Asphalt softening microwave heating box

A microwave heating and asphalt technology, applied in microwave heating, tar asphalt/petroleum asphalt/natural asphalt processing, electric/magnetic/electromagnetic heating, etc. High degree of automation, improved heating efficiency, fully and evenly heated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

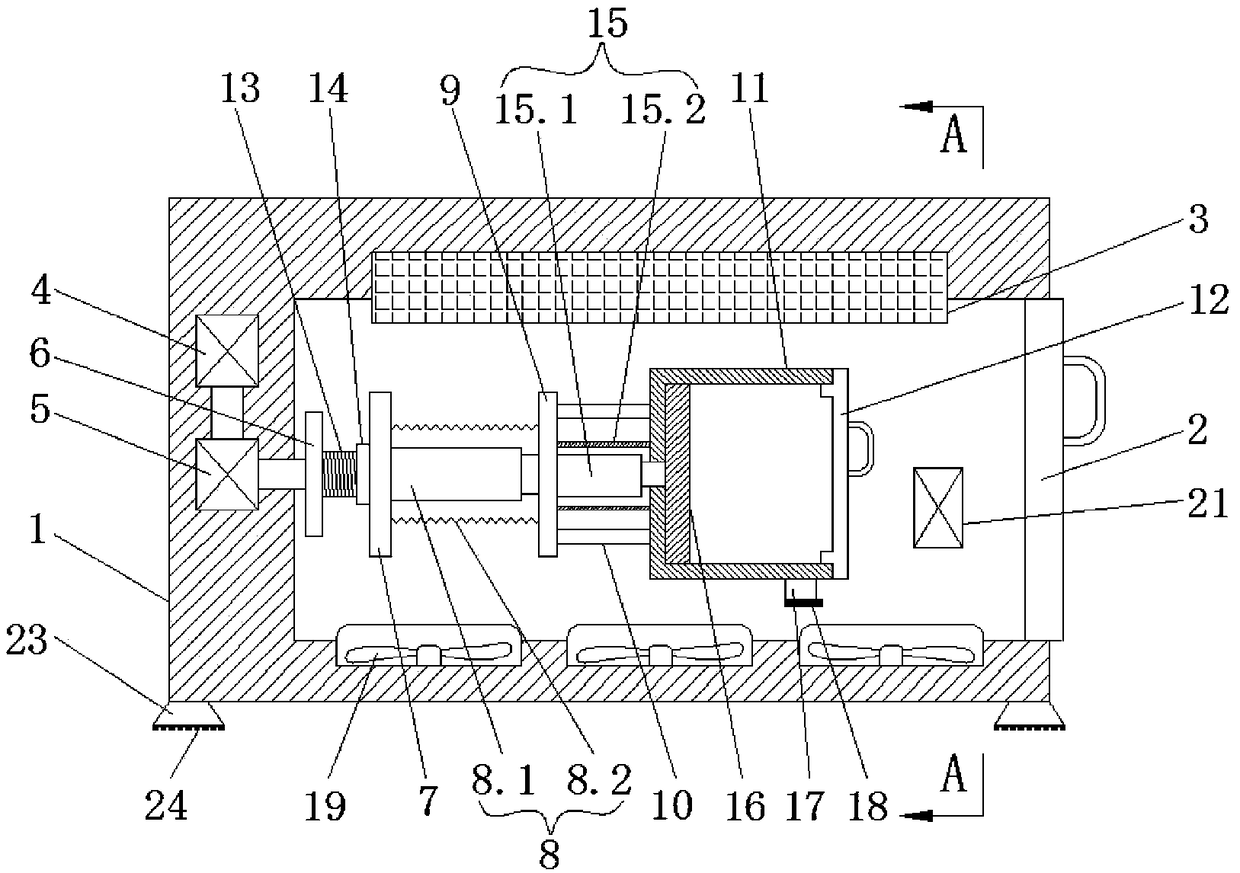

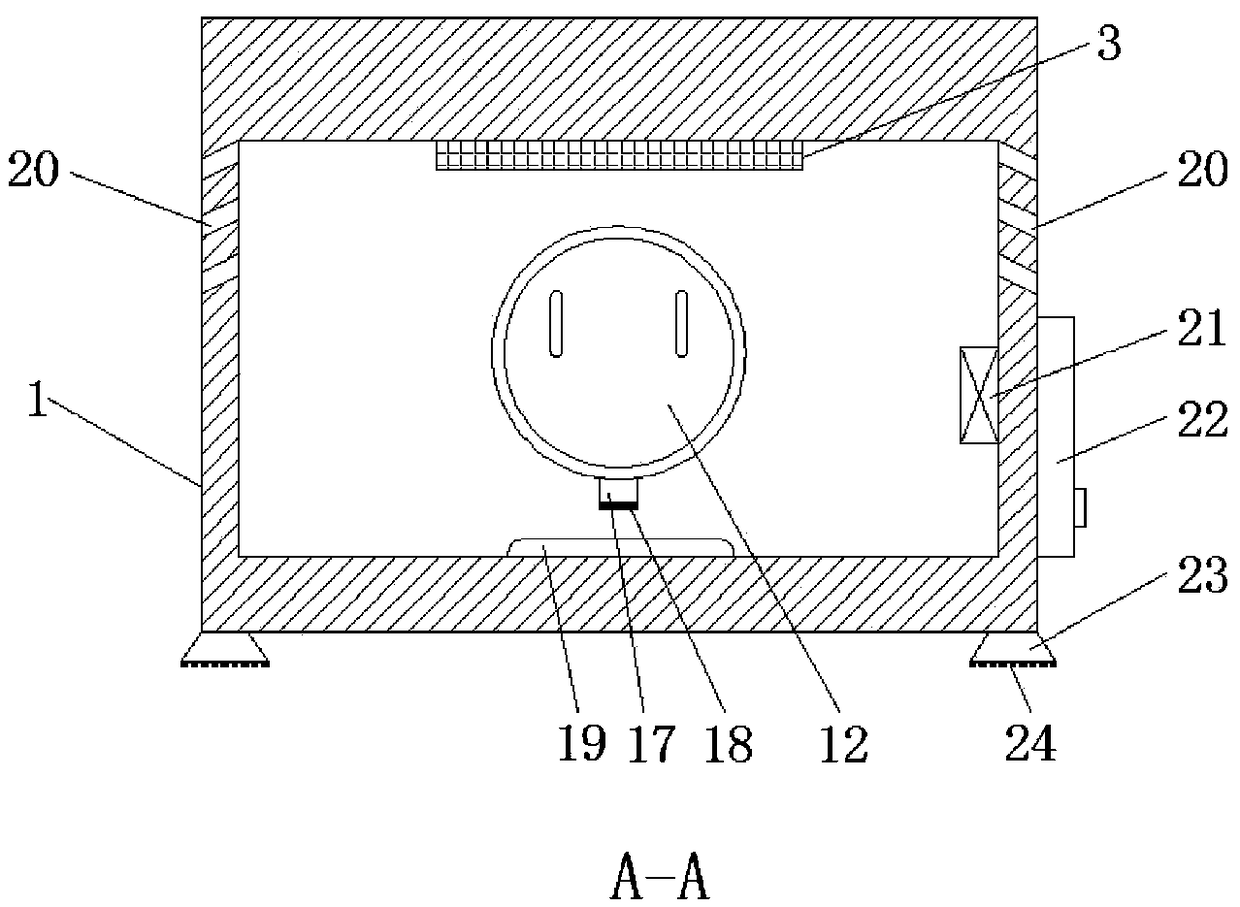

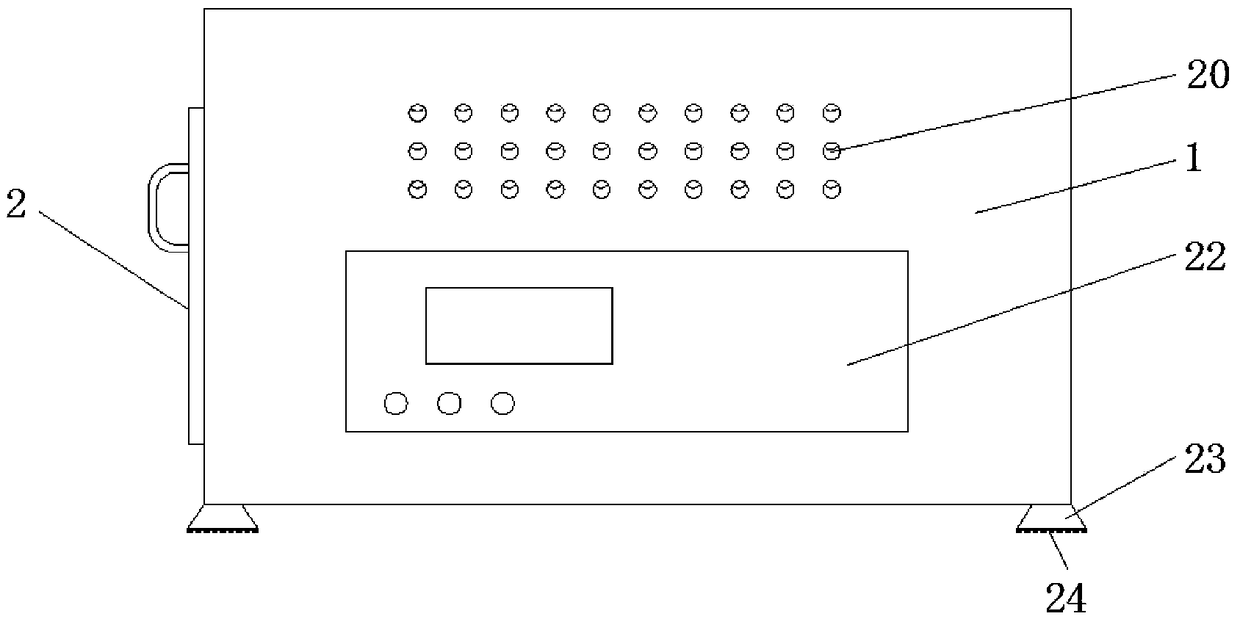

[0030] Such as Figures 1 to 4 As shown, this embodiment provides an asphalt softening microwave heating box, which includes a box body 1, a box door 2 is hinged at the side end of the box body 1, a heating device 3 is arranged on the top of the box body 1, and the box body 1 is located in the box door. 2 The opposite inner wall is provided with a driving motor 4, the driving motor 4 is connected to a reducer 5, the output shaft of the reducer 5 is connected to a rotating disc 6 located in the box body 1, and the rotating disc 6 is detachably connected to a first mounting plate 7. The first mounting plate 7 is connected to the first telescopic mechanism 8, the first telescopic mechanism 8 is connected to the second mounting plate 9, and the second mounting plate 9 is connected to a heating cylinder 11 for holding asphalt through several connecting rods 10, A side end of the heating cylinder 11 near the box door 2 is hinged with an end cover 12 .

[0031] In this embodiment, w...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a threaded rod 13 is provided at the center of the rotating disk 6, and a belt that cooperates with the threaded rod 13 is provided at the center of the first mounting plate 7. Internally threaded sleeve 14 is arranged.

[0034] In this embodiment, the sleeve on the first mounting plate is removed from the threaded rod, and all the mechanisms connected to the first mounting plate can be taken out of the box, which is convenient for cleaning the heating cylinder and will be used for the next time. Prepare for use.

Embodiment 3

[0036] Such as Figures 1 to 4 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the first telescopic mechanism 8 includes a hydraulic telescopic cylinder A8.1 arranged on the first mounting plate 7, and a hydraulic telescopic cylinder A8.1 The piston rod is connected to the second mounting plate 9, the hydraulic telescopic cylinder A8.1 is covered with a high temperature resistant telescopic bellows 8.2, and the telescopic bellows 8.2 is connected between the first mounting plate 7 and the second mounting plate 9, the second The second telescopic mechanism 15 is arranged on the second mounting plate 9, and the second telescopic mechanism 15 includes the hydraulic telescopic cylinder B15.1 arranged on the second mounting plate 9, and the hydraulic telescopic cylinder B15.1 is provided with a high temperature resistant protective tube 15.2, the protective tube 15.2 is connected between the second mounting plate 9 and the heating cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com