Nano-micron spherical powder and preparation method and equipment thereof

A spherical powder, nano-micron technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to realize industrial production, difficult to control particle size, complicated process flow, etc., to shorten the process time and improve The effect of spheroidization and simplification of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

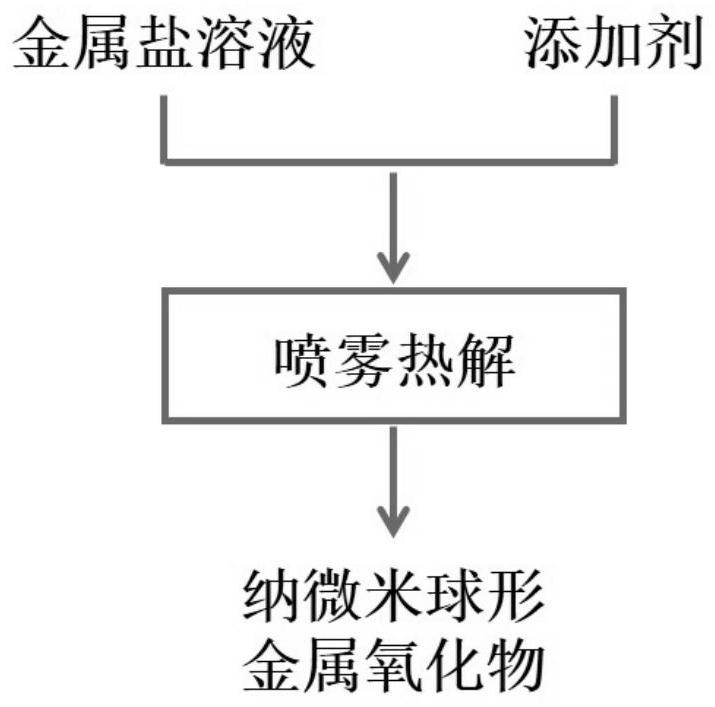

[0041] figure 1 A schematic flow chart of the method for preparing nano-micron spherical powder in the first embodiment of the present invention is schematically shown. Such as figure 1 As shown, the preparation method of a nano-micron spherical powder provided by the present invention may include: adding additives to the first solution to obtain a precursor solution, and the first solution is a metal salt solution or a plurality of metal salts A mixed solution formed from a solution; the precursor solution is sprayed and pyrolyzed to obtain a nano-micron spherical metal oxide through one-step continuous atomization and thermal decomposition. Wherein, the nano-micron spherical metal oxide is a single metal oxide powder or a composite powder of multiple metal oxides. In this embodiment, the particle size D of the nano-micron spherical metal oxide powder 50 =0.5-1.5μm, spheroidization>95%.

[0042] Further, when the prepared first solution is a mixed solution formed of multi...

Embodiment 11

[0067] First configure 1.5mol / l FeCl 3 solution, adding FeCl 3 The solute mass of the solution is 0.5wt% polyethylene glycol, and then the solution is atomized into fine droplets, which enter the pyrolysis furnace through the air carrier gas to react. The pyrolysis temperature is 700°C, and the carrier gas flow rate is 20L / min , and finally get the nanometer (D 50 =0.8 μm) spherical iron oxide powder. The scanning electron microscope (SEM) figure of this embodiment 11 is as follows Figure 6 As shown, it can be seen that the product obtained in this embodiment has good dispersion and uniformity, and the degree of spheroidization is very high.

Embodiment 12

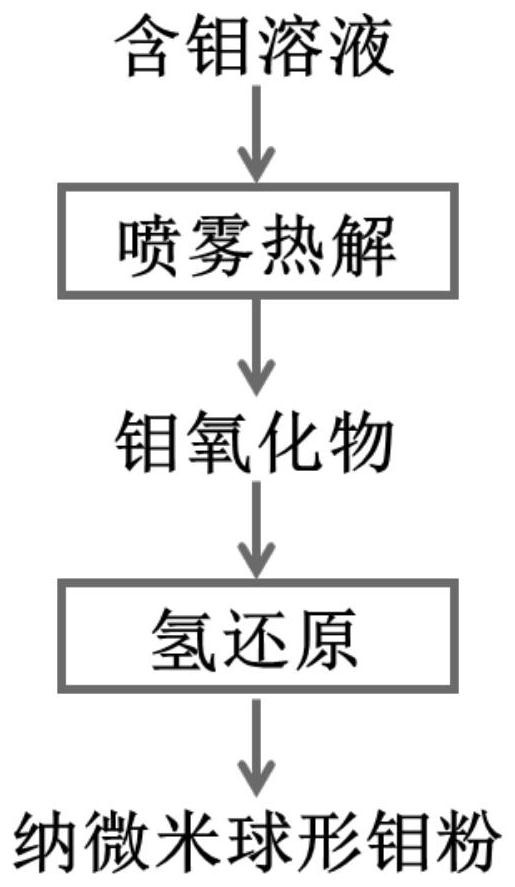

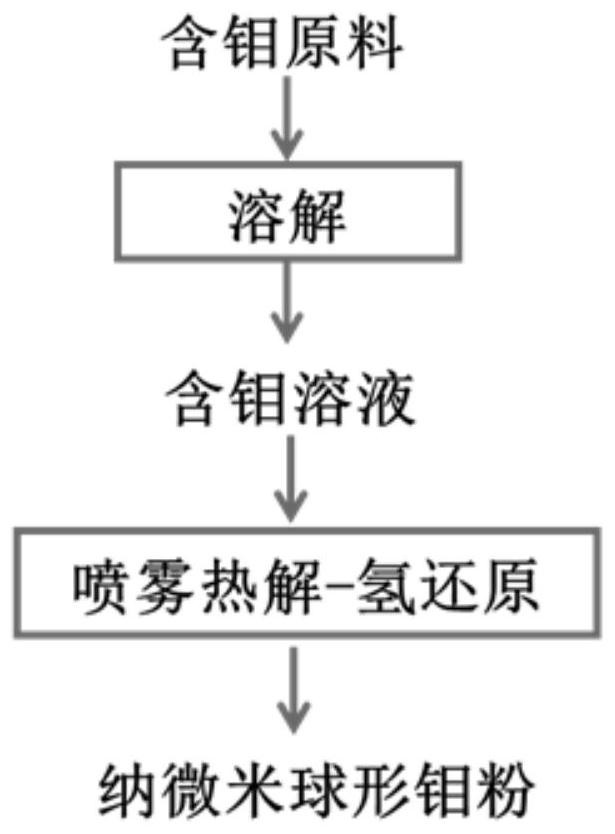

[0069] First configure 0.1mol / l (NH 4 ) 6 Mo 7 o 24 4H 2 O solution, add (NH 4 ) 6 Mo 7 o 24 4H 2 O solution solute mass of 2wt% ethylene glycol, then atomize the solution into fine droplets, enter the pyrolysis furnace through the nitrogen carrier gas to react, the pyrolysis temperature is 1400 °C, and the carrier gas flow rate is 50L / min, Finally, nanometers (D 50 =1 μm) spherical molybdenum oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com