Application of lactam as solvent in nano-grade material preparation

A nanomaterial and lactam technology, applied in the field of nanomaterials, can solve the problems of narrow particle size distribution, affecting the subsequent application of synthetic nanoparticles, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Synthesis of Nano Magnesium Hydroxide by Precipitation Method Using Caprolactam as Solvent

[0077] Take 20.3g MgCl 2 ·6H 2 O was added to 100 g of molten caprolactam (caprolactam purity ≥ 80%, water content ≤ 20%), and stirred at 100°C for 30 min to fully dissolve the magnesium chloride. 10 g of ammonia water (containing 26% ammonia) was quickly added under stirring conditions, and the temperature was kept at 100° C. for 24 hours. The obtained mixture was centrifugally washed three times with deionized water, each time with 200 g of water, fully dried and pulverized to obtain nanometer Mg(OH) 2 Powder.

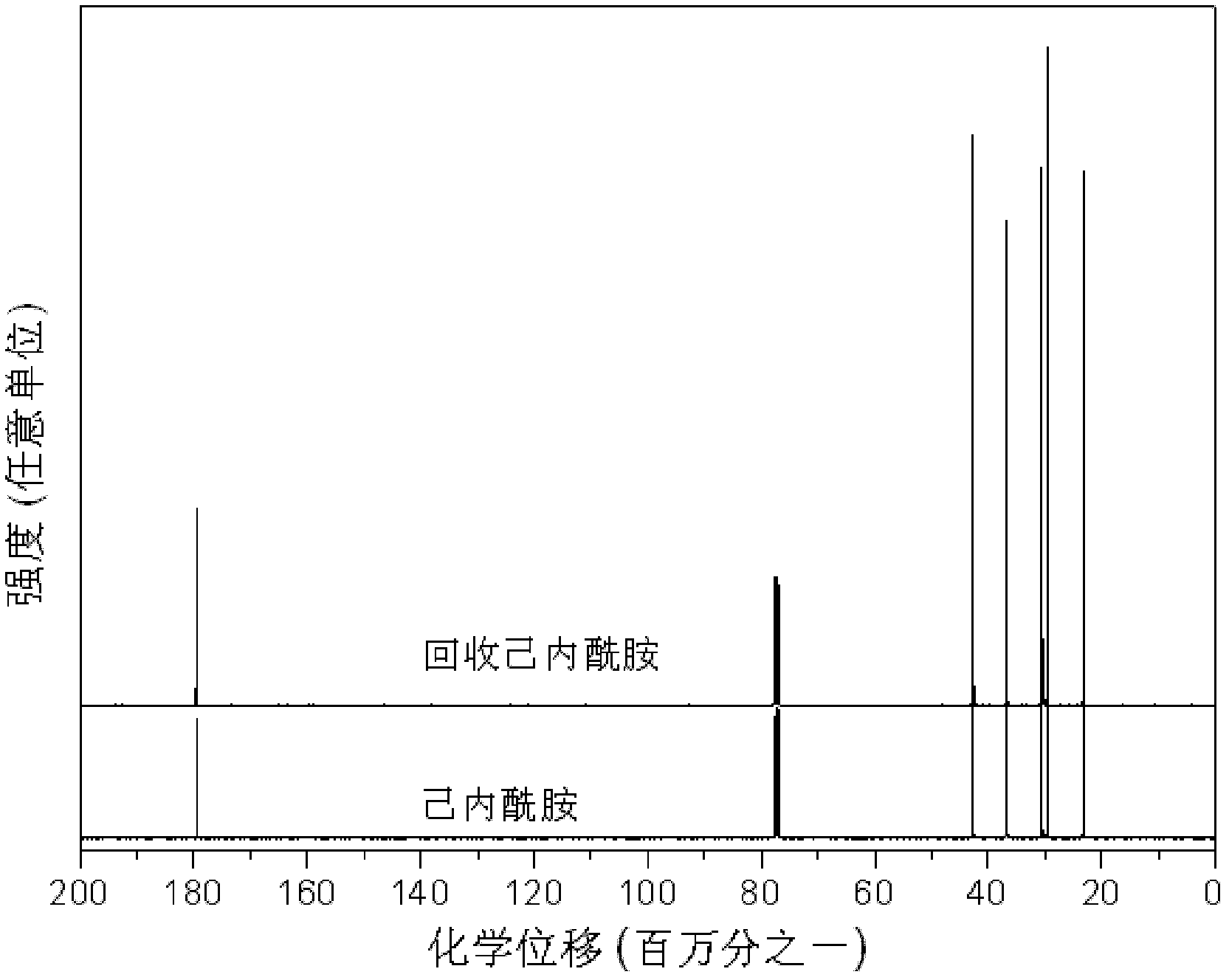

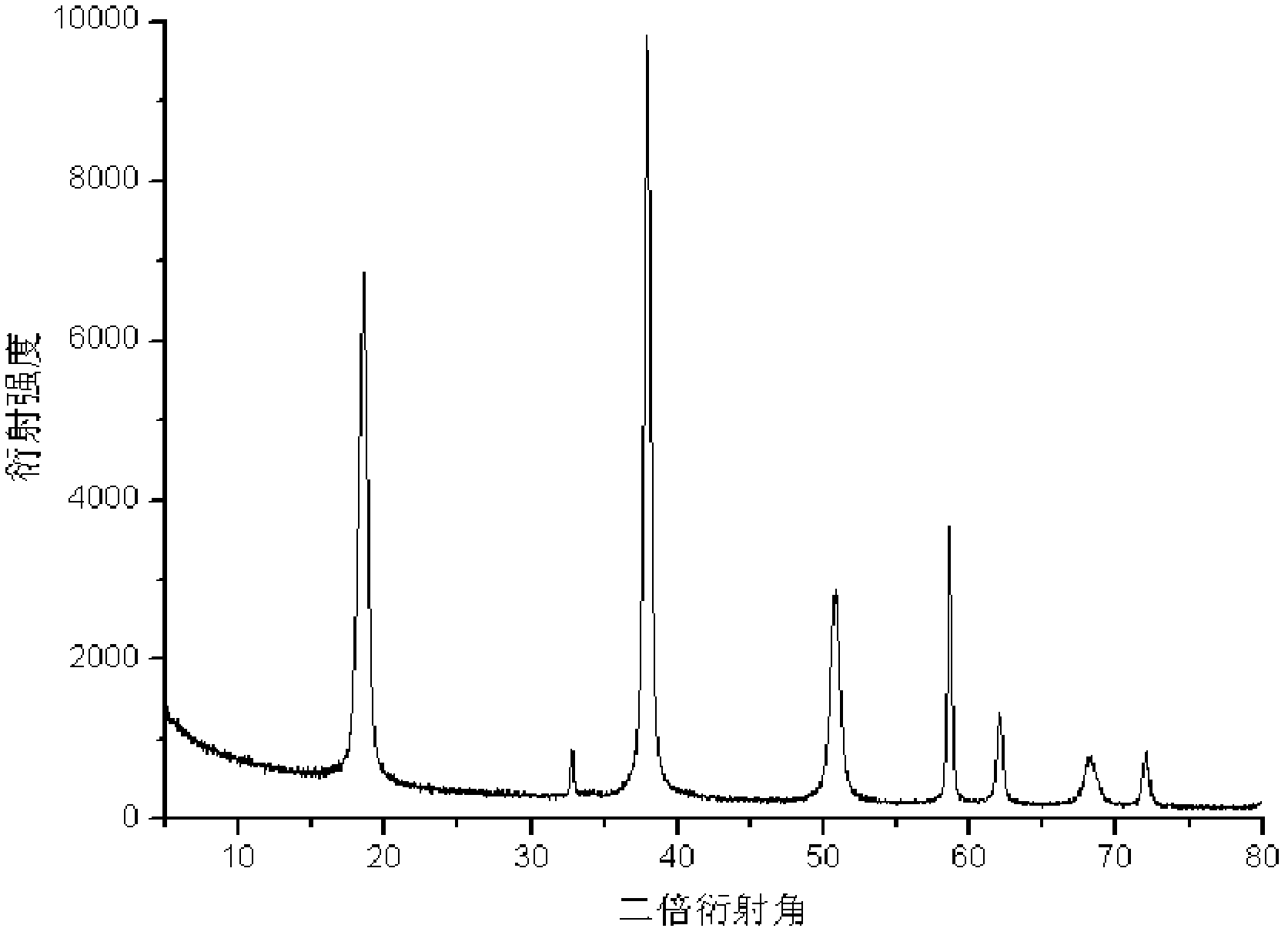

[0078] figure 1 It is caprolactam as the carbon nuclear magnetic resonance spectra before and after solvent use ( 13 C-NMR), the use solvent is deuterated chloroform, and caprolactam remains unchanged as the collection of spectra before and after solvent use, shows that the caprolactam solvent can be recycled. figure 2 It is the synthetic nanometer Mg(OH) of pre...

Embodiment 2

[0080] Synthesis of Nanometer Neodymium Hydroxide by Precipitation Method Using Caprolactam as Solvent

[0081] Take 10.96g Nd(NO 3 ) 3 ·6H 2 O was added to 100g of molten caprolactam (caprolactam purity ≥ 80%, moisture ≤ 20%), stirred at 200°C for 30min, and Nd(NO 3 ) 3 ·6H 2 O is fully dissolved. Add 3g NaOH quickly under stirring condition, and keep the temperature at 200°C for 24h. The obtained mixture was centrifugally washed three times with deionized water, each time with 200 g of water, fully dried and pulverized to obtain nanometer Nd(OH) 3 Powder. Figure 4 It is the transmission electron microscope (TEM) picture of the synthetic nanometer Nd(OH) powder of present embodiment method, and observation result shows that Nd(OH) 3 The powder is composed of uniformly dispersed rod-shaped nanoparticles, the average length of the nanoparticles is about 40nm, and the average diameter is about 7nm.

Embodiment 3

[0083] Synthesis of Nano-sized Aluminum Hydroxide / Yttrium Hydroxide Composite by Precipitation Method Using Caprolactam as Solvent

[0084] Take 3.83g Y(NO 3 ) 3 ·6H 2 O and 4.02g AlCl 3 9H 2 O (the molar ratio is [Y 3+ ] / [Al 3+ ]=3 / 5) was added to 100g molten caprolactam (caprolactam purity ≥ 80%, moisture ≤ 20%), stirred at 200°C for 30min, and Y(NO 3 ) 3 ·6H 2 O and AlCl 3 9H 2 O is fully dissolved. Add 8g of NaOH quickly under stirring condition, and keep the temperature at 200°C for 24h. The mixture obtained was washed three times with deionized water, 200g of water each time, fully dried and pulverized to obtain nanometer Al(OH) 3 / Y(OH) 3 Powder. Figure 5 It is the synthetic nanometer Al(OH) of present embodiment method 3 / Y(OH) 3 The TEM picture of the powder shows that the product is composed of small particles with a diameter of about 5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com