Preparation method of nano dysprosium oxide for dielectric ceramic capacitor

A technology of nano-dysprosium oxide and dielectric ceramics, applied in the direction of rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve problems such as grinding, achieve easy dispersion, reasonable design, and promising application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

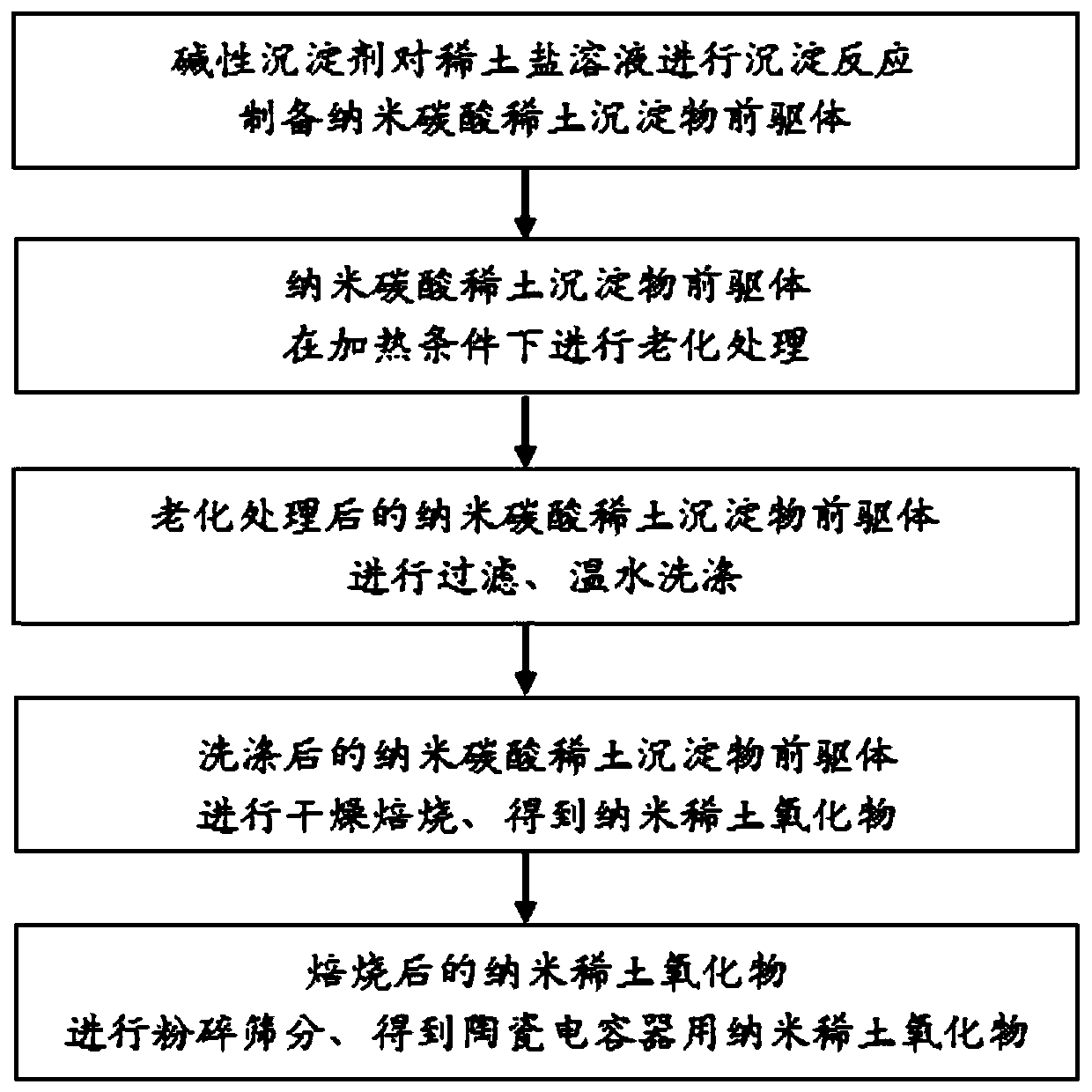

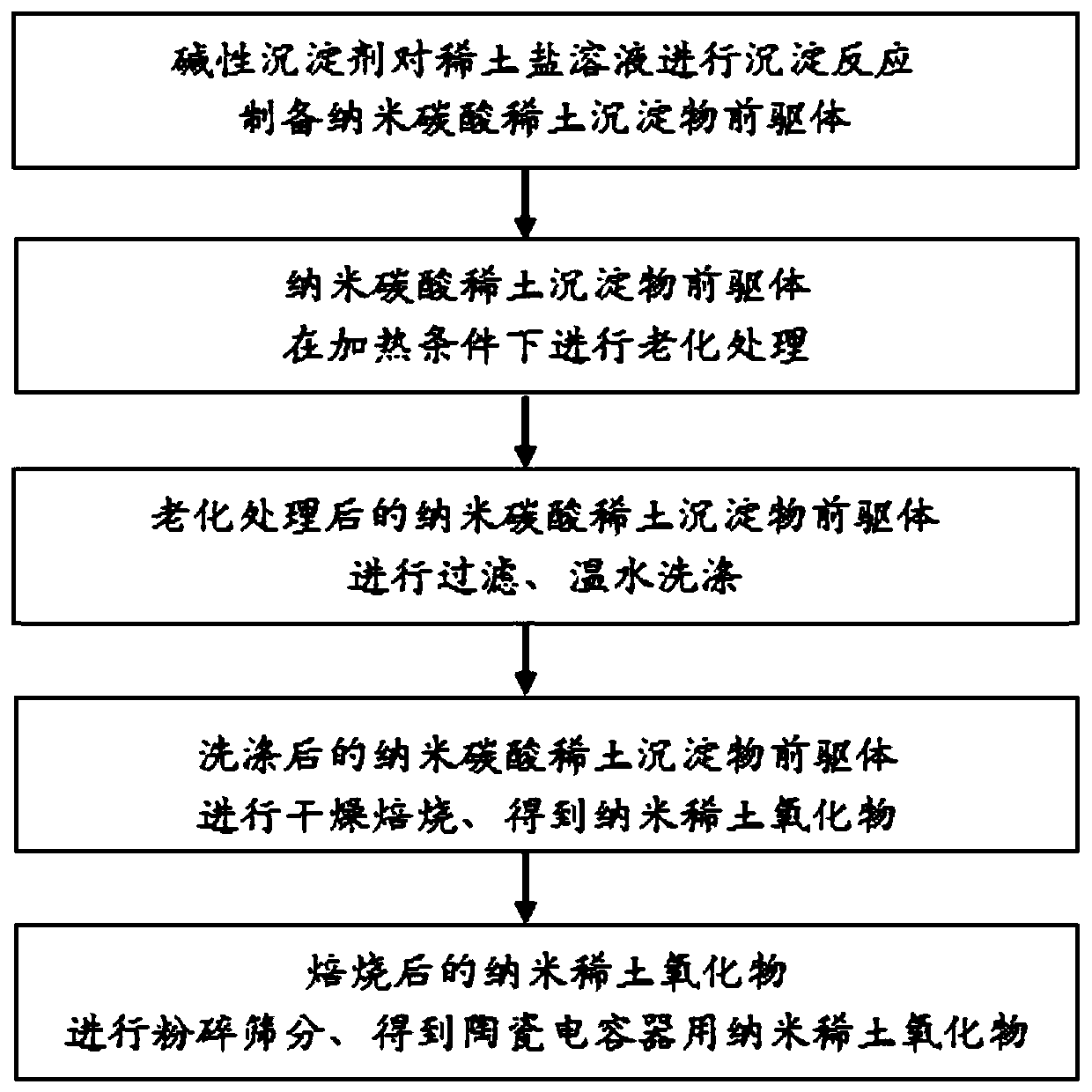

Method used

Image

Examples

Embodiment 1

[0026] In a 2L three-necked flask, add 0.5L of dysprosium chloride (DyCl 3 ) solution, its dysprosium oxide (Dy 2 o 3 ) conversion concentration is 50g / L, free acid concentration is 0.1mol / L, stirring and heating to 50°C;

[0027] Precipitating agent sodium carbonate (Na 2 CO 3 ) solution, its concentration is 0.5mol / L, is slowly added dropwise in the above-mentioned dysprosium chloride solution, and the dropwise addition time is 1h, and the final pH value of the solution after precipitation is controlled between 6.0-6.5;

[0028] After precipitation, carry out aging treatment, the aging temperature is 50°C, and the aging time is 1h;

[0029] After the aging treatment, the slurry is filtered and washed with warm water at 50-60°C until the conductivity of the filtrate is less than 1 μs / cm;

[0030] The washed filter cake was dried overnight at 110°C and then roasted at a temperature of 700°C for 5 hours;

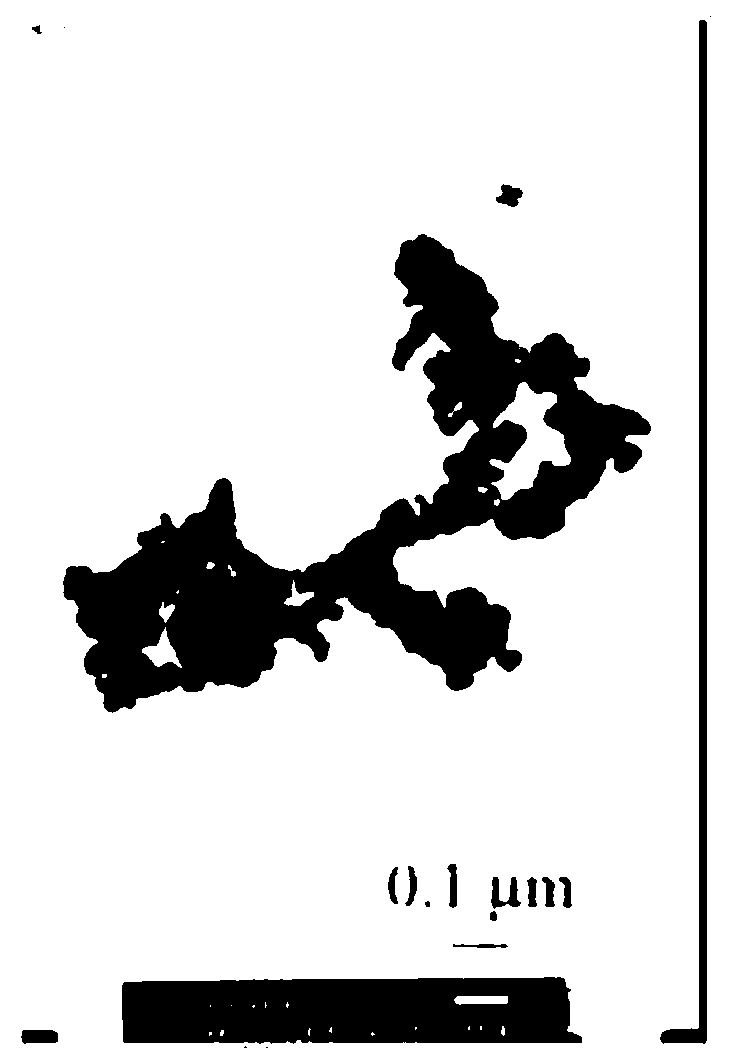

[0031] After roasting, the oxide product is crushed and sieved to ...

Embodiment 2

[0033] Carry out according to the preparation method described in embodiment 1, difference is to use dysprosium oxide (Dy 2 o 3 ) conversion concentration is 50g / L dysprosium sulfate (Dy 2 (SO 4 ) 3 ) solution as starting material for precipitation reaction.

Embodiment 3

[0035] Carry out according to the preparation method described in embodiment 1, difference is to use dysprosium oxide (Dy 2 o 3 ) conversion concentration of dysprosium nitrate (Dy(NO 3 ) 3 ) solution as starting material for precipitation reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com