Energy-saving and high-yielding rock wool production line

A production line and rock wool technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as unreasonable structure, high cost of rock wool production, low cotton output efficiency, etc., achieve uniform and sufficient heating, improve curing effect, and produce The effect that the cotton efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

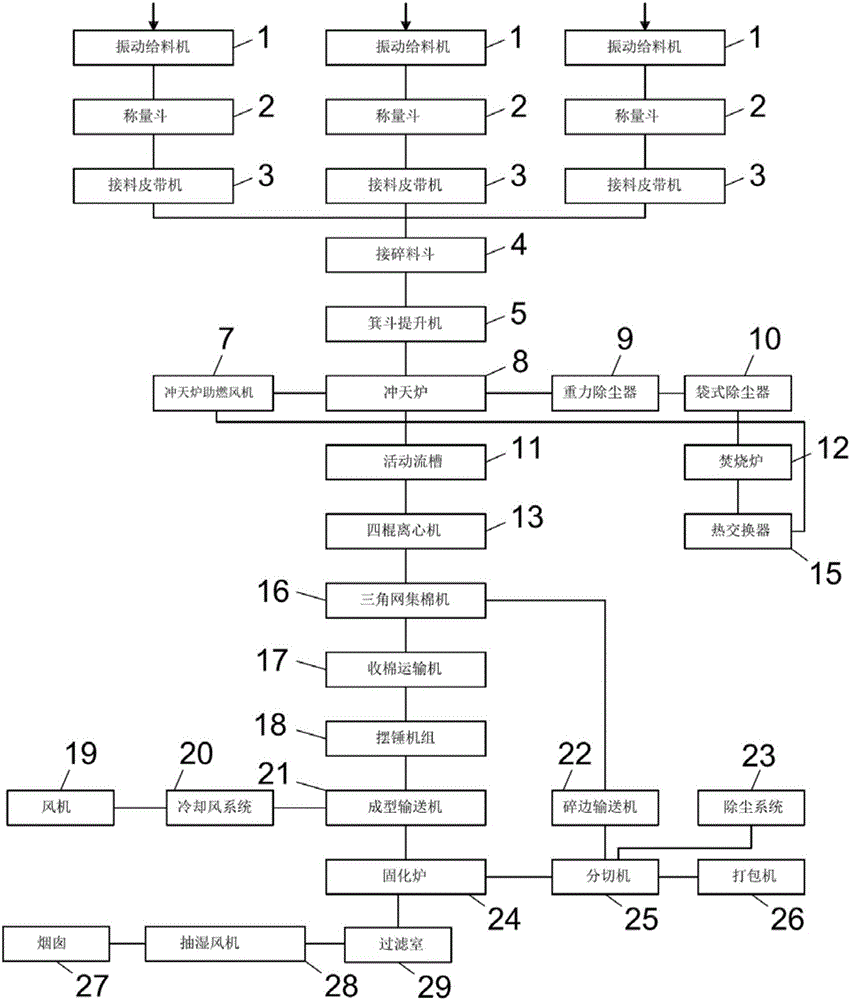

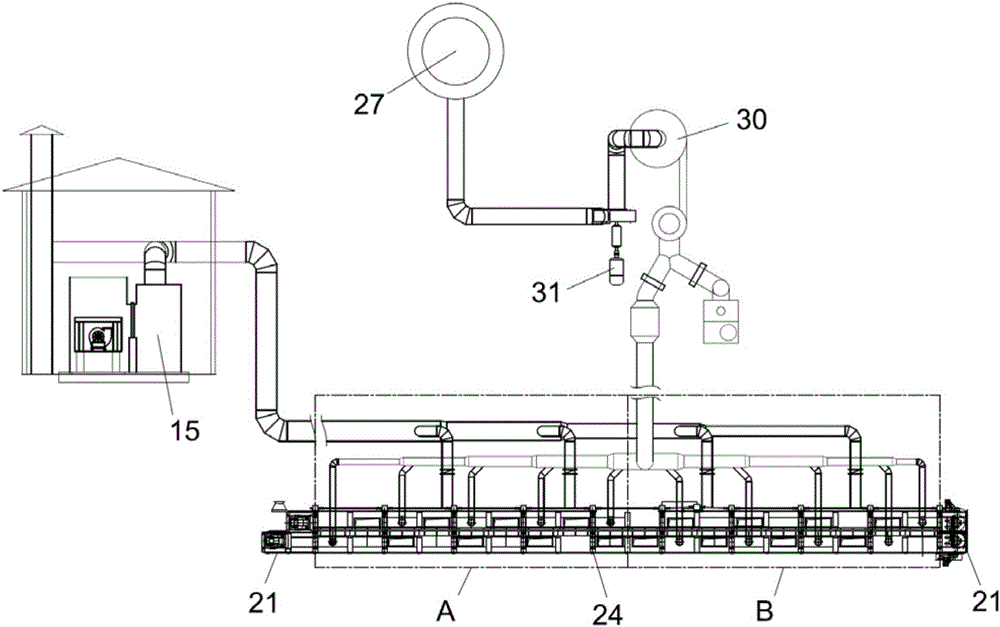

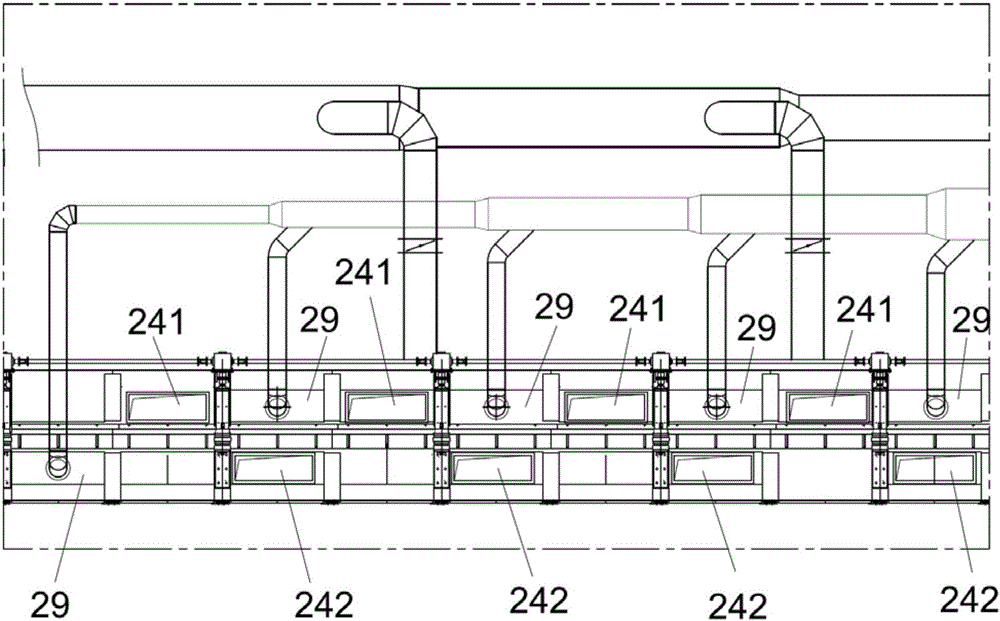

[0022] refer to figure 1 , figure 2 , an energy-saving and high-yield rock wool production line of the present invention includes a feeding mechanism, a crushing hopper 4, a cupola 8, a four-roll centrifuge 13, a triangular net cotton collector 16, a pendulum unit 18, a curing furnace 24, a Cutting mechanism 25 and packing machine 26.

[0023] The feeding mechanism is provided with at least three groups, including a vibrating feeder 1, a weighing hopper 2 and a material receiving belt conveyor 3. The material receiving belt conveyor 3 of each group of feeding mechanism is respectively connected to the crushing hopper 4, and the crushing hopper 4 Between the cupola 8 and the cupola 8 there is a skip hoist 5 for transferring the crushed material in the crushing hopper 4 to the cupola 8 . Each group of feeding mechanism undertakes different raw materials, including coke, basalt, dolomite and slag, etc., and sends different raw materials into the vibrating feeder 1, and the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com