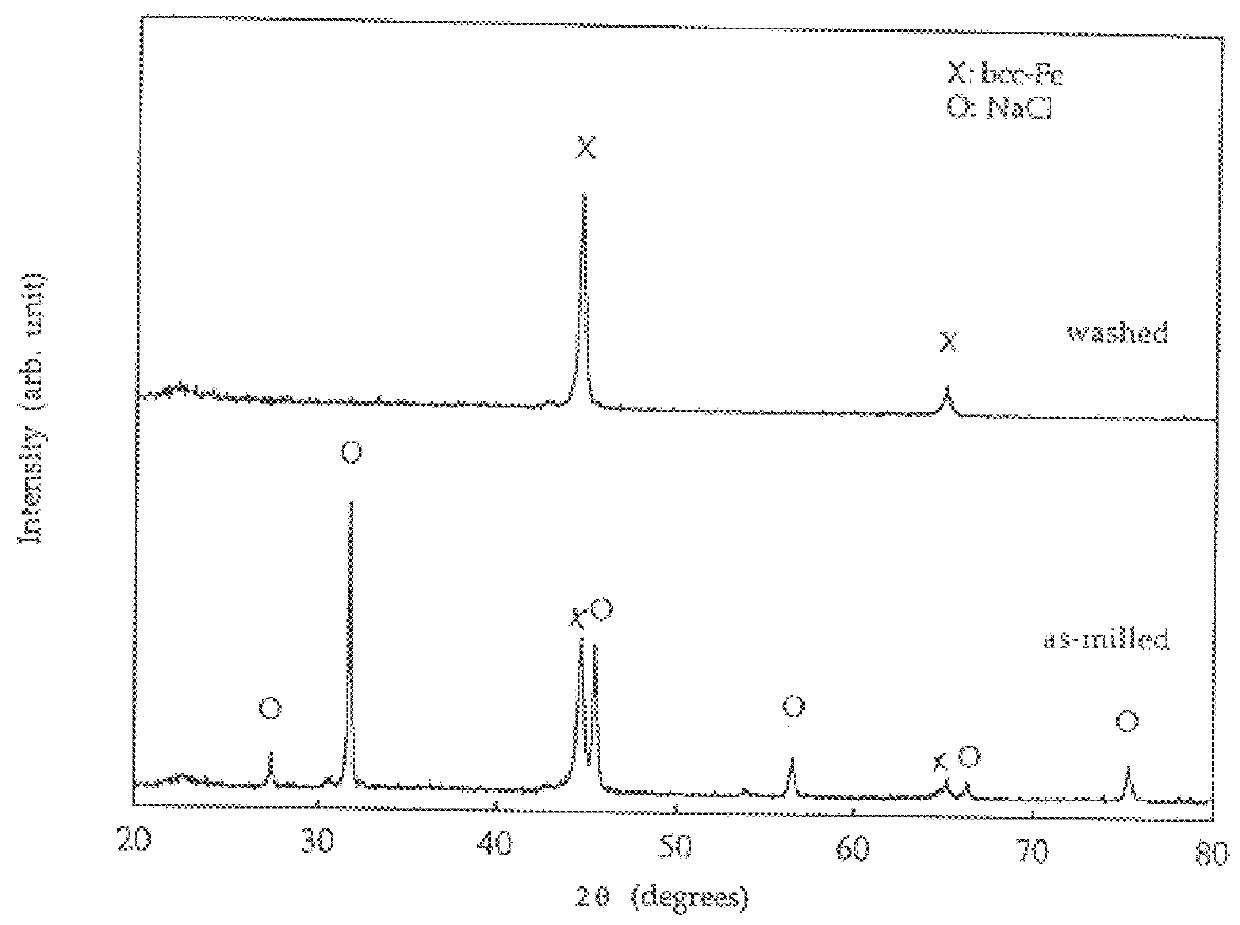

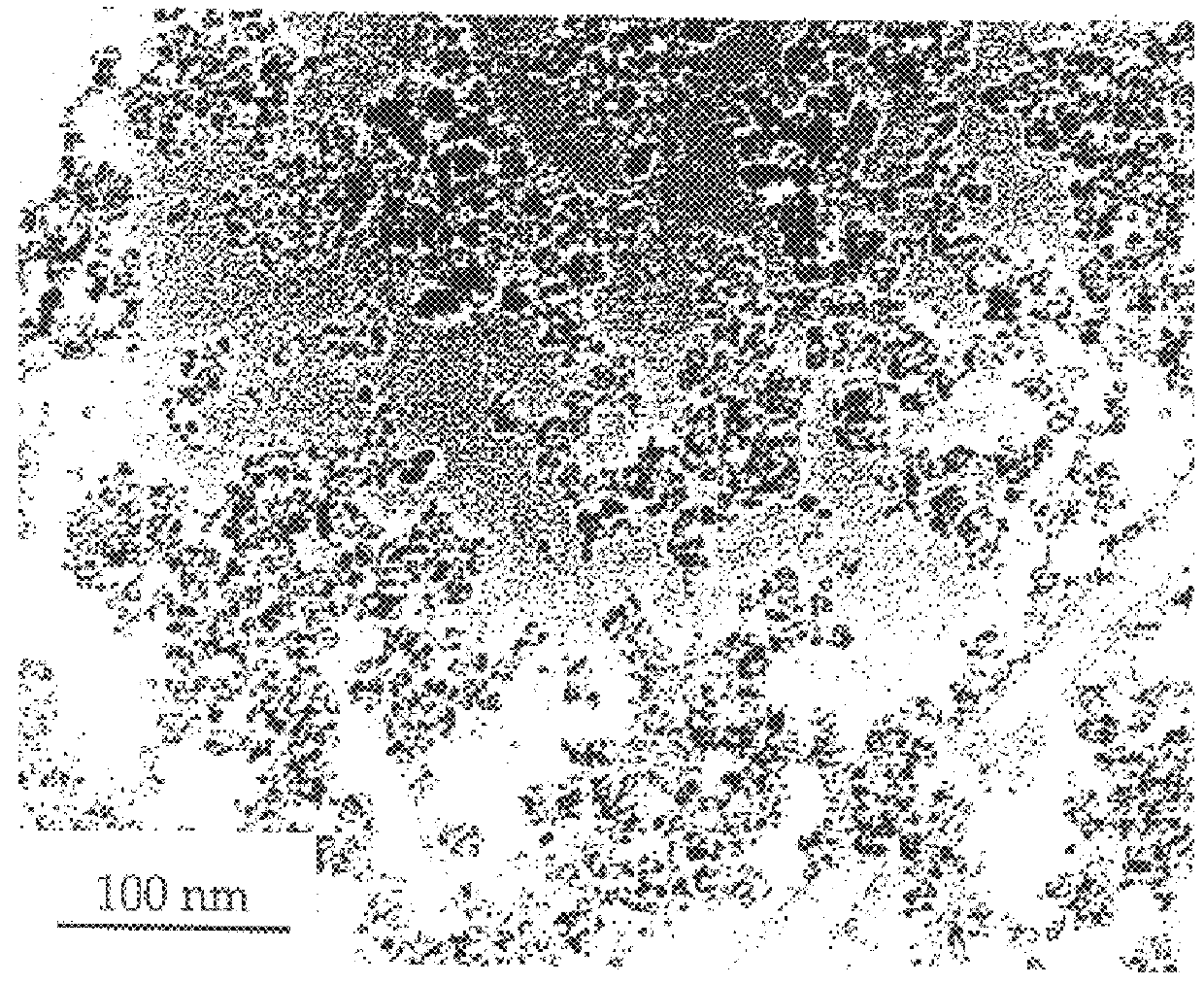

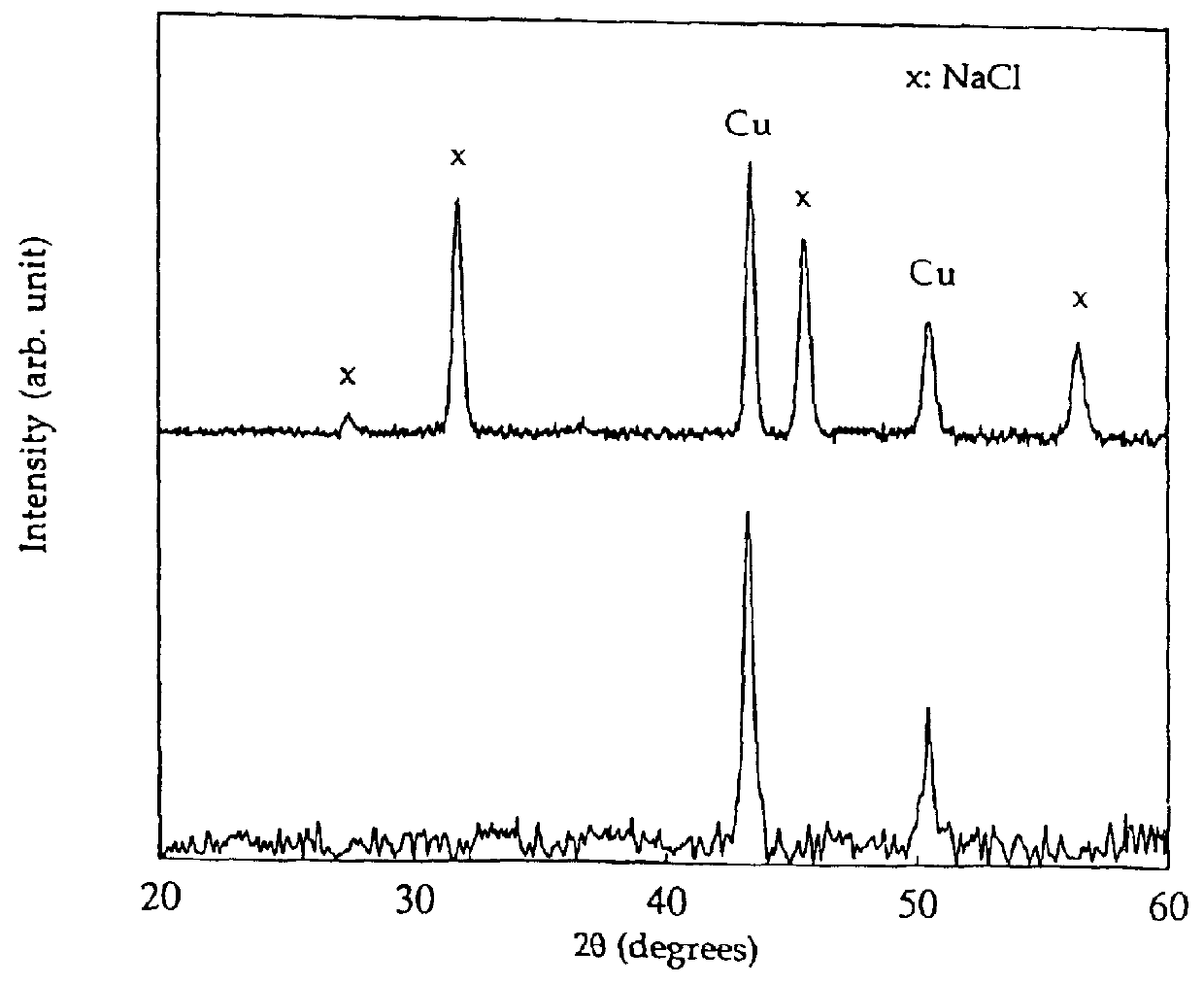

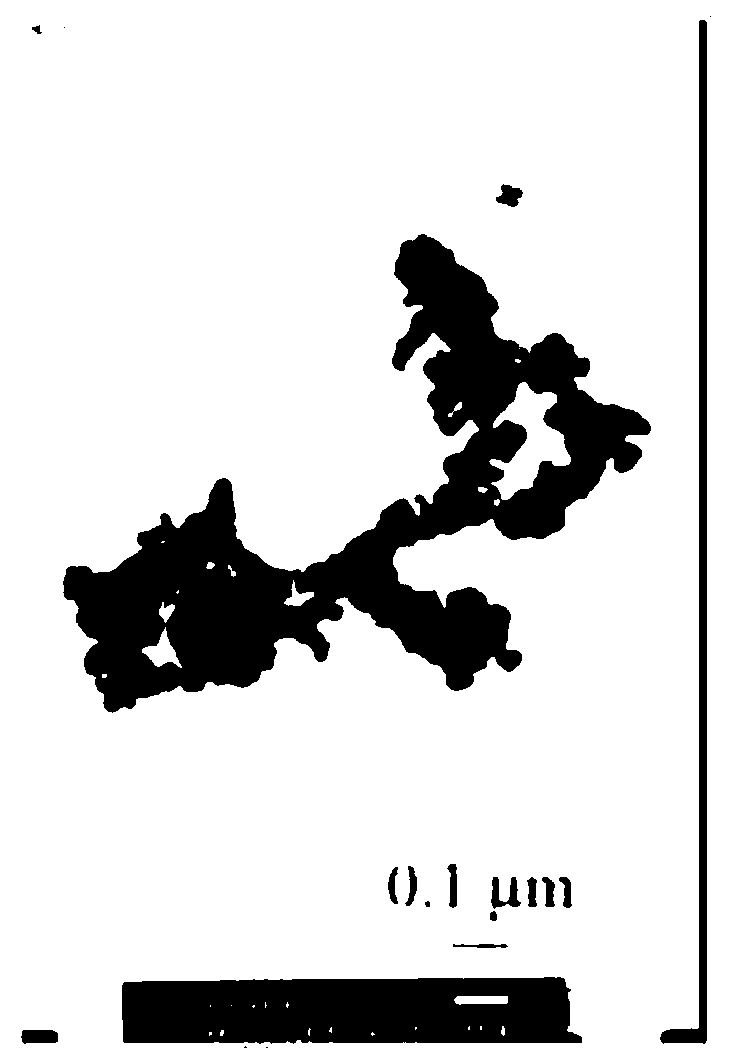

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

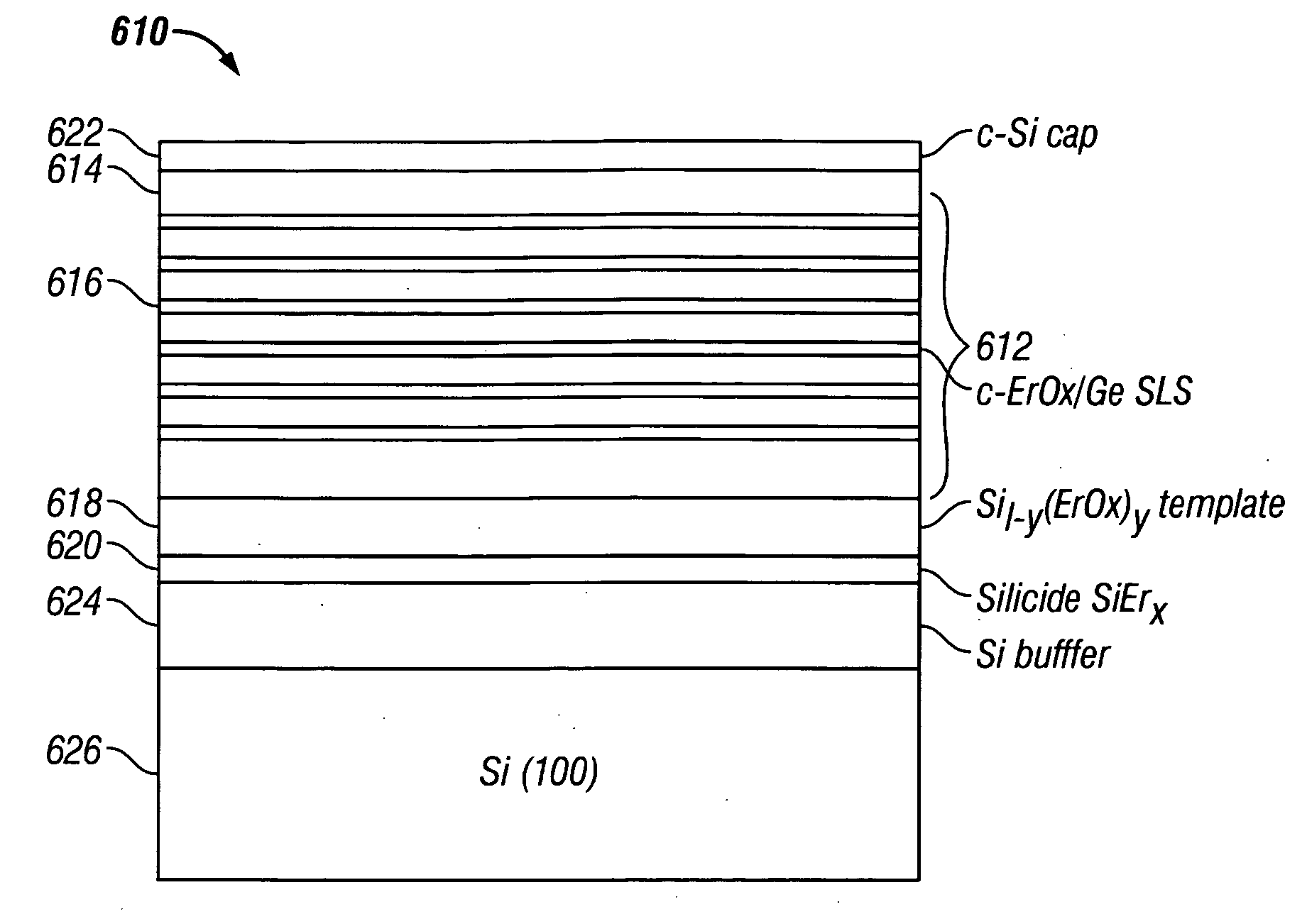

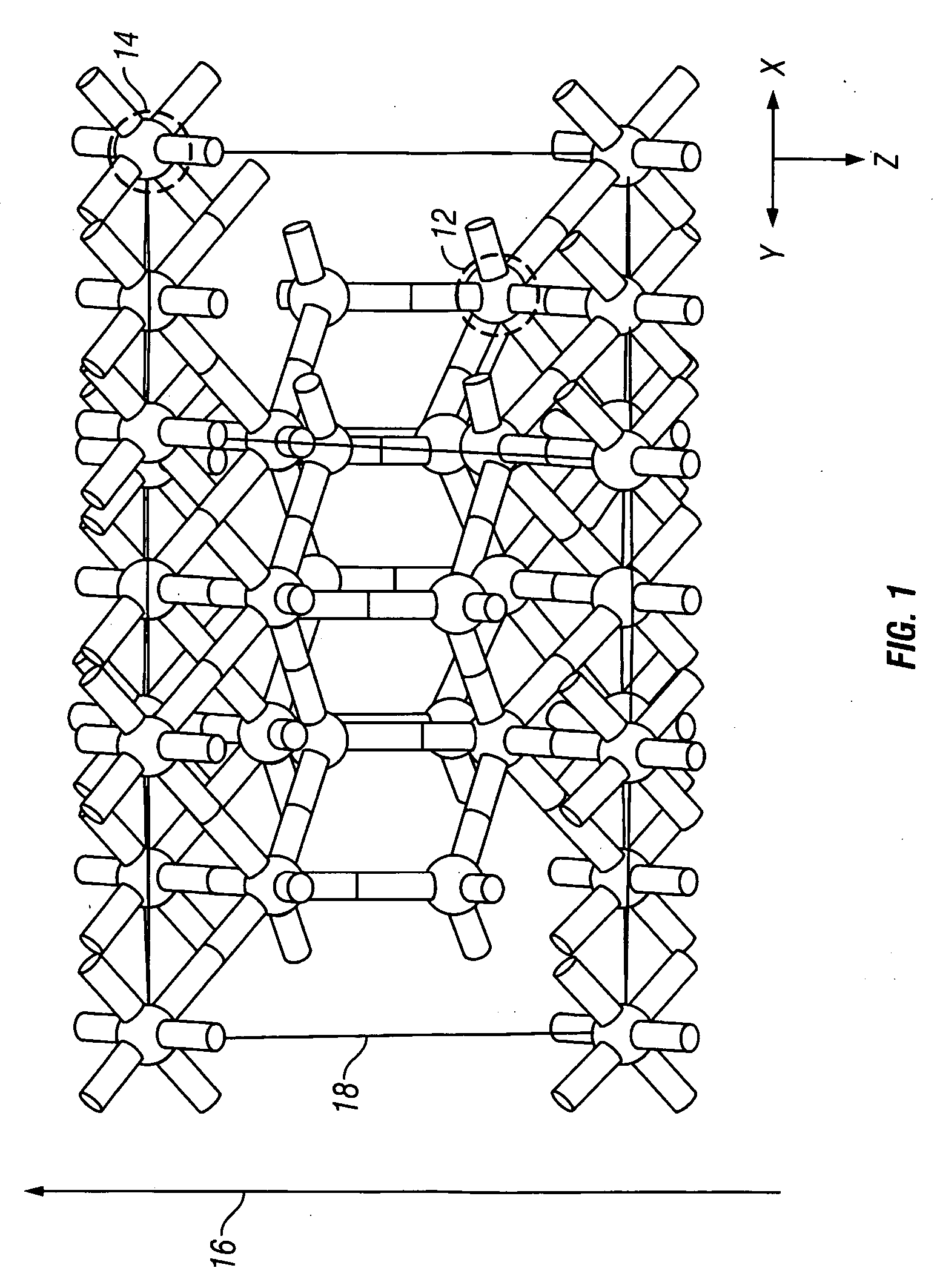

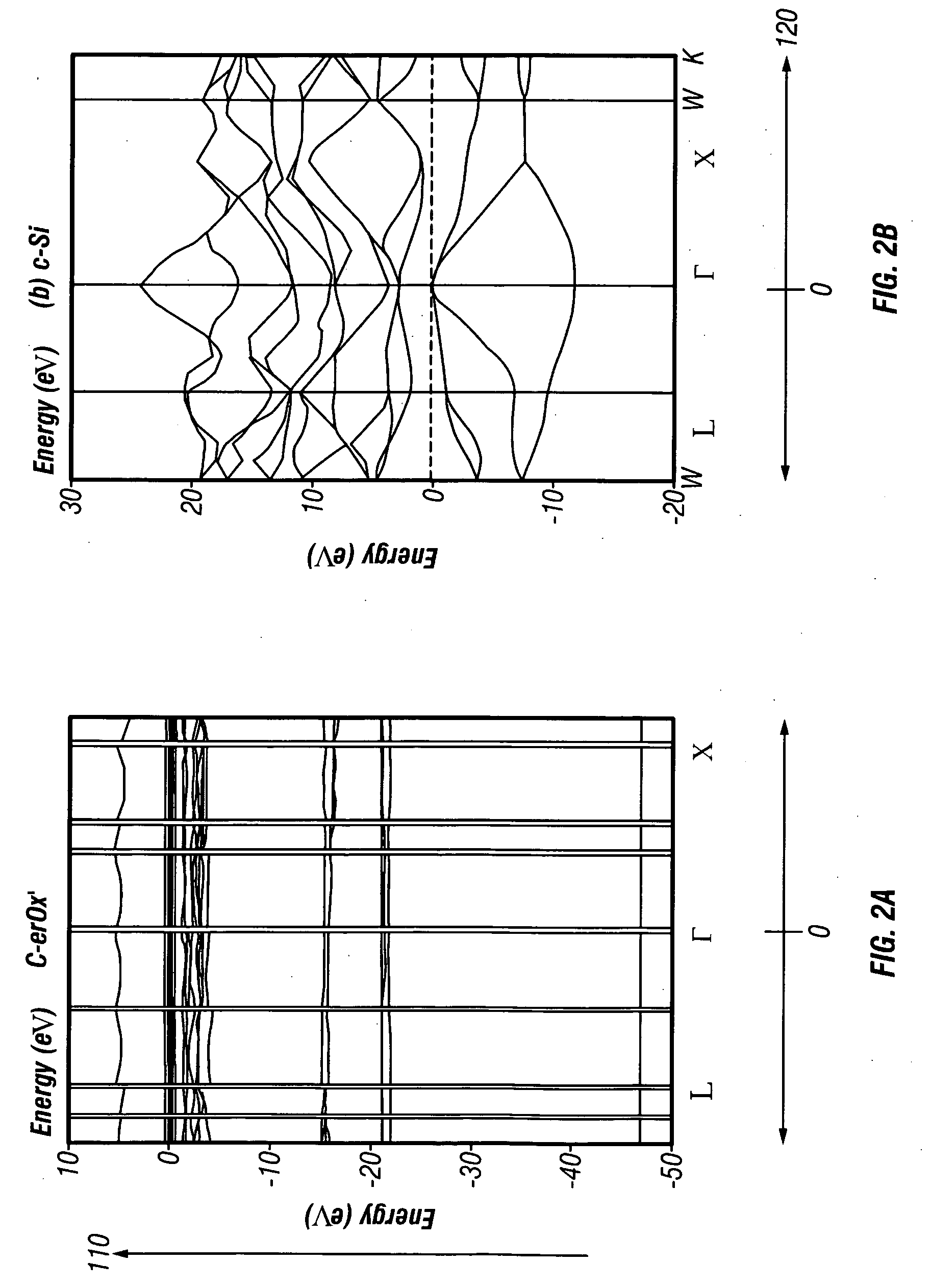

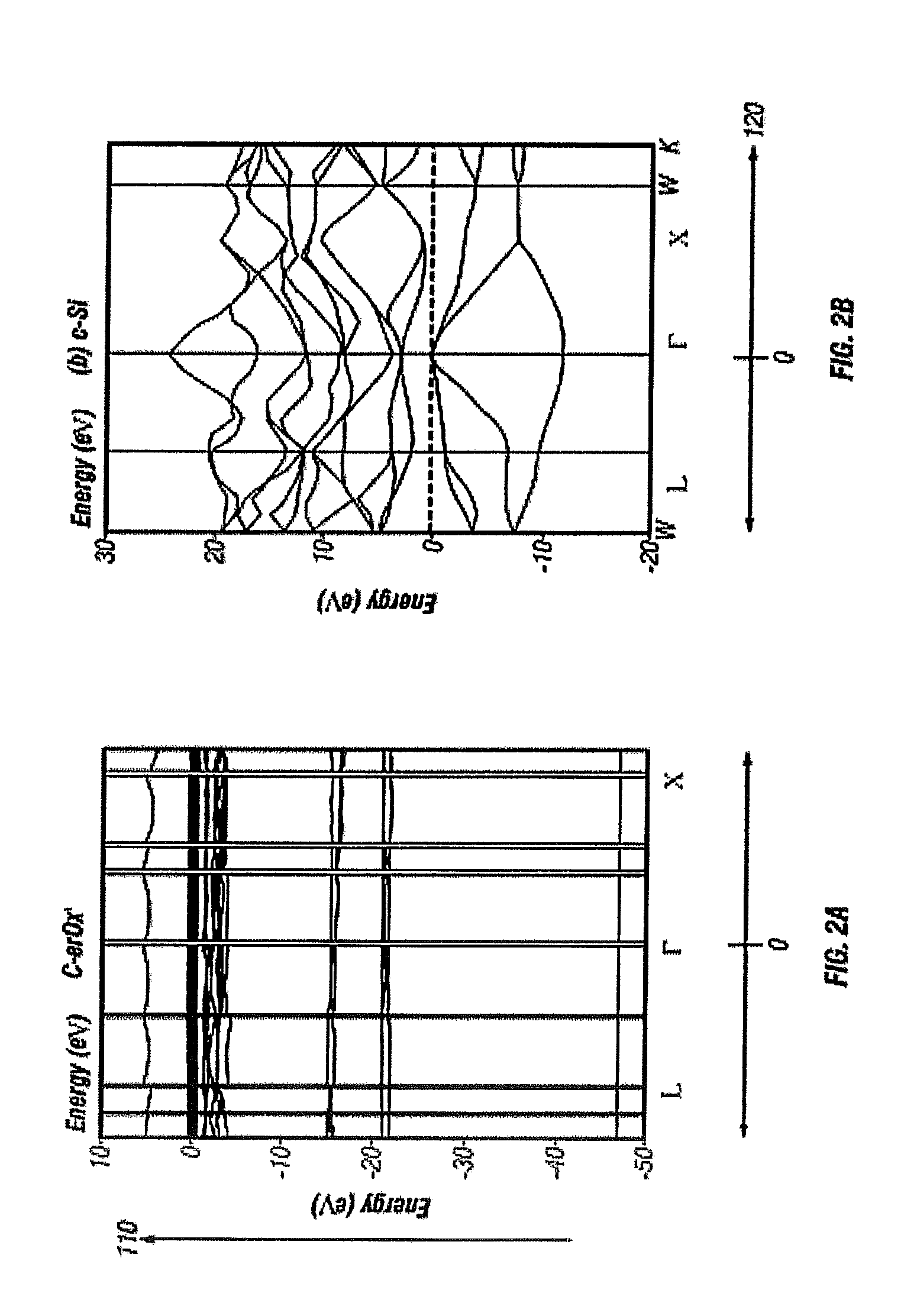

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

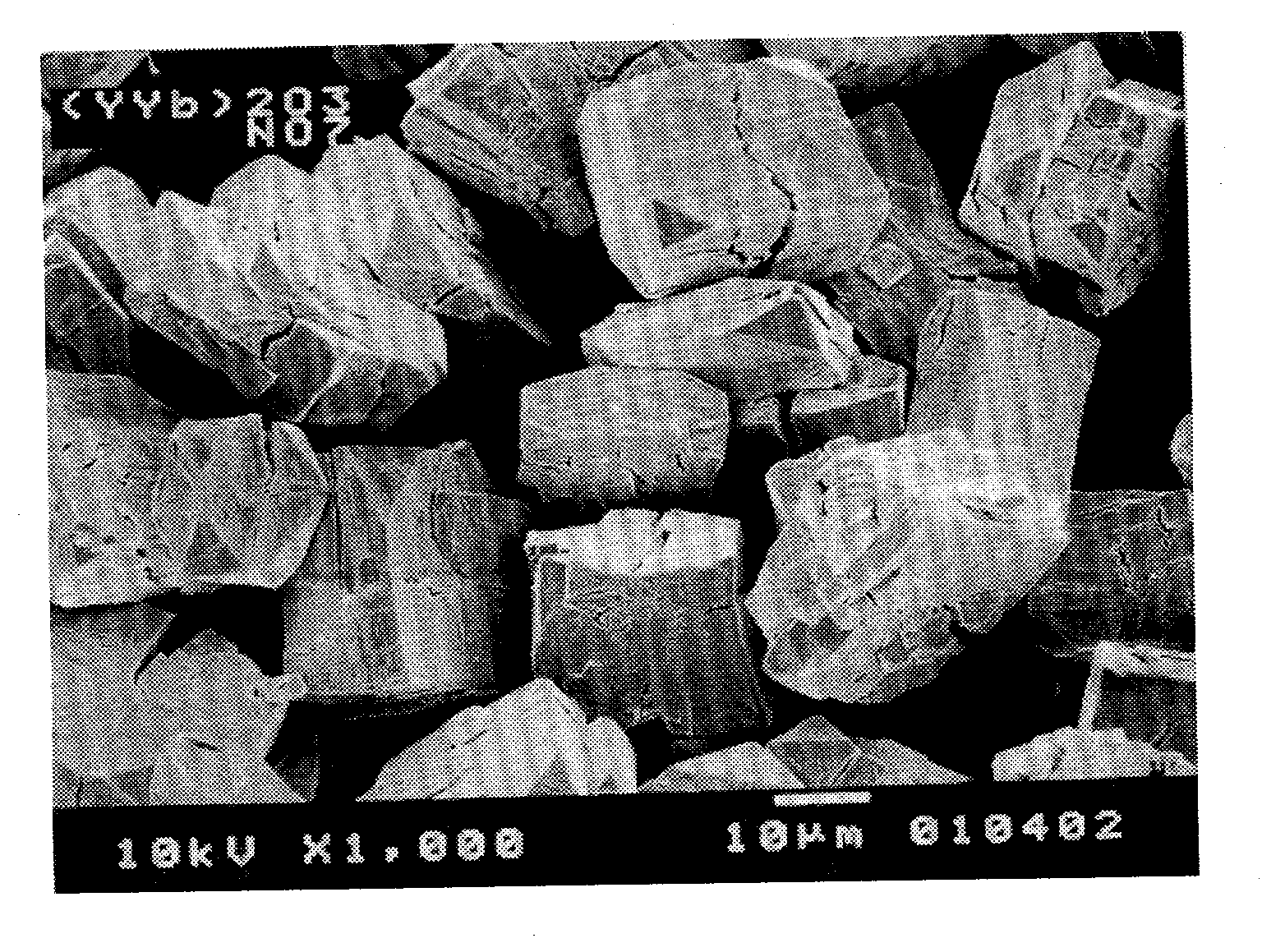

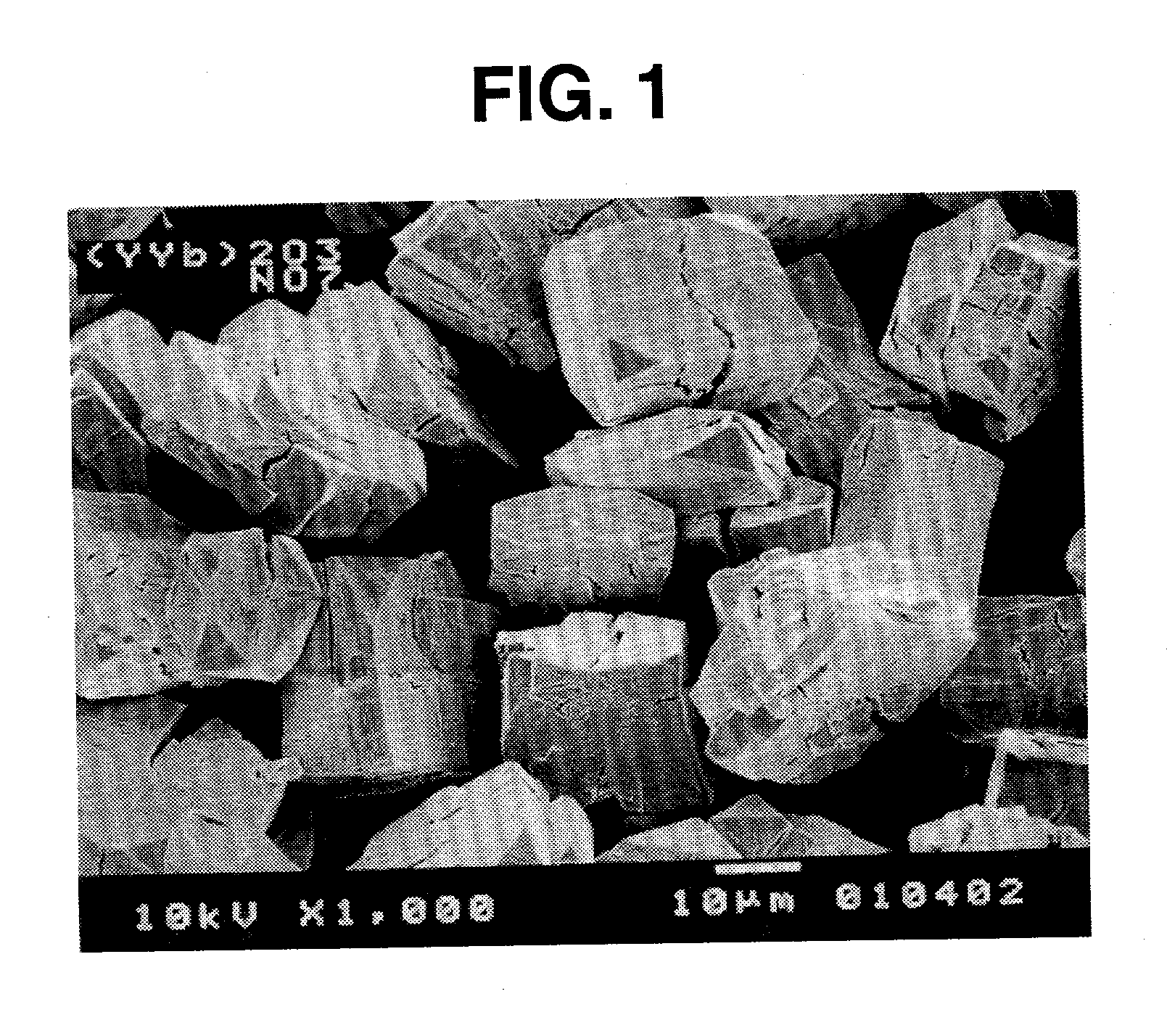

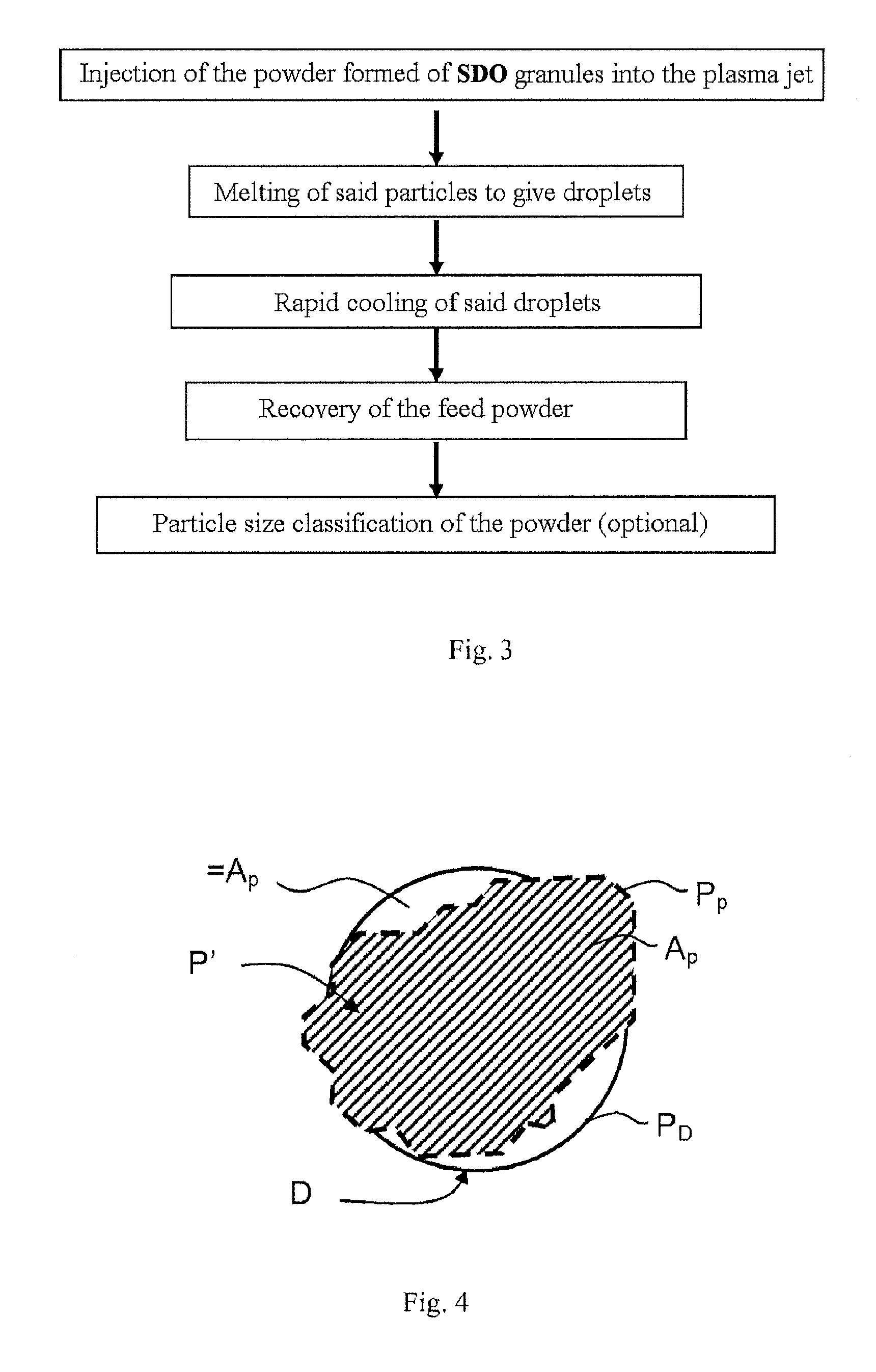

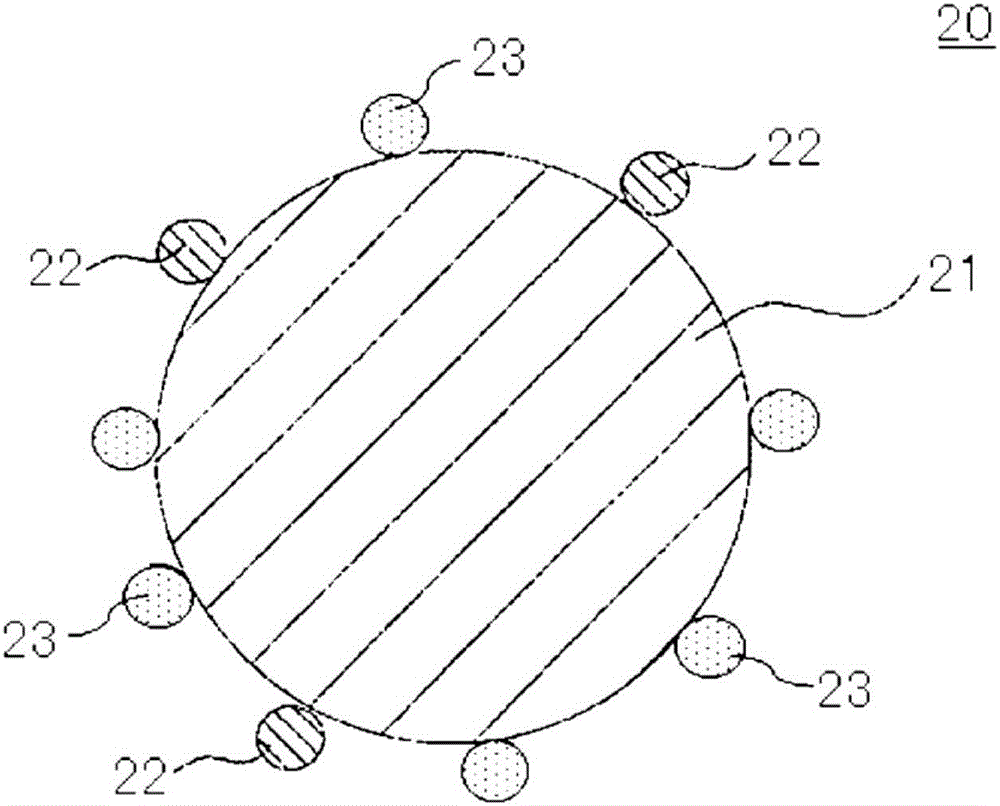

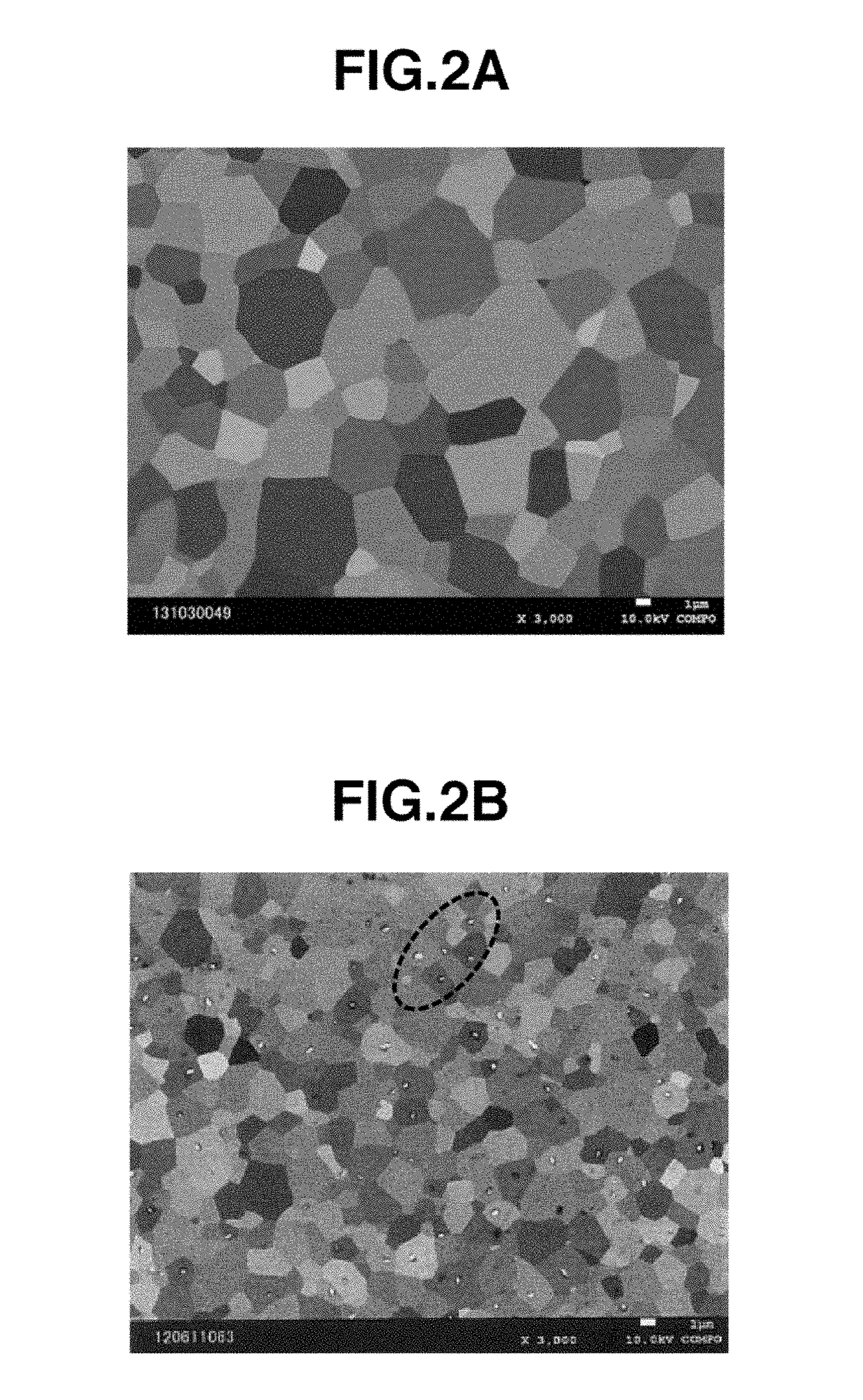

Thermal spray particles and sprayed components

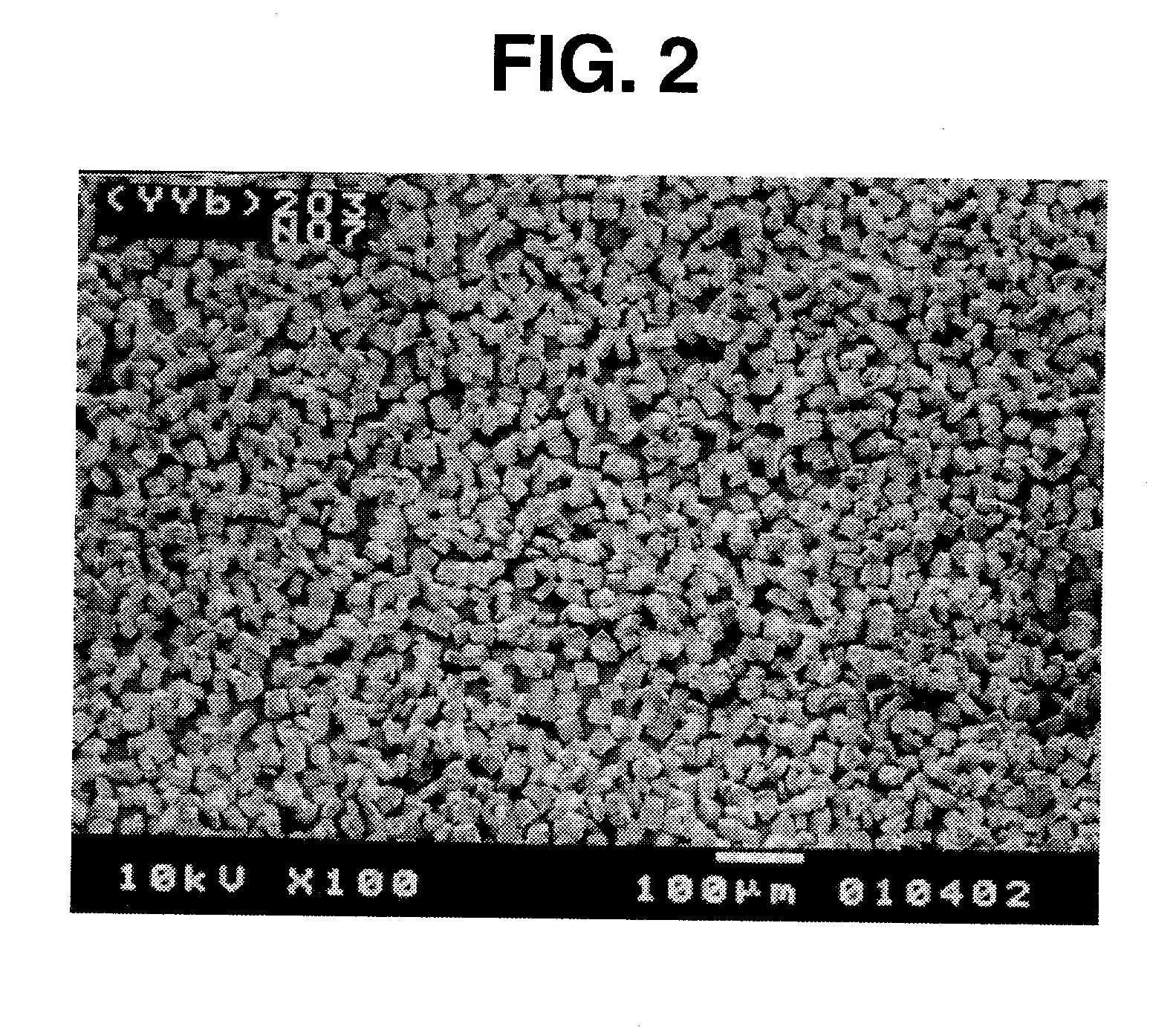

InactiveUS20020177014A1High densityHigh strengthLanthanide oxides/hydroxidesMolten spray coatingThermal sprayingMetallurgy

Rare earth-containing compound particles of polyhedral shape having an average particle diameter of 3-100 .mu.m, a dispersion index of up to 0.5, and an aspect ratio of up to 2 can be thermally sprayed to form an adherent coating, despite the high melting point of the rare earth-containing compound. A sprayed component having the particles spray coated on a substrate surface is also provided.

Owner:SHIN ETSU CHEM IND CO LTD

Security pigments and the process of making thereof

InactiveUS20080274028A1Low costVerify authenticityMaterial nanotechnologyPigmenting treatmentRare earthPigment

Disclosed are methods for using color inconstancy pigments and / or dyes, such as rare earth doped color inconstancy pigments, in security applications including semi-overt and covert security application.

Owner:SUN CHEM CORP

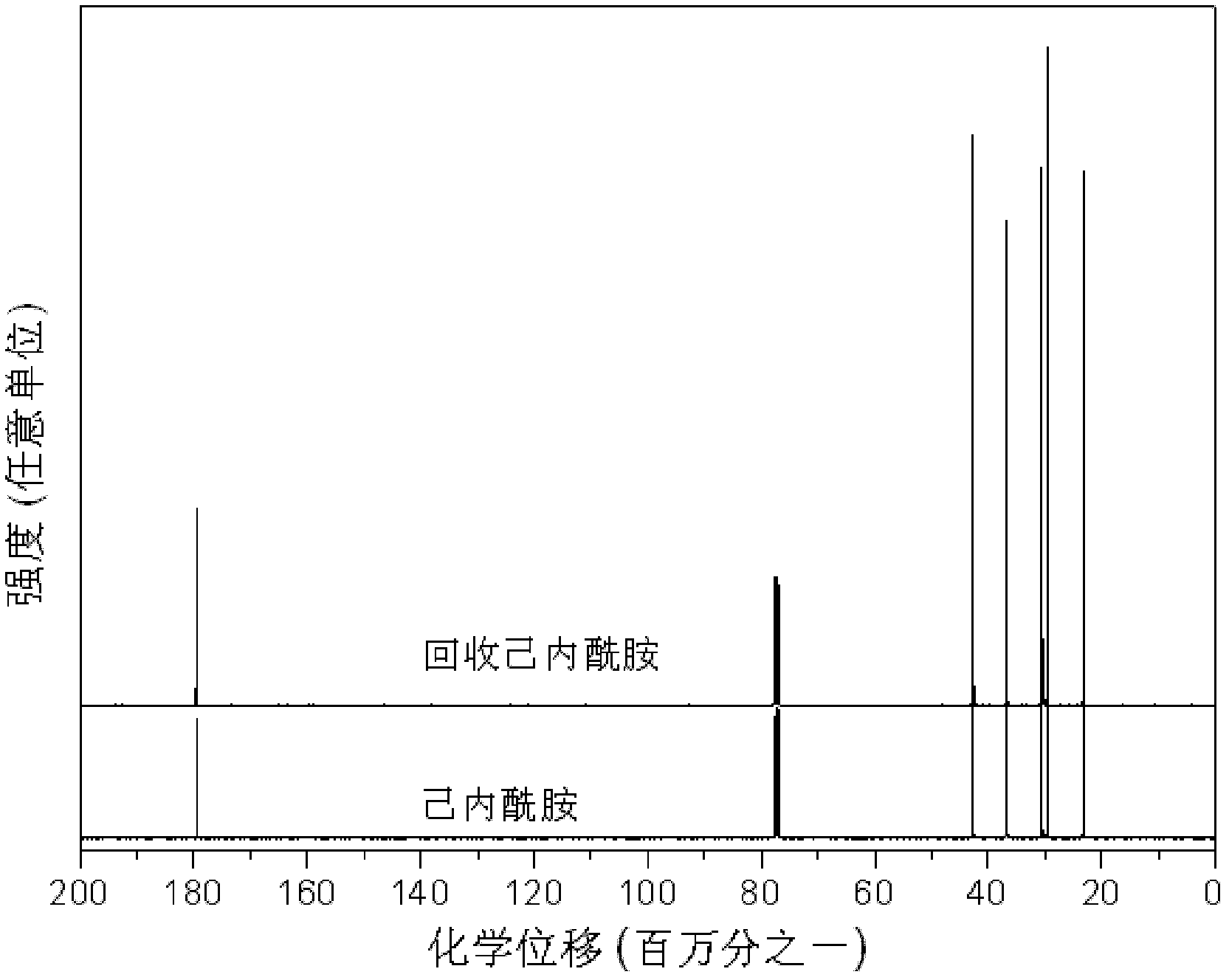

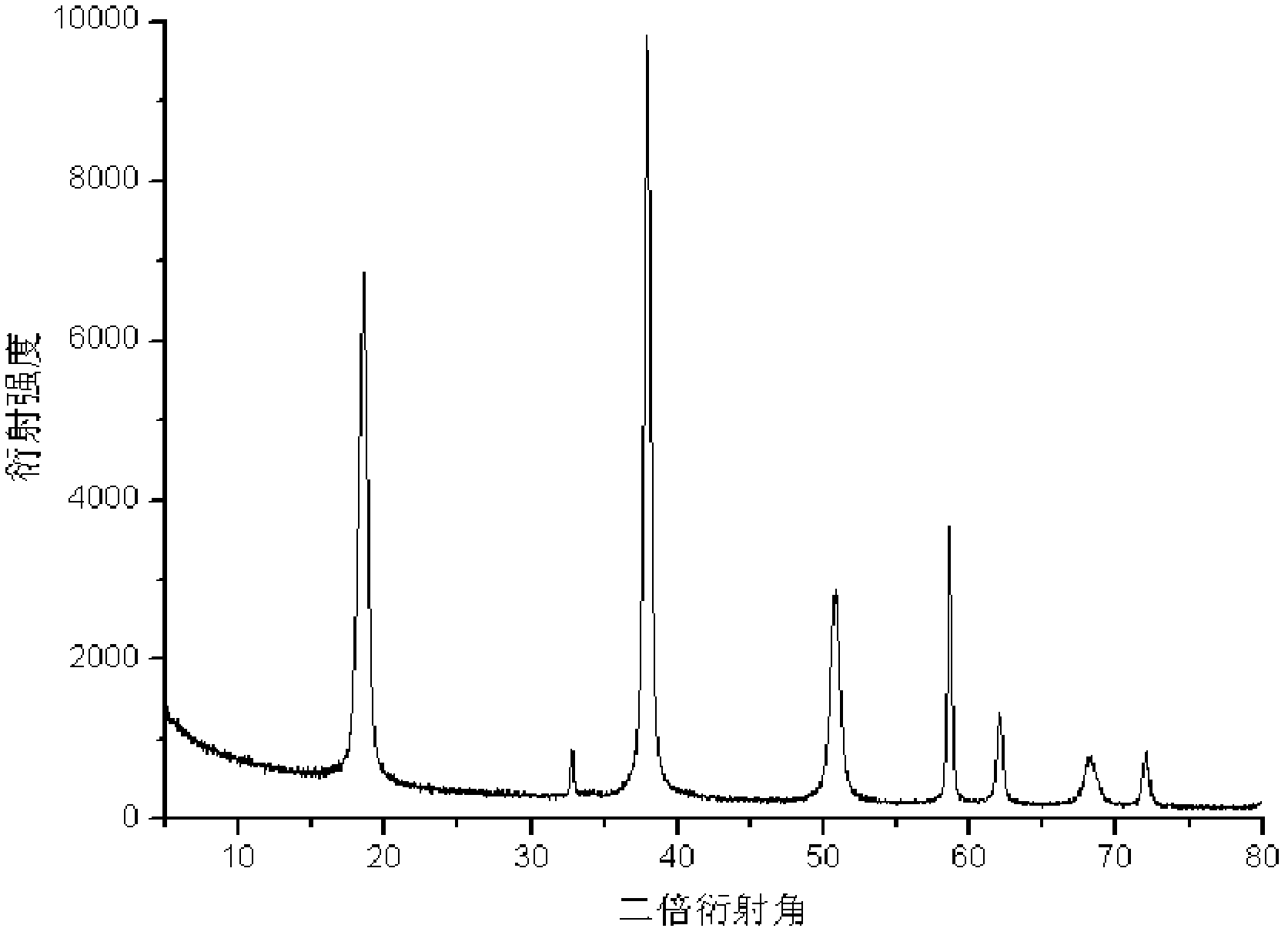

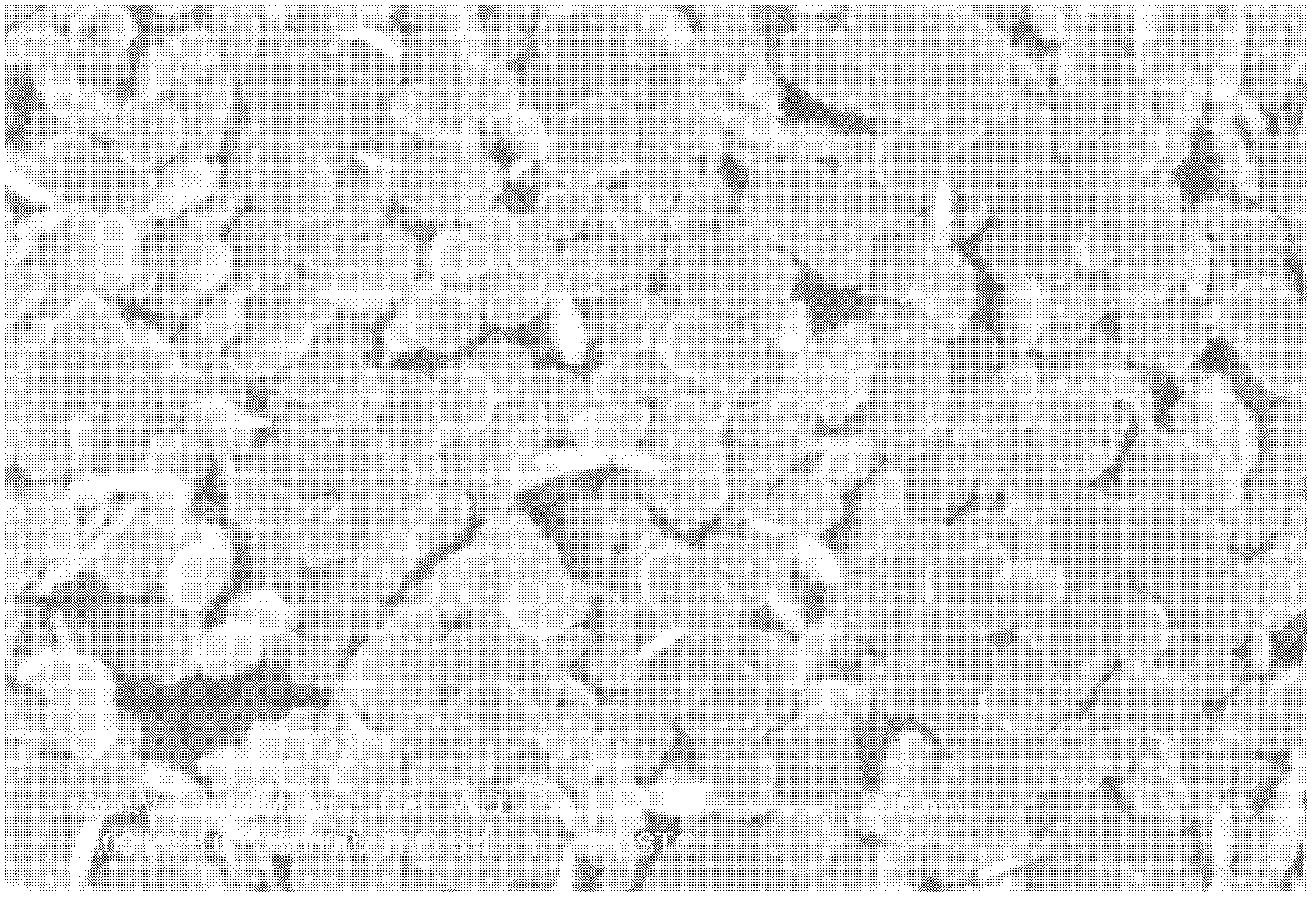

Application of lactam as solvent in nano-grade material preparation

ActiveCN103204525AIncrease added valueMeet the requirements of green environmental protectionMaterial nanotechnologySilicaSolventMacromolecule

Disclosed is an application of lactam as a solvent in nanomaterial preparation. The preparation method comprises a precipitation method, a sol-gel method or a high-temperature pyrolysis method. The method achieves recycling utilization of the lactam solvent, which meets the requirements of environmental protection.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Thermal-insulating coating with low thermal conductivity

A ceramic material having particular utility as a thermal insulating or thermal barrier coating on metallic substrates is provided. The ceramic material broadly comprises at least one lanthanide sesquioxide and the balance comprising a first oxide selected from the group consisting of zirconia, ceria, and hafnia. The lanthanide sesquioxide has a formula A2O3 where A is selected from the group consisting of La, Pr, Nd, Sm, Eu, Tb, In, Sc, Y, Dy, Ho, Er, Tm, Yb, Lu, and mixtures thereof. The present invention also broadly relates to an article having a metal substrate and a thermal barrier coating as discussed above.

Owner:UNITED TECH CORP

Method of recovering rare-earth elements

ActiveUS20150086449A1Reduce profitabilityImprove leaching efficiencyLanthanide oxides/hydroxidesSolid waste disposalRare-earth elementSlurry

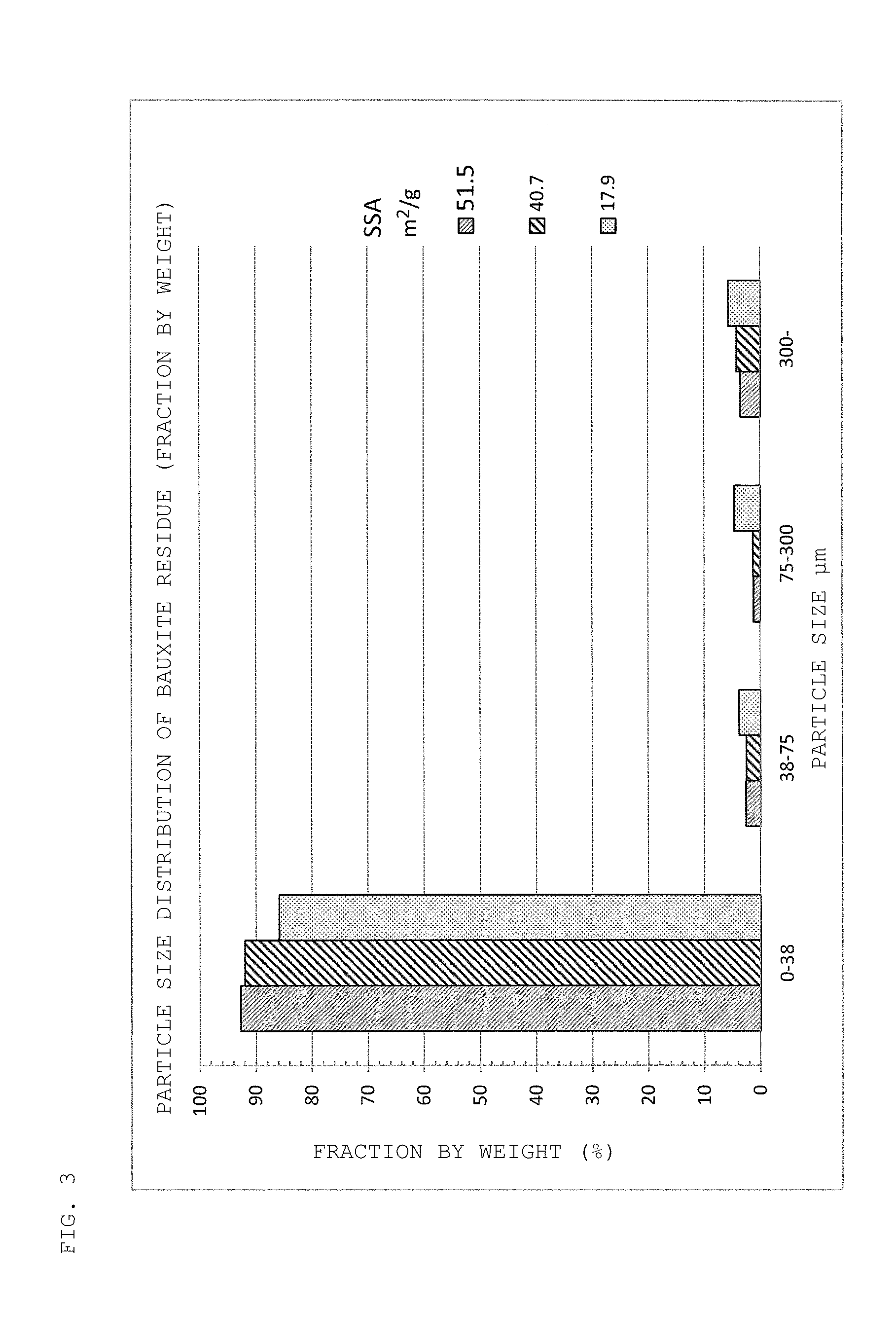

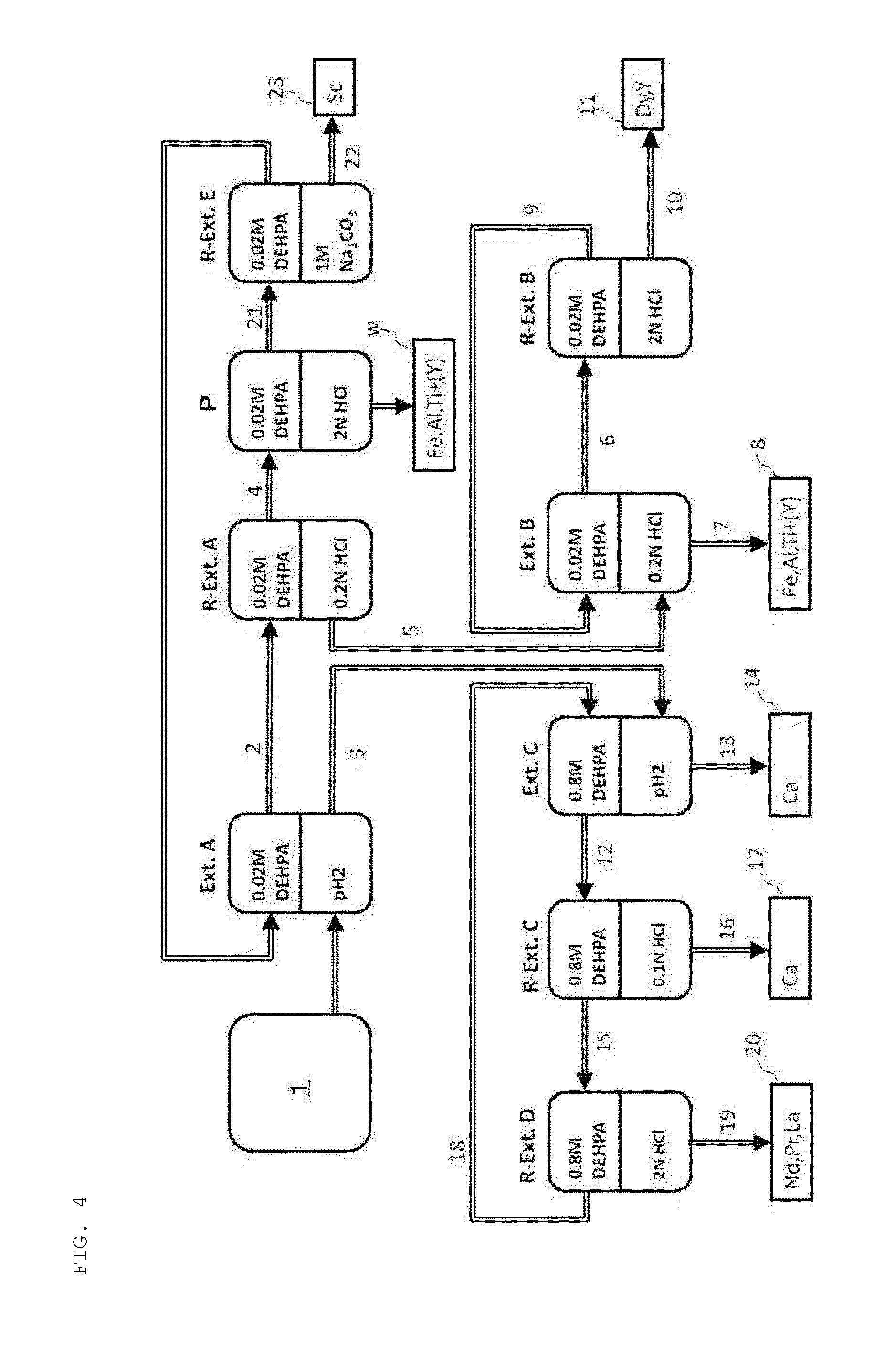

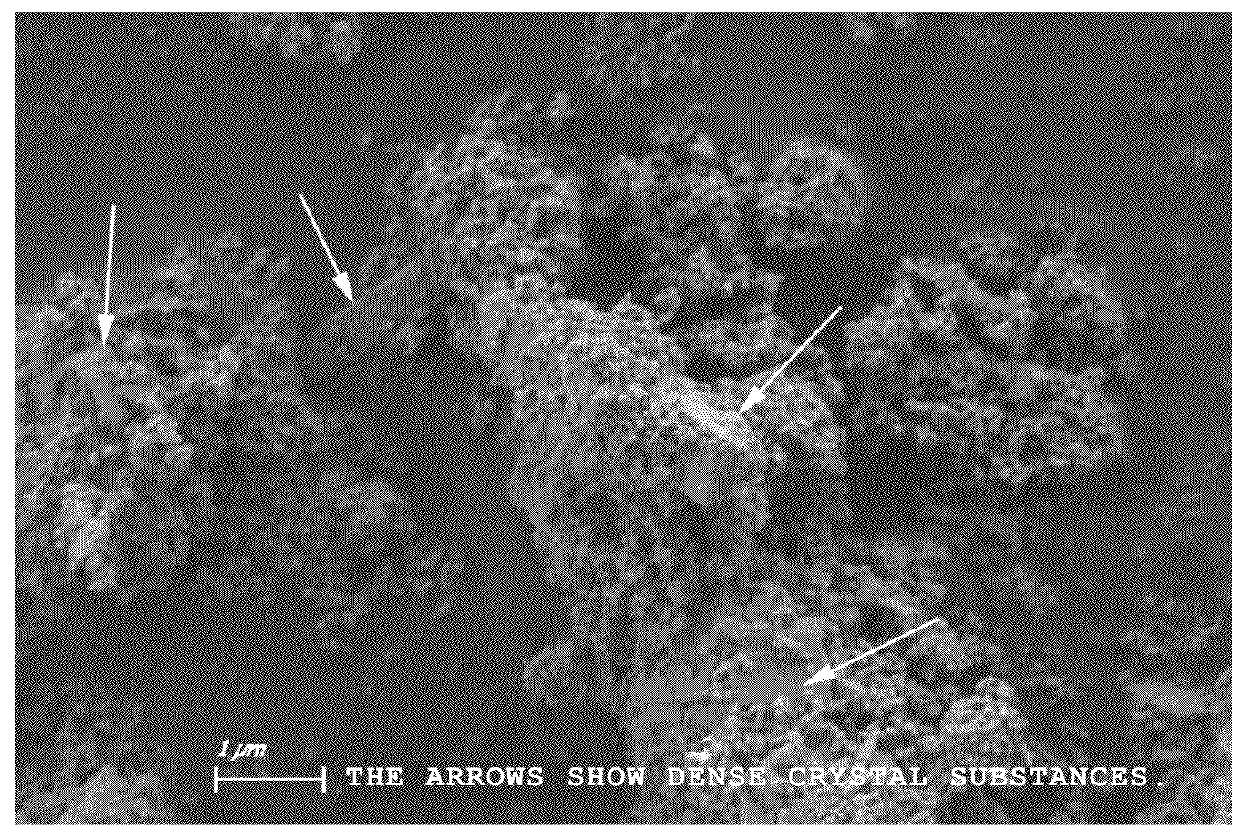

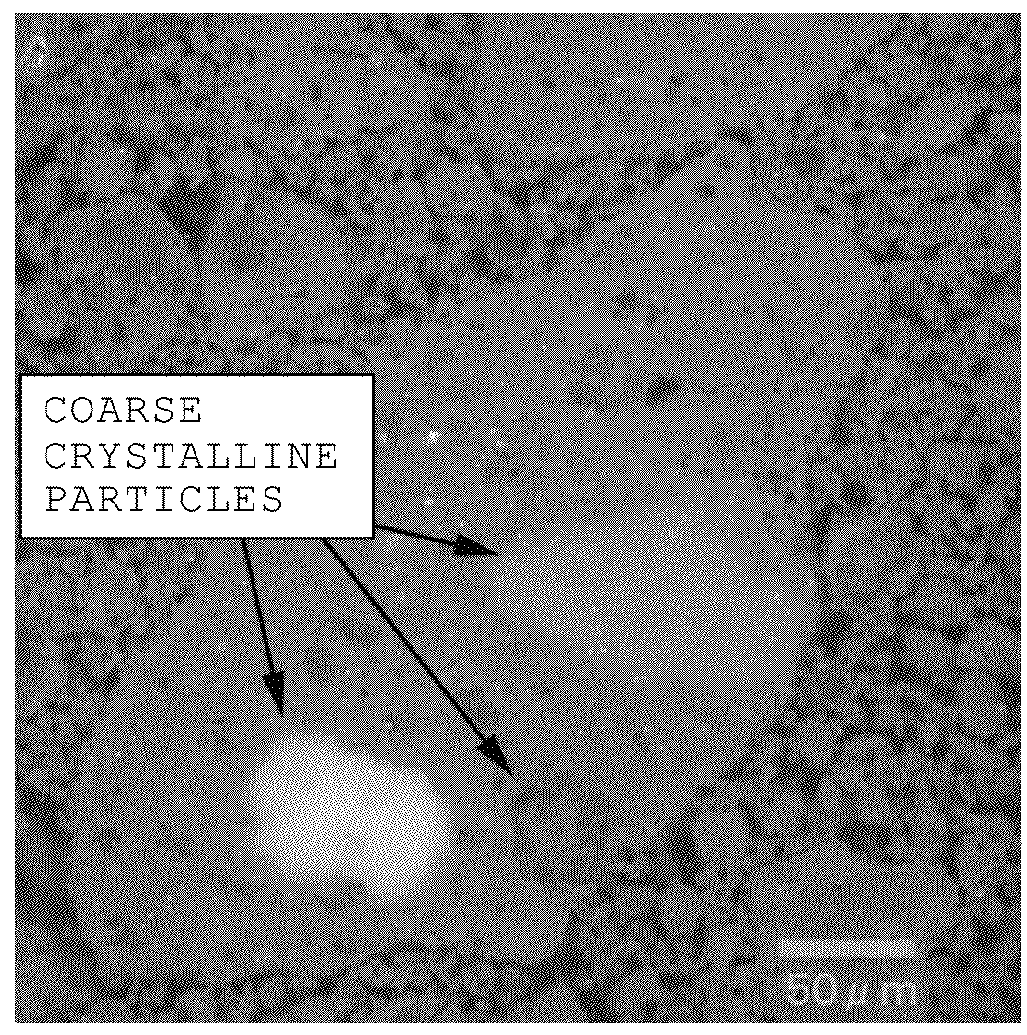

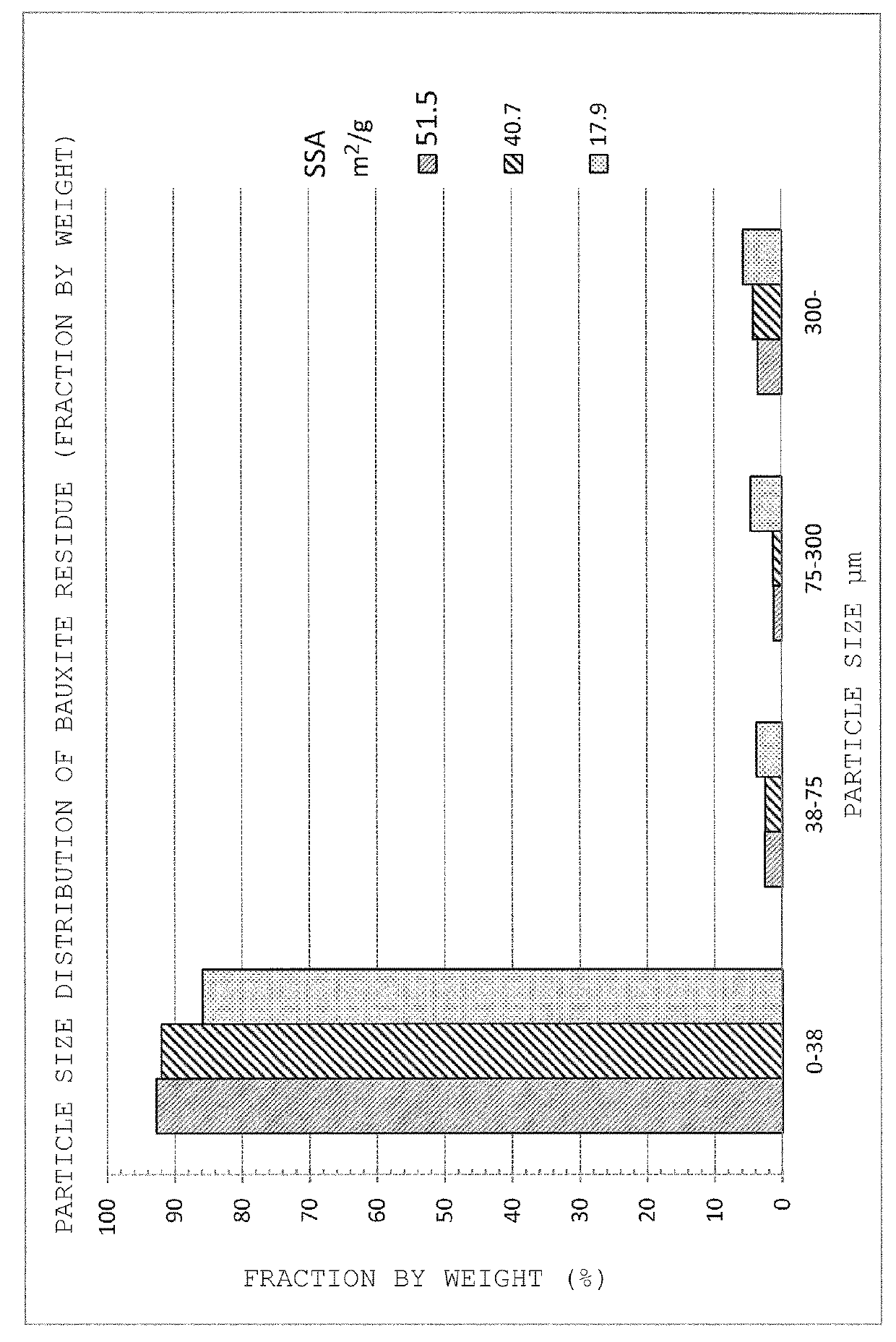

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

Highly pure powder intended for thermal spraying

ActiveUS20150298986A1High purityMolten spray coatingGlass/slag layered productsApparent densityThermal spraying

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

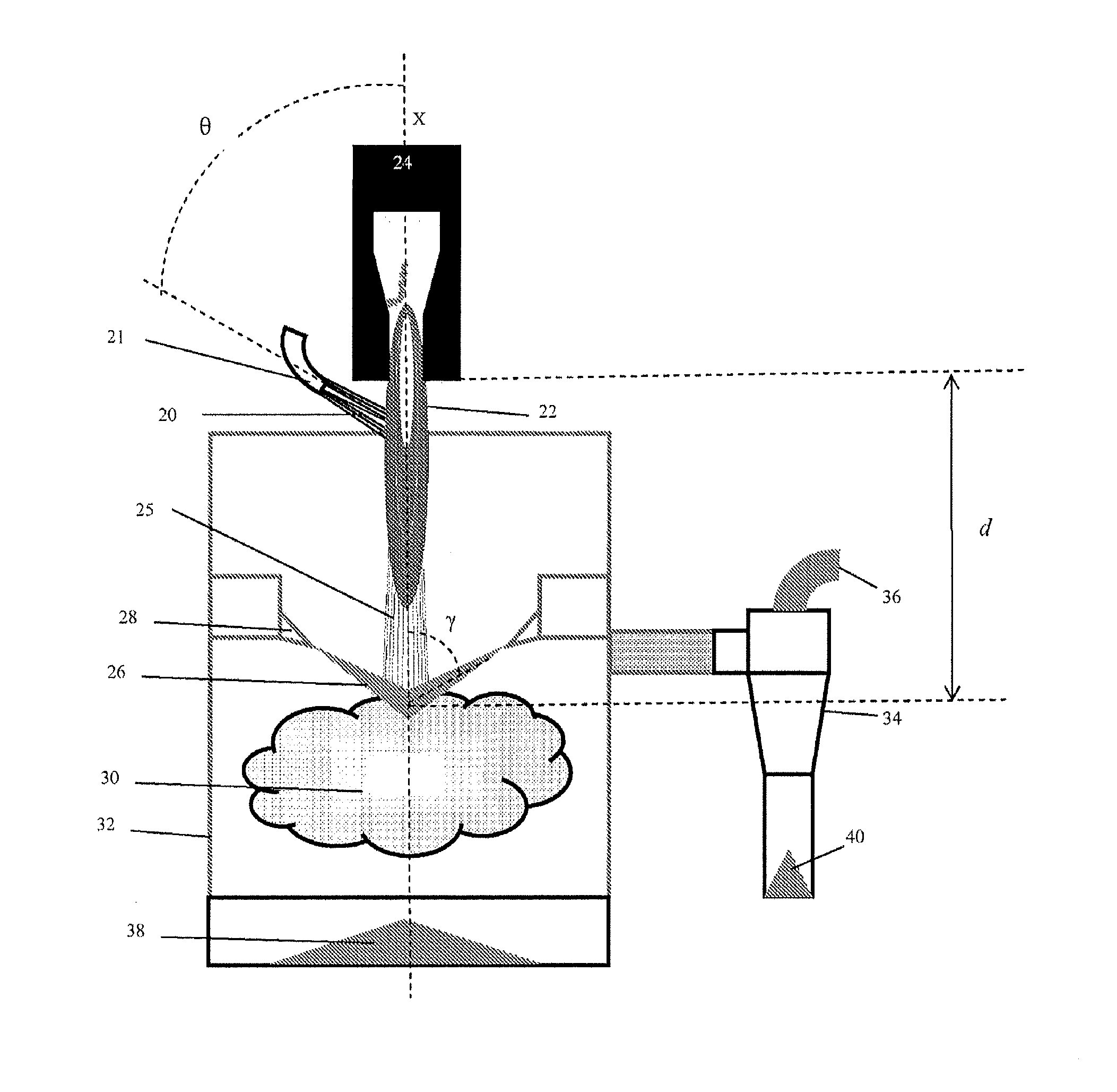

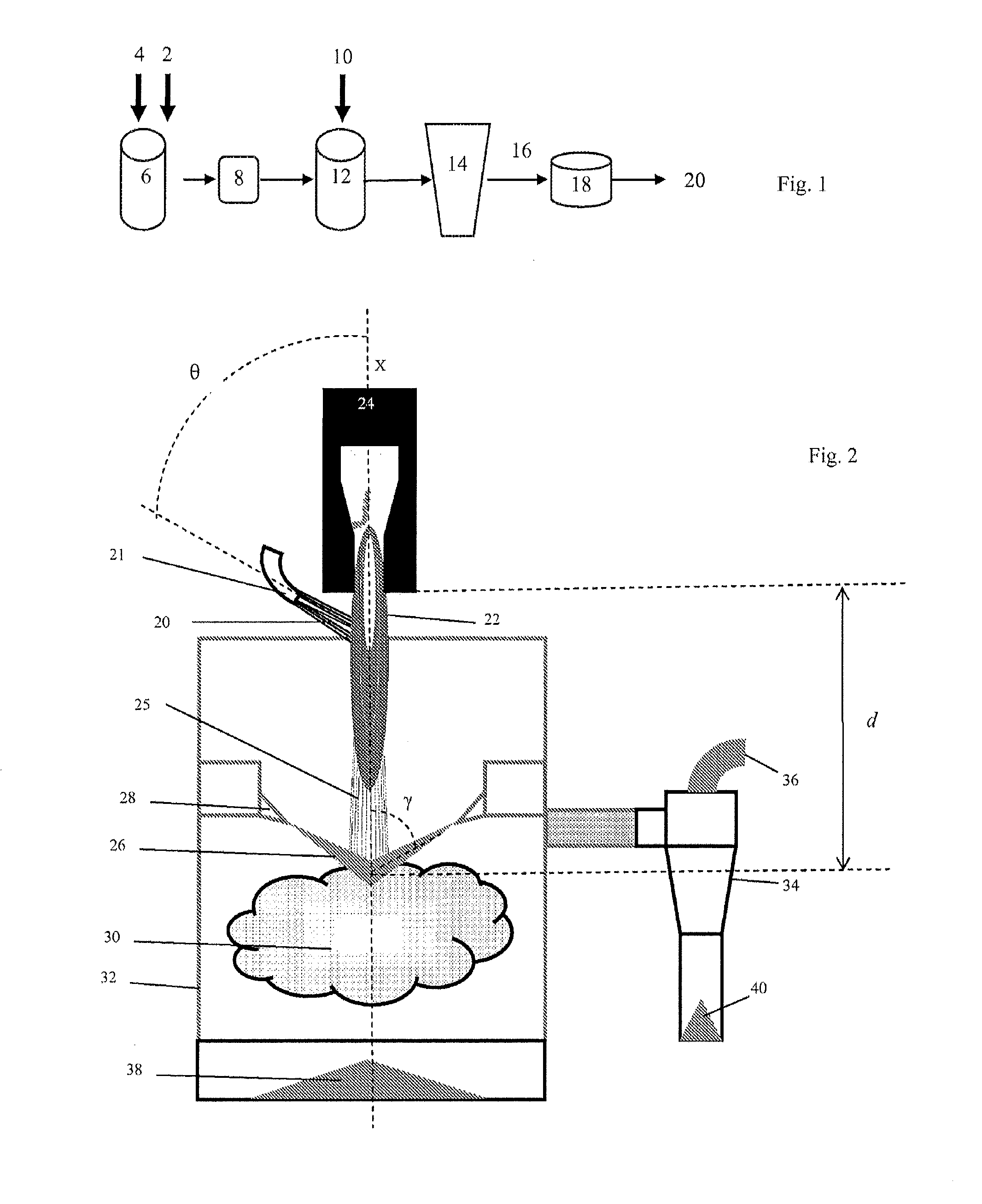

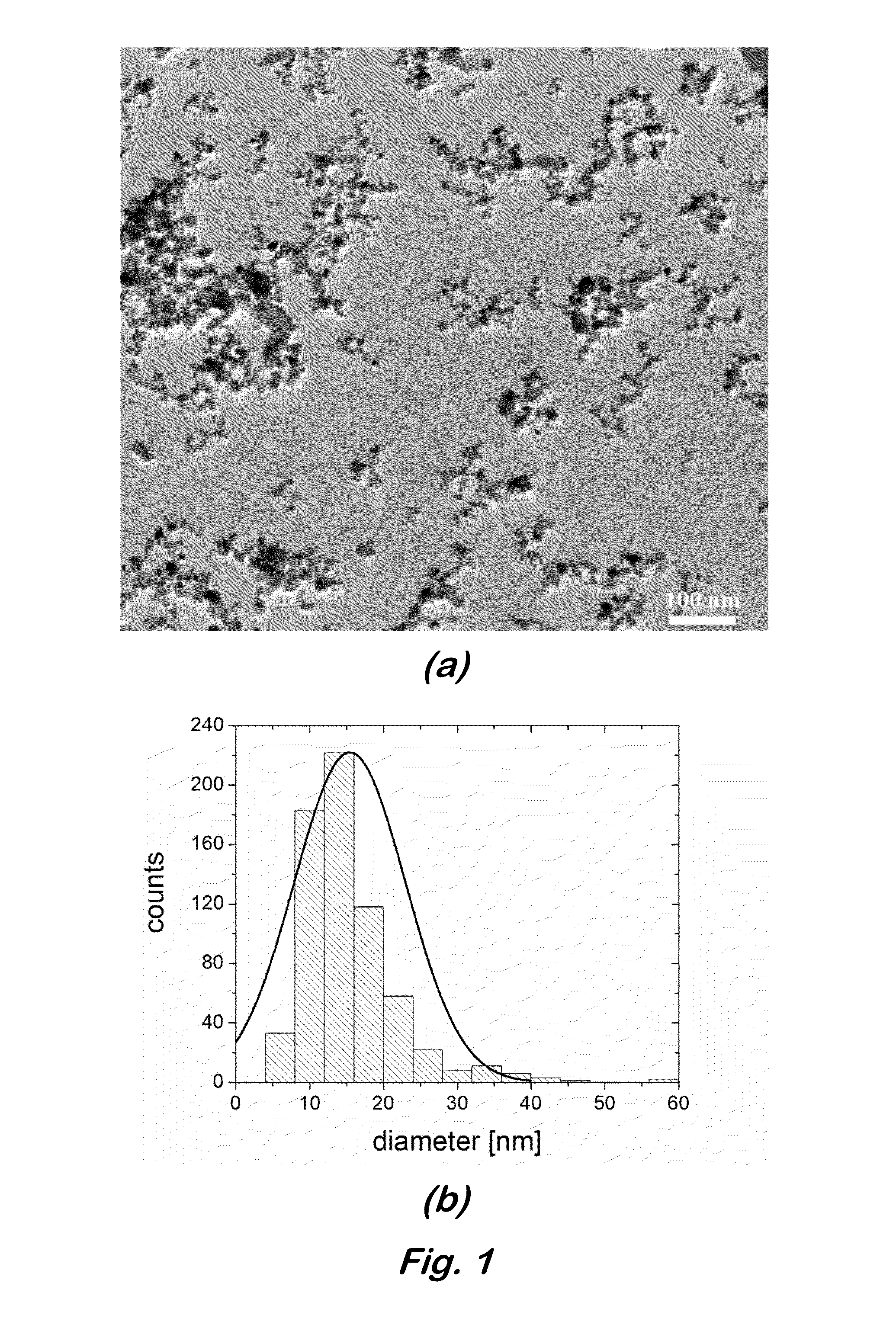

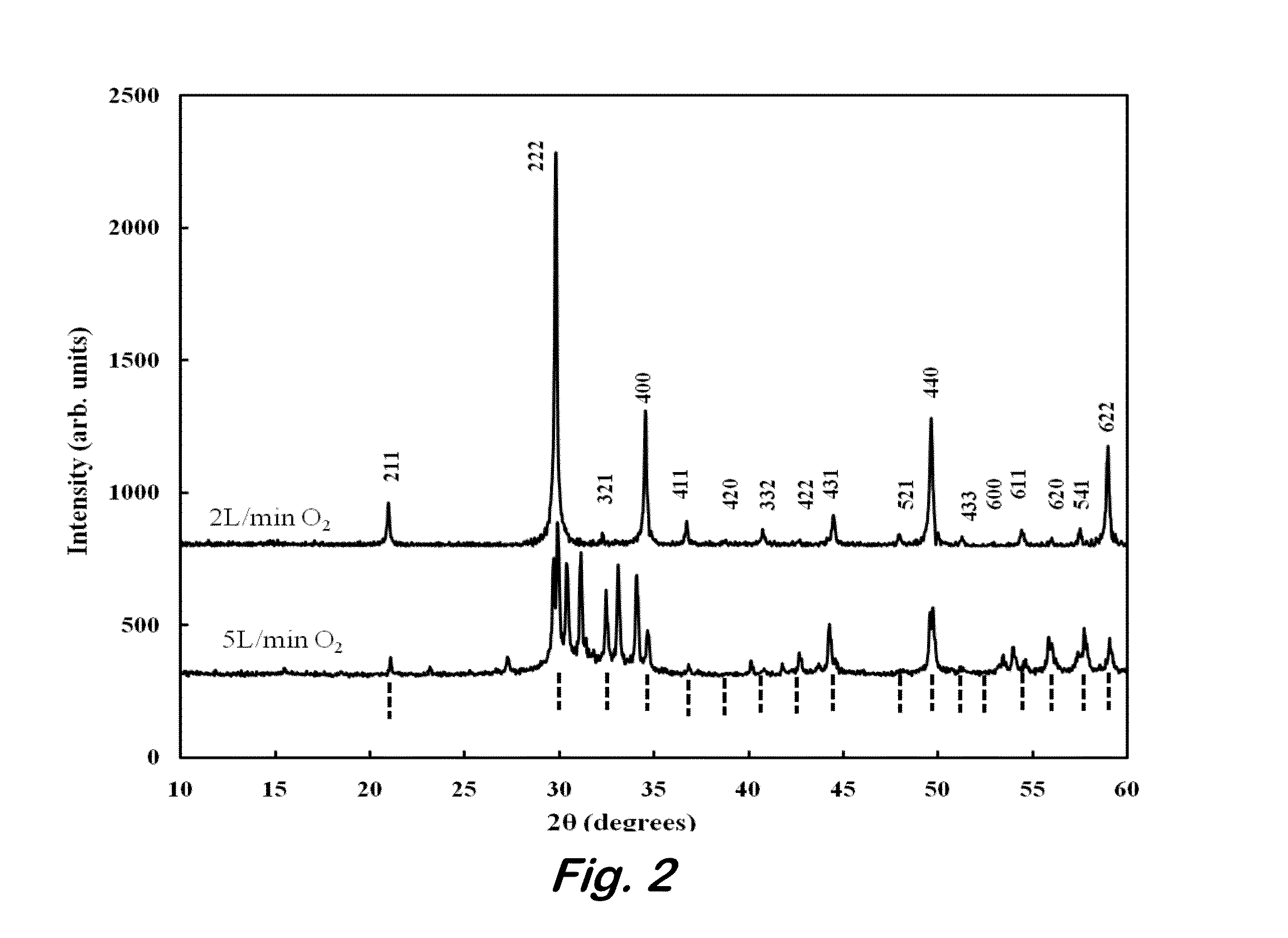

FLAME SPRAY SYNTHESIS OF Lu2O3 NANOPARTICLES

A nanoparticle containing monoclinic lutetium oxide. A method of: dispersing a lutetium salt solution in a stream of oxygen gas to form droplets, and combusting the droplets to form nanoparticles containing lutetium oxide. The combustion occurs at a temperature sufficient to form monoclinic lutetium oxide in the nanoparticles. An article containing lutetium oxide and having an average grain size of at most 10 microns

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

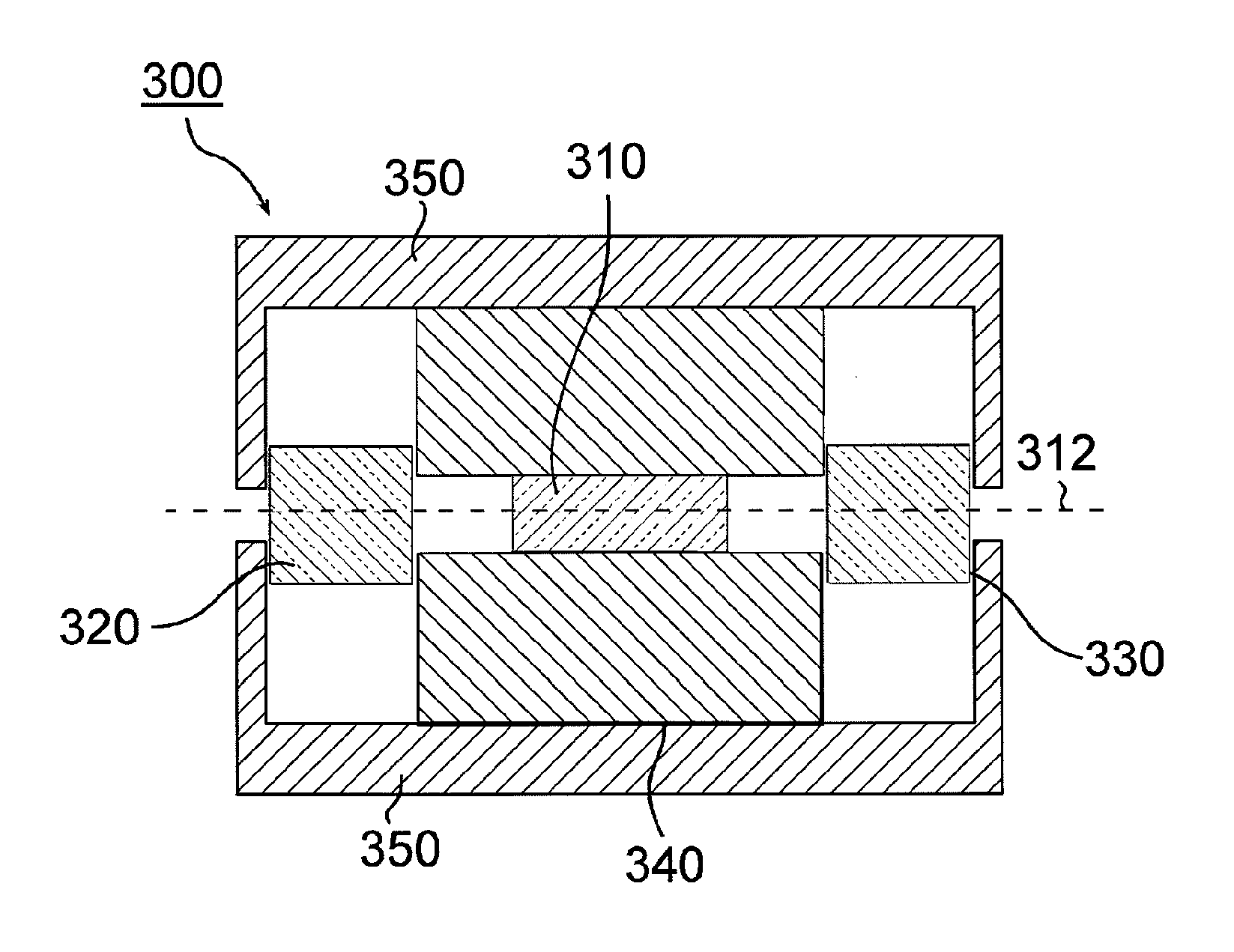

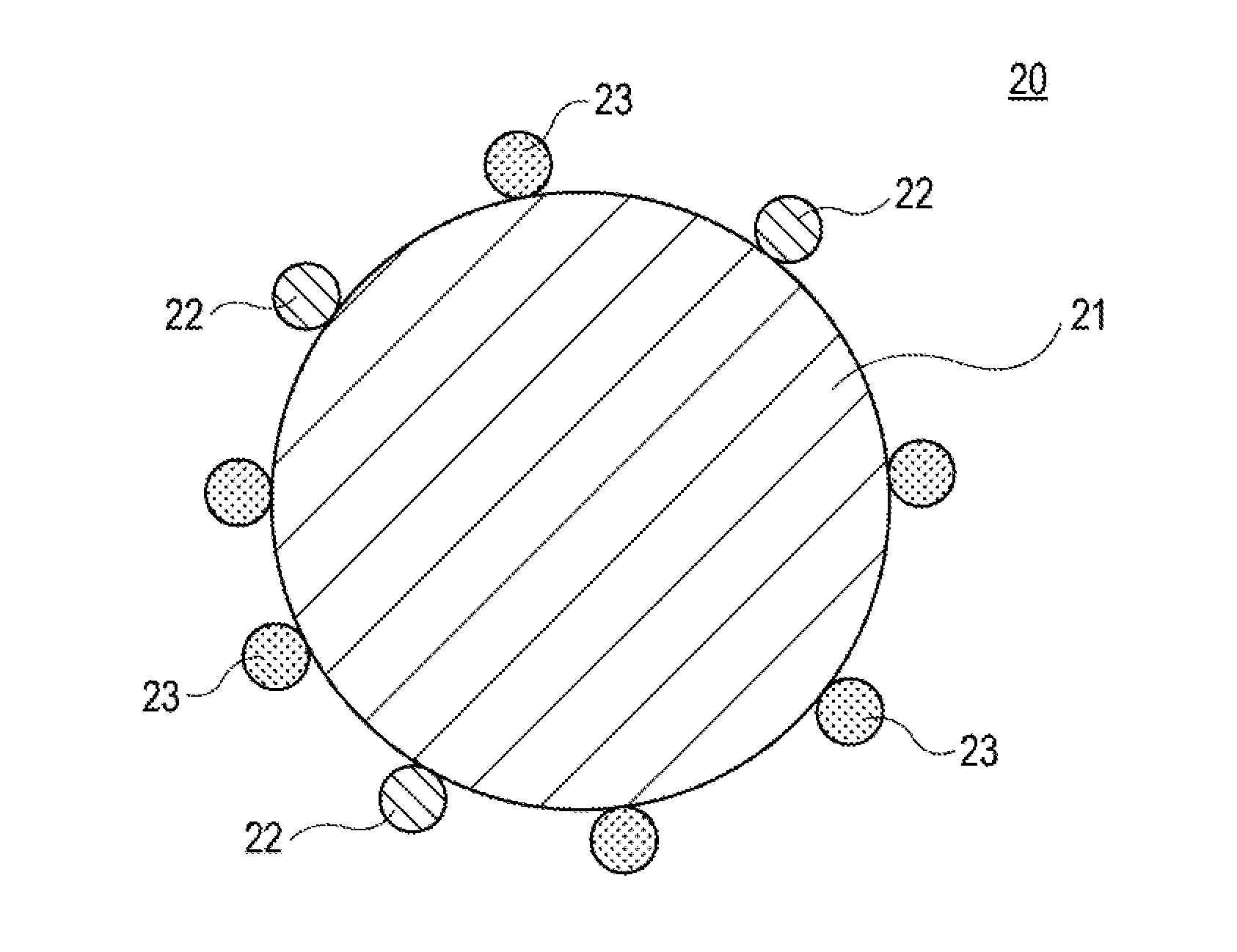

Positive-electrode active material for nonaqueous-electrolyte secondary battery and positive electrode for nonaqueous-electrolyte secondary battery

ActiveCN106104869ADissolution inhibitionLanthanide oxides/hydroxidesPositive electrodesRare-earth elementEngineering

Owner:PANASONIC ENERGY CO LTD MORIGUCHI SHI

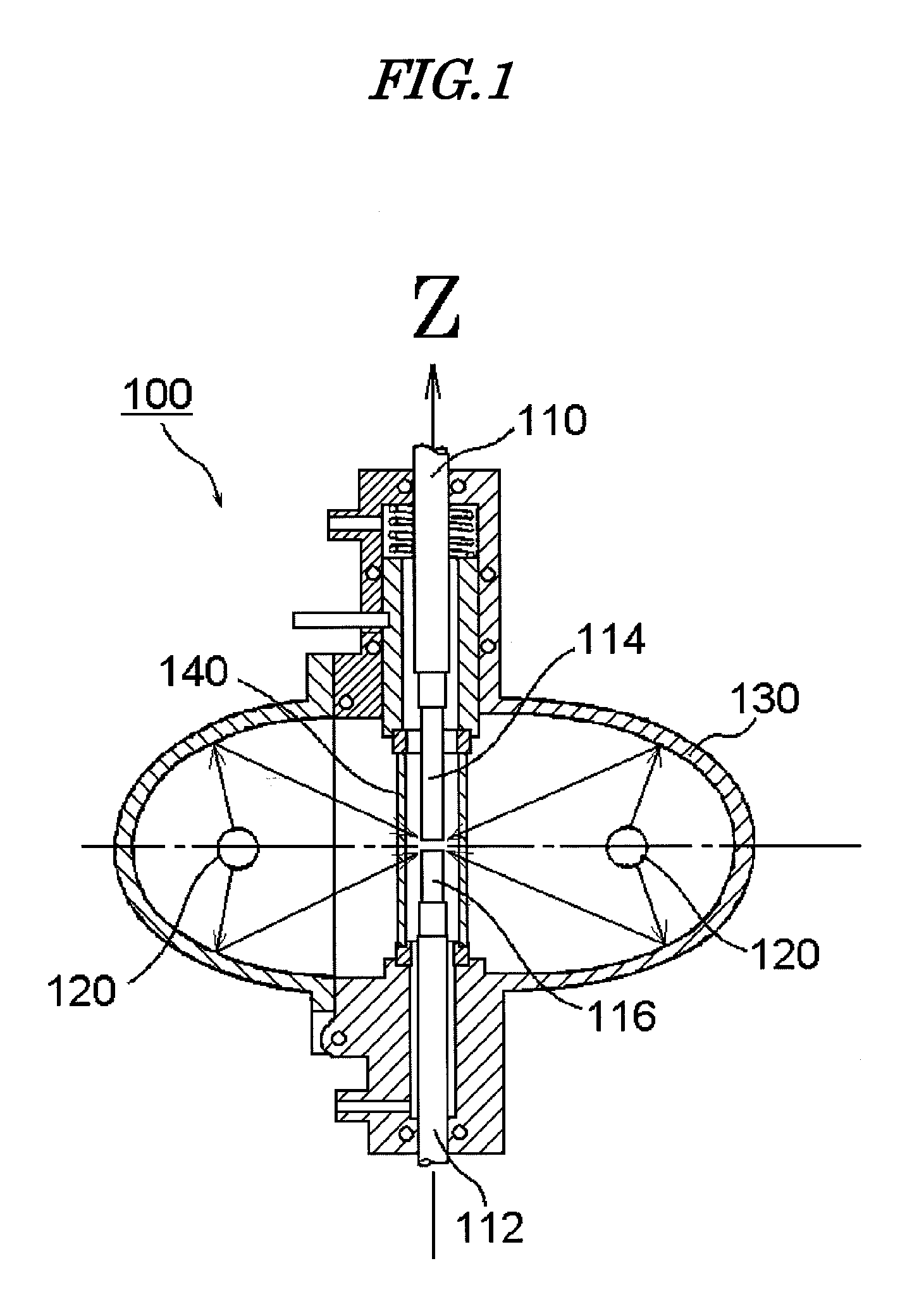

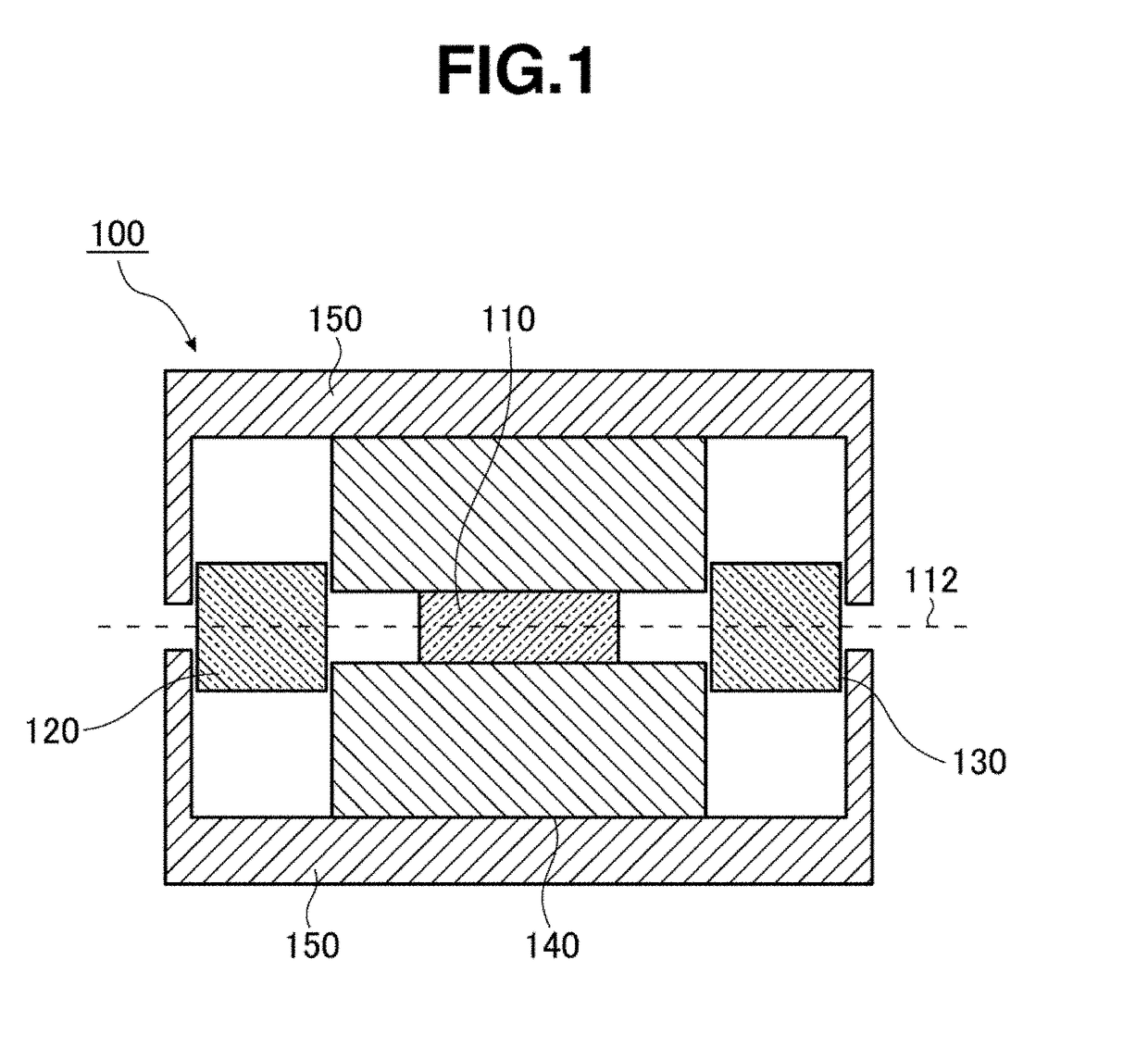

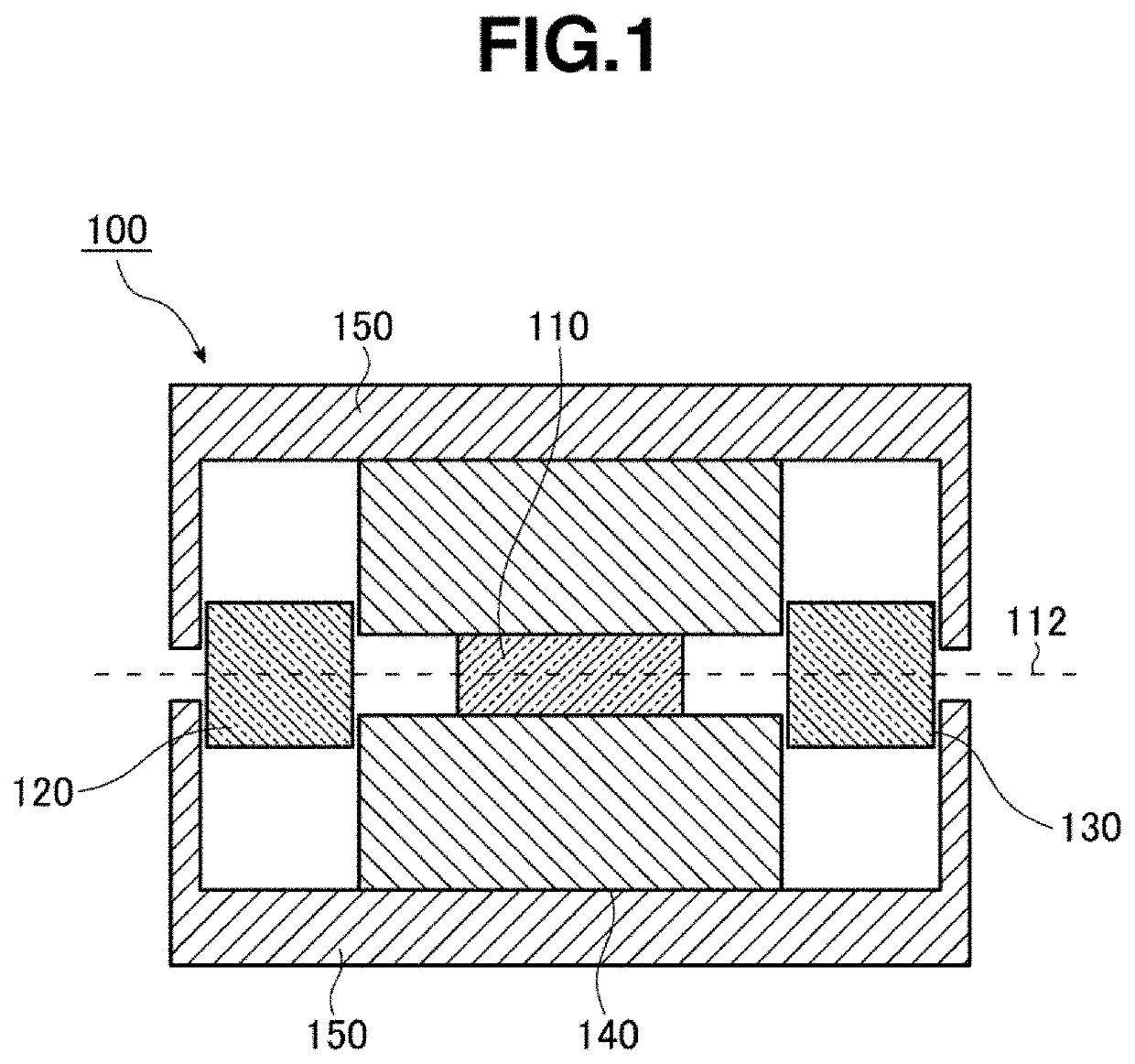

Magneto-optical material, faraday rotator, and optical isolator

ActiveUS20130222909A1High transparencyDownsized optical isolatorPolycrystalline material growthLaser detailsOptical isolatorLanthanide

It is an object of the present invention to provide a magneto-optical material containing as a main component an oxide that includes a terbium oxide and having a large Verdet constant at a wavelength in the 1.06 μm region (0.9 to 1.1 μm) and high transparency, and to provide a small-sized optical isolator suitably used in a fiber laser for a processing machine.The magneto-optical material of the present invention contains an oxide represented by Formula (I) below at a content of at least 99 wt %.(TbxR1-x)2O3 (I)(In Formula (I), x satisfies 0.4≦x≦1.0 and R includes at least one element selected from the group consisting of scandium, yttrium, and lanthanoid elements other than terbium.)

Owner:SHIN ETSU CHEM IND CO LTD

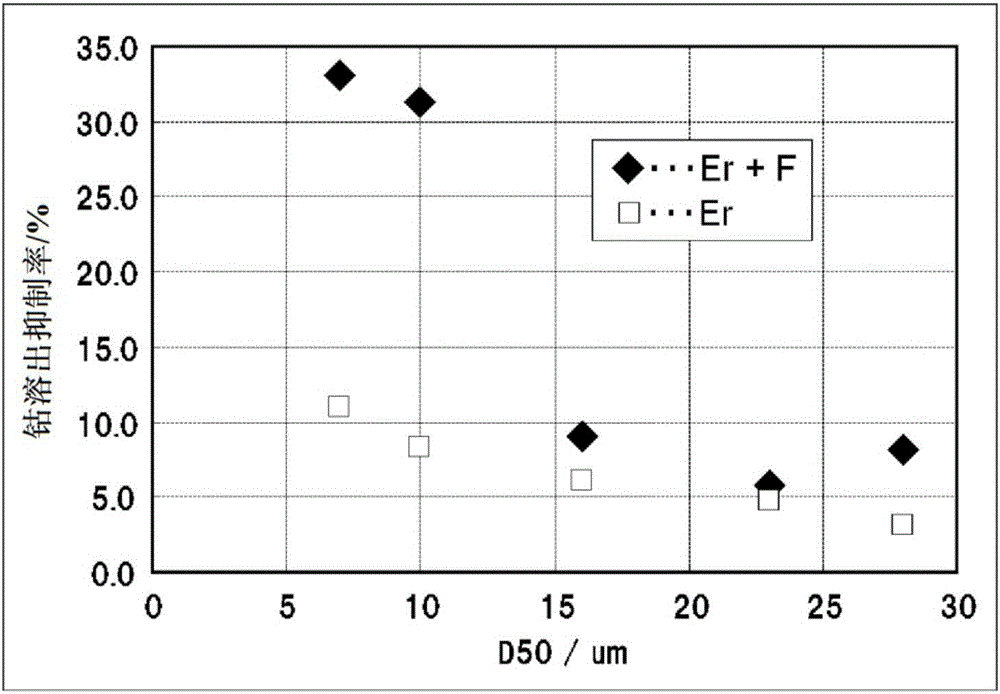

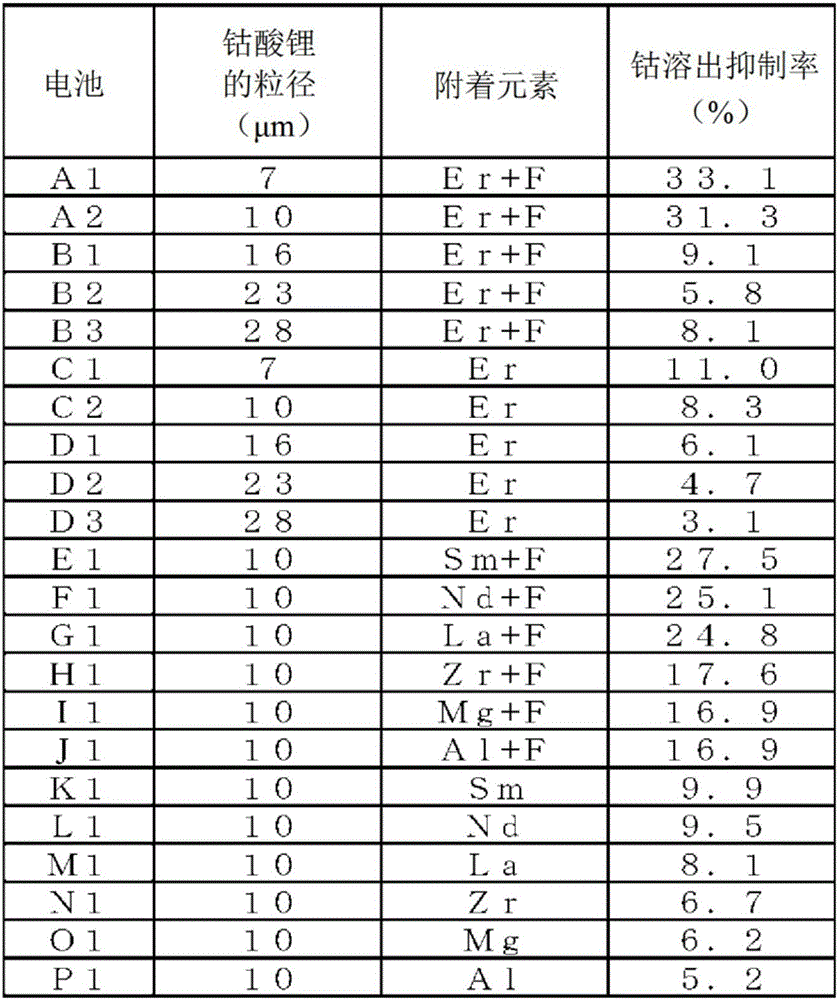

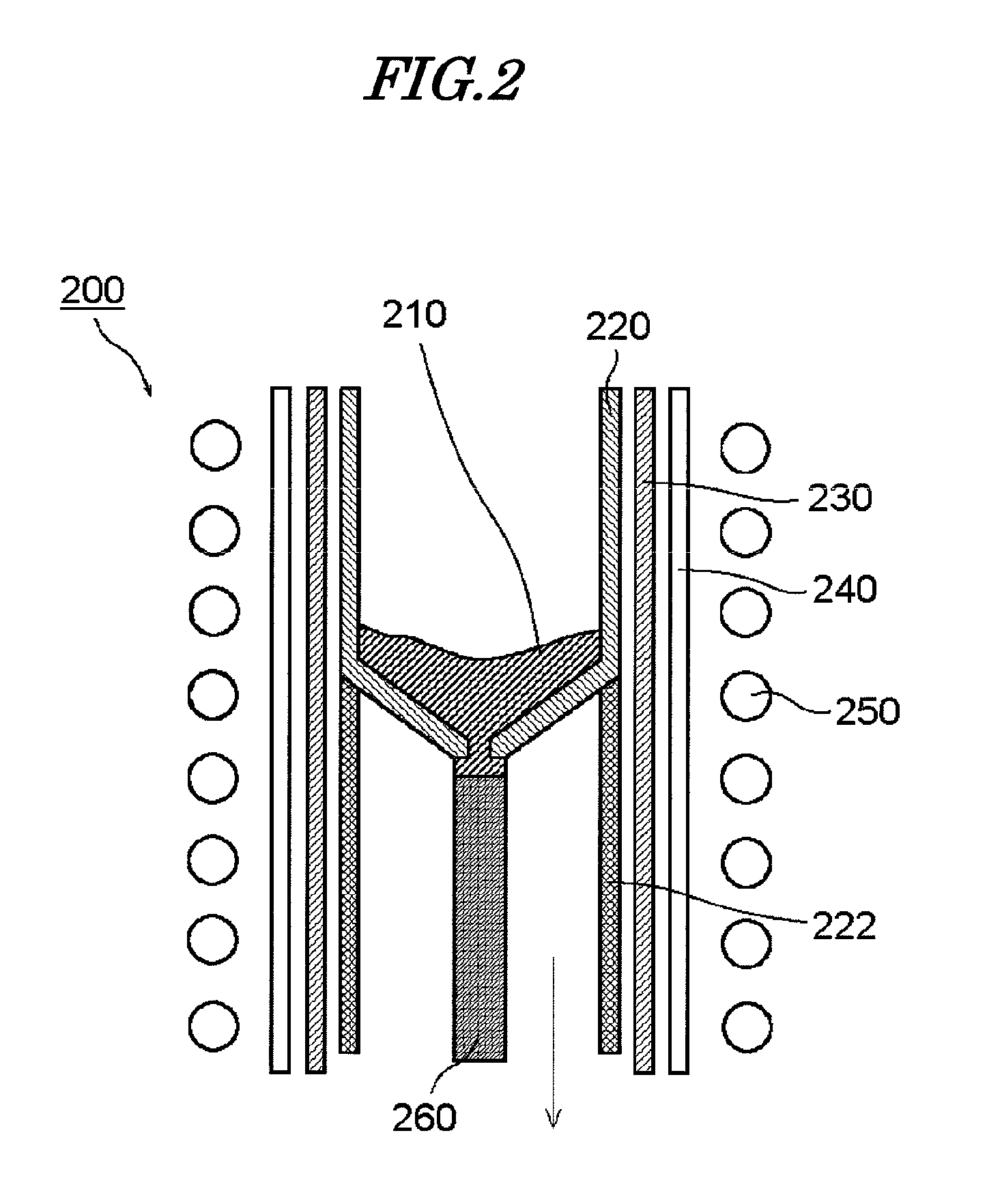

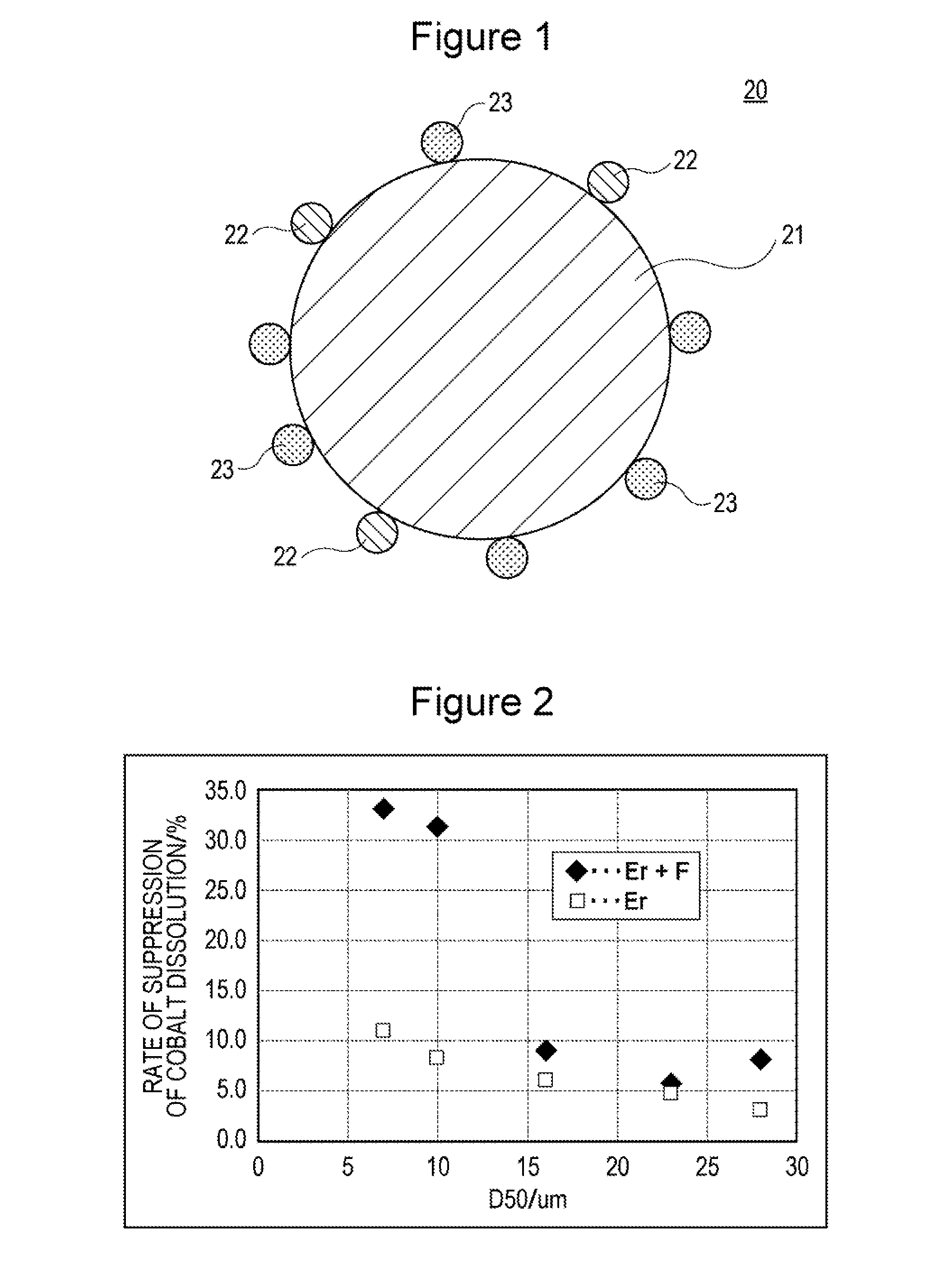

Positive electrode active material for nonaqueous electrolyte secondary battery and positive electrode for nonaqueous electrolyte secondary battery

InactiveUS20170018772A1Inhibition of dissolutionDissolution of cobalt from the positive electrode active material is suppressedLanthanide oxides/hydroxidesPositive electrodesRare-earth elementLithium

Dissolution of cobalt from a positive electrode active material is suppressed. Disclosed is a positive electrode active material for a nonaqueous electrolyte secondary battery that contains a lithium transition metal oxide. Fluorine and at least one element selected from zirconium, titanium, aluminum, magnesium, and rare earth elements adhere to the surface of the lithium transition metal oxide, and the lithium transition metal oxide contains cobalt. The lithium transition metal oxide has an average particle diameter of 10 μm or less.

Owner:SANYO ELECTRIC CO LTD

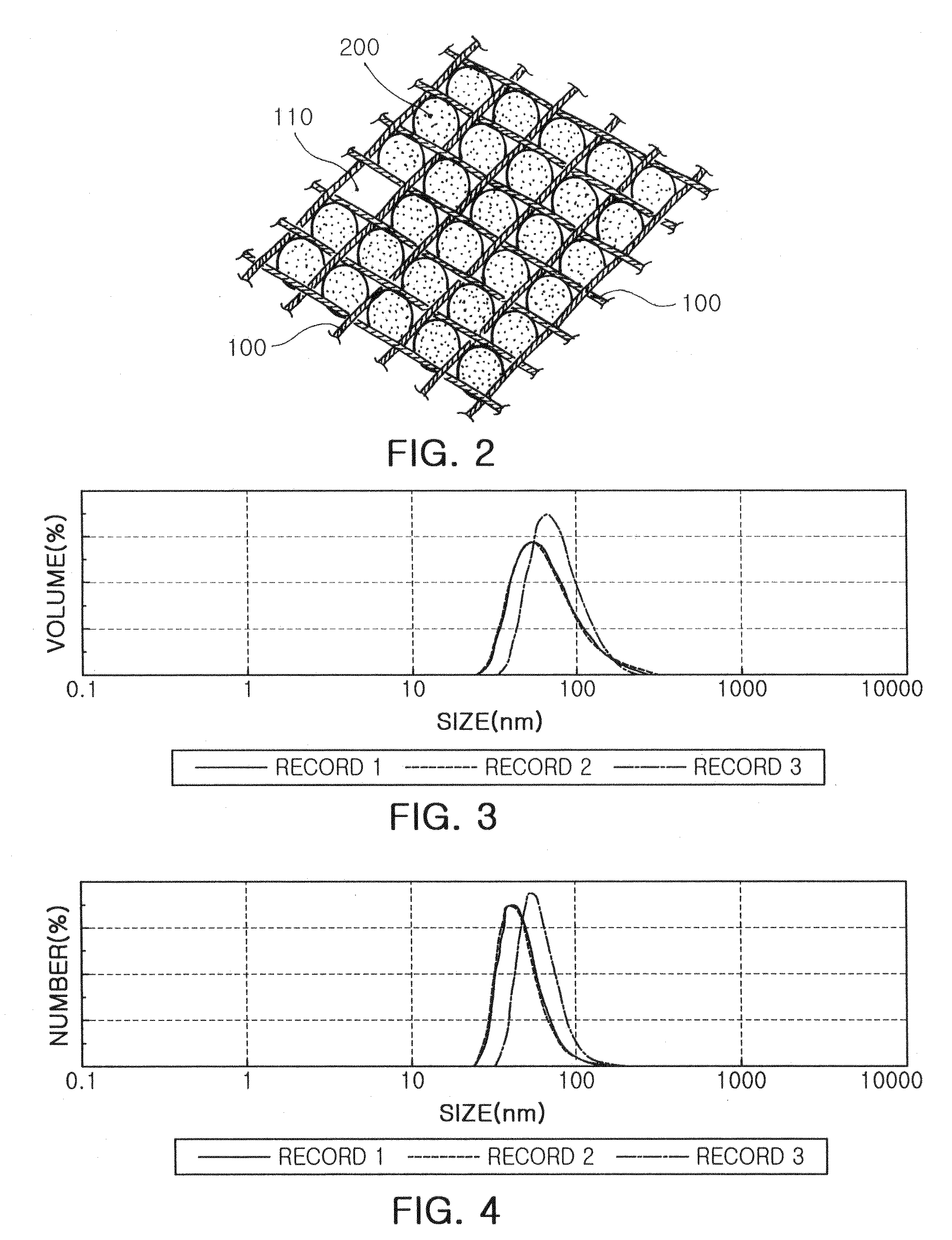

Method of manufacturing dysprosium oxide nanoparticles and method of manufacturing dysprosium oxide nanosol

InactiveUS20090170961A1High yieldSimple and low-cost processMaterial nanotechnologyNanostructure manufactureNanoparticleDysprosium

Disclosed are a method of manufacturing dysprosium oxide nanoparticles and a method of manufacturing a dysprosium oxide nanosol, which can prepare dysprosium oxide particles having a size of tens of nanometers with high yield by using a simple, low-cost process. The method of manufacturing dysprosium oxide nanoparticles includes preparing a dysprosium salt solution by dissolving a dysprosium salt in a solvent; impregnating an organic polymer comprising a nanosized pore with the dysprosium salt solution; and heating the organic polymer impregnated with the dysprosium salt solution until the organic polymer is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

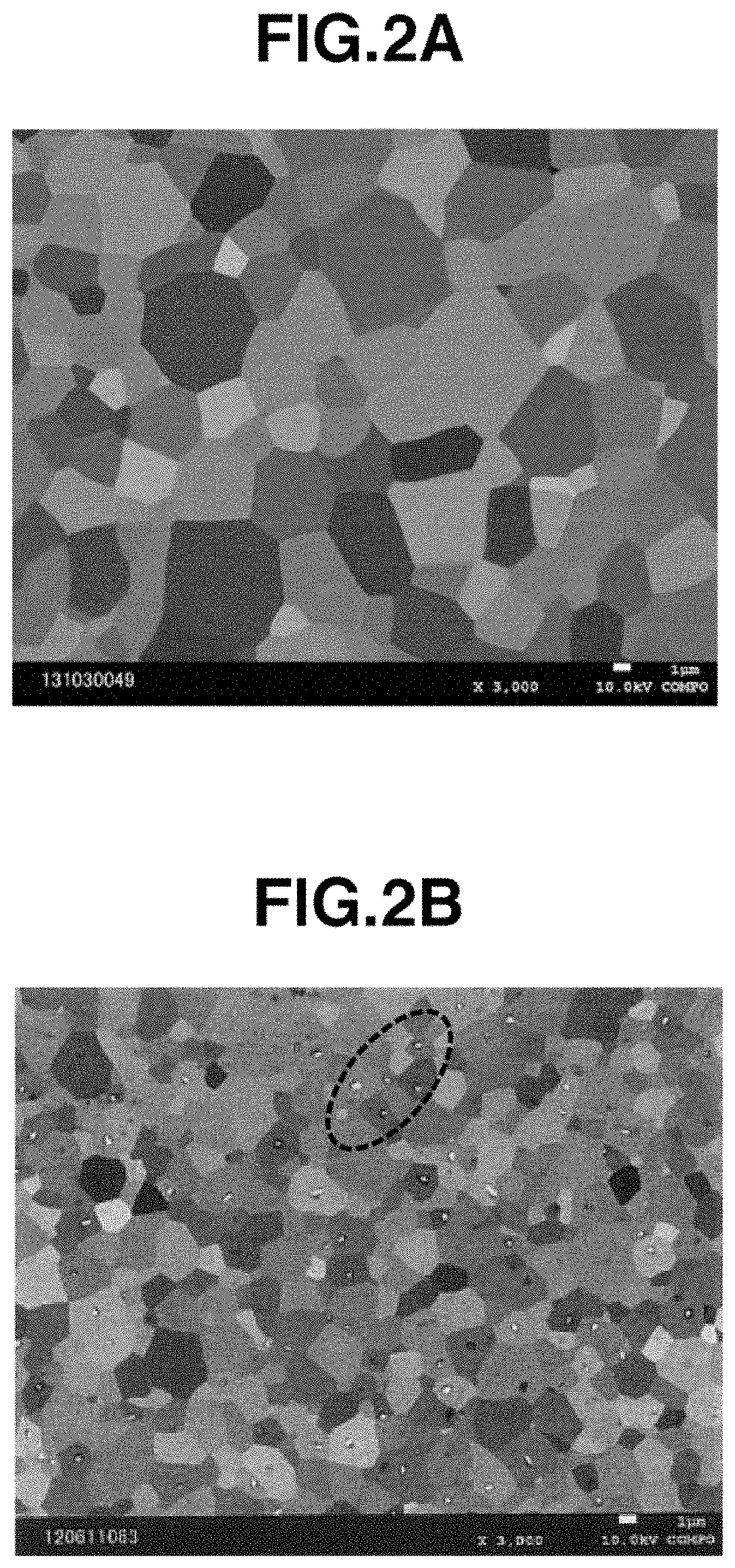

Method for producing transparent ceramic, transparent ceramic, magneto-optical device and rare earth oxide powder for sintering

ActiveUS20170205643A1Improve featuresExcellent optical propertiesLanthanide oxides/hydroxidesNon-linear opticsRare-earth elementRare earth ions

A starting material powder, which contains a rare earth oxide that is composed of terbium oxide and at least one other rare earth oxide selected from among yttrium oxide, scandium oxide and oxides of lanthanide rare earth elements (excluding terbium) and a sintering assistant that is formed of an oxide of at least one element selected from among group 2 elements and group 4 elements, is produced by having (a) terbium ions, (b) ions of at least one other rare earth element selected from among yttrium ions, scandium ions and lanthanide rare earth ions (excluding terbium ions) and (c) ions of at least one element selected from among group 2 elements and group 4 elements coprecipitate in an aqueous solution containing the components (a)-(c), then filtering and separating the coprecipitate, and subjecting the separated coprecipitate to thermal dehydration.

Owner:SHIN ETSU CHEM IND CO LTD

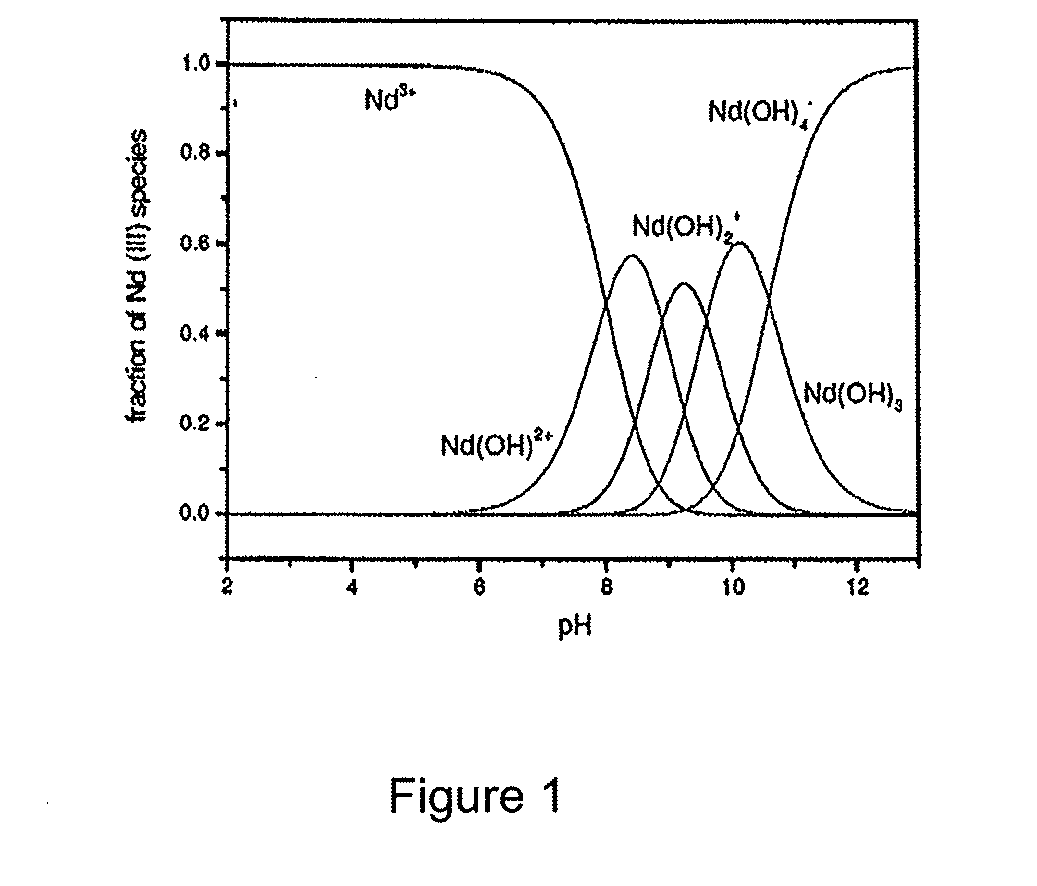

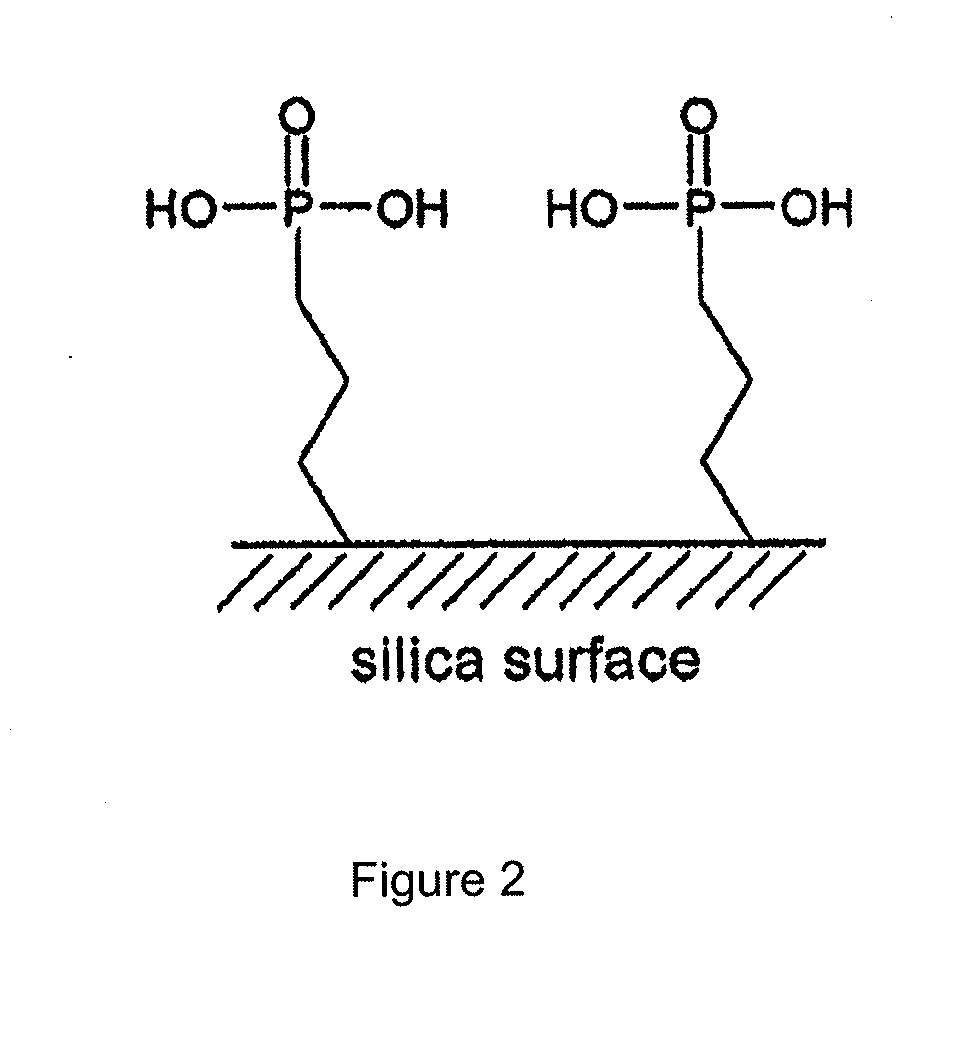

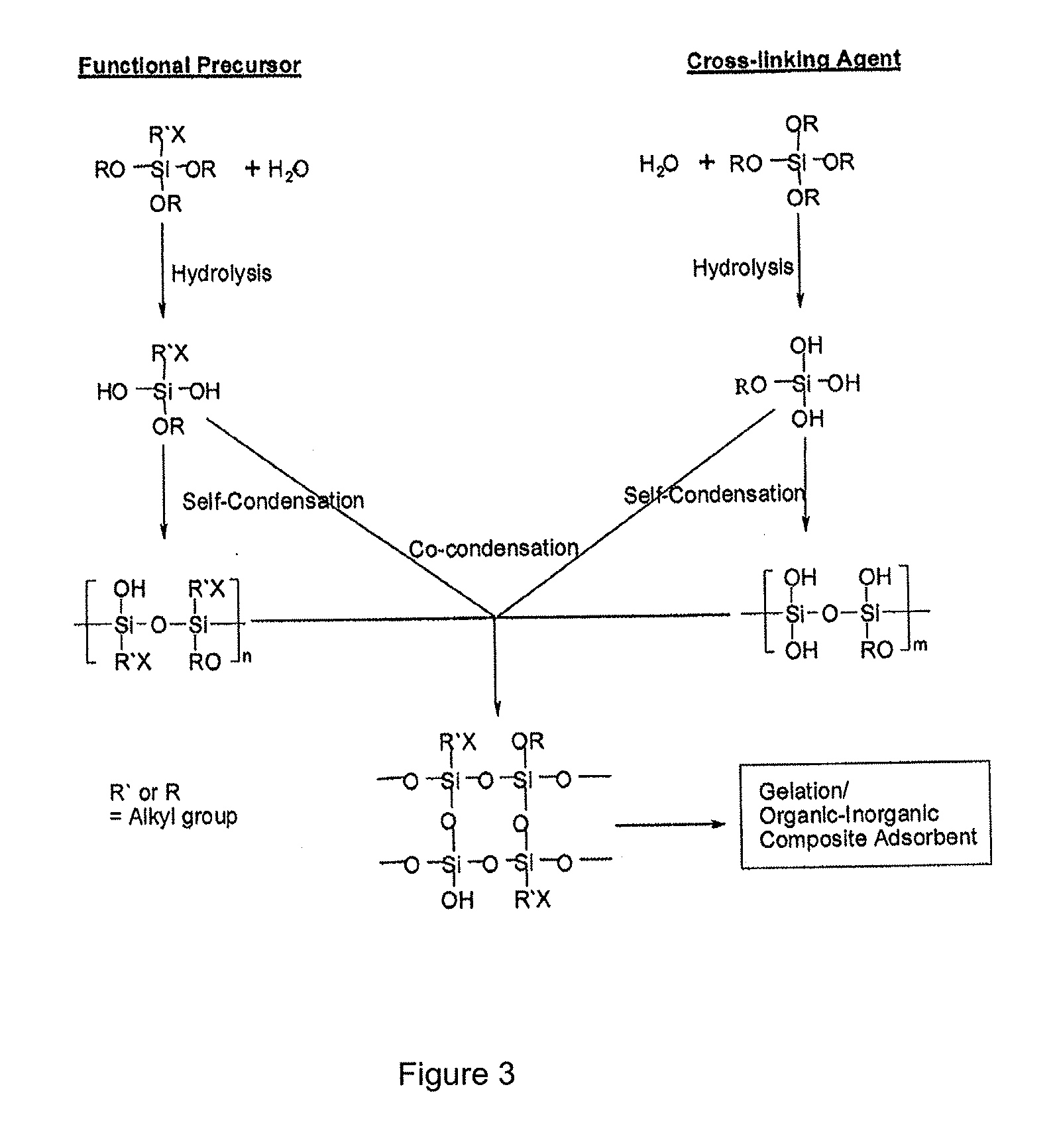

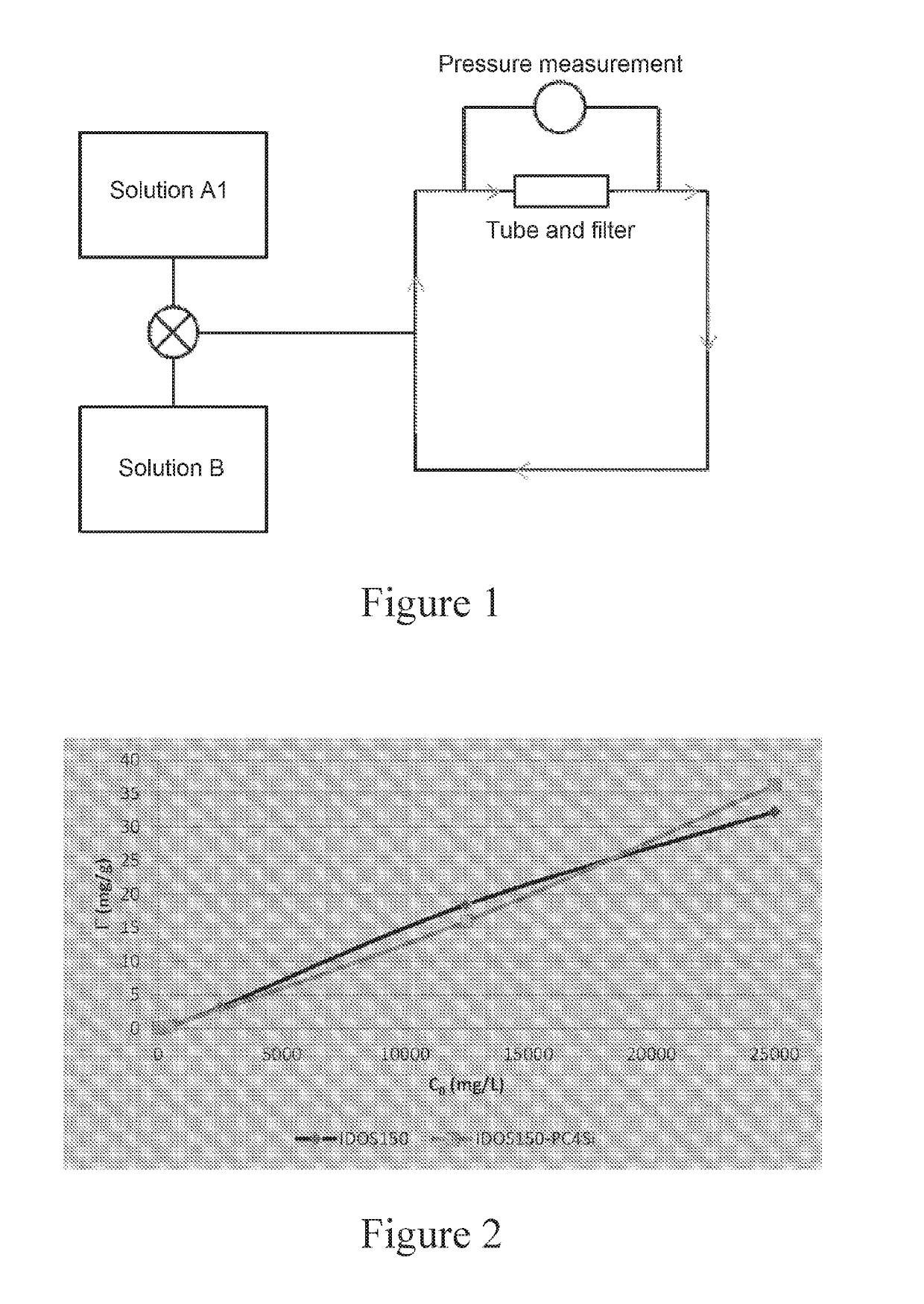

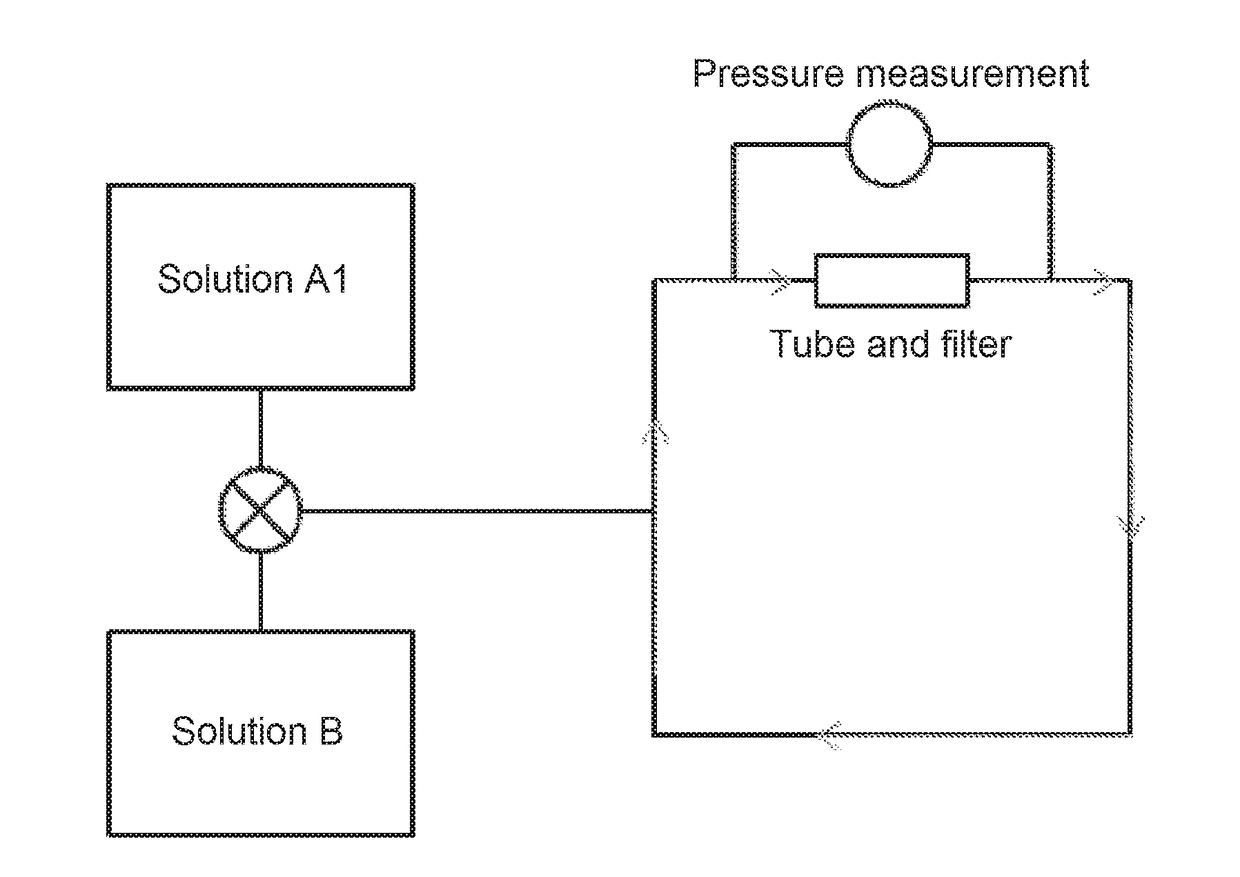

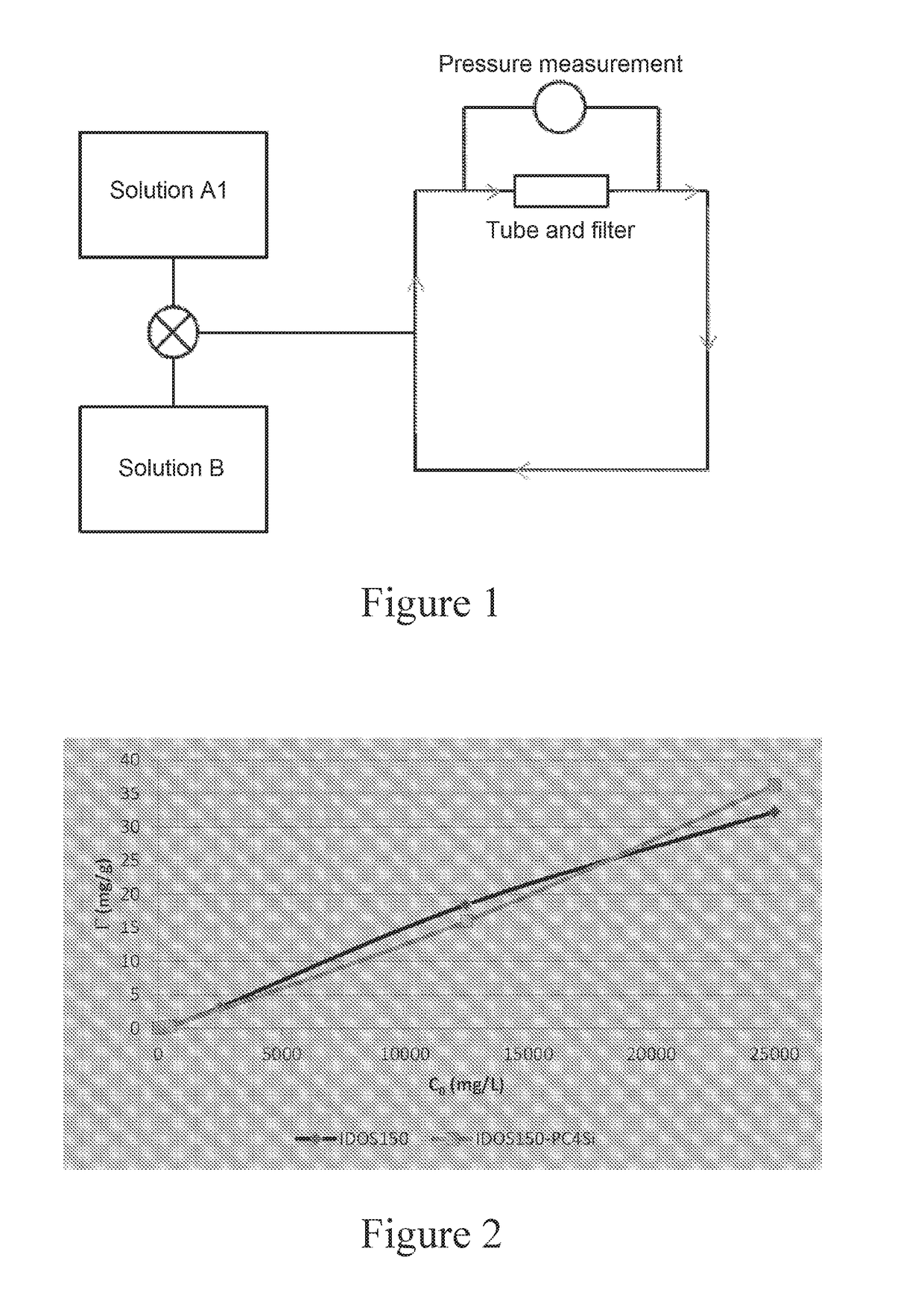

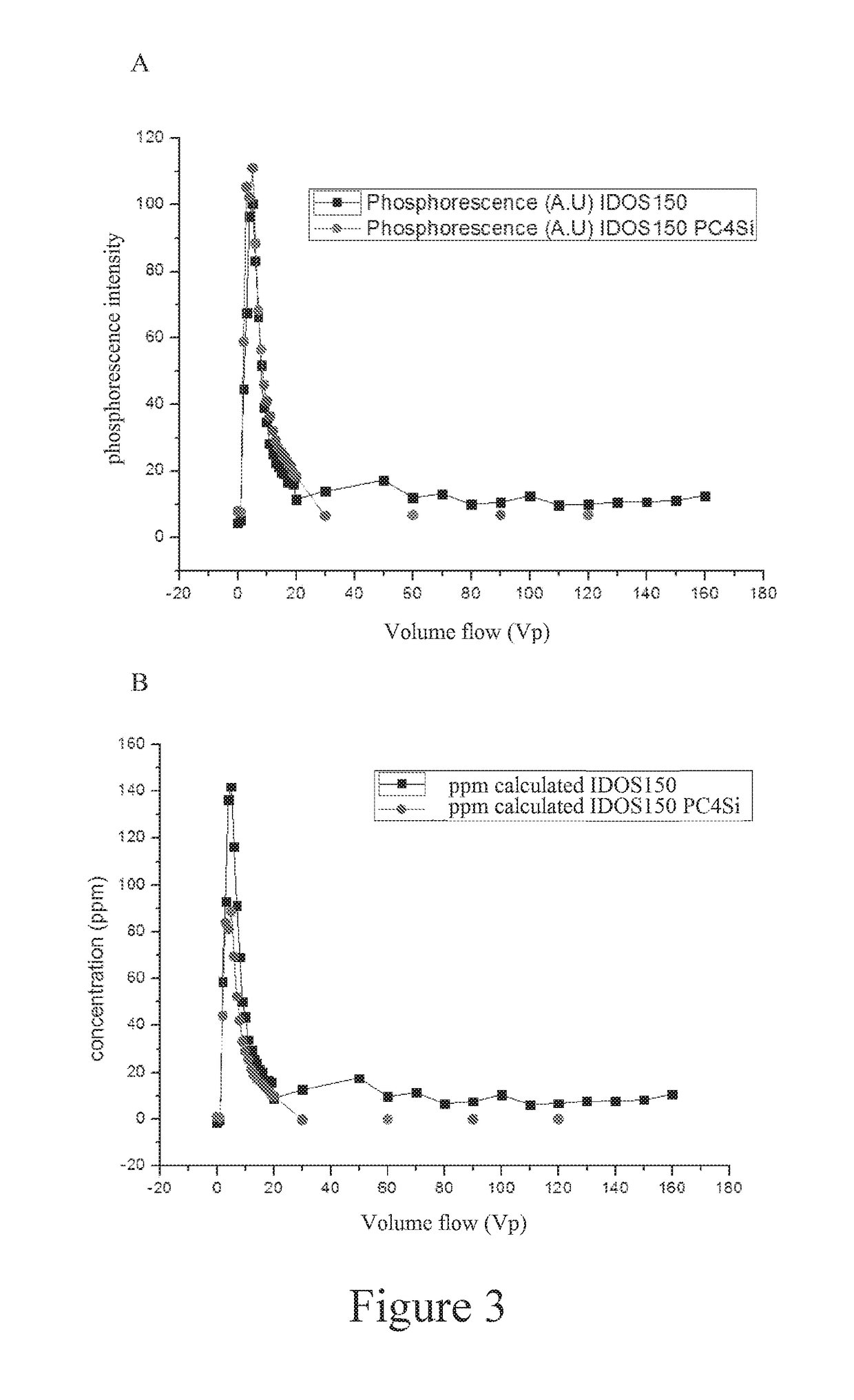

Rare Earth Elements Separation Using Phosphorus Based Adsorbent

ActiveUS20120100049A1Large capacityControlled distributionWater treatment parameter controlLanthanide oxides/hydroxidesRare-earth elementSorbent

The present invention relates to methods for the separation of rare earth elements from aqueous solutions and, more particularly, to the separation of lanthanides (e.g., neodymium(III)) from aqueous solutions using an organo phosphorus functionalized adsorbent.

Owner:SYRACUSE UNIVERSITY

Method of recovering rare-earth elements

ActiveUS9228248B2Improve leaching rateRaise the ratioMetal recyclingLanthanide oxides/hydroxidesRare-earth elementSlurry

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

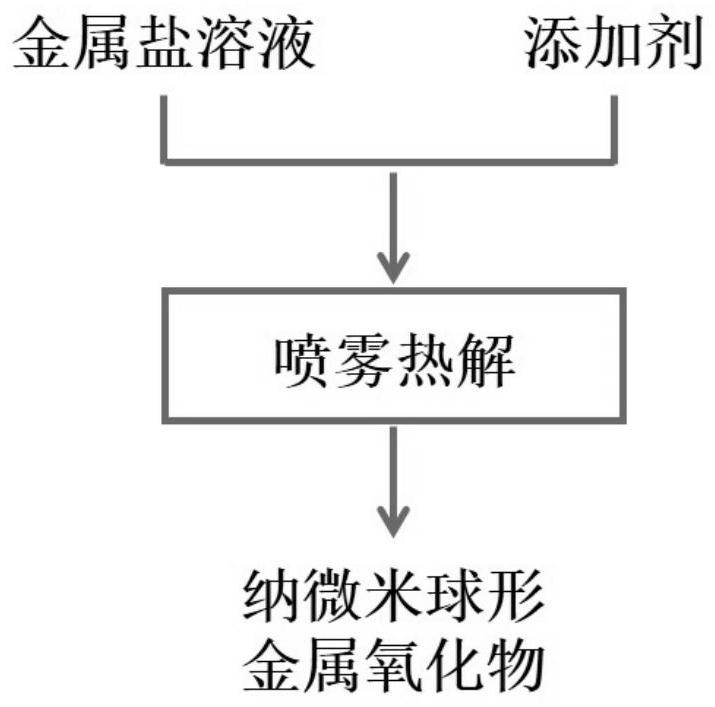

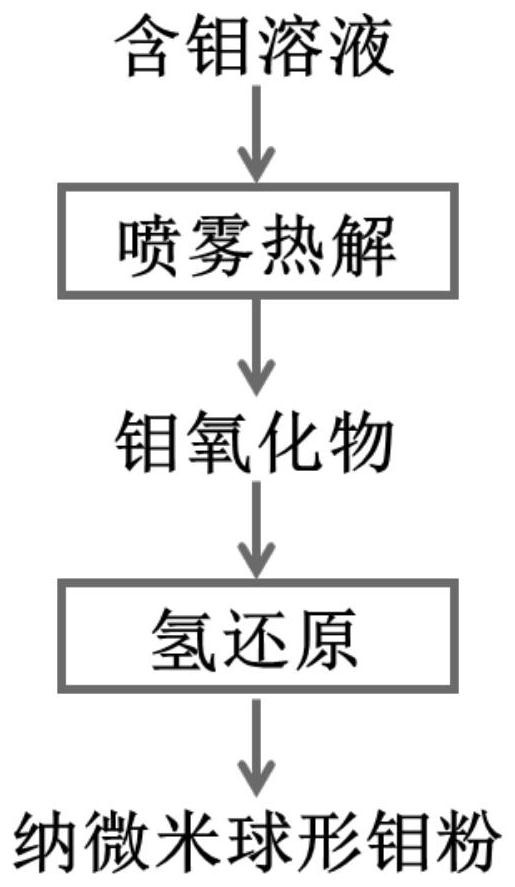

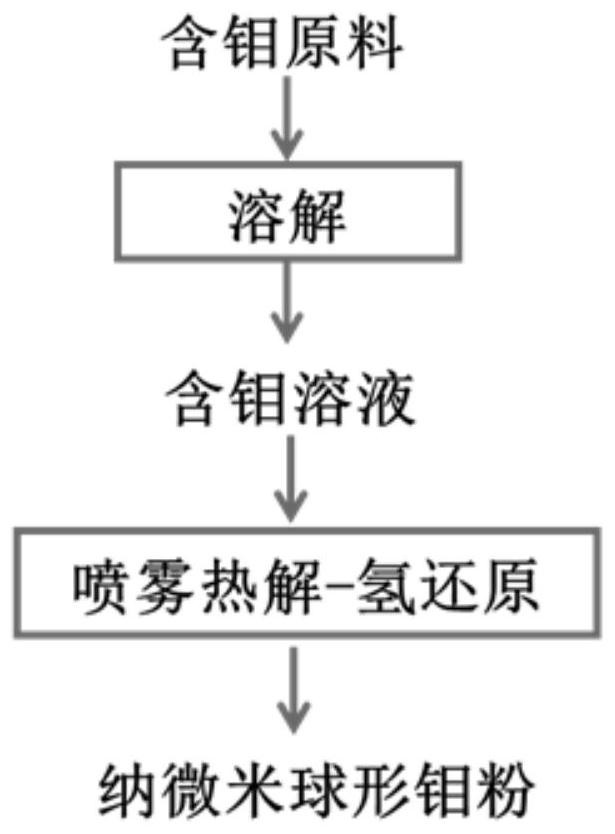

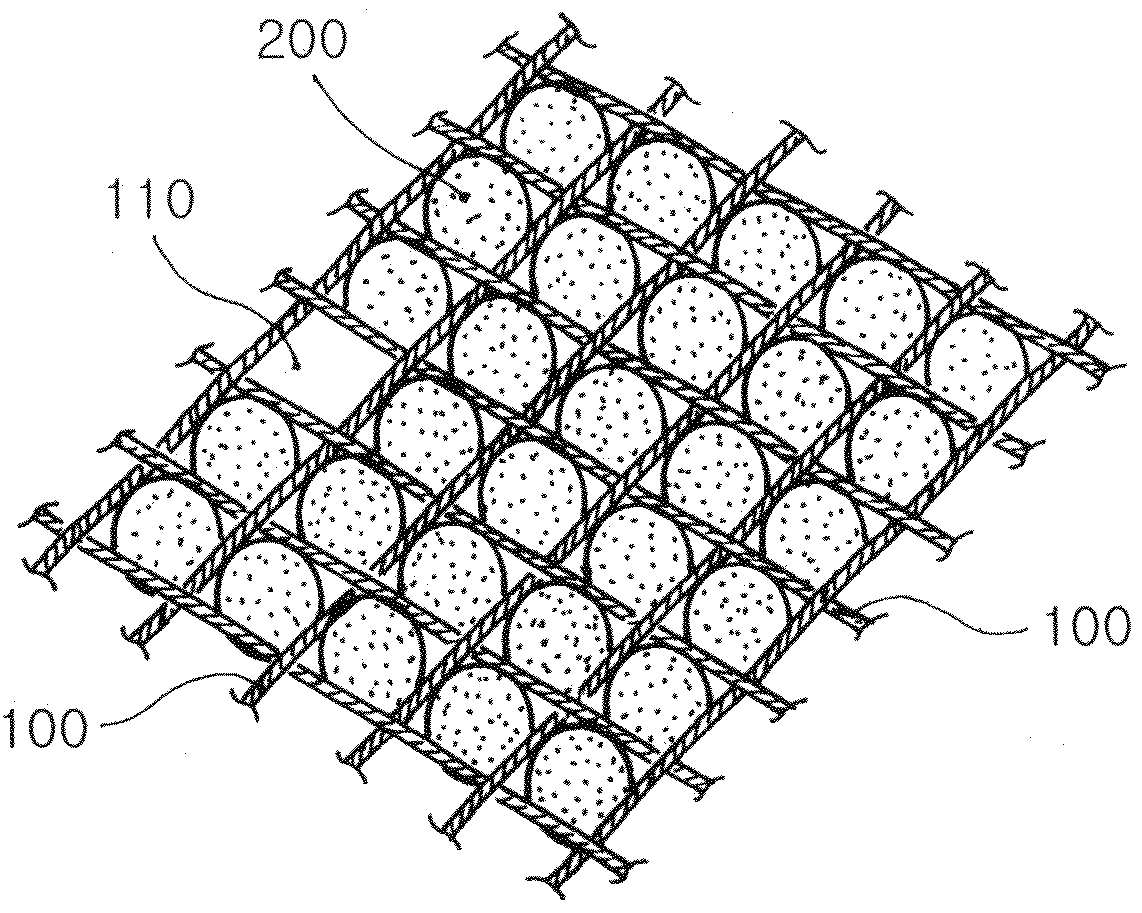

Nano-micron spherical powder and preparation method and equipment thereof

ActiveCN113371682AAvoid reunionHigh purityMaterial nanotechnologyOxygen/ozone/oxide/hydroxidePhysical chemistrySpray pyrolysis

The invention discloses nano-micron spherical powder as well as a preparation method and equipment thereof. The method comprises the following steps of: adding an additive into a solution, and carrying out spray pyrolysis to obtain nano-micron spherical metal oxide powder. The method comprises the following steps of: carrying out one-step continuous atomization and thermal decomposition by adopting spray pyrolysis, and then carrying out hydrogen reduction to obtain nano-micron spherical metal powder; or carrying out one-step continuous atomization, thermal decomposition and hydrogen reduction in a multi-section temperature zone by adopting spray pyrolysis to directly obtain the nano-micron spherical metal powder. By adopting the method, particle aggregation can be avoided, the balling degree is improved, the technological process and time are shortened, the cost is reduced, and the purpose of industrial production is achieved; and the prepared nano-micron spherical metal oxide and metal powder have the advantages of being good in dispersity, narrow in particle size distribution, small in particle size, uniform in particle size and high in purity.

Owner:CHINA ENFI ENGINEERING CORPORATION

Nano-inhibitors

ActiveUS10472556B2Reduce resistanceImprove suppression propertiesLanthanide oxides/hydroxidesNanotechnologyNanoparticleSulfur

Novel hybrid nanoparticles, useful for inhibiting or slowing down the formation of sulfur deposits or minerals in a well during the extraction of gas or oil. Specifically, the nanoparticles each include (i) a polyorganosiloxane (POS) matrix; and, optionally as a coating over a lanthanide oxide core, (iii) at least one polymeric scale inhibitor during the extraction of gas or oil. The invention also relates to the method for obtaining the nano-inhibitors and the application of same.

Owner:TOTAL PUTEAUX FR +2

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

InactiveUS7902546B2Improve thermal conductivityLaser detailsNitrogen compoundsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

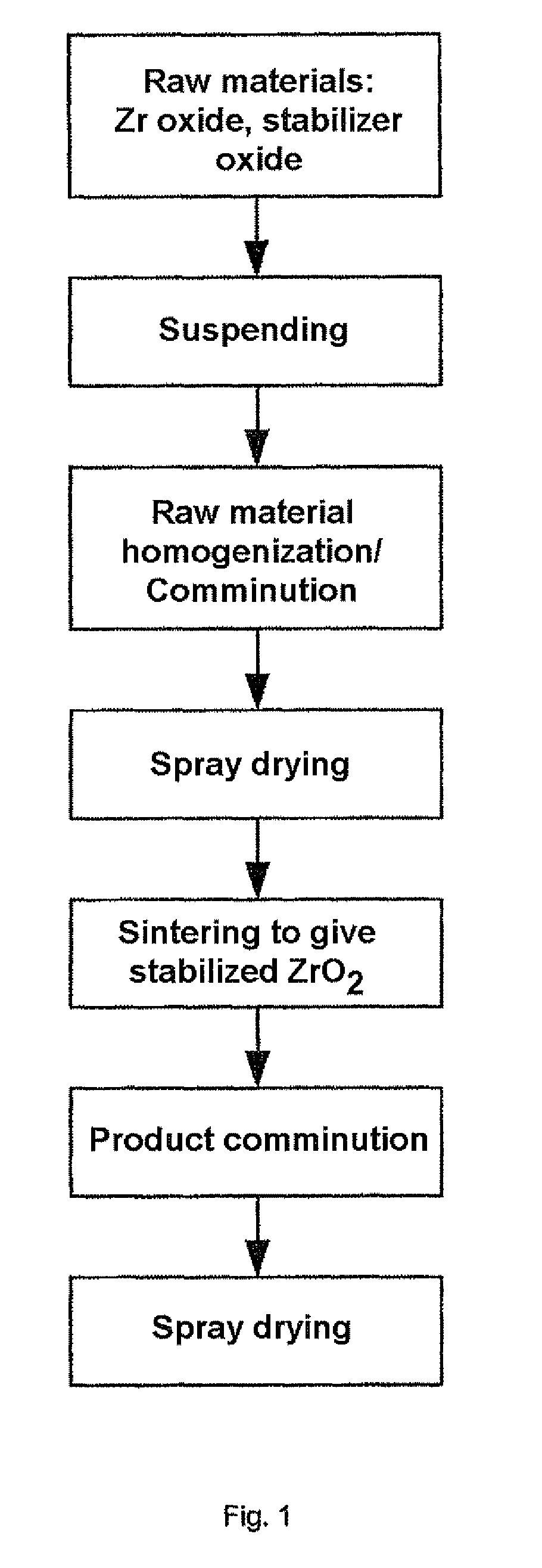

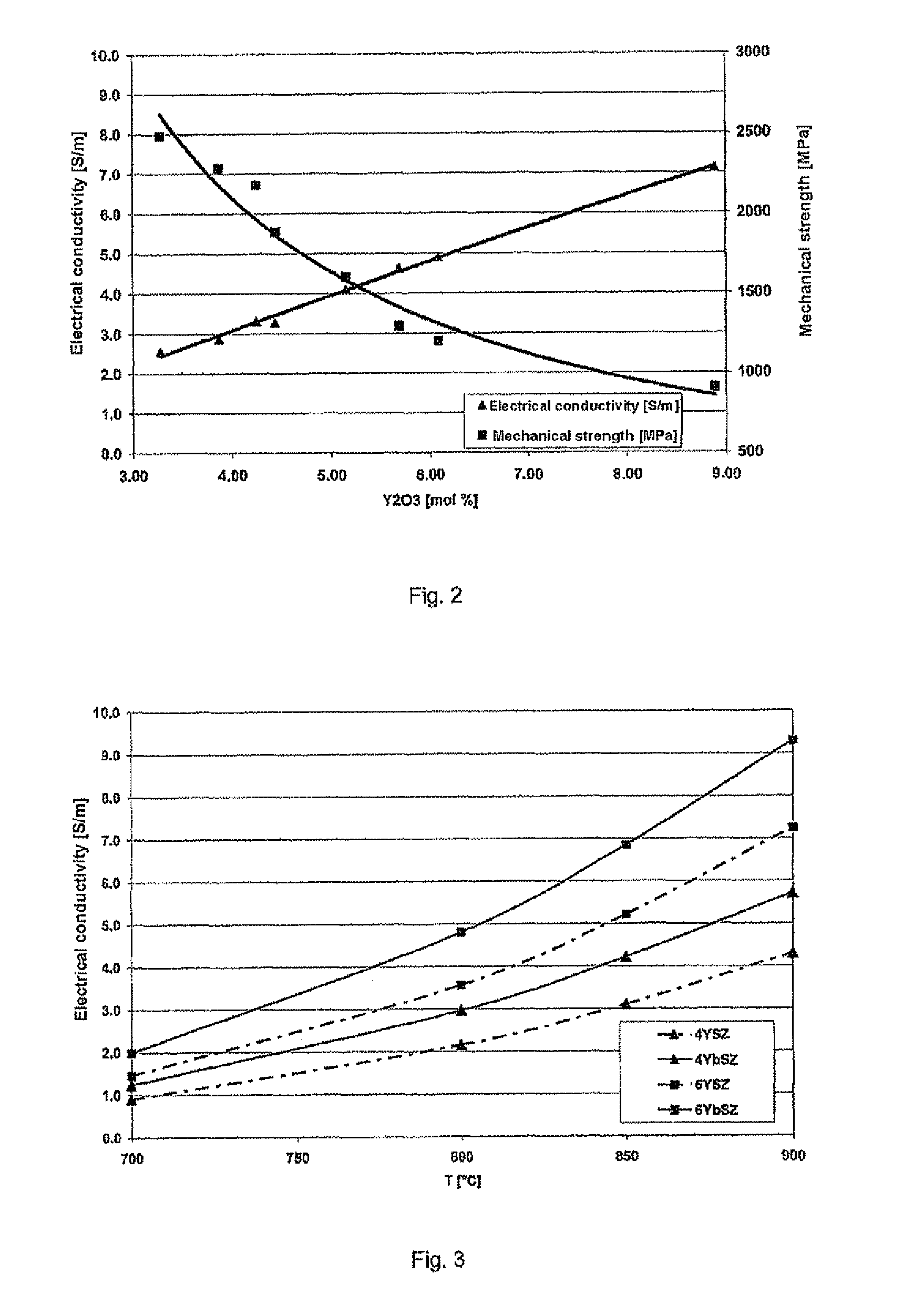

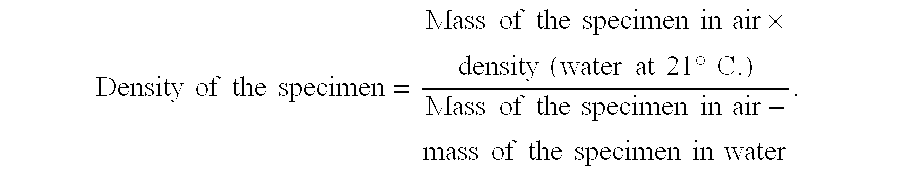

Zirconium oxide and method for the production thereof

InactiveUS8383266B2High mechanical strengthMaterial nanotechnologyLanthanide oxides/hydroxidesFuel cellsRare earth

The invention relates to a pulverulent zirconium oxide containing metal oxides from the group consisting of scandium, yttrium, rare earths and mixtures thereof, processes for producing them and their use in fuel cells, in particular for the production of electrolyte substrates for ceramic fuel cells.

Owner:H C STARCK GMBH

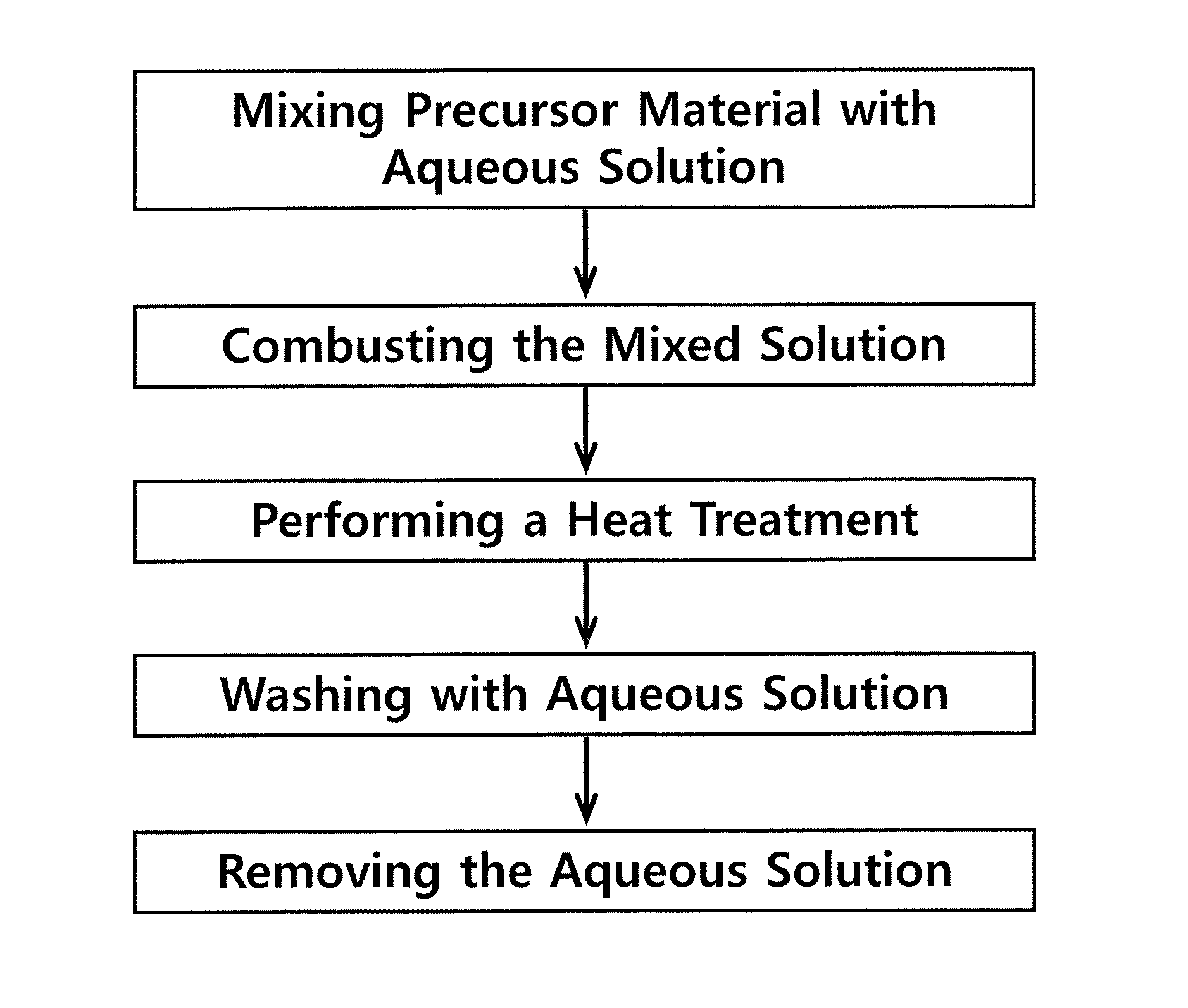

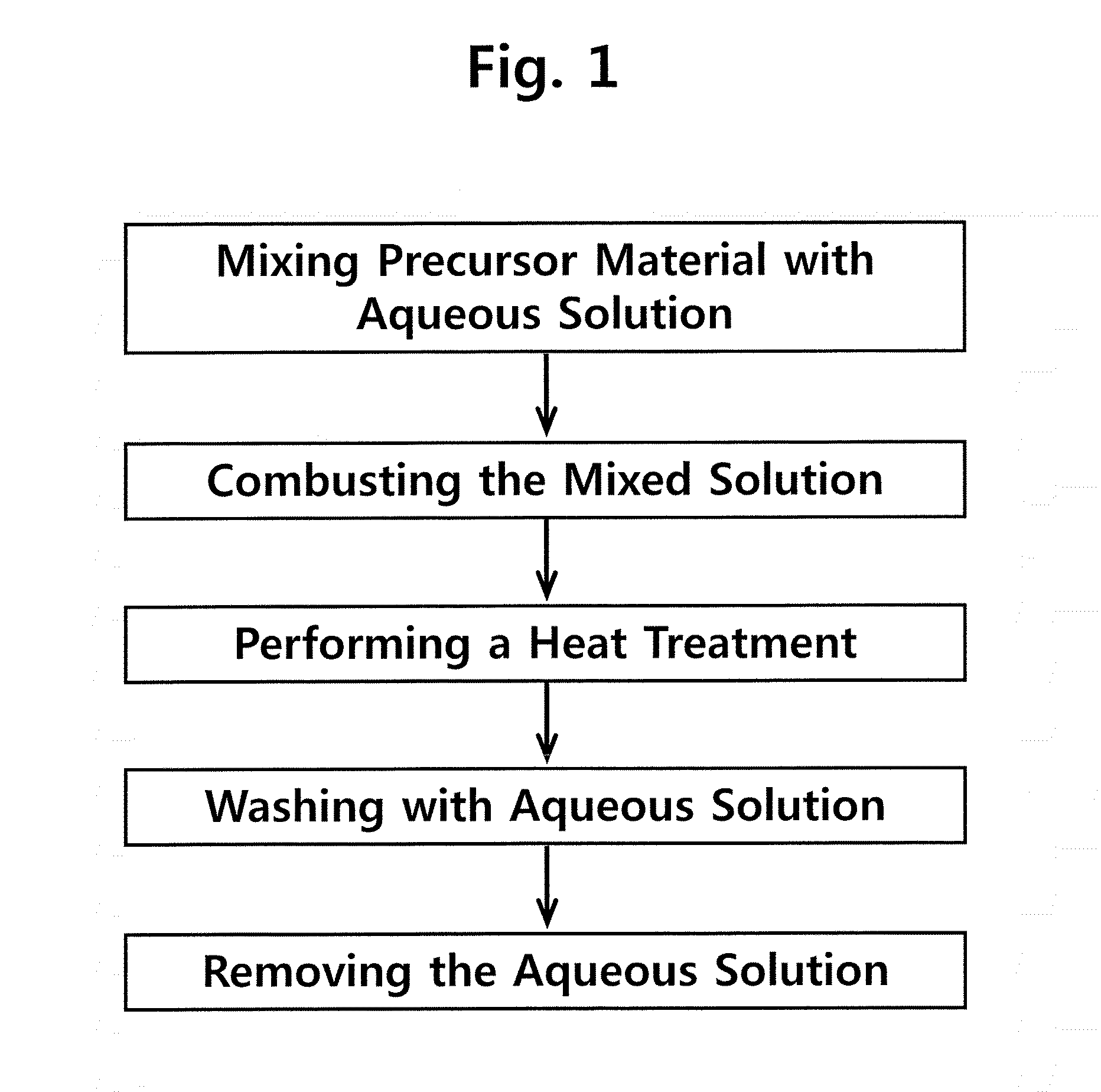

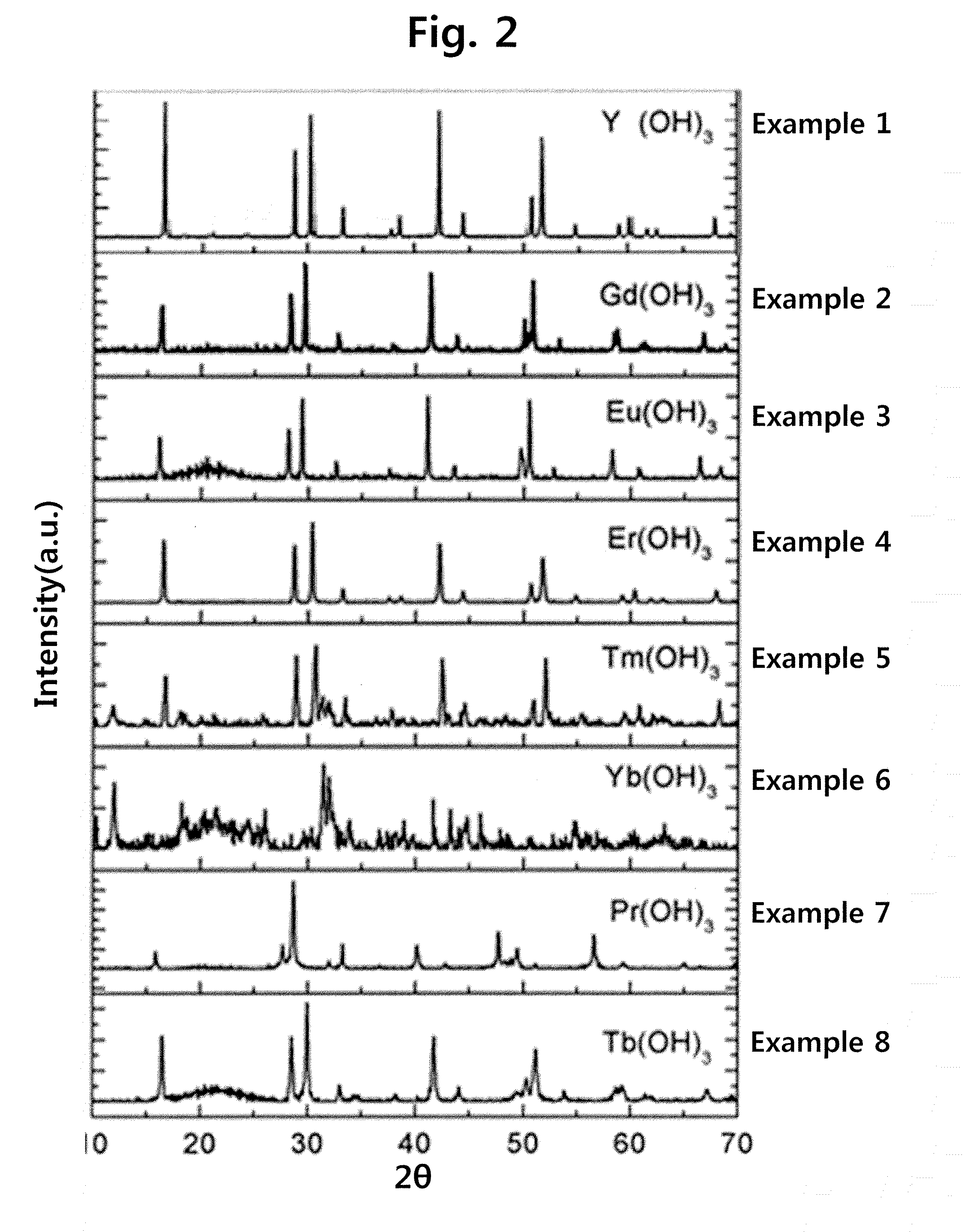

Water-insoluble metal hydrate containing an alkali metal and preparation methods thereof

ActiveUS20160090527A1Easy to useImprove sintering performanceLanthanide oxides/hydroxidesRare earth metal compounds preparation/treatmentSorbentWater insoluble

The present invention relates to a novel method for preparing a water-insoluble metal hydroxide, and a use thereof. The water-insoluble metal hydroxide of the present invention is conveniently and efficiently prepared s through the high-temperature heat treatment step two times and the washing step, and thus contains a small amount of an alkali metal and has a high crystallinity and a phase purity. The water-insoluble metal hydroxide of the present invention or metal oxide therefrom exhibits an absorption wavelength at a low wavelength range (for example, 490 nm or less) and a light emitting wavelength at a high wavelength range (for example, from 500 nm or more to less than 1,100 nm). Accordingly, the water-insoluble metal hydroxide of the present invention may be efficiently used in various applications such as a fire retardant, an antacid, an adsorbent and so forth, and may also be doped with another metal ion to be utilized as a raw material for fabricating a catalyst, a fluorescent material, an electrode material, a secondary battery material and the like.

Owner:KOREA INST OF SCI & TECH

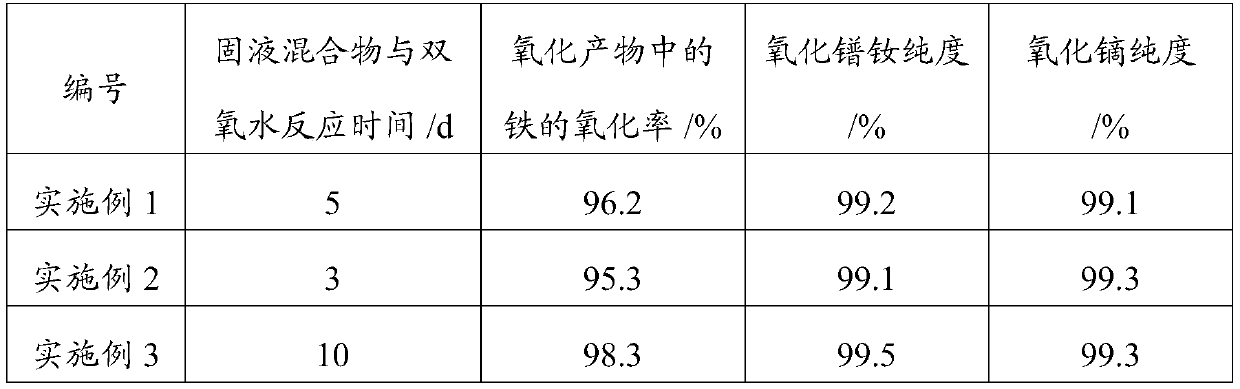

Comprehensive utilization method of ammonium chloride wastewater

ActiveCN111573890ARealize high value utilizationReduce processing timeLanthanide oxides/hydroxidesWater contaminantsSmelting processEnvironmental engineering

The invention discloses a comprehensive utilization method of ammonium chloride wastewater. The comprehensive utilization method comprises the following steps: (1) forming a hydrochloric acid-ammoniumchloride mixed solution I from the ammonium chloride wastewater; (2) mixing the hydrochloric acid-ammonium chloride mixed solution I with a neodymium-iron-boron magnet waste material to obtain a solid-liquid mixture; reacting the solid-liquid mixture with hydrogen peroxide at 5-60 DEG C to obtain an oxidation product; wherein the ammonium chloride wastewater is ammonium chloride wastewater generated in a rare earth smelting process. The comprehensive utilization method provided by the invention can realize the reutilization of the ammonium chloride wastewater in recovery of the neodymium-iron-boron magnet waste material.

Owner:BAOTOU RES INST OF RARE EARTHS

Method of manufacturing magnesium oxide nanoparticles and method of manufacturing magnesium oxide nanosol

InactiveUS20090148609A1High yieldSimple and low-cost processMaterial nanotechnologyNanostructure manufactureNanoparticleMagnesium salt

Disclosed are a method of manufacturing magnesium oxide nanoparticles and a method of manufacturing a magnesium oxide nanosol, which can prepare magnesium oxide particles having a size of tens of nanometers with high yield by using a simple, low-cost process. The methods of manufacturing magnesium oxide nanoparticles and manufacturing magnesium oxide nanosol include preparing a magnesium salt solution by dissolving a magnesium salt in a solvent; impregnating an organic polymer comprising a nanosized pore with the magnesium salt solution; and heating the organic polymer impregnated with the magnesium salt solution until the organic polymer is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

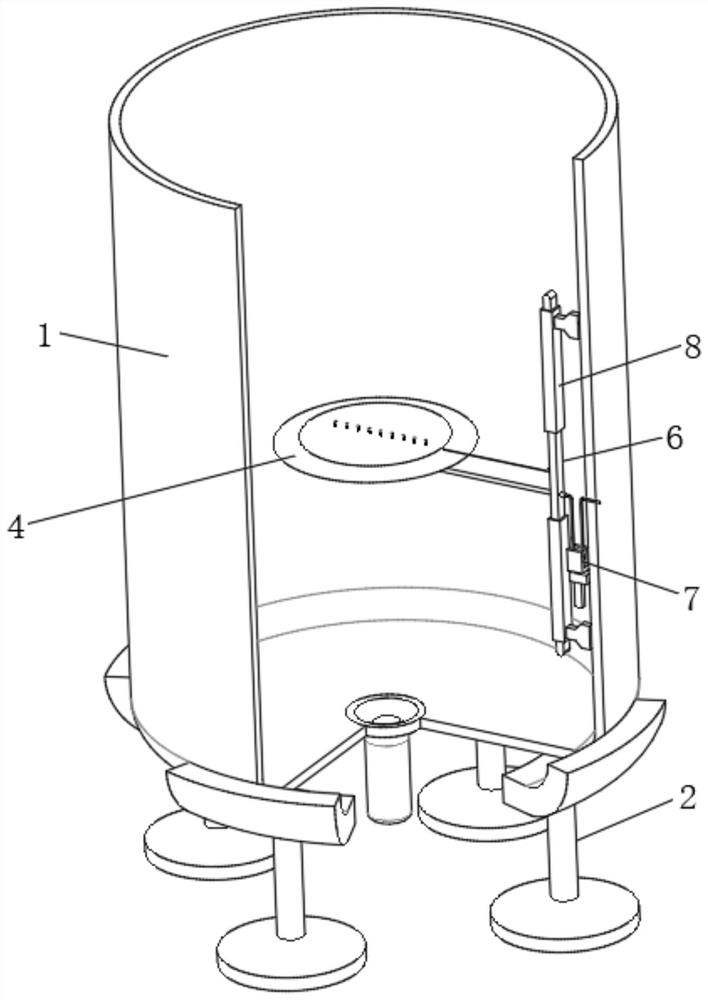

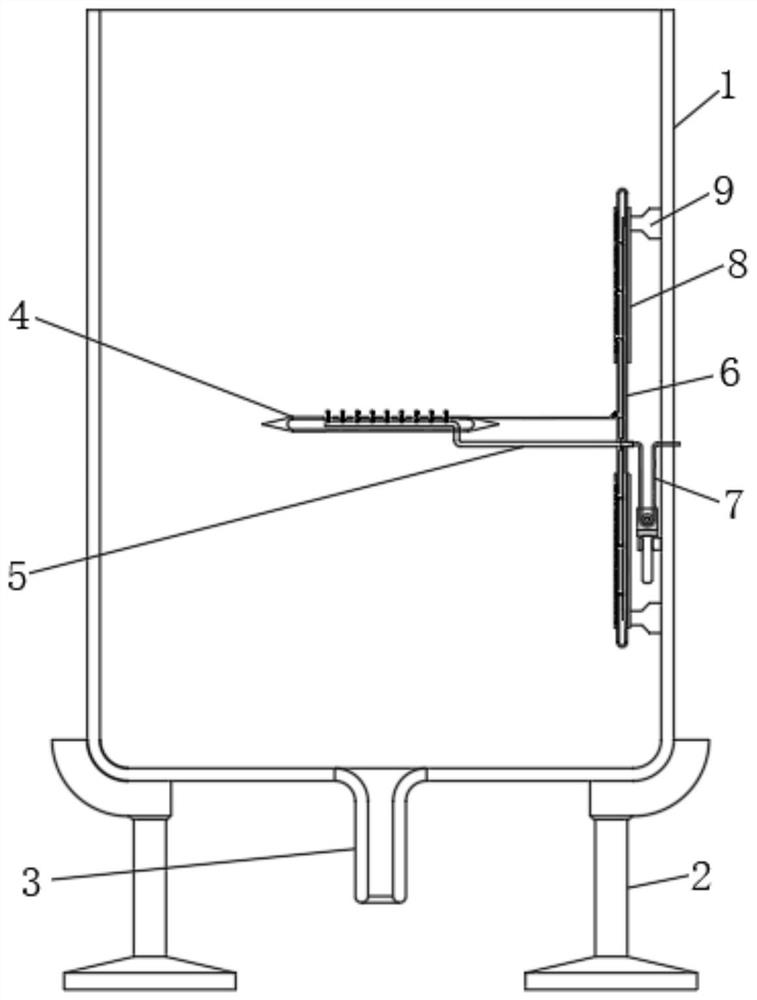

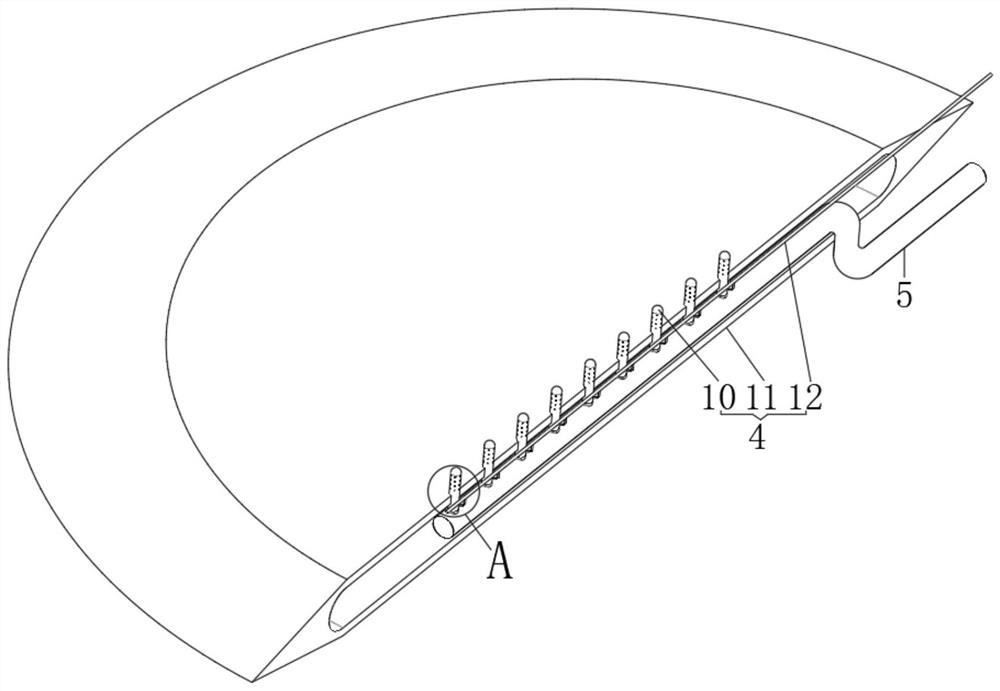

Stable extraction device for neodymium oxide preparation

ActiveCN113350829APlay the effect of intercepting liquidRealize automatic controlLanthanide oxides/hydroxidesLiquid solutions solvent extractionLiquid layerWater flow

The invention relates to the technical field of extraction devices, in particular to a stable extraction device for neodymium oxide preparation, the device comprises a main barrel, a plurality of uniformly distributed supporting legs are fixedly and annularly arranged at the edge of the bottom end of the main barrel, and a bottom pipe is fixedly connected to the middle of the bottom end of the main barrel; a disc assembly, a hard pipe, a control device, a hose assembly, a square barrel and an inner plate are arranged in the inner cavity of the main barrel. By means of the structural design, after extraction work is finished, supernatant is automatically discharged, the whole process is automatically controlled, the disc shell is impacted by water flow, and the influence of liquid layering on the disc shell in the extraction process is utilized, the disc shell moves up and down to trigger a gas supply mechanism of the intercepting device, and thus the intercepting device plays a role in intercepting liquid before the extraction work is finished, the intercepting state of the intercepting device can be automatically broken after the extraction work is finished for a certain time, and the whole process is automatically controlled.

Owner:JIANGSU GUOSHENG RARE EARTH CO LTD

Nano-inhibitors

ActiveUS20170349810A1Remarkable resistance to degradationReduce resistanceLanthanide oxides/hydroxidesNanotechnologySulfurNanoparticle

Novel hybrid nanoparticles, useful for inhibiting or slowing down the formation of sulfur deposits or minerals in a well during the extraction of gas or oil. Specifically, the nanoparticles each include (i) a polyorganosiloxane (POS) matrix; and, optionally as a coating over a lanthanide oxide core, (iii) at least one polymeric scale inhibitor during the extraction of gas or oil. The invention also relates to the method for obtaining the nanoinhibitors and the application of same.

Owner:TOTAL PUTEAUX FR +2

Method for producing transparent ceramic, transparent ceramic, magneto-optical device and rare earth oxide powder for sintering

ActiveUS10642073B2Improve featuresExcellent optical propertiesLanthanide oxides/hydroxidesNon-linear opticsRare earth ionsPhysical chemistry

A starting material powder, which contains a rare earth oxide that is composed of terbium oxide and at least one other rare earth oxide selected from among yttrium oxide, scandium oxide and oxides of lanthanide rare earth elements (excluding terbium) and a sintering assistant that is formed of an oxide of at least one element selected from among group 2 elements and group 4 elements, is produced by having (a) terbium ions, (b) ions of at least one other rare earth element selected from among yttrium ions, scandium ions and lanthanide rare earth ions (excluding terbium ions) and (c) ions of at least one element selected from among group 2 elements and group 4 elements coprecipitate in an aqueous solution containing the components (a)-(c), then filtering and separating the coprecipitate, and subjecting the separated coprecipitate to thermal dehydration.

Owner:SHIN ETSU CHEM CO LTD

Terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and organic extraction agent

InactiveCN113355538AHigh degree of continuous extractionHigh degree of continuityLanthanide oxides/hydroxidesProcess efficiency improvementO-Phosphoric AcidPhysical chemistry

The invention relates to the technical field of rare earth extraction, in particular to a terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and an organic extraction agent, and solves the technical problems that in the prior art, a nitric acid method is adopted for decomposing the ion ore to produce phosphoric acid, and then rare earth is separated out through neutralization precipitation, extraction and other processes; and the problem of co-precipitation exists in neutralization precipitation, and certain difficulties exist in both the economic aspect and the technical aspect. The terbium oxide extraction process for treating ion ore through combination of hydrochloric acid and an organic extraction agent comprises the following steps: producing phosphoric acid by decomposing the ion ore with hydrochloric acid when wet-process phosphoric acid is adopted, and feeding one part of rare earth into a phosphoric acid solution and the other part of rare earth into phosphogypsum in the treatment process. According to the mode provided by the invention, the continuous degree of extraction is relatively high, the recovery rate and the purity are obviously improved, meanwhile, the process for extracting the rare earth from the phosphoric acid is simple, and particularly, the continuous extraction method is high in continuous degree and easy to realize industrial production.

Owner:中稀(常州)稀土新材料有限公司

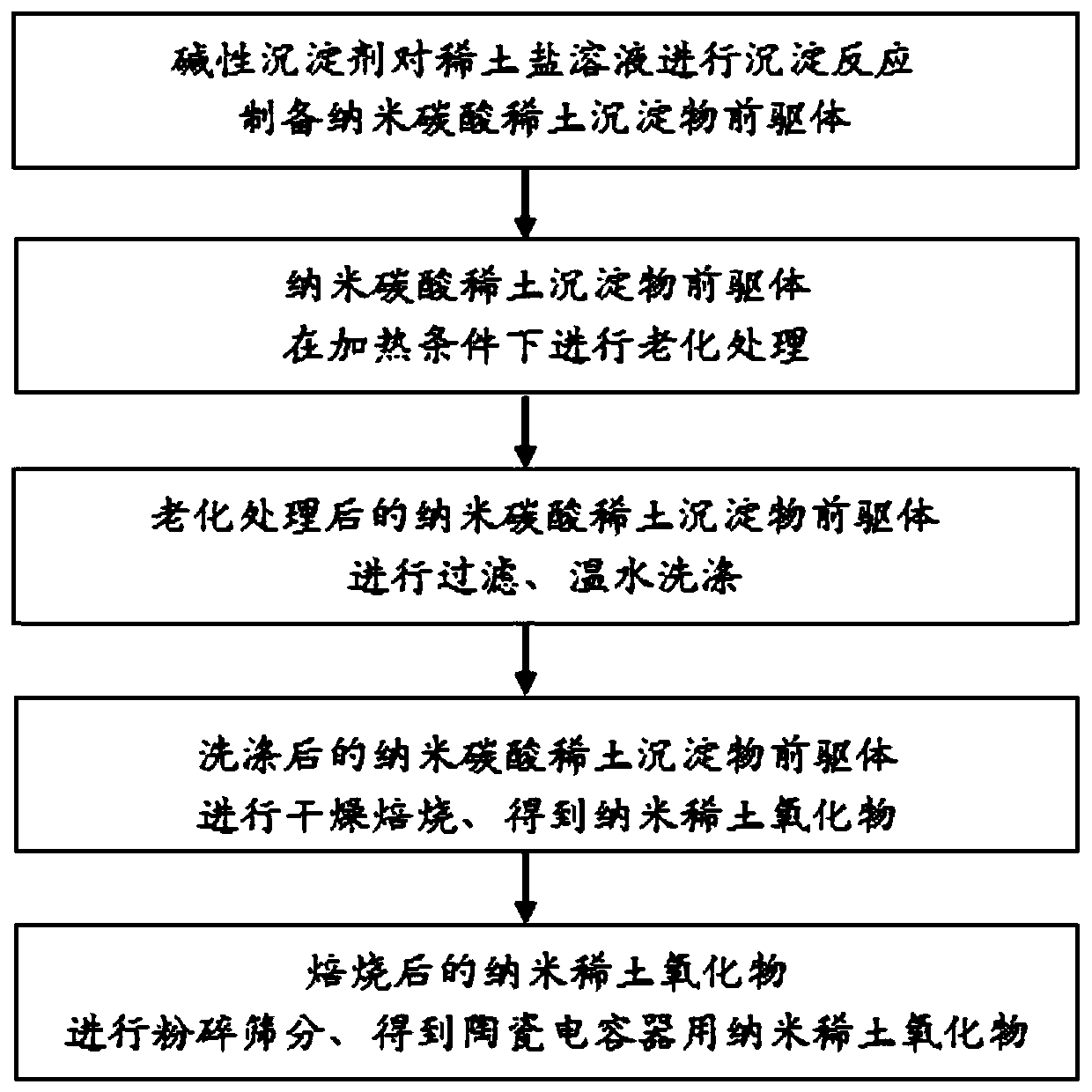

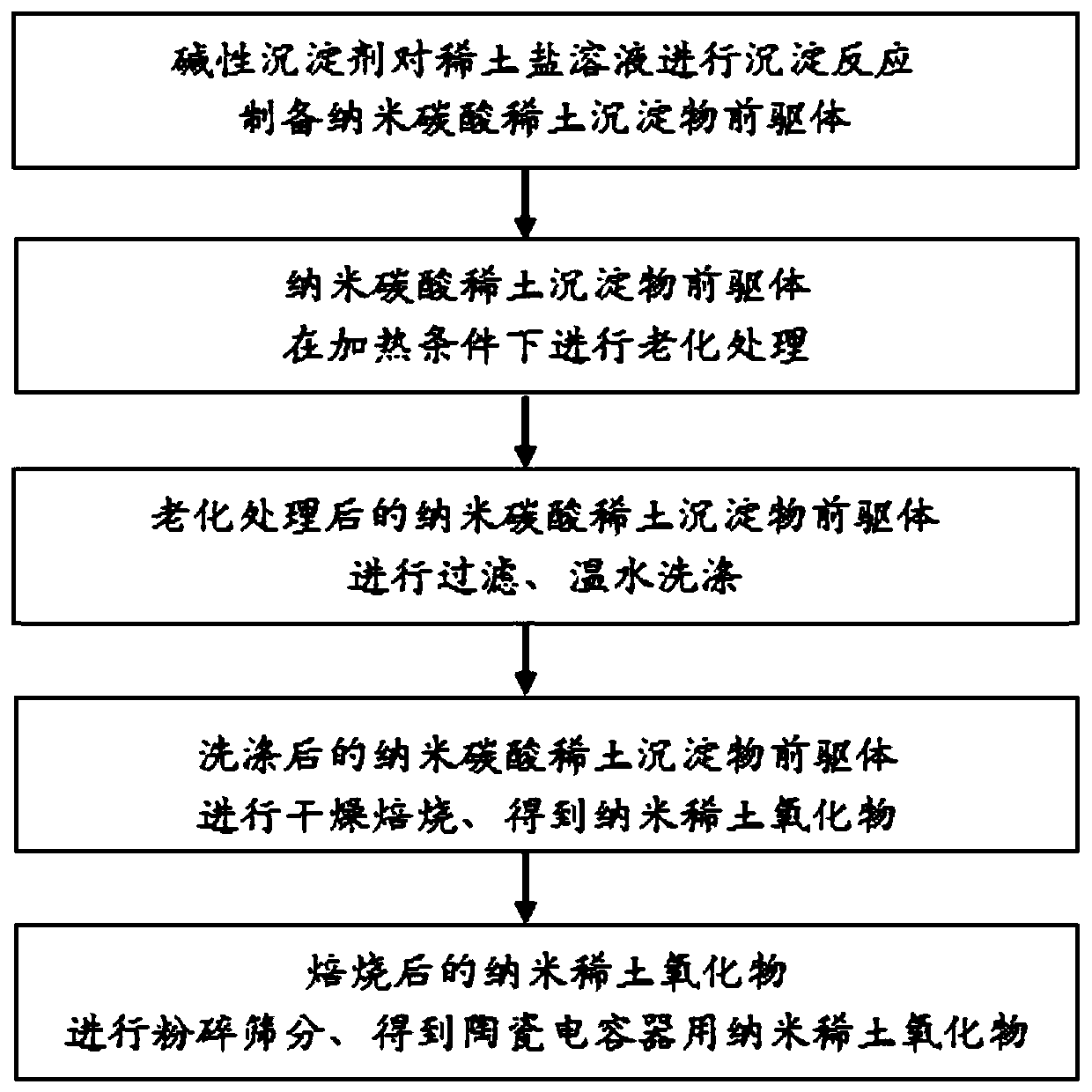

Preparation method of nano dysprosium oxide for dielectric ceramic capacitor

PendingCN111017977AReasonable designGood dispersionLanthanide oxides/hydroxidesPhysical chemistryCeramic capacitor

The invention discloses a preparation method of nano dysprosium oxide for a dielectric ceramic capacitor, and aims to solve the problems of large particle size and poor dispersion performance of existing rare earth oxide. The method comprises the following specific steps: step 1, preparing a dysprosium salt solution and an alkaline precipitant solution; step 2, stirring and heating the dysprosiumsalt solution to 30-100 DEG C, slowly dripping the alkaline precipitant solution into the dysprosium salt solution, and controlling the final pH value of the precipitated solution to be 4.5-9.0; step3, carrying out aging treatment on a precipitate precursor; step 4, filtering and water-washing the precipitate precursor subjected to aging treatment; and step 5, drying, roasting, crushing and screening the washed precipitate precursor to obtain a finished product. The obtained nano rare earth oxide finished product can reach the nano size, is easy to disperse, and is especially suitable for production of miniaturized or microminiaturized dielectric ceramic capacitors.

Owner:江西鑫泰功能材料科技有限公司

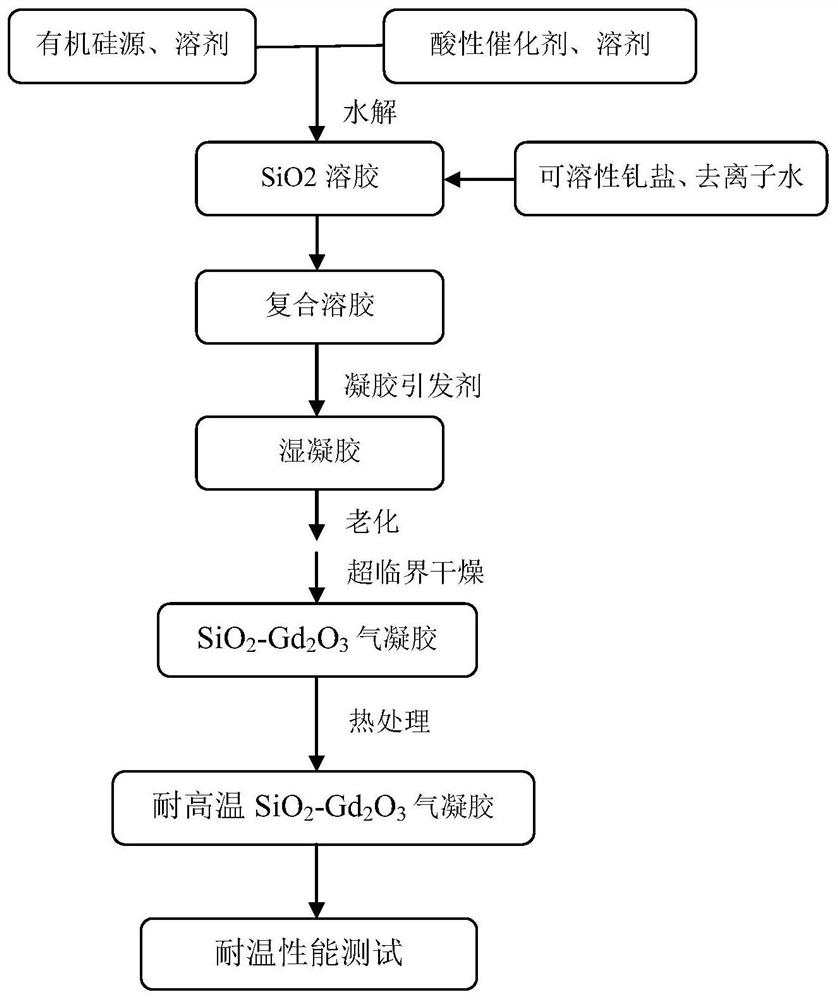

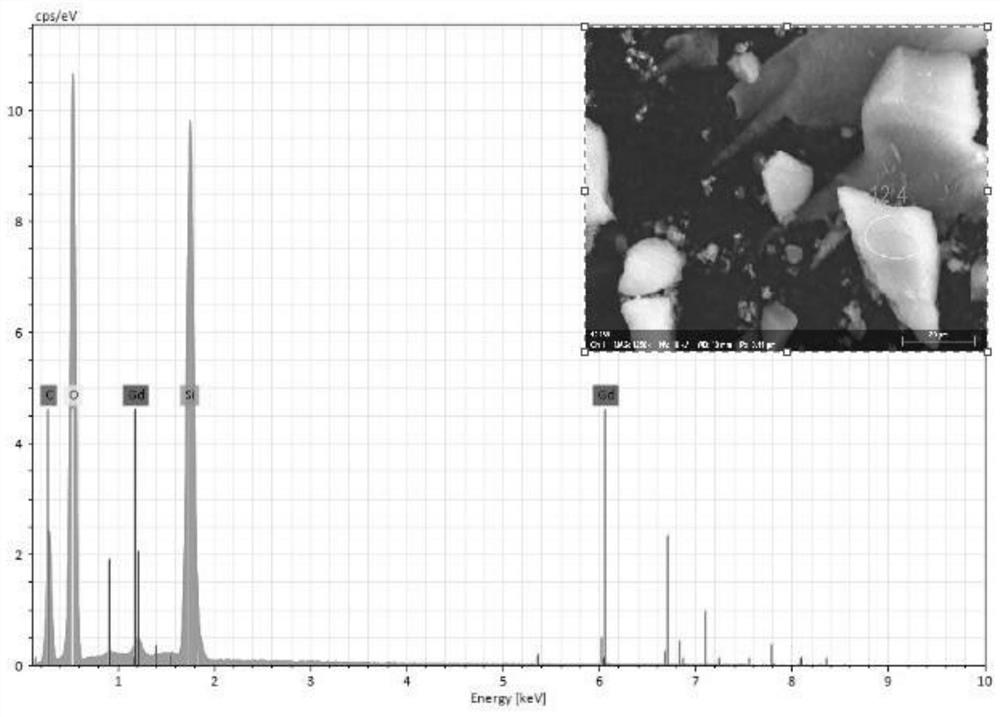

High-temperature-resistant SiO2-Gd2O3 composite aerogel and preparation method thereof

ActiveCN112320833AShort manufacturing cycleSavings in industrial preparation costsLanthanide oxides/hydroxidesRare earth metal compounds preparation/treatmentSupercritical dryingAir atmosphere

The invention discloses high-temperature-resistant SiO2-Gd2O3 composite aerogel and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing organosilicone alkoxide, an acidic catalyst, deionized water, a solvent, soluble gadolinium salt, a gel initiator and the like to obtain a colorless clear SiO2-Gd2O3 composite sol solution, standing at a certainenvironment temperature, waiting for gelation and aging, then drying a sample by adopting a supercritical drying method, and finally carrying out heat treatment in an air atmosphere to obtain the high-temperature-resistant SiO2-Gd2O3 composite aerogel. The preparation method is simple to operate, and the prepared aerogel not only retains the advantages of low density and low thermal conductivity of pure SiO2 aerogel, but also has higher temperature resistance due to the addition of rare earth elements. The prepared material can be used in the fields of aerospace, petroleum and petrochemical engineering, ships and the like, can also be used in the field of nuclear industry, and has a good application prospect.

Owner:CHANGSHA RONGLAN MACHINERY

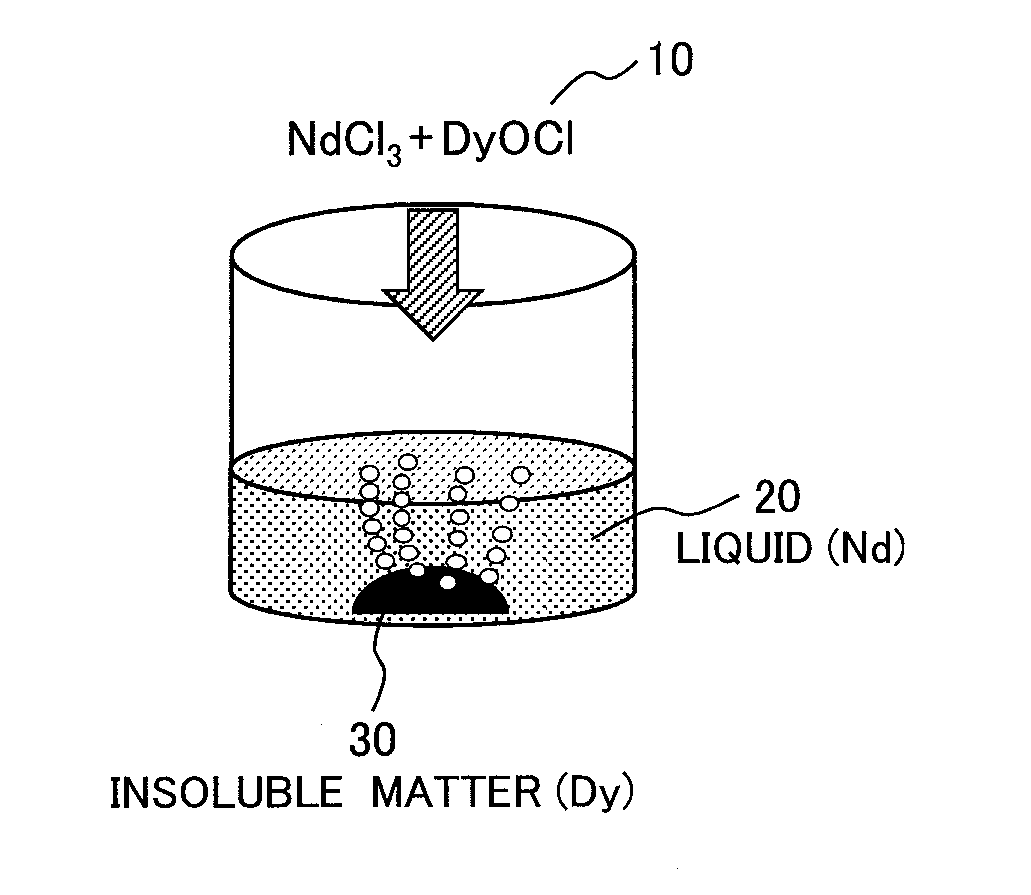

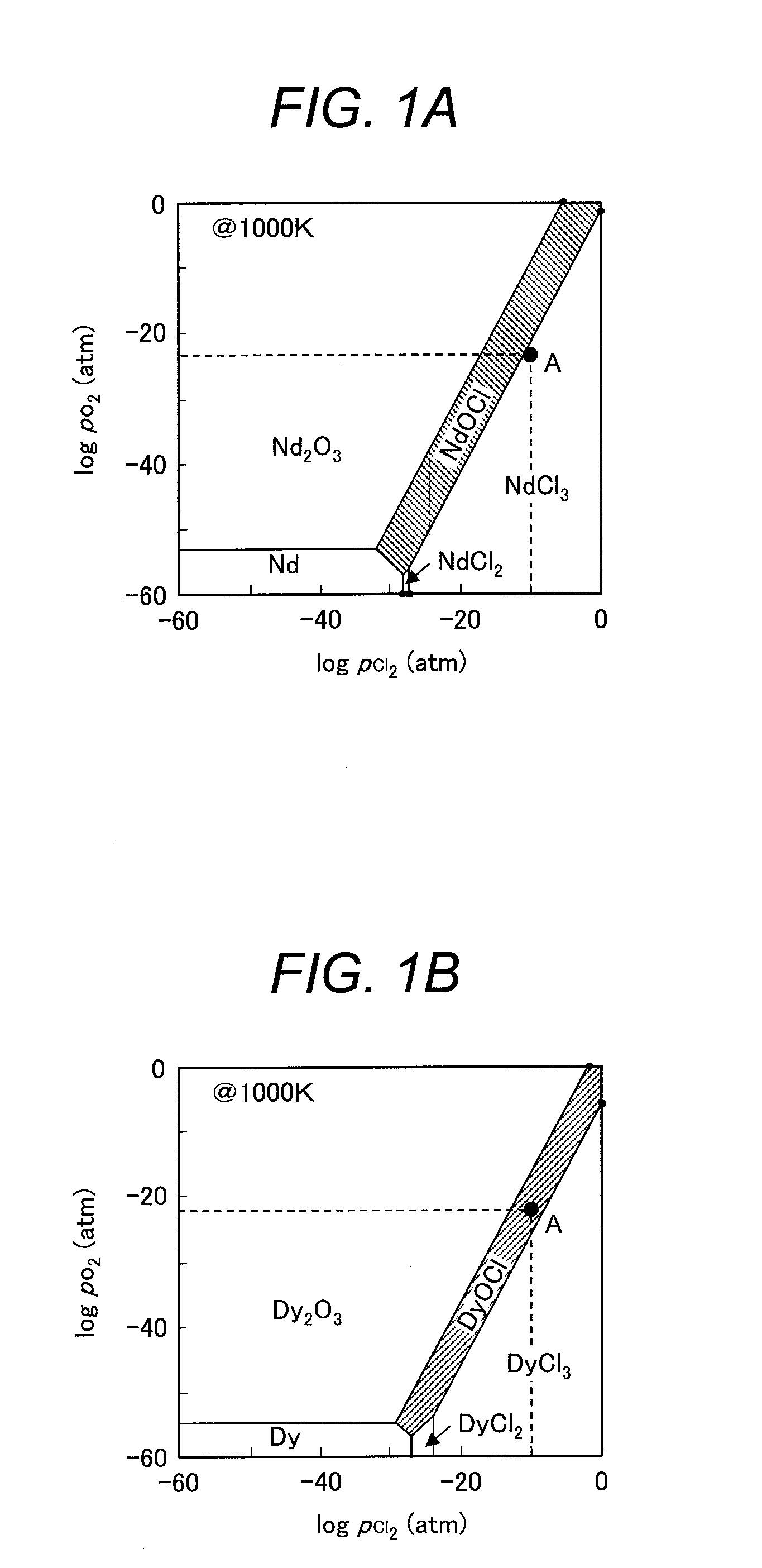

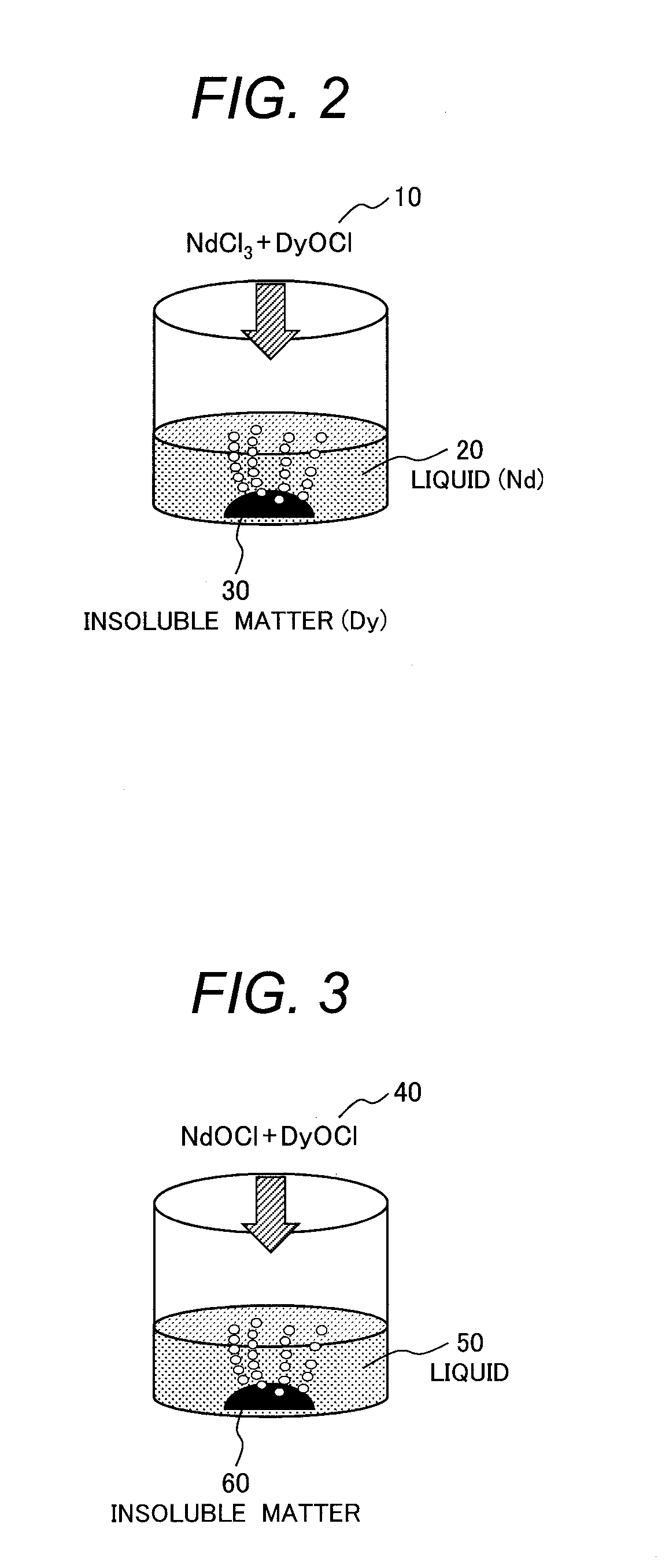

Method for Separating and Recovering Rare-Earth Elements

ActiveUS20140356258A1Less effectHigh separation rateRare earth metal chloridesLanthanide oxides/hydroxidesRare-earth elementTrace element

A method for separating and recovering a plurality of rare-earth elements, the method including a step of introducing, into a liquid, a mixture containing a rare-earth oxychloride and a rare-earth chloride, the rare-earth oxychloride constituted from a rare-earth element different from a rare-earth element constituting the rare-earth chloride, thereby obtaining an insoluble matter containing the rare-earth oxychloride and a liquid in which the rare-earth chloride is dissolved, a step of recovering the rare-earth oxychloride from the insoluble matter, and a step of recovering the rare-earth chloride from the liquid in which the rare-earth chloride is dissolved.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com