Patents

Literature

82results about How to "Realize continuous industrial production" patented technology

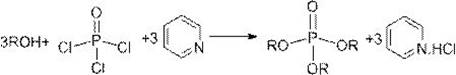

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

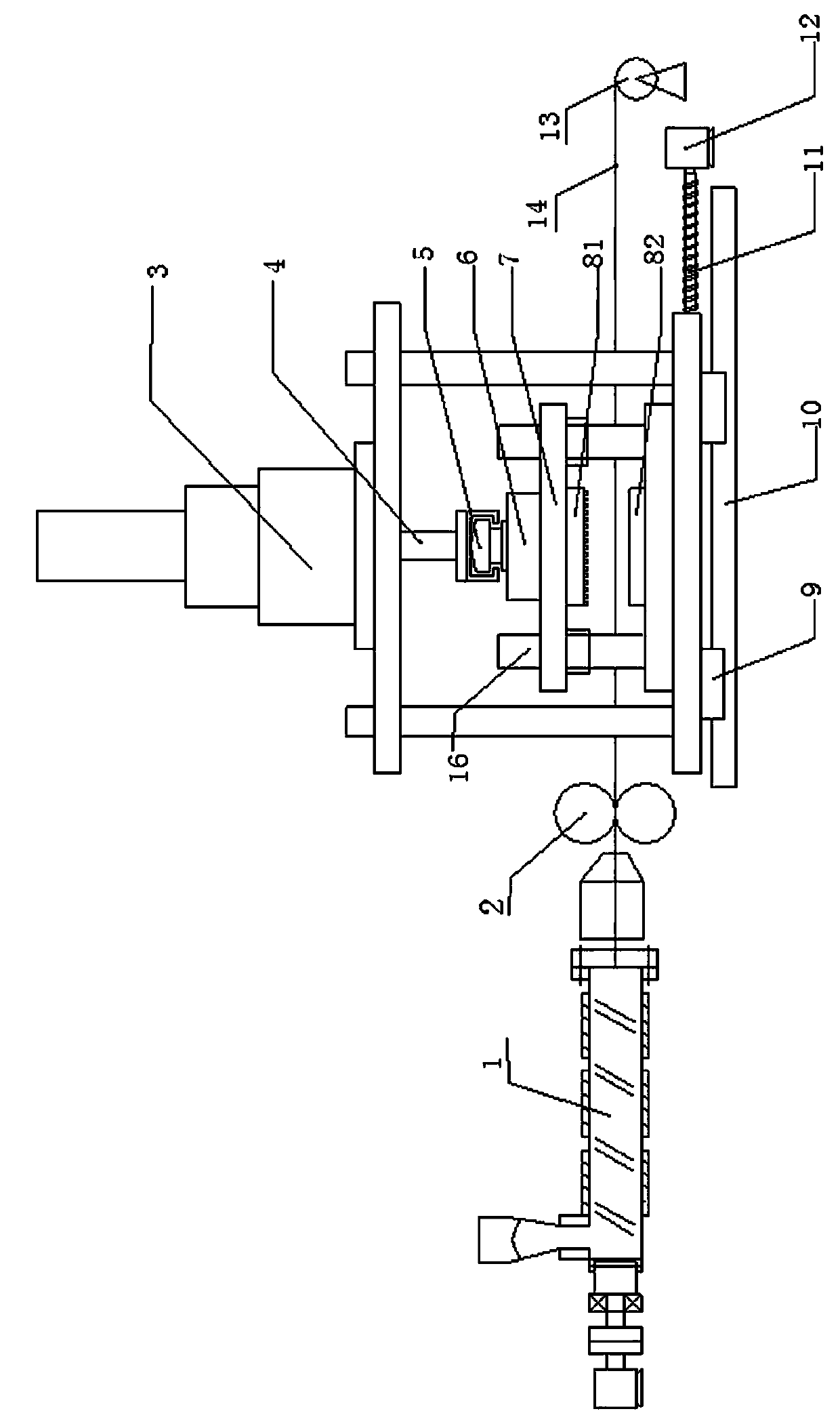

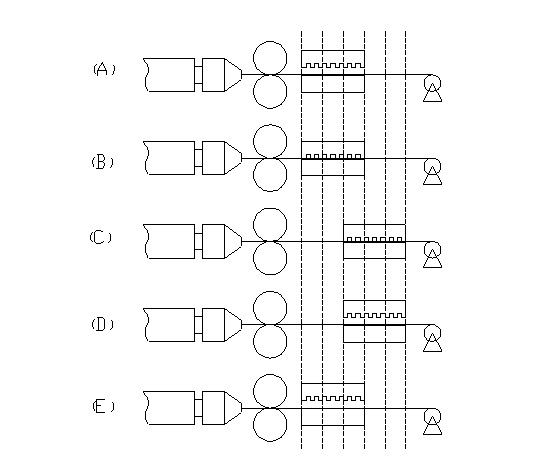

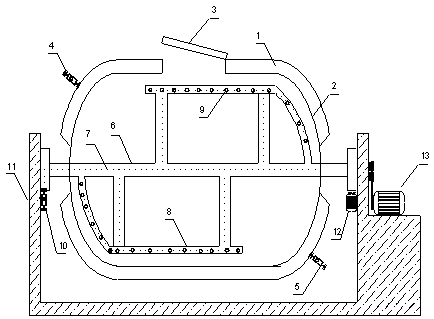

Pressing device and method of polymer microstructure

ActiveCN103624992AAvoid stress deformationGuaranteed flatness and heat uniformityPolymeric surfacePolymer substrate

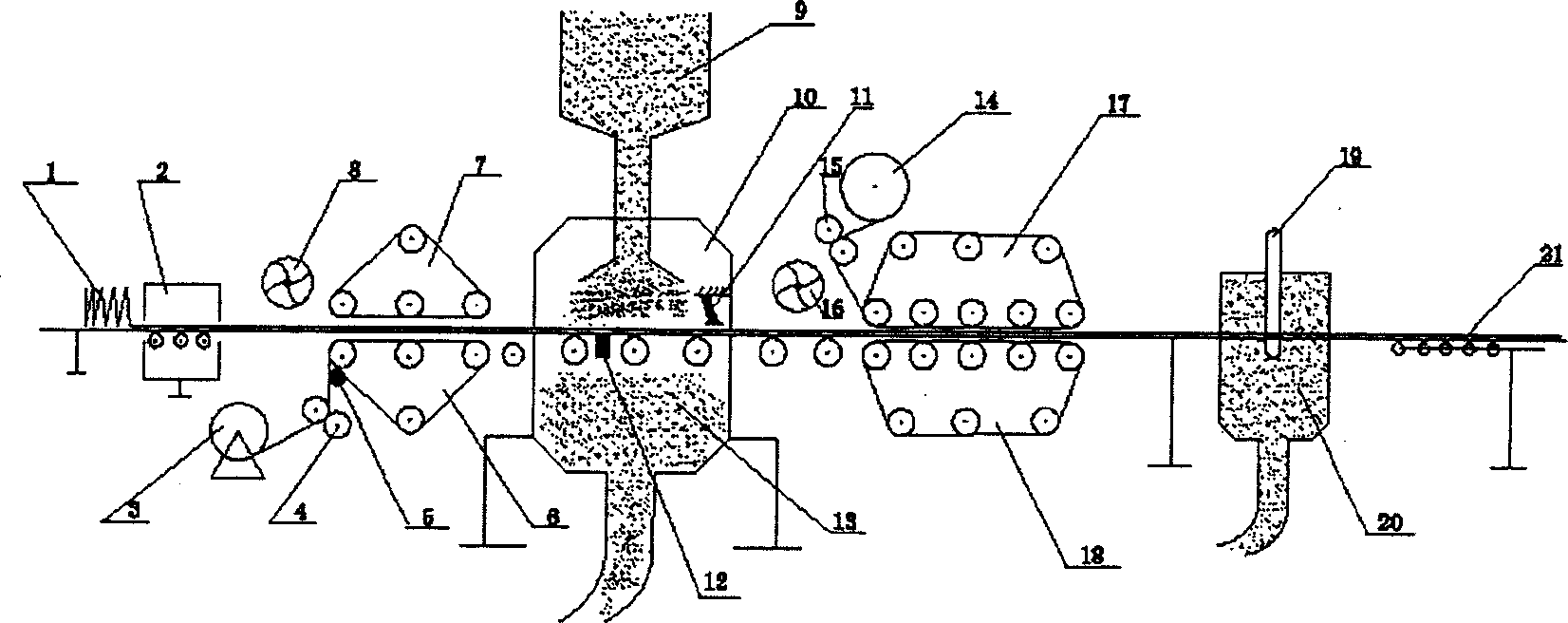

The invention discloses a pressing device and a pressing method of a polymer microstructure. The pressing device comprises a sheet extrusion machine, a compression roller device capable of leveling and regulating thickness, and a mold press. The pressing method comprises the steps of directly entering slab pressing equipment after a polymer substrate is extruded from the extrusion machine; flattening the polymer substrate through rolling of two rollers and shaping preliminarily, carrying out rapid heating treatment on the surface of the polymer, and enabling the polymer substrate to enter a slab pressing mold when the temperature of the surface of the polymer substrate is higher than a glassy state or a melting point to press the microstructure. According to the pressing device and the pressing method, the microstructure slab pressing equipment is connected with the extrusion machine in series, so that abundant energy is saved, and the production efficiency is improved, meanwhile, with the slab pressing technology for preparing the polymer microstructure, enough pressure-maintaining cooling and shaping time, accurate cooling temperature and high geometric replication rate can be ensured and continuous large-scale high-efficiency industrial production for slab pressing can be realized.

Owner:BEIJING UNIV OF CHEM TECH

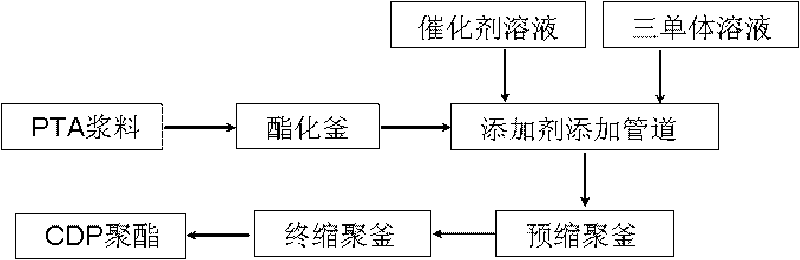

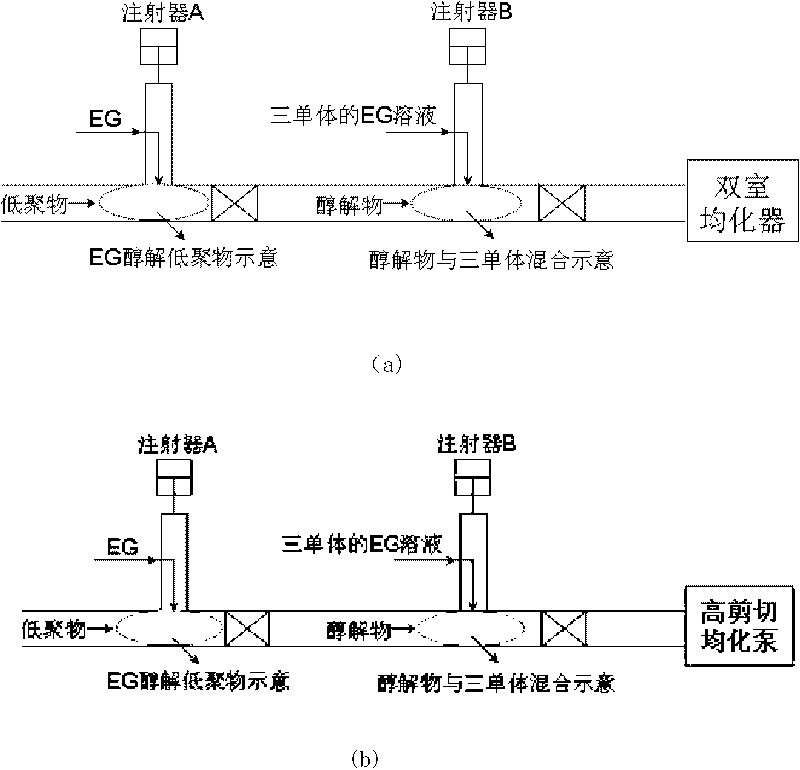

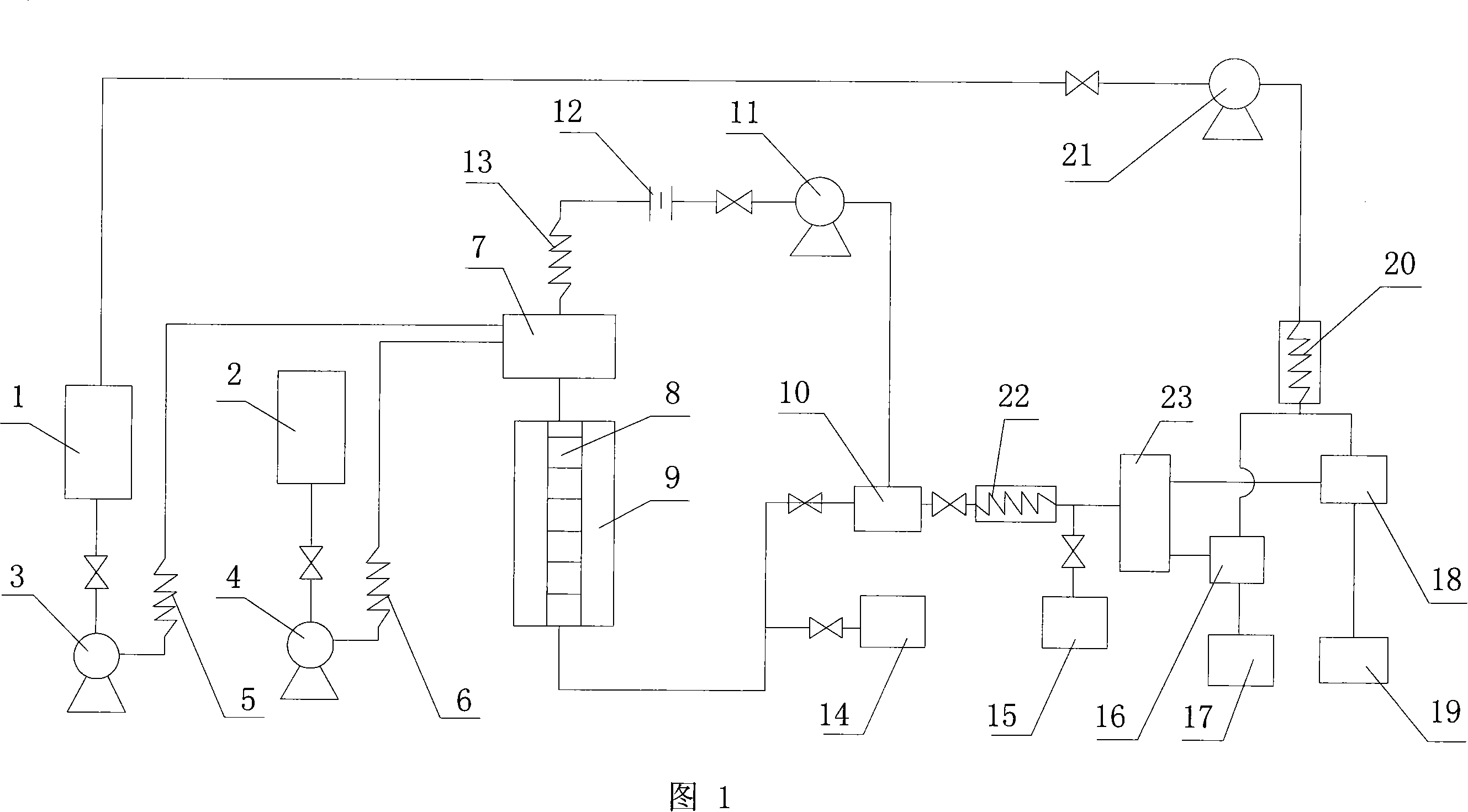

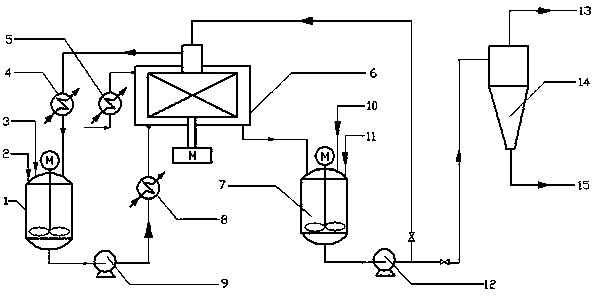

Method for continuously preparing modified polyester

ActiveCN101735430AEvenly dispersedExtended stayMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentPolymer scienceEsterification reaction

The invention relates to a method for continuously preparing modified polyester, comprising the following steps: conveying PET AND EG to an esterification autoclave from a feed port for esterification reaction, so as to obtain terephthalic acid ethylene glycol low polymer; then inputting the low polymer melt to a polycondensation autoclave through a pipeline for polymerization reaction with SIPM or multi-simplexes and addition agent, thus obtaining modified polyester melt and then carrying out granulation or direct spinning; wherein the two ends of the pipeline are respectively connected with the esterification autoclave and the polycondensation autoclave, when the low polymer melt flows through the pipeline, ethylene glycol solution of the SIPM or multi-simplexes and addition agent are added to the pipeline and mixed evenly with the low polymer melt in the pipeline, meanwhile the later-stage esterification reaction is carried out, and the mixture enters the polycondensation autoclave for polymerization reaction. With the method of the invention adopted, continuous industrialized production is realized, production cost is greatly reduced; in addition the SIPM or multi-simplexes with special groups are evenly distributed on the backbone of the polyester, as a result, high quality modified polyester products can be obtained for sure in the later stage.

Owner:SHANGHAI JUYOU CHEM ENG

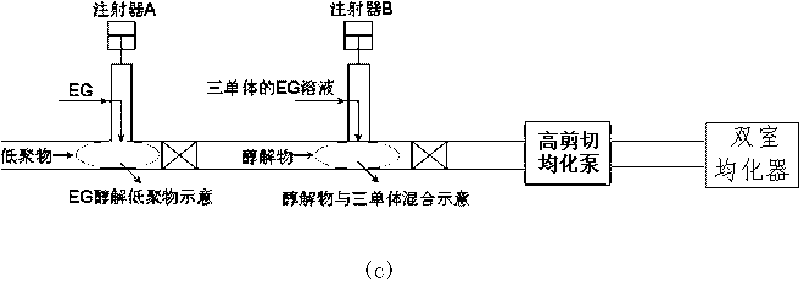

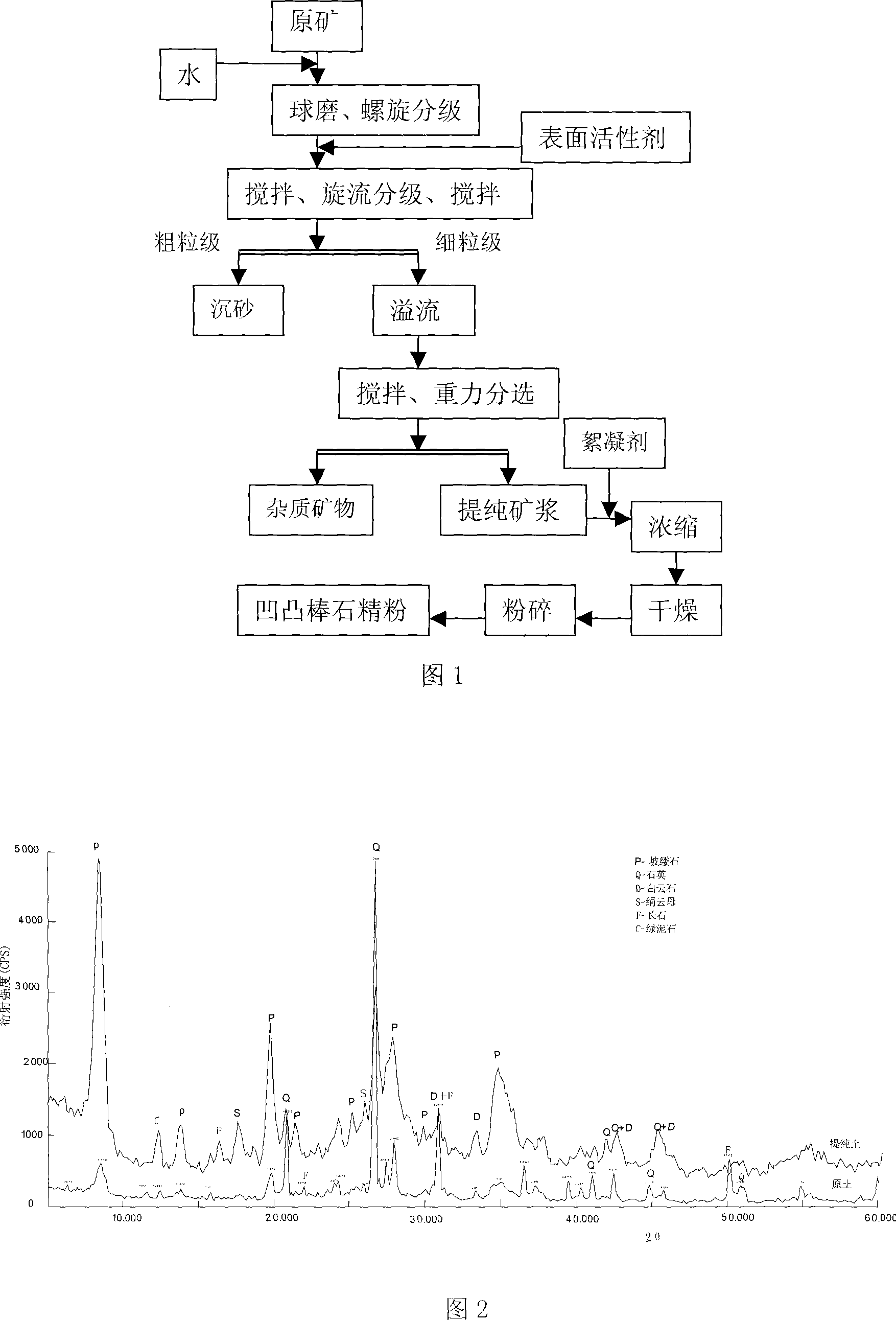

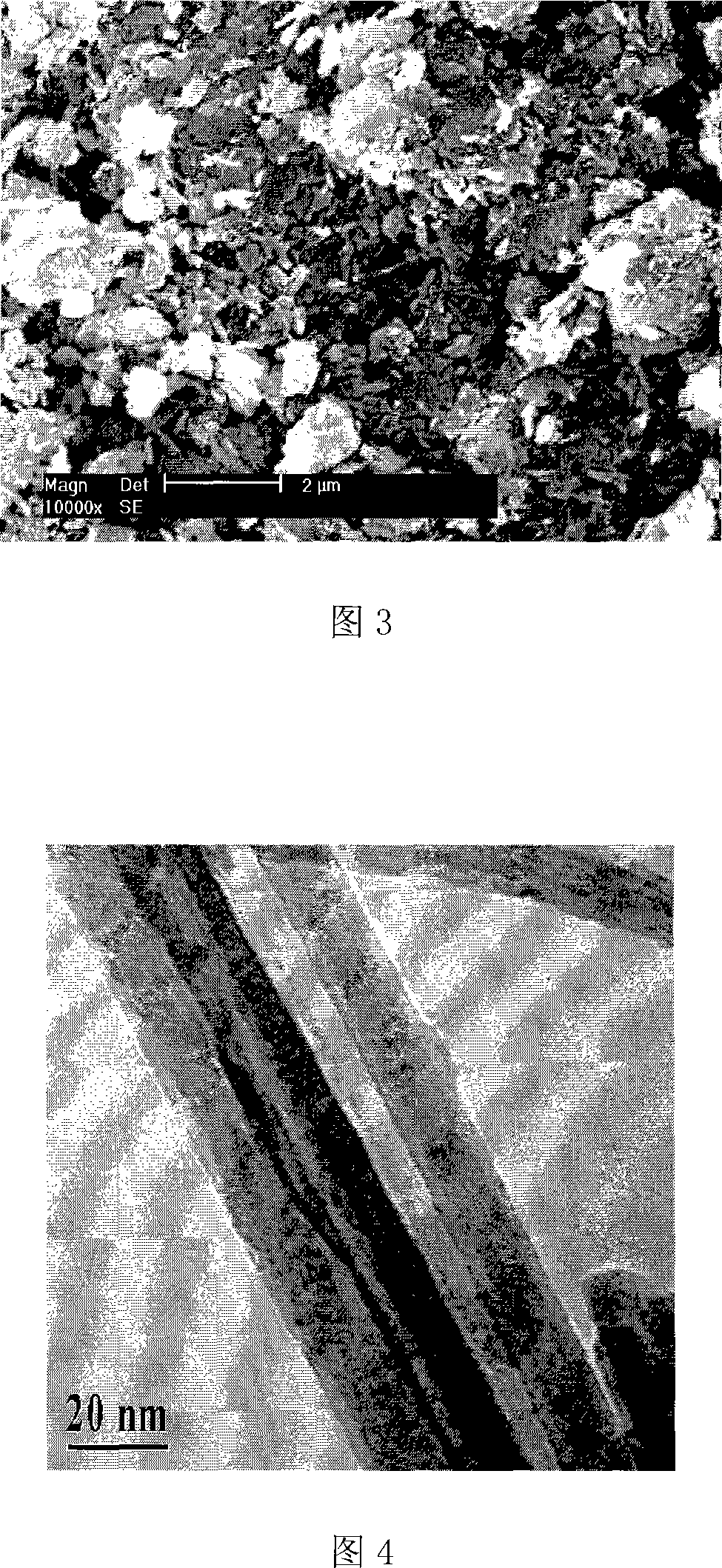

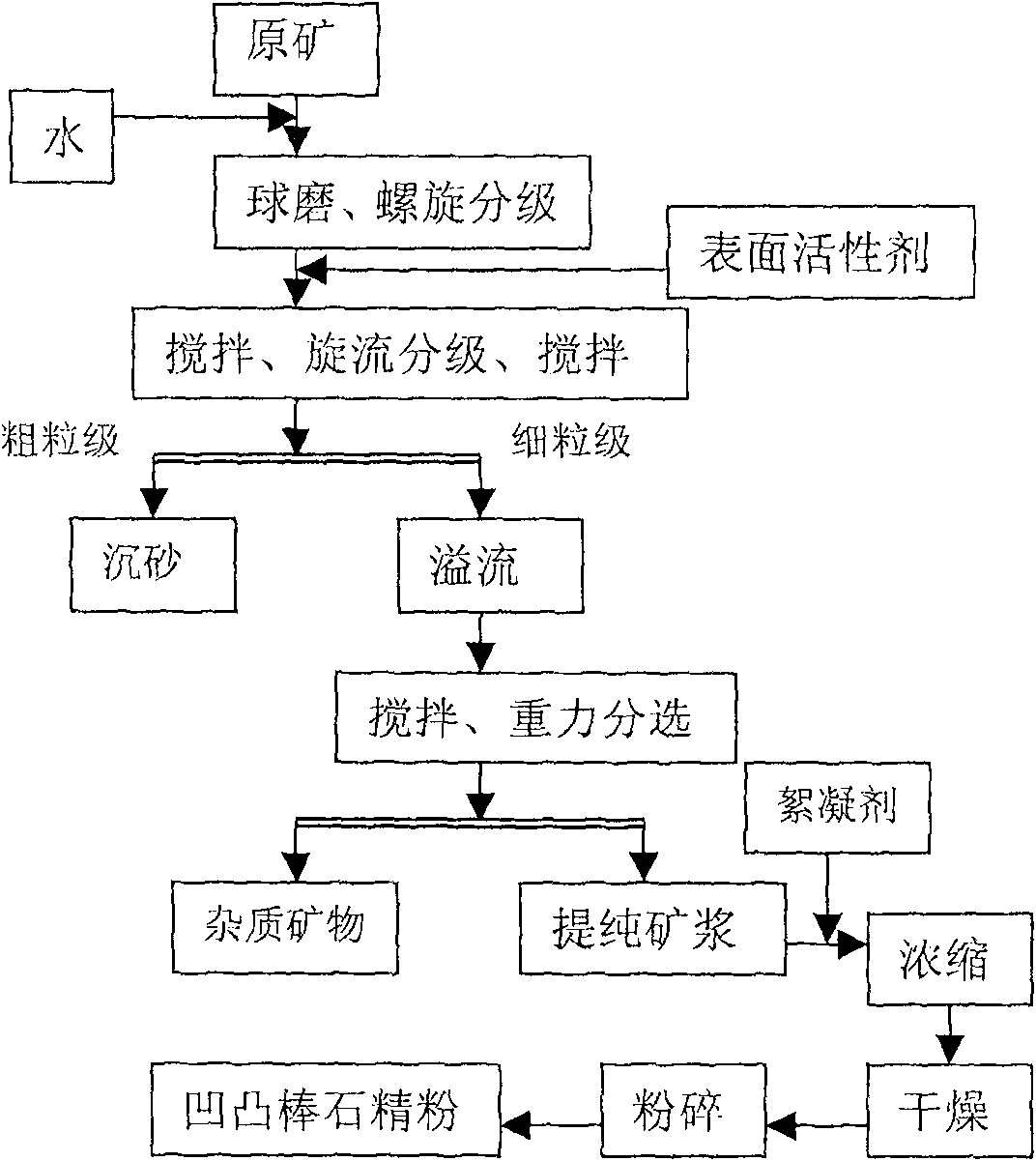

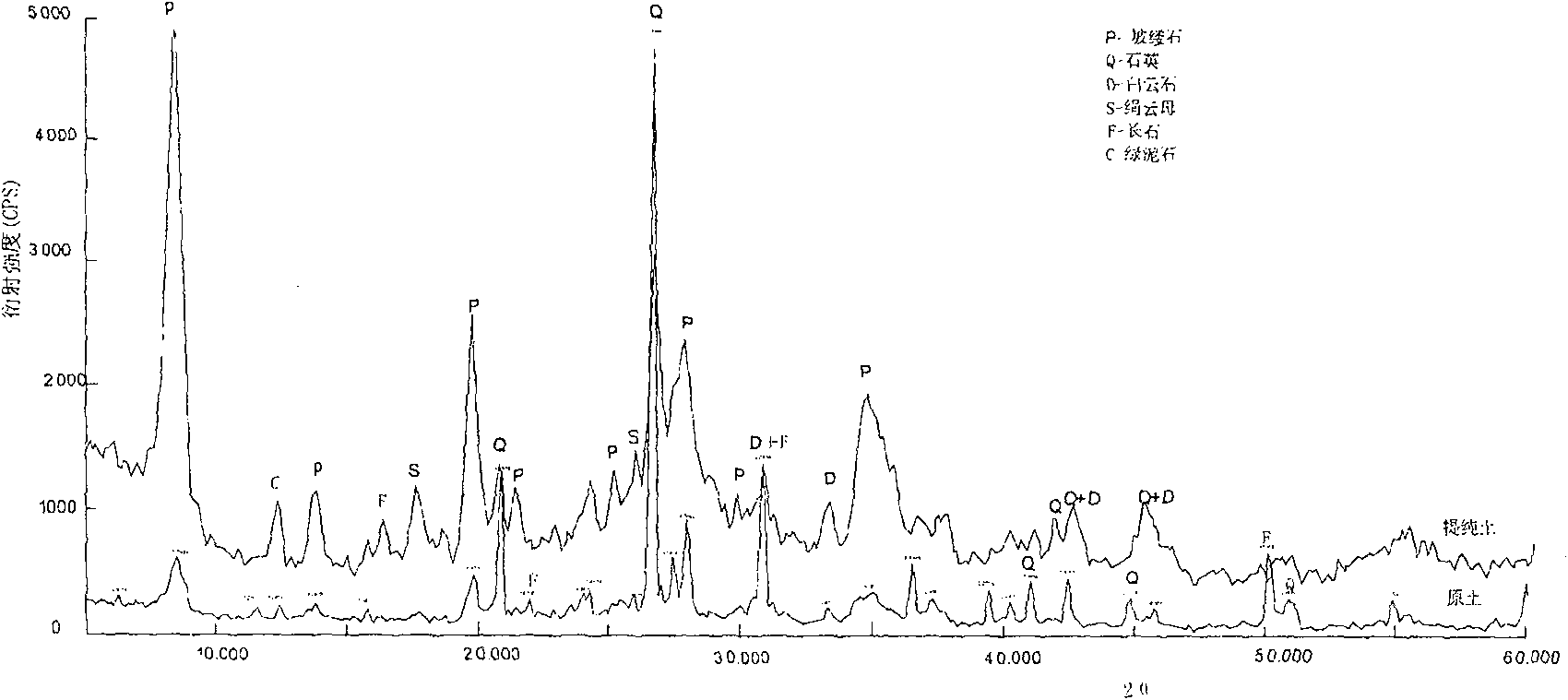

Method for purifying and processing attapulgite clay mineral

InactiveCN101214968AMeet the needs of industrial mineral processing and purificationEase of industrial productionEnergy inputSilicon compoundsSeparation factorClay minerals

The invention relates to a purifying and processing method of attapulgite clay minerals, which belongs to the technical field of the wet separating technique of minerals. The specific steps comprise utilizing spiral classifier for primary purification, utilizing cyclone classifier for secondary purification, employing gravity separation equipment for three-stage purification, concentration, drying and disintegration, thereby preparing ultrafine powders of the purified attapulgite clay minerals with the average particle size of 0.93-2.0 micron, and particle size of the largest particle is 3.5-5.0 micron. The method employs spiral classifier to remove the partly impure minerals with bigger particles in raw ores in advance, reinforcing the dispersion effect and the difference of suspension property of the attapulgites and impure minerals by means of surfactants, increasing separation factor, utilizing gravity separation equipment to separate the impure minerals and the attapulgite clay minerals efficiently, thereby overcoming the shortcomings that the prior art is difficult to achieve industrial production and obtain qualified purification products.

Owner:HEBEI UNIV OF TECH

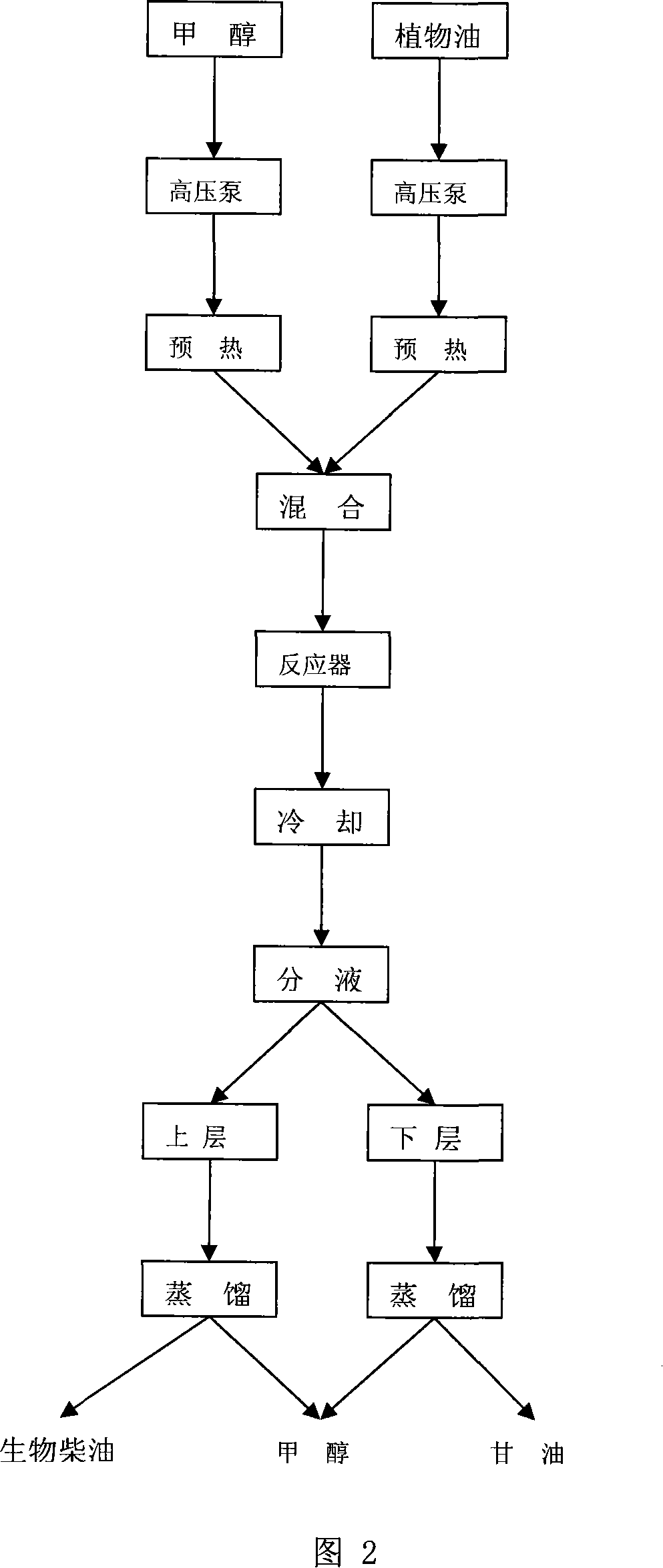

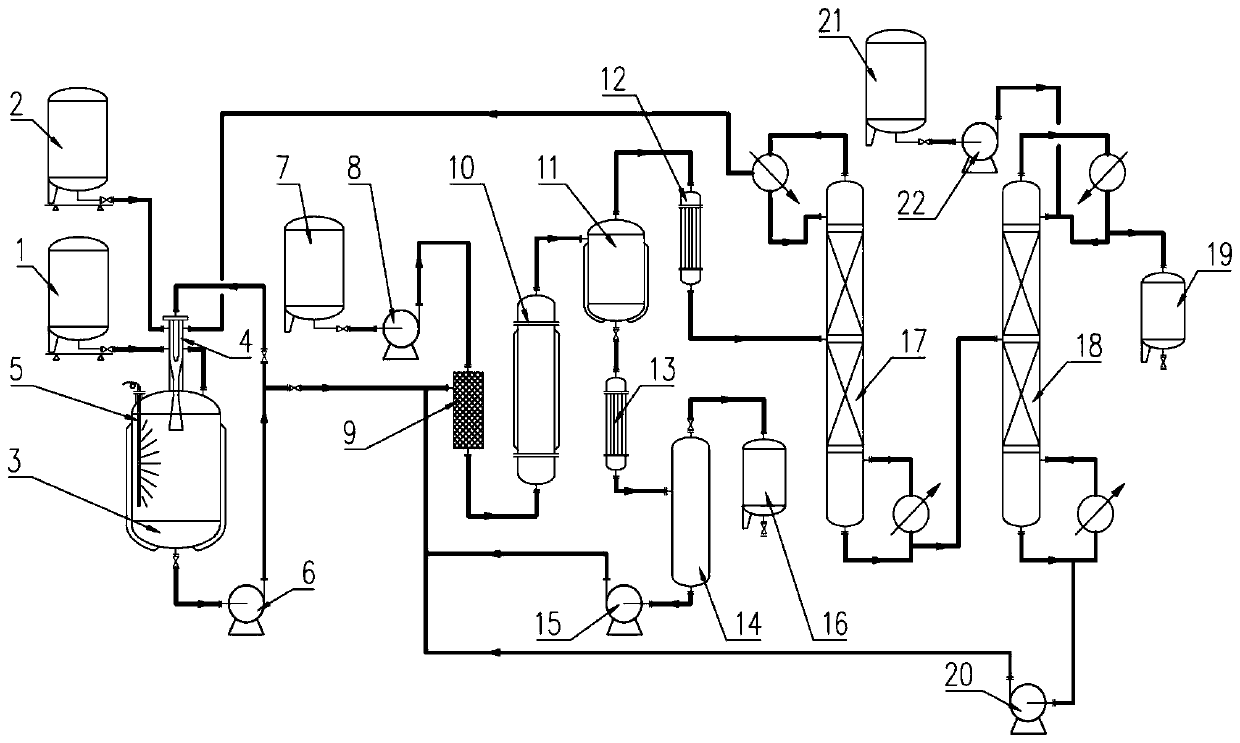

Technique for hypercritical continuous preparation of biological diesel oil and equipment thereof

InactiveCN101104812AFewer separation stepsReduce processBiofuelsLiquid hydrocarbon mixture productionVegetable oilBiodiesel

The invention relates to preparation technology for bio-diesel and the producing equipments. The technology for supercritical continuously producing of bio-diesel comprises the following steps: preparing a reserve of methanol and vegetable oil in a mole ratio of 30-50 to one; mixing methanol with vegetable oil in a mixer after preheating the methanol and vegetable oil at a constant temperature respectively of 200DEG C and 250 DEG C which are pumped by high pressure pump into two independent preheaters; sending the fully-mixed methanol and vegetable oil into the tubular reactor at a temperature of 300-350 DEG C, a pressure of 18-20MPa and letting the reaction last for eight to ten minutes; 4.putting the reaction products into a preliminary separator after a complete reaction, wherein the methanol is separated for recycling use and the head product is decompressed and cooled; taking the cooled substance out and keeping the cooled substance still for separation; distilling the upper and lower layers respectively, wherein the bio-diesel is obtained by steaming the methanol out of the upper layer and the by-product of glycerol is obtained by steaming out methanol out of the lower layer; putting the steamed methanol into a tank for recycling use. The invention is characterized by simple technology, environment protection, rapid preparation and high yield.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

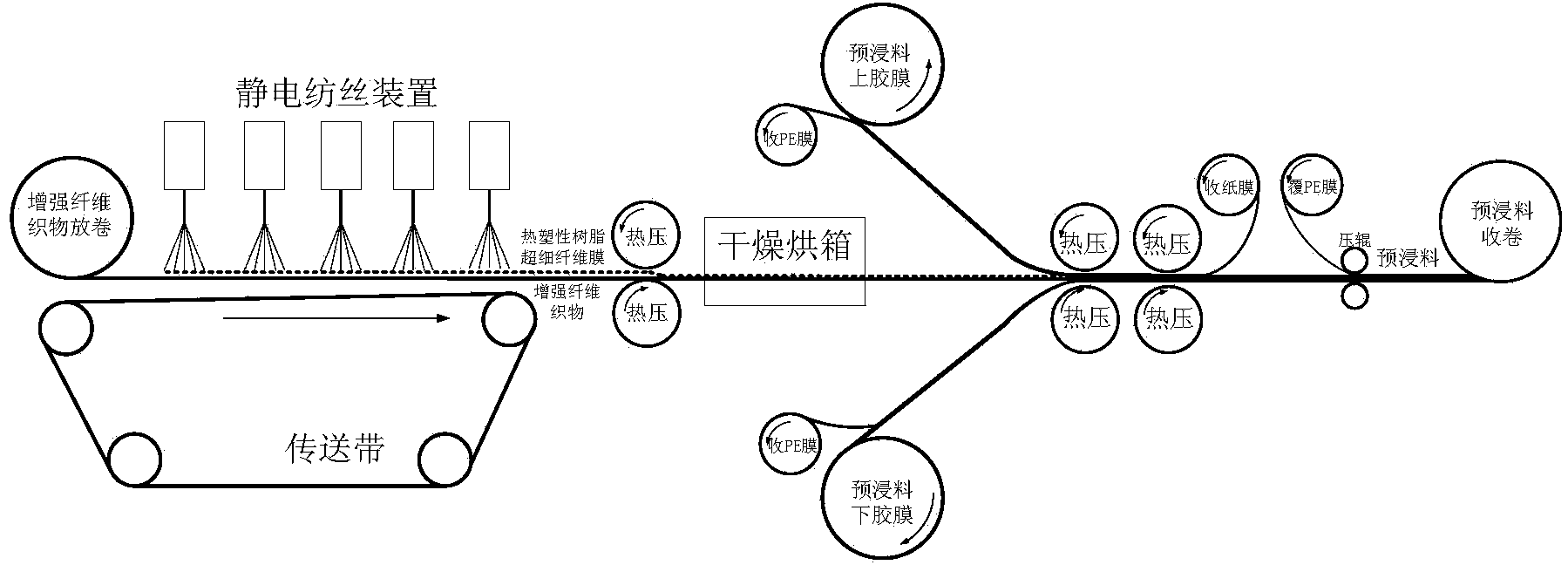

Preparation method of ultrafine fibrous membrane-toughened prepreg of thermoplastic resin

ActiveCN103552331ARedistribution has little effectDoes not affect stickinessSynthetic resin layered productsLaminationFiberPolymer science

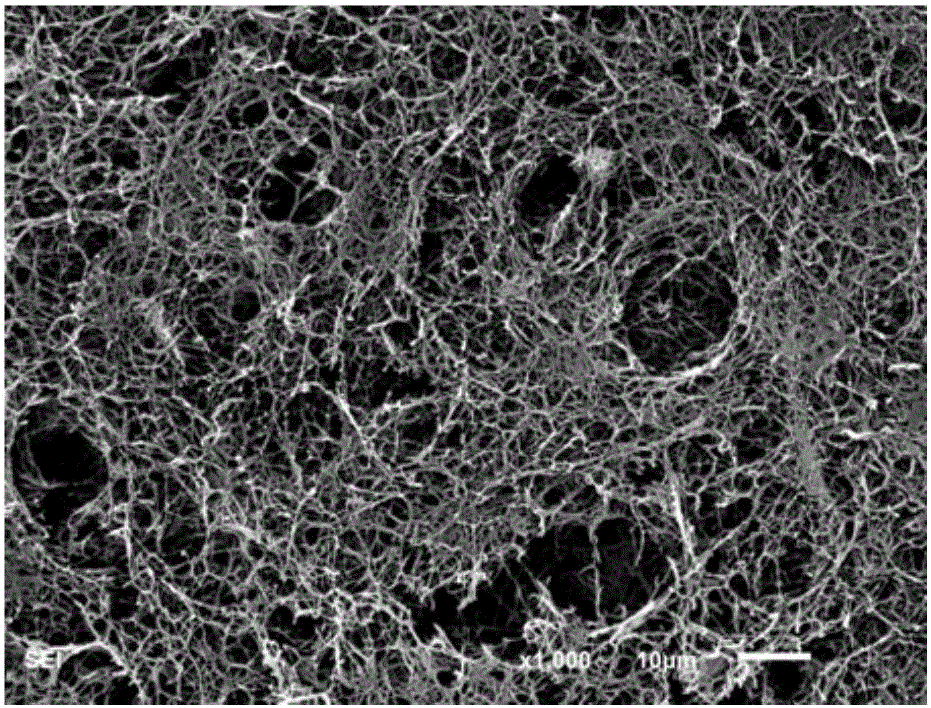

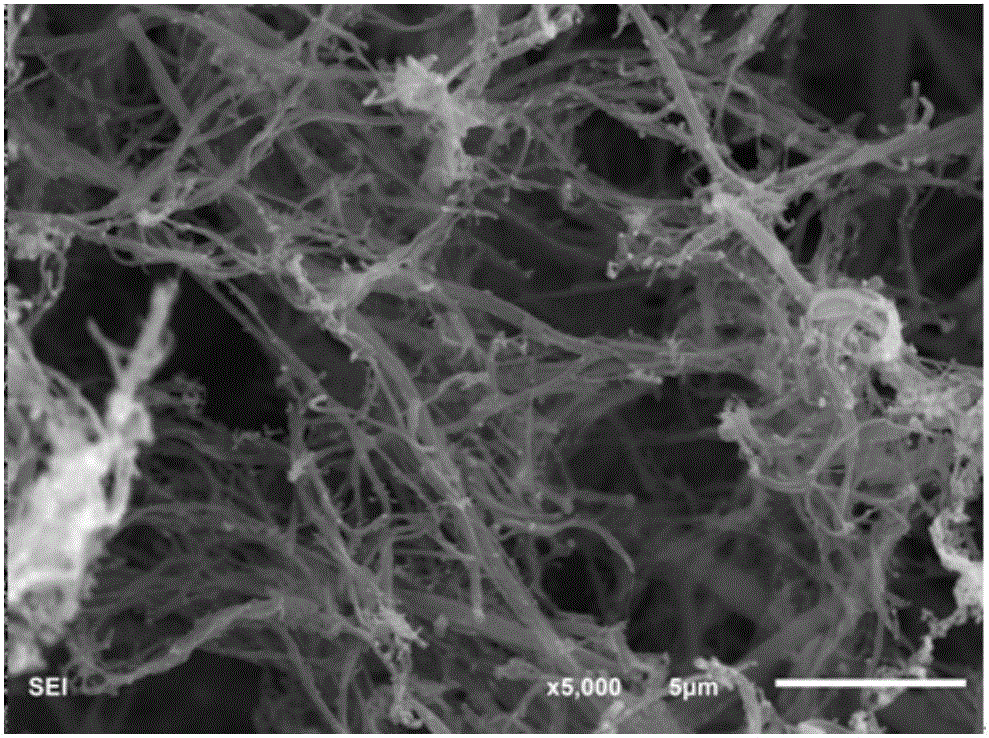

The invention belongs to the field of preparation of composite materials, and relates to a preparation method of ultrafine fibrous membrane-toughened prepreg of thermoplastic resin with a toughening function. The method comprises the following steps: electrostatically spinning a toughening agent of thermoplastic resin to obtain ultrafine fibers of the thermoplastic resin with diameter of 100-5000nm, and directly spraying the fibers on the surface of a reinforced fiber fabric so as to form a toughening layer consisting of thermoplastic resin fibers which are distributed irregularly and are uniform in surface density on the surface of the fiber fabric; attaching the toughening layer with the fiber fabric to form a whole through a hot rolling process; and then, compounding the fiber fabric product with the toughening function and a prepreg resin base body to prepare the ultrafine fibrous membrane-toughened prepreg product of thermoplastic resin. The preparation method provided by the invention is simple in technical process and easy to implement, and can realize continuous production of high toughness prepreg, thereby greatly improving the production efficiency.

Owner:AVIC COMPOSITES

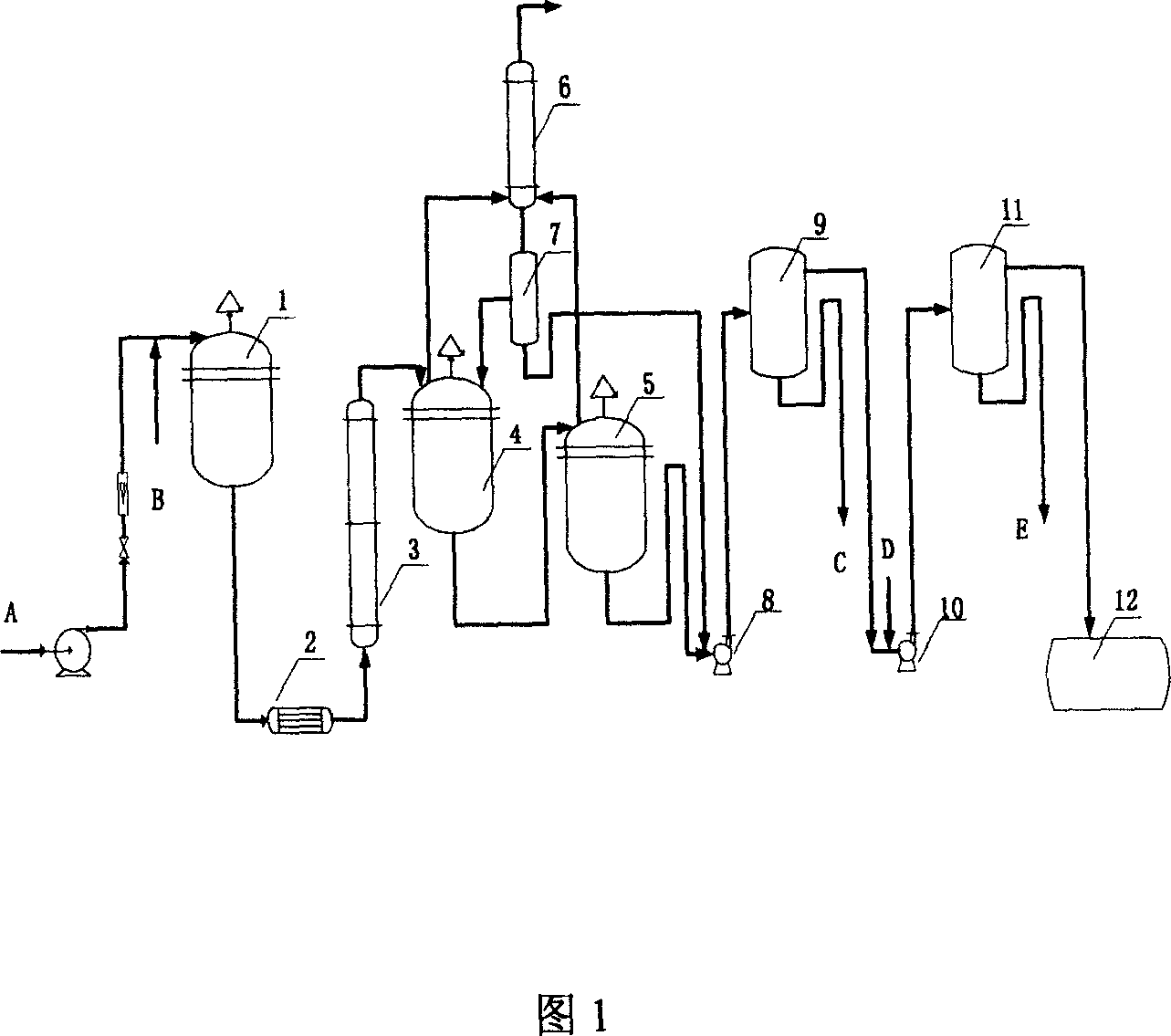

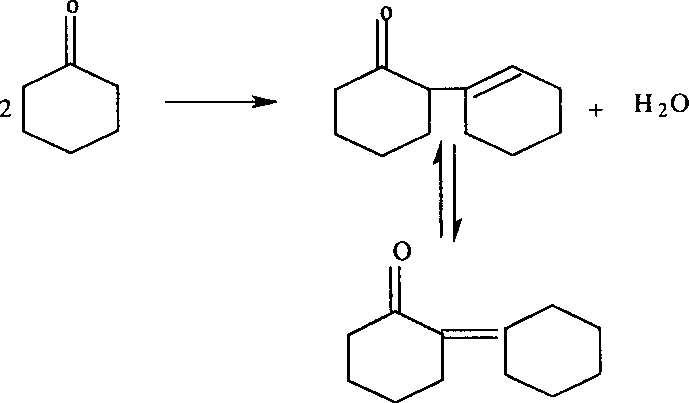

Method for producing cyclohexenyl anone from continuous condensating anone

InactiveCN101003471AReduce dosageRealize continuous industrial productionOrganic compound preparationCarbonyl compound preparationCyclohexanoneO-Phenylphenol

This invention relates to a method for producing cyclohexenyl cyclohexanone, an intermediate of 2-phenylphenol, from cyclohexanone by continuous condensation. The method comprises: premixing, preheating, performing multiple reactions, water washing, and alkali washing. The one-pass conversion rate of cyclohexanone is 50%, and the selectivity of cyclohexenyl cyclohexanone is higher than 96%.

Owner:江苏华派新材料科技有限公司 +1

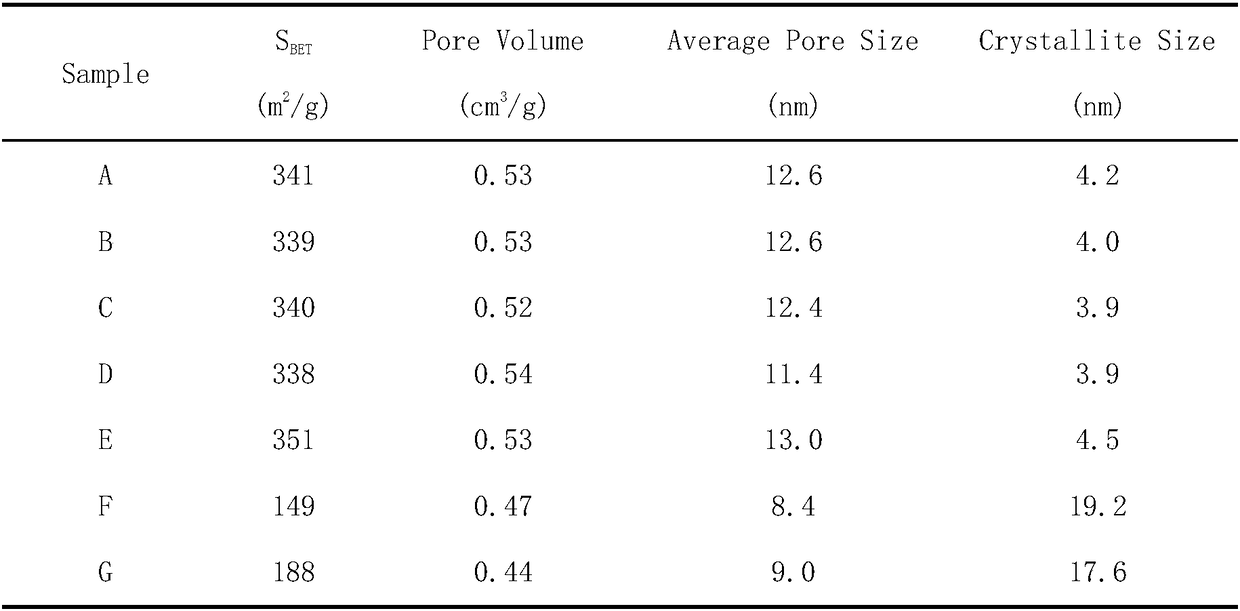

Preparation method and application for iron oxyhydroxide

ActiveCN108101116AIncrease reaction rateGrowth inhibitionIron oxides/hydroxidesHydrocarbon oil crackingSlurryIron oxyhydroxide

The invention belongs to the technical field of preparation of metal oxyhydroxides, and specifically relates to a preparation method and an application for iron oxyhydroxide. The preparation method comprises the following steps: under the condition of supergravity, mixing a Fe2+ metal salt solution with an alkaline solution, and allowing oxygen to reversely contact with a reaction solution at thesame time so as to obtain a mixed reaction slurry; subjecting the mixed reaction slurry to gas-liquid separation, and subjecting an obtained liquid to aging under the conditions of stirring and bubbling oxidation so as to prepare a suspension containing the iron oxyhydroxide; and subjecting the suspension to liquid-solid separation, and subjecting an obtained solid phase to washing and drying so as to obtain the iron oxyhydroxide. According to the invention, the precipitation process and the bubbling aging process of a supergravity reaction are performed in different reactors, so the processesof crystal nucleus generation and crystal nucleus growth are separated; through adjustment of parameters of temperature, time and stirring degree in bubbling aging, the environment of crystal nucleusgrowth is controlled; and preferably, nanoscale or submicron iron oxyhydroxide can be prepared, and has the characteristics of small average particle size, large specific surface area and uniform particle size distribution.

Owner:FUZHOU UNIV +1

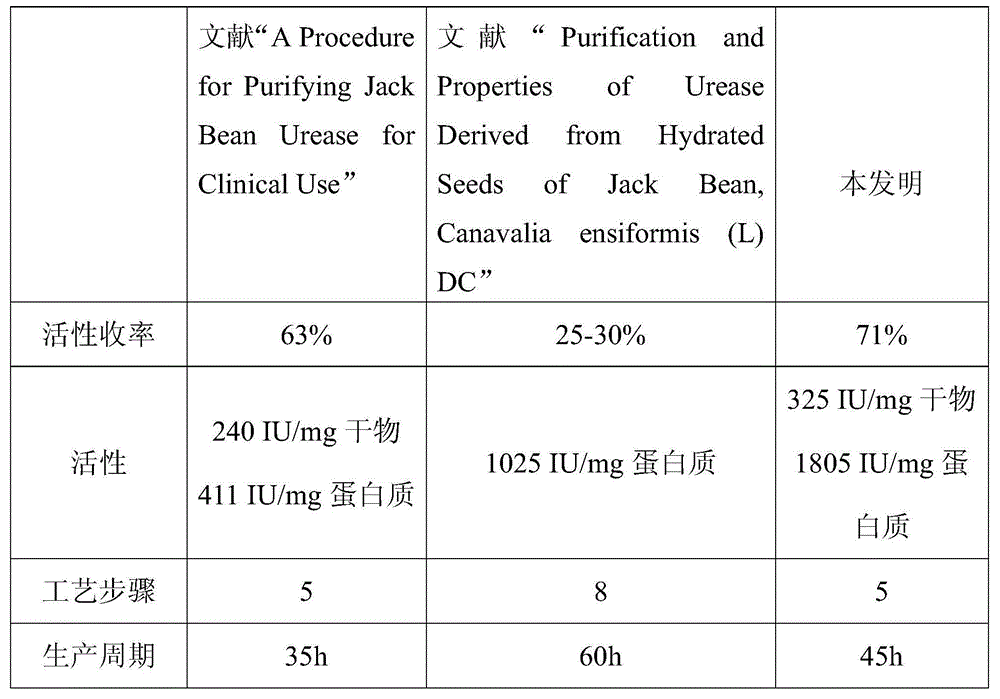

Method for extracting urease from jack beans

ActiveCN104480092AReduce degradationShorten the extraction and purification processHydrolasesMicrofiltrationPollution

The invention provides a method for extracting urease from jack beans, and mainly solves the problems of complex process, high inactivation rate of products, low recovery rate and unsuitability for industrial production in the prior art. The method for extracting urease from the jack beans comprises the following steps: (1), extraction; (2), sedimentation; (3), neutralization; (4), microfiltration and (5), ultrafiltration. The method for extracting urease from the jack beans has the advantages of simple process, easiness in operation, low cost, small pollution, high sample recovery rate, capability of reduction of the inactivation rate of the products and facilitation of industrial production.

Owner:SHAANXI JIAHE PHYTOCHEM

Continuous production process and apparatus of honeycomb card board with stuffing

InactiveCN1772470ARealize continuous industrial productionSimple processLayered productsPaper sheetFilling materials

The continuous production process of honeycomb card board with stuffing includes the following steps: covering the lower facing layer to the stretched and settled honeycomb card core, filling light granular or powdered sound and heat insulating material into the honeycomb card core via constant vibration, scraping the upper surface of the honeycomb card core to eliminate excessive stuffing, covering the upper facing layer, and cutting. The present invention features filling the light granular or powdered sound and heat insulating material into the honeycomb card board. The stuffing is light porous material with certain adsorption and can speed the curing of the adhesive.

Owner:淄博豪特集成房屋制造有限公司

Preparation method of nanofiber aerogel material with hard magnetism

ActiveCN106334538AImprove mechanical propertiesGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesFiberAir filtration

The invention discloses a preparation method of a nanofiber aerogel material with hard magnetism, and belongs to the field of nanofiber functional materials. The preparation method comprises the following steps: 1) preparing demagnetized composite particles; 2) blending the demagnetized composite material and cellulose acetate butyrate, performing melting extrusion and extracting to prepare composite nanofiber; 3) dissolving the composite nanofiber by using a solvent, mixing with a bonding agent, freezing and drying to prepare a composite nanofiber aerogel; 4) magnetizing the composite nanofiber aerogel. The preparation method is simple in process and pollution-free, and is suitable for industrial production; the prepared hard-magnetism aerogel has the advantages of superparamagnetism and relatively high strength, has the characteristics of a high specific surface area, high porosity, low heat conductivity and the like, and can be widely applied to the fields of air filtration, electromagnetic shielding, energy absorption and the like.

Owner:WUHAN TEXTILE UNIV +1

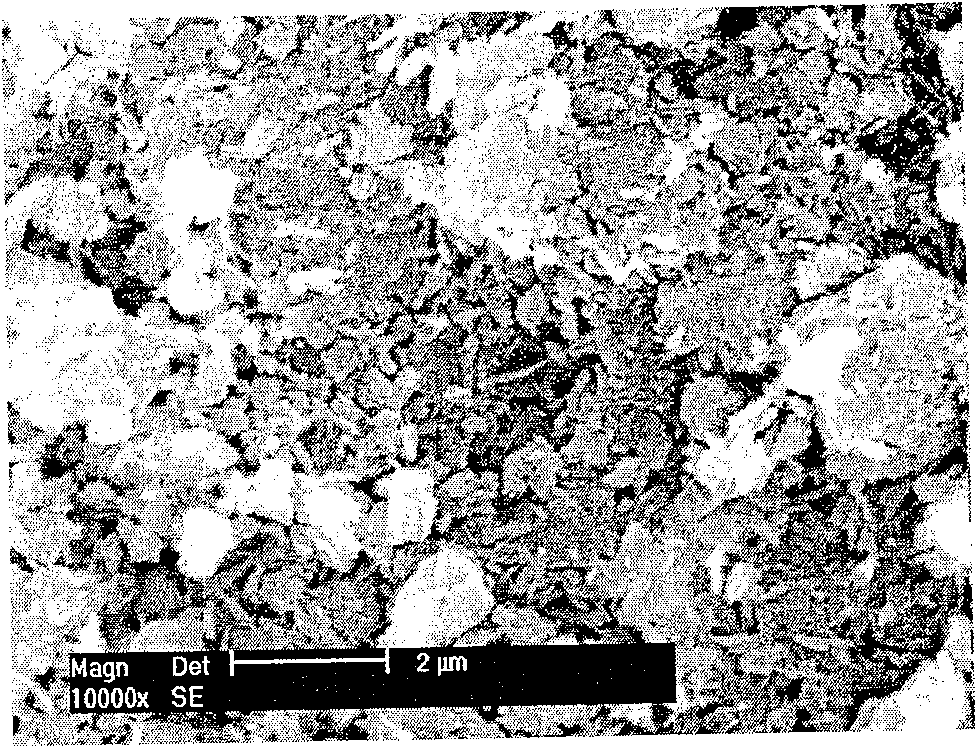

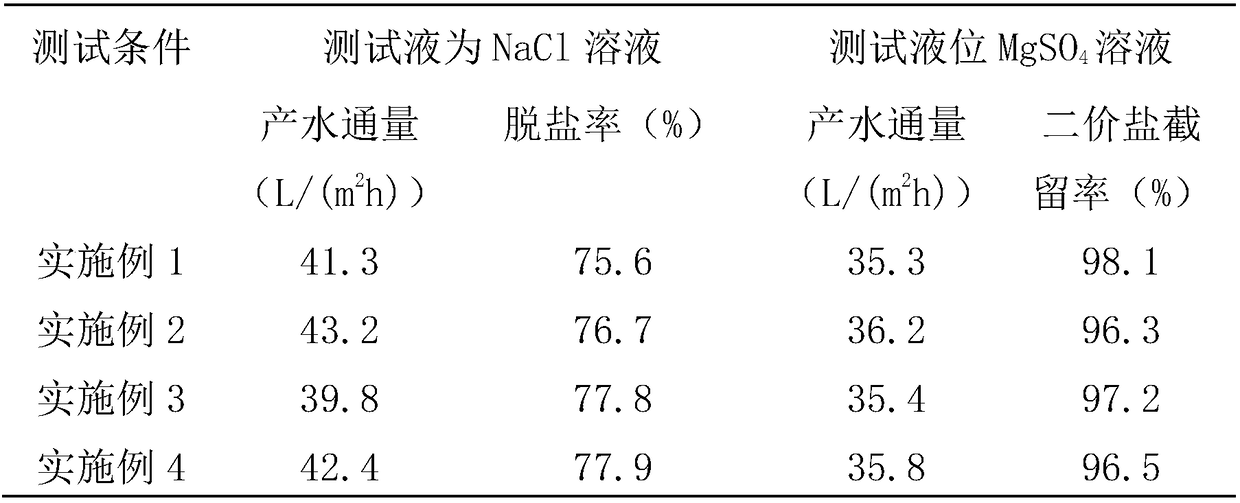

Preparation method for hollow fiber composite nanofiltration membrane

InactiveCN106268378AExcellent salt rejectionGood chemical stabilitySemi-permeable membranesHollow fibreFiber

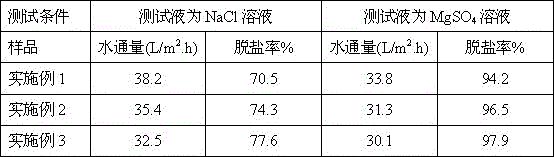

The invention relates to a preparation method for a hollow fiber composite nanofiltration membrane. The method comprises the following steps: (Step 1) ceramic powder, macromoleclar polymer, organic solvent and dispersing agent are mixed according to certain proportions and agitated, so that uniform and stable membrane-casting solution is produced, air bubbles in the membrane-casting solution are removed by vacuum suction, and the membrane-casting solution is sprayed out via a hollow fiber spinneret under the drive of pressure, and is shaped under certain core liquid flow velocity and air section distance conditions to get into external gel bath; after being aired under normal temperature, the phase-inversed raw hollow fiber is sintered under high temperature, and thereby a hollow fiber ceramic support is obtained; (Step 2) sulfonated polyethersulfone, membrane-forming solvent and additive are mixed according to certain proportions and agitated, so that homogeneous solution is produced, the hollow fiber ceramic support is immersed in the homogeneous solution in a certain way for a period of time and airflow is adopted to blow off the thick liquid membrane layer of the surface of the support after the hollow fiber ceramic support is taken out, which are repeated for multiple times, the hollow fiber ceramic support is finally put into deionized water to sufficiently remove the solvent, and is dried under a certain temperature in an oven, and thereby the hollow fiber composite nanofiltration membrane is obtained. The preparation method for the hollow fiber composite nanofiltration membrane disclosed by the invention has the advantages of high chemical and thermal stability and high mechanical strength.

Owner:李祥庆

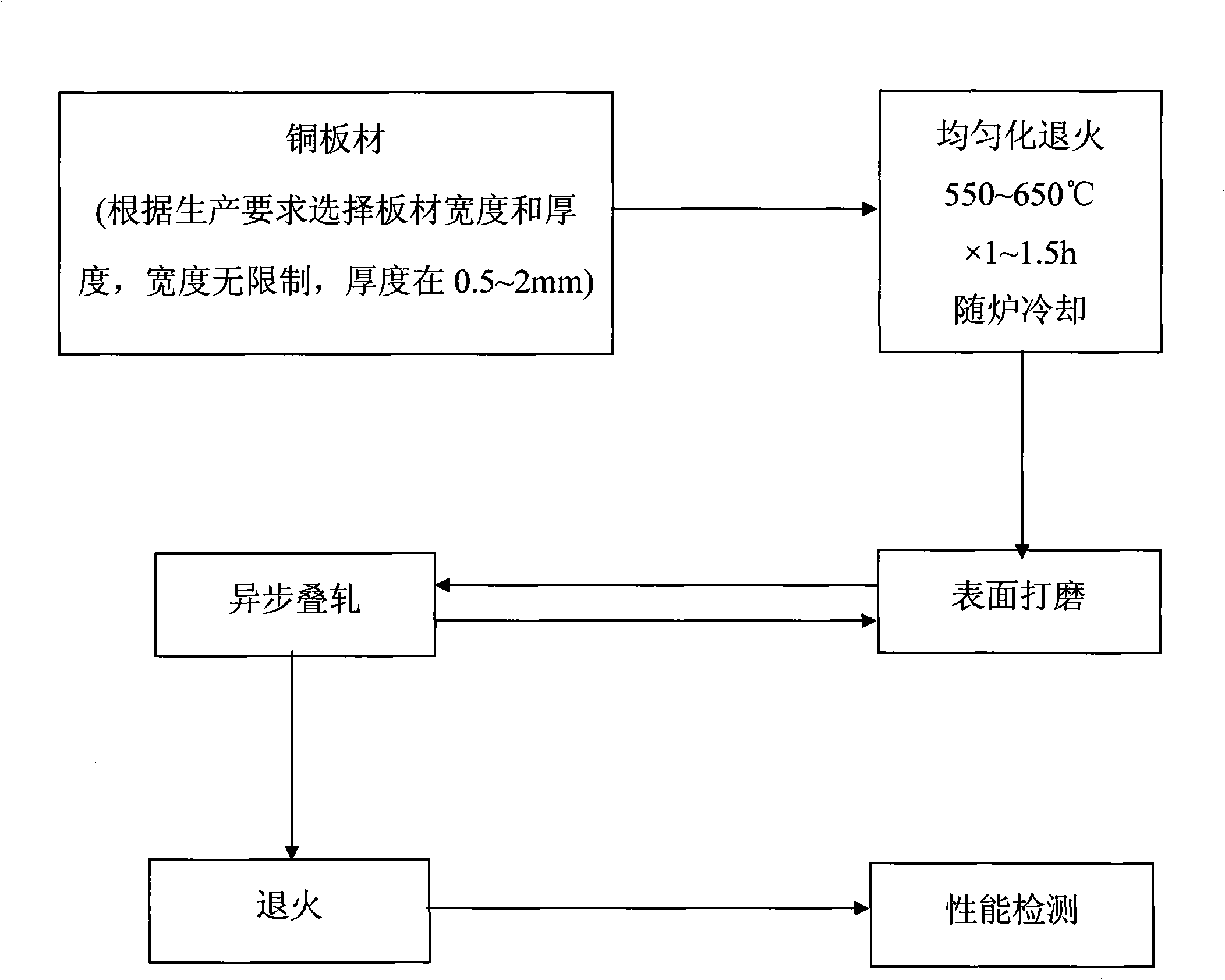

Preparation method of high-strength superfine ultra-fine grain copper strip

InactiveCN101288876AOvercoming cluster growthOvercoming pollutionRoll mill control devicesFurnace typesExtensibilityNonferrous metal

The invention provides a preparation method of a high-strength ultra-fine crystal copper strip material, belonging to the field of mechanism and metallurgy combination processing of nonferrous ultra-fine crystal material. The method of the invention adopts a multi-time asynchronous lamination rolling process method to lead the grains of large-grain copper plate to be fined; the strength of the gained ultra-fine crystal copper material is improved by twice, the electrical conductivity is not reduced and the gained material has good extensibility. The method of the invention solves the composition of interface in the deformation of the material, reduces the rolling pressure and energy consumption, improves the precision of the product and realizes the continuous preparation and production of the high-strength ultra-fine crystal material.

Owner:KUNMING UNIV OF SCI & TECH

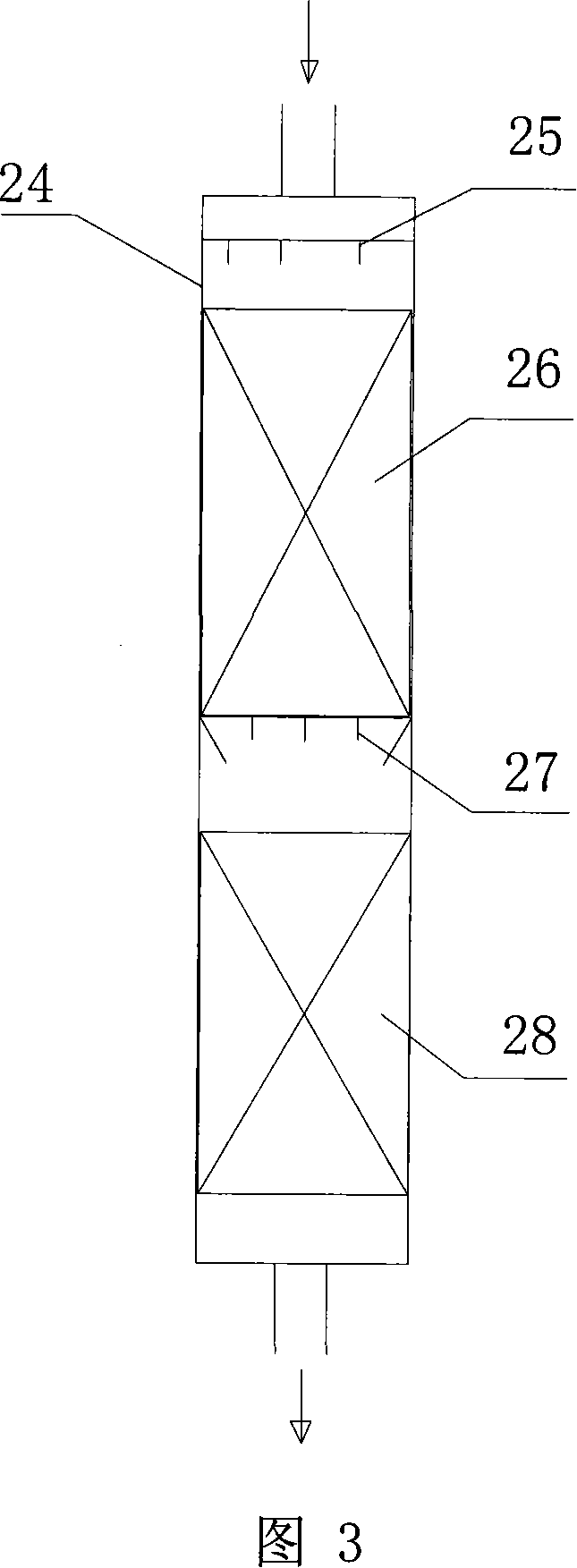

Preparation method and production equipment of acrylonitrile-based carbon fiber spinning solution

ActiveCN101736442AResolve Radial DifferencesImprove delivery qualityFibre chemical featuresChemical reactionAcrylonitrile

The invention discloses a preparation method and production equipment of an acrylonitrile-based carbon fiber spinning solution. The preparation method comprises the step of carrying out a polyreaction in a tubular reactor, wherein a turbulent plate or a cross over disk is arranged in a tube cavity of the tubular reactor, and a device for controlling the temperature of the tube cavity is arranged on the outer wall of the tube cavity. Because components including the turbulent plate or the cross over disk are arranged in the tube cavity of the tubular reactor adopted by the preparation method of the invention, central and peripheral materials can crosswise flow, the radial difference of the materials in a tube is effectively solved, the fluid transportation quality is improved, heat transfer and mass transfer are provided, the chemical reaction efficiency is improved and the flow resistance is relatively lower, thereby improving the uniformity of polymers and realizing continuous industrial production.

Owner:KINGFA SCI & TECH CO LTD +1

IQF (individual quick freezing) raw head-on prawn preservative and application thereof

InactiveCN105394160AImprove toughnessEnhanced crack resistanceMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsProtein proteinTrehalose

The invention provides an IQF (individual quick freezing) raw head-on prawn preservative and an application thereof. The preservative consists of the following raw materials in parts by weight: 20-25 parts of trehalose, 0.5-0.8 part of antioxidants of bamboo leaves, 1-1.6 parts of citric acid and 72.6-78.5 parts of aqueous extract of tremella. The preservative can effectively maintain the quality of the IQF raw head-on prawn and effectively prevent the problems such as blackening, fat oxidation, drying loss and protein freezing denaturation in the freezing preservation process; and the processing method is applicable to industrial continuous operation.

Owner:FUJIAN AGRI & FORESTRY UNIV

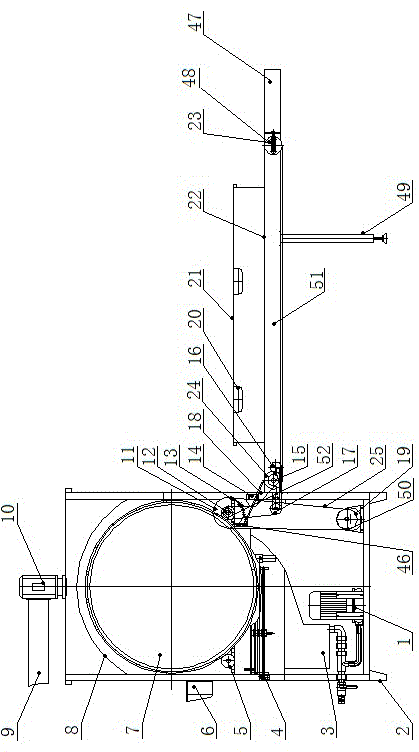

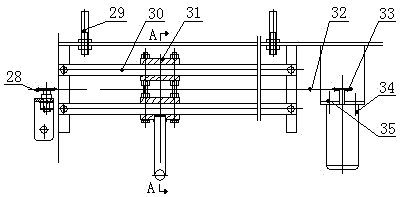

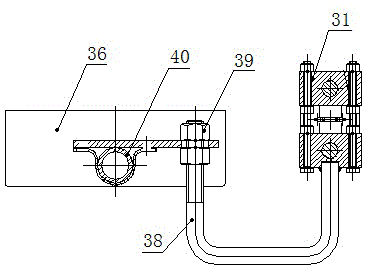

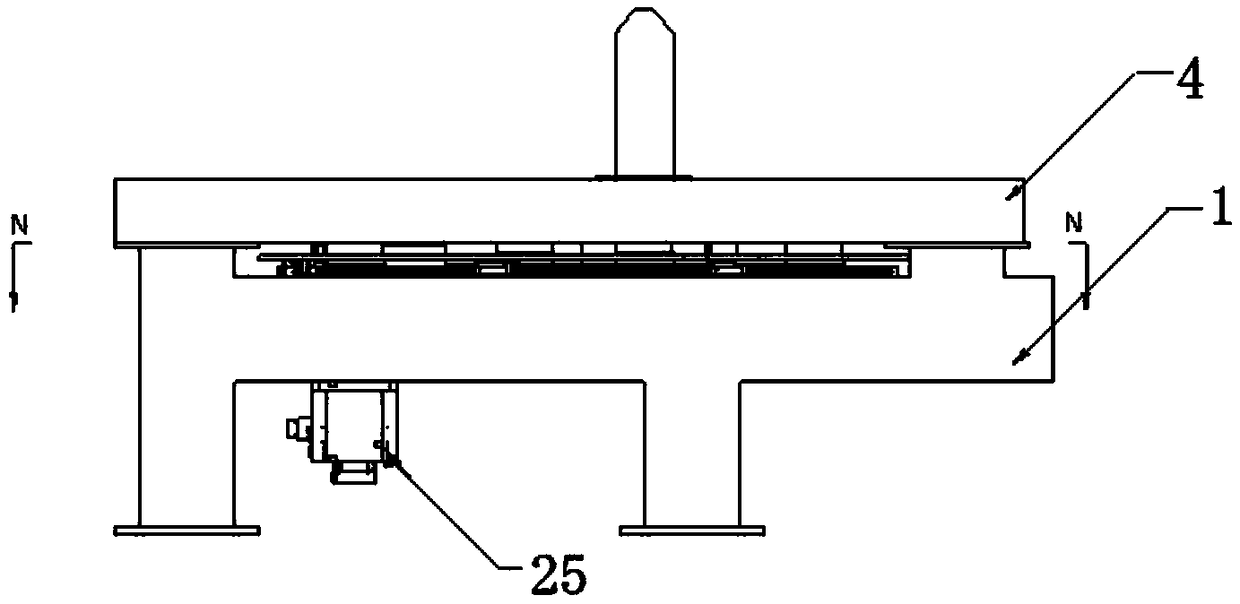

Thin pancake machine

ActiveCN105309529AReduce labor intensityNovel structureOil/fat bakingPancakes bakingElectrical controlSlurry

The invention discloses a thin pancake machine which comprises a rack, a roller die, a spraying mechanism, a transmitting mechanism, a conveying mechanism and an electrical control part, wherein the roller die is of a circular roller structure; a plurality of circular dies projected outwards are uniformly distributed on the external circular surface; the spraying mechanism comprises a liquid pump, a trough, a spraying pipeline, a spraying mouth walking and adjusting mechanism and a spraying mouth; the spraying mouth is arranged under the roller die; the liquid pump transmits slurry in the trough to the spraying mouth so as to spray the slurry onto the circular dies of the roller die. The thin pancake machine adopts batter spraying, die forming, baking, conveying and cooling as a whole, batter is automatically sprayed onto the preheat dies through a centrifugal pump body and is baked to form a small cake, and the small cake is shaved off through a shaving plate, conveyed through a conveying chain and cooled. The product is novel in structure and high in automation and hygiene level, the continuous industrial production can be realized, the number of operating personnel is reduced, the efficiency is improved, and the labor intensity of the operating personnel is relieved.

Owner:SHANDONG YINYING COOKING MACHINERY

Equipment and process for industrially producing graphene by microwaves

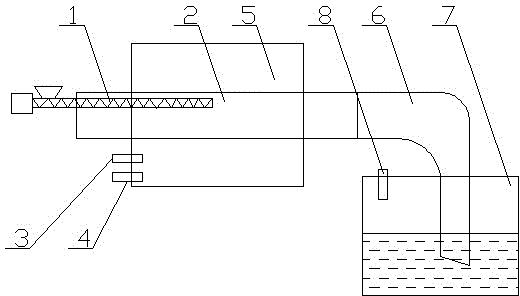

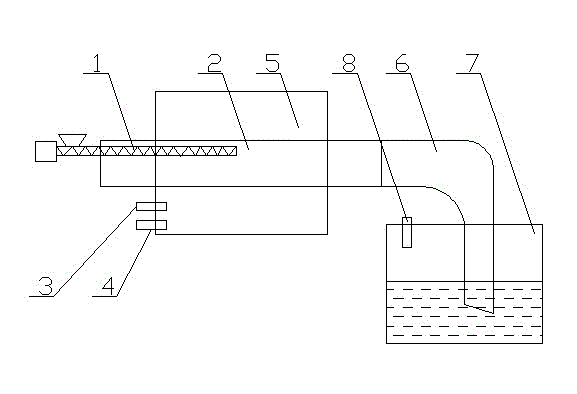

The invention relates to equipment and process for industrially producing graphene by microwaves. The equipment comprises a spiral feeder, a furnace tube, a microwave cavity, a material discharging pipe and a product collector, wherein the furnace tube is connected to the microwave cavity in a penetrating manner; the input end of the furnace tube is connected with the spiral feeder; the output end of the furnace tube is connected with the product collector through the material discharging pipe; an inert gas inlet and a compressed air inlet are formed in the input end of the furnace pipe. Graphite is oxidized into oxidized graphite under the action of strong acid and strong oxidant such as H2SO4, HNO3 and HClO4s or is hydrolyzed into oxidized graphite under the electrochemical peroxidation effect; the oxidized graphite is prepared after being subjected to filtering, granulation and the like; inert gas is used for replacing air in the furnace tube; under the inert gas atmosphere, the oxidized graphite is dissociated by the microwaves and is reduced into flocculent graphene easy to fly; the compressed air inlet is opened, and the reduced graphene enters the product collector along with the compressed air and is completely absorbed by water pre-stored in the device; suspension is filtered and dried to be solid powder, so that the production process for the graphene is finished.

Owner:江苏江大环保科技开发有限公司

Equipment for industrially producing graphene by microwaves

The invention relates to equipment for industrially producing graphene by microwaves. The equipment comprises a spiral feeder, a furnace tube, a microwave cavity, a material discharging pipe and a product collector, wherein the furnace tube is connected to the microwave cavity in a penetrating manner; the input end of the furnace tube is connected with the spiral feeder; the output end of the furnace tube is connected with the product collector through the material discharging pipe; an inert gas inlet and a compressed air inlet are formed in the input end of the furnace pipe. Graphite is oxidized into oxidized graphite under the action of strong acid and strong oxidant such as H2SO4, HNO3 and HClO4s or is hydrolyzed into oxidized graphite under the electrochemical peroxidation effect; the oxidized graphite is prepared after being subjected to filtering, granulation and the like; inert gas is used for replacing air in the furnace tube; under the inert gas atmosphere, the oxidized graphite is dissociated by the microwaves and is reduced into flocculent graphene easy to fly; the compressed air inlet is opened, and the reduced graphene enters the product collector along with the compressed air and is completely absorbed by water pre-stored in the device; suspension is filtered and dried to be solid powder, so that the production process for the graphene is finished.

Owner:江苏江大环保科技开发有限公司

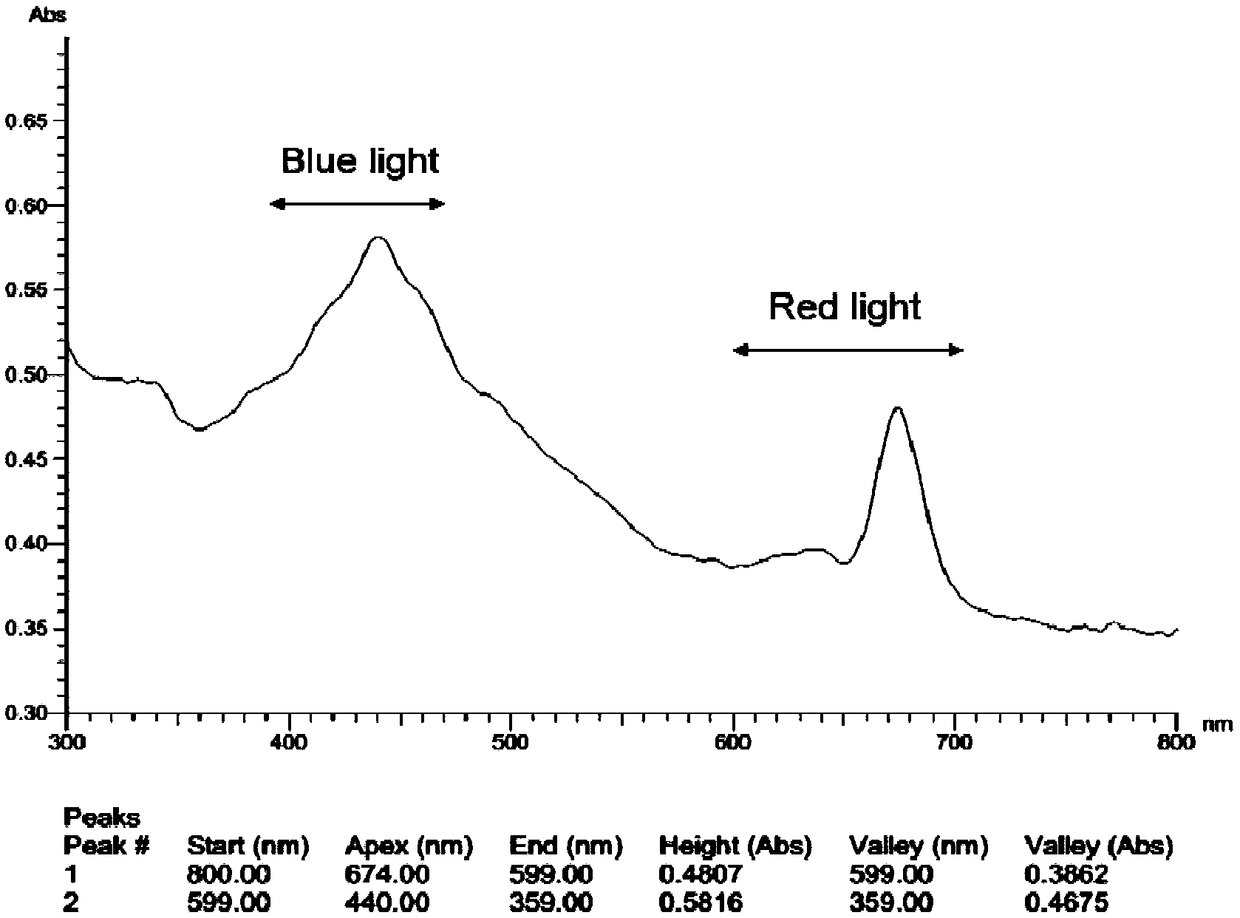

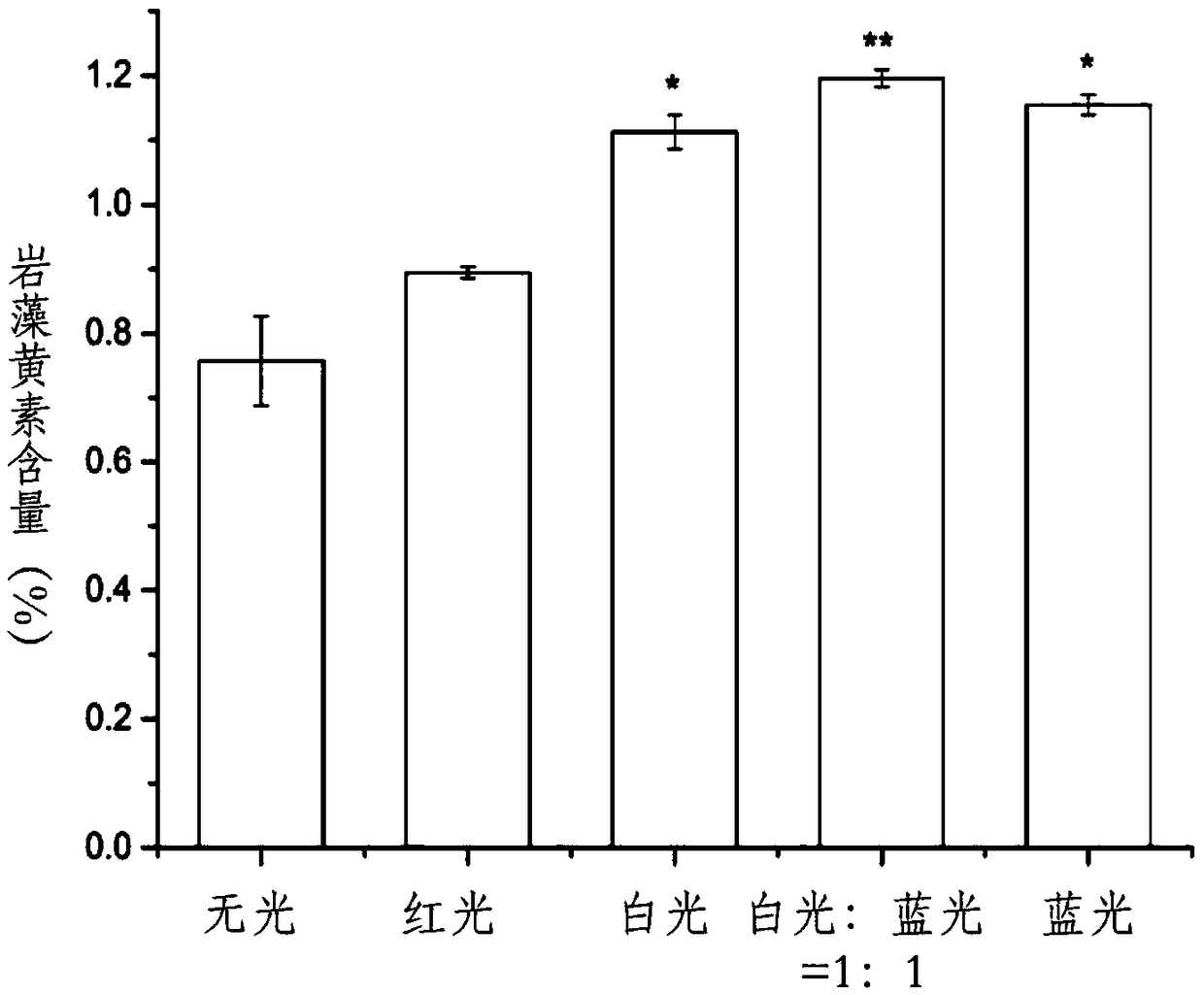

Method for increasing content of fucoxanthin in heterotrophic cultured smooth nitzschia fermentation liquid by utilizing illumination

ActiveCN108841887AIncrease contentRealize continuous industrial productionMicroorganism based processesFermentationMacrocystis pyriferaFucoxanthin

The invention belongs to post-treatment of fermentation liquid, and particularly relates to a method for increasing the content of fucoxanthin in heterotrophic cultured smooth nitzschia fermentation liquid by utilizing illumination. The method comprises process processing steps of preparing smooth nitzschia fermentation liquid by adopting a heterotrophic culture method; transferring the prepared smooth nitzschia fermentation liquid into a photobioreactor under the illumination of single-colored light or hybrid light, performing ventilation for induced culture under the illumination condition and the like. The method solves the technical problem that the content of the fucoxanthin in the smooth nitzschia fermentation liquid prepared by heterotrophic culture is low in the prior art. The method has the advantages that the content of the fucoxanthin in prepared dry smooth nitzschia powder is high, continuous industrial production can be stably realized, general pollutants in the ocean suchas heavy metals and polychlorinated biphenyl can be controlled from the source of a culture medium, and the fucoxanthin from relatively large-sized alga is safer.

Owner:PEKING UNIV

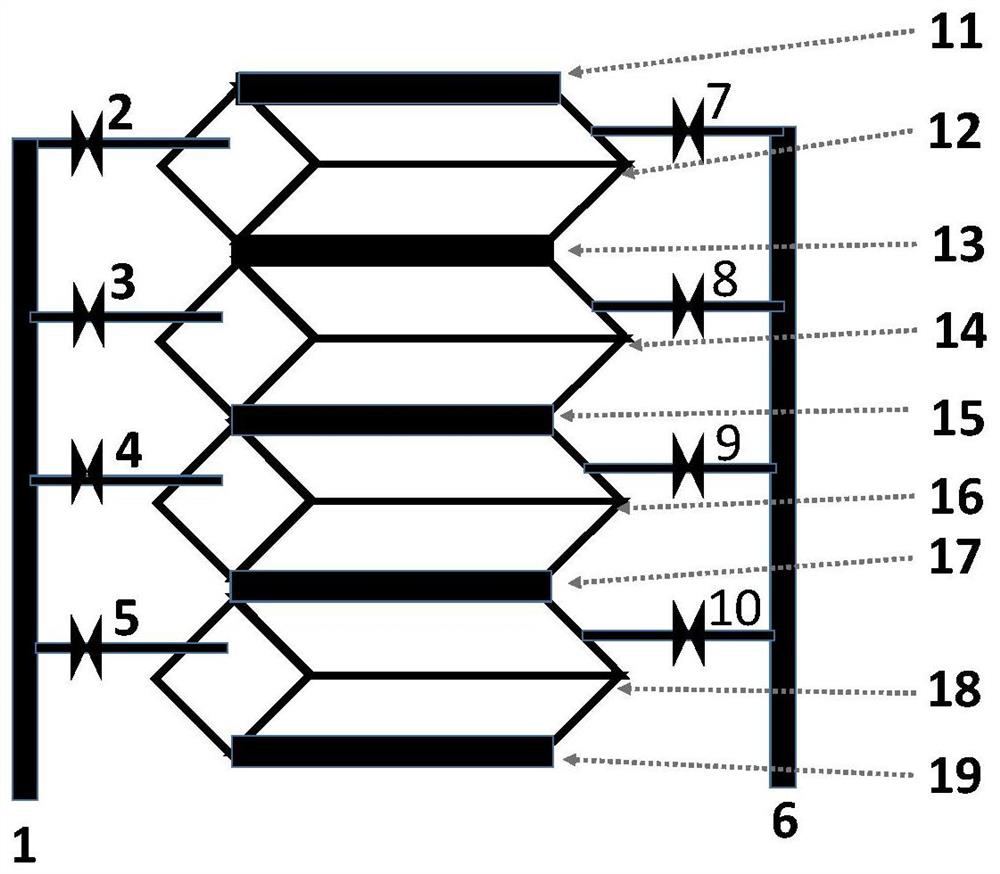

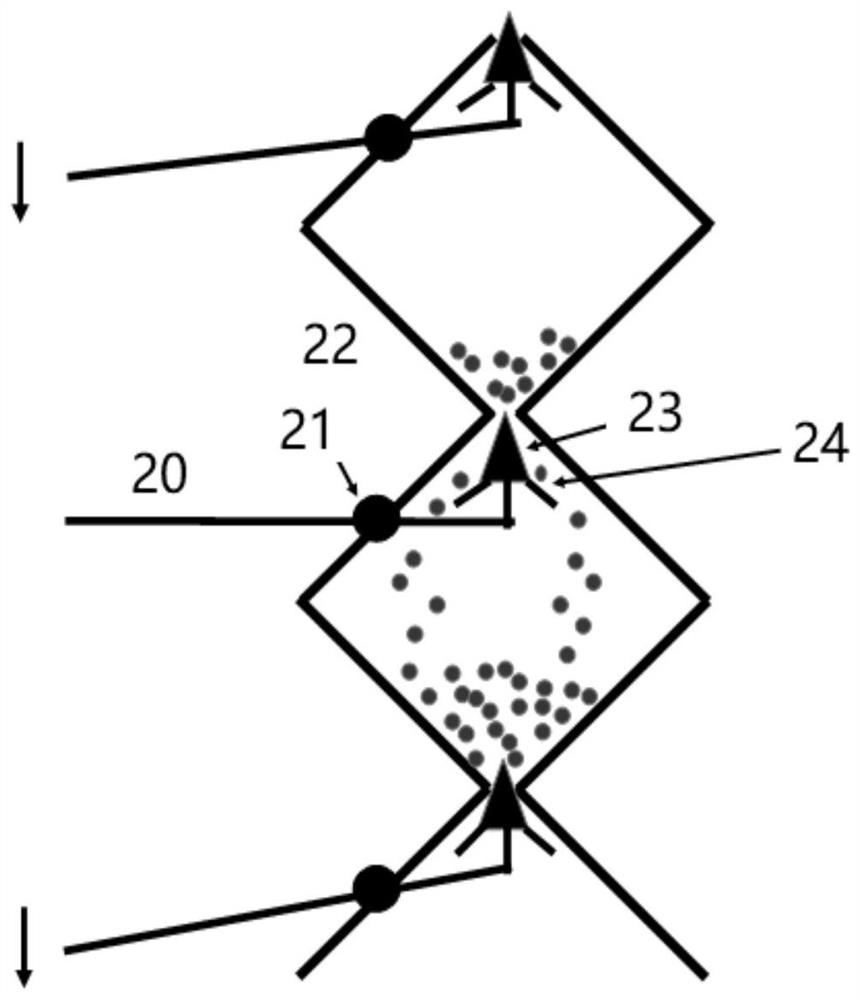

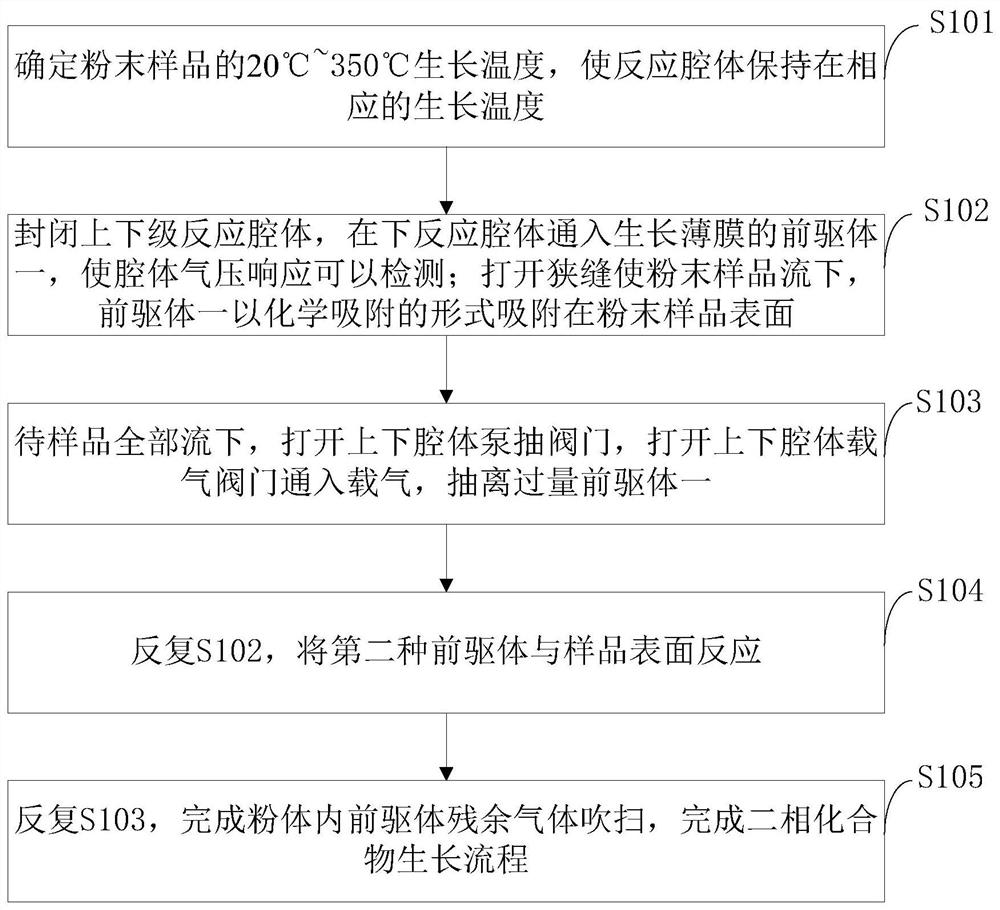

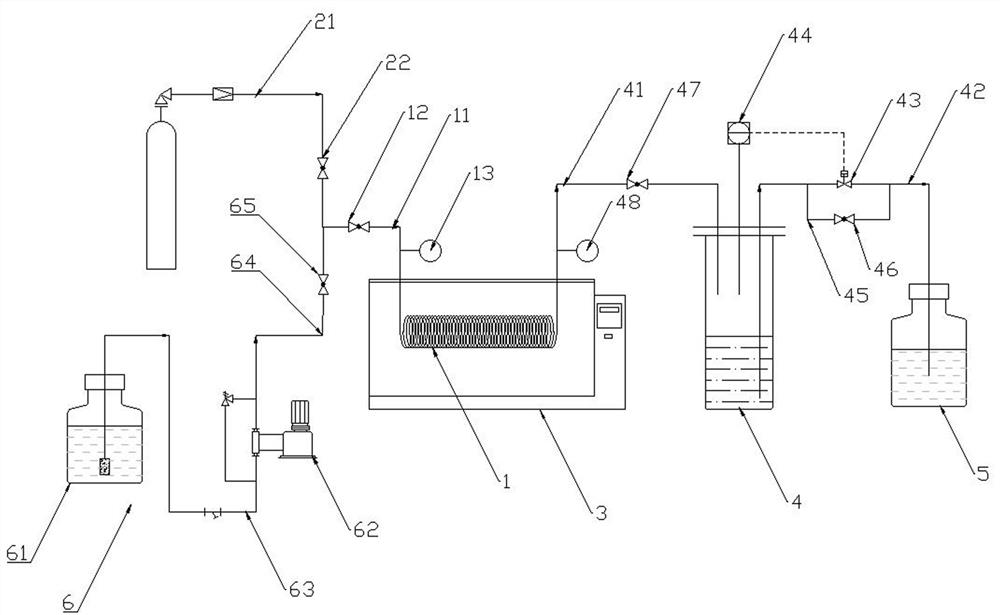

Gravity-driven spatial resolution powder atomic layer deposition equipment, method and application

ActiveCN112342530AImprove the efficiency of coatingLow costChemical vapor deposition coatingPhysicsGas pipeline

The invention belongs to the technical field of atomic layer deposition and discloses gravity-driven spatial resolution powder atomic layer deposition equipment, a gravity-driven spatial resolution powder atomic layer deposition method and application. The powder atomic layer deposition equipment is provided with heatable main chambers; movable sealing structures are arranged between the multiplestages of heatable main chambers, and the heatable main chambers are sealed through rubber-metal / rubber; heatable gas pipelines are fixed to the two ends of each stage of heatable main chamber, and powder filters are arranged at the joints of the heatable gas pipelines; one end of each stage of heatable main chamber is connected with a precursor and carrier gas through the corresponding heatable gas pipeline, and opening and closing are controlled via an electromagnetic valve; the other end of each stage of heatable main chamber is connected with a vacuum pump through the corresponding heatable gas pipeline, opening and closing are controlled via an electromagnetic or pneumatic valve, and residual gas analyzers or vacuum gauges can be arranged at the two ends of the valve; and the whole equipment can be provided with a vibrator. According to the gravity-driven spatial resolution powder atomic layer deposition equipment, the gravity-driven spatial resolution powder atomic layer deposition method and application, a chamber body is designed in a continuous growth mode, the coating efficiency is obviously improved, and the powder coating cost is reduced.

Owner:NANKAI UNIV

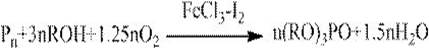

Pipelined continuous preparation method and device of triisoamyl phosphate for spent fuel post-treatment

ActiveCN112225754ARealize continuous productionGuaranteed normal productionGroup 5/15 element organic compoundsPressure vessels for chemical processFuel reprocessingPhosphate

The invention provides a preparation device of triisopentyl phosphate. The device comprises: a reaction coil pipe used as a reaction container of a mixed solution; an air source communicated with theinlet of the reaction coil pipe through an air inlet pipe, wherein an air inlet switch is arranged on the air inlet pipe; a heating unit used for heating the reaction coil pipe; a high-pressure buffertank, wherein the upper portion of the space in the high-pressure buffer tank is communicated with the outlet of the reaction coil pipe through a first liquid outlet pipe; a reaction liquid collecting tank communicated with the bottom of the space in the high-pressure buffer tank through a second liquid outlet pipe, wherein a first liquid outlet switch is arranged on the second liquid outlet pipe; a feeding unit used for conveying the mixed solution into the reaction coil pipe; and a first pressure gauge arranged on the high-pressure buffer tank and used for measuring the pressure of the reaction environment. The invention also provides a method for preparing triisopentyl phosphate by adopting the device. According to the invention, continuous industrial production of triisopentyl phosphate is realized, the generated byproduct methanol does not react with triisopentyl phosphate, the yield is high, and the process risk is low.

Owner:HANGZHOU JINGYE INTELLIGENT TECH CO LTD

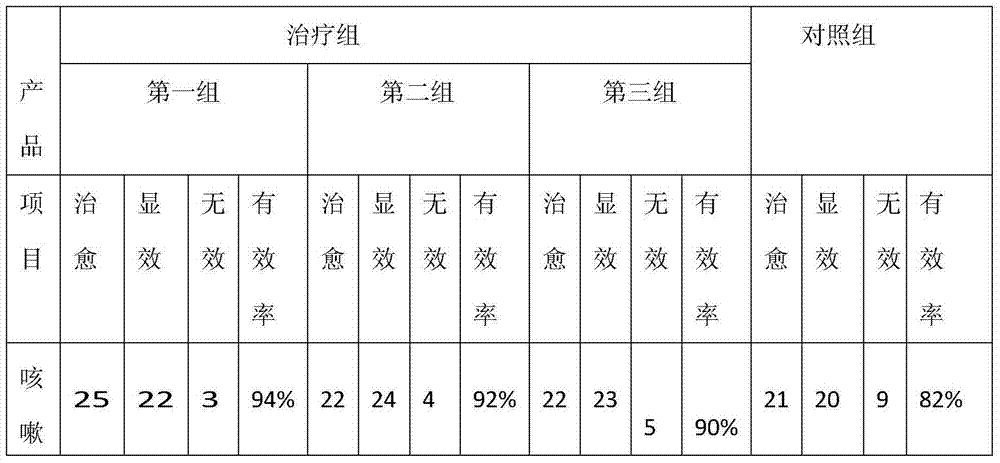

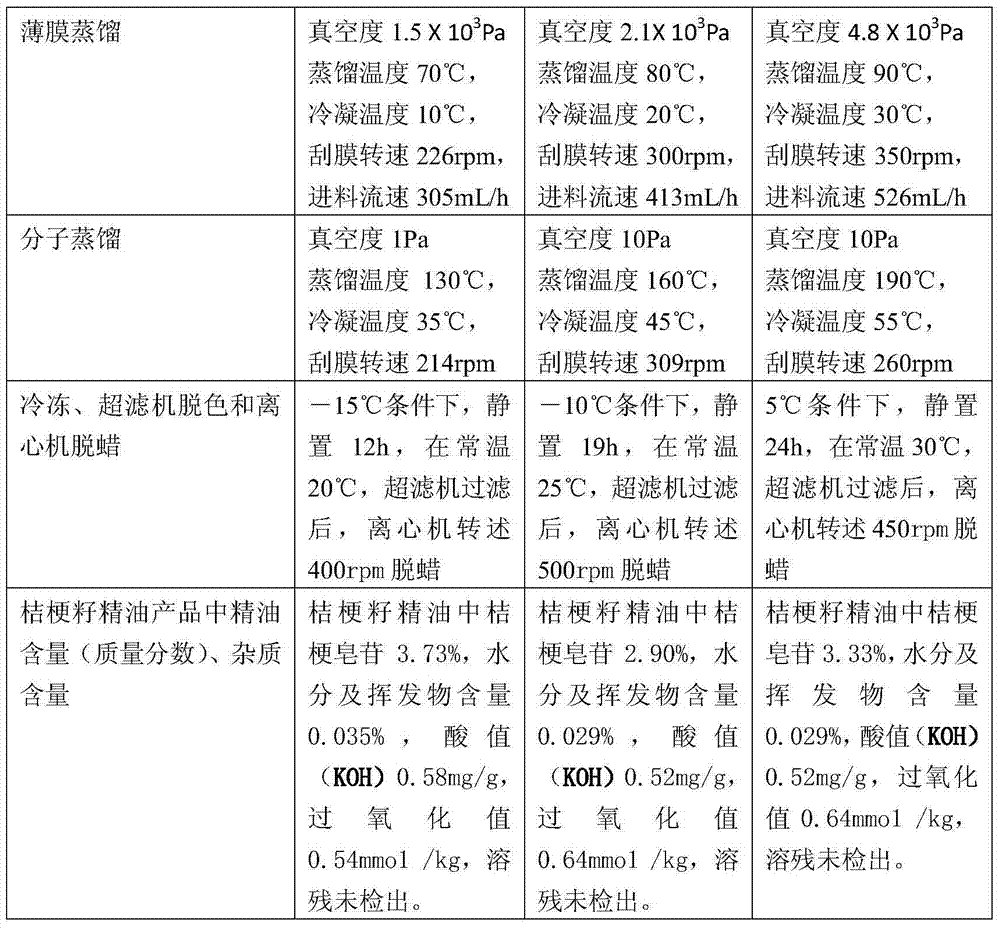

Preparation method and health product of platycodon grandiflorum seed essential oil

InactiveCN104232314AImprove oil yieldReduce lossesAntipyreticAnalgesicsDistillationHealth production

The invention discloses a preparation method and a health production of platycodon grandiflorum seed essential oil. The method comprises the steps of CO2 supercritical fluid extraction, thin-film distilling for dehydrating and deodorizing, molecular distillation for depickling, freezing, decolorizing through a superfilter, and dewaxing through a centrifugal machine, wherein the extraction is performed under a pressure of 20 to 36MPa and at a temperature of 45 to 55 DEG C; the separation I is performed under a pressure of 7 to 9MPa and at a temperature of 30 to 50 DEG C; the separation II is performed under a pressure of 4 to 6MPa and at a temperature of 30 to 50 DEG C; the obtained crude oil of platycodon grandiflorum is subjected to thin-film distilling for dehydrating and deodorizing, molecular distillation for depickling, freezing, decolorizing through a superfilter, and dewaxing through a centrifugal machine to obtain the platycodon grandiflorum seed essential oil. The health product of the platycodon grandiflorum seed essential oil comprises 70 to 90% of platycodon grandiflorum seed essential oil, 8 to 28% of liquiritigenin extractive, and 2% of vitamin E. The method is high in oil yield of platycodon grandiflorum seed, green and safe, free of residual solvent, and simple and convenient, and realizes continuous industrial production. The health product of the platycodon grandiflorum seed essential oil has the effects of opening the inhibited lung-energy, expelling the phlegm to arrest coughing, and resisting inflammation.

Owner:云南省农业科学院高山经济植物研究所

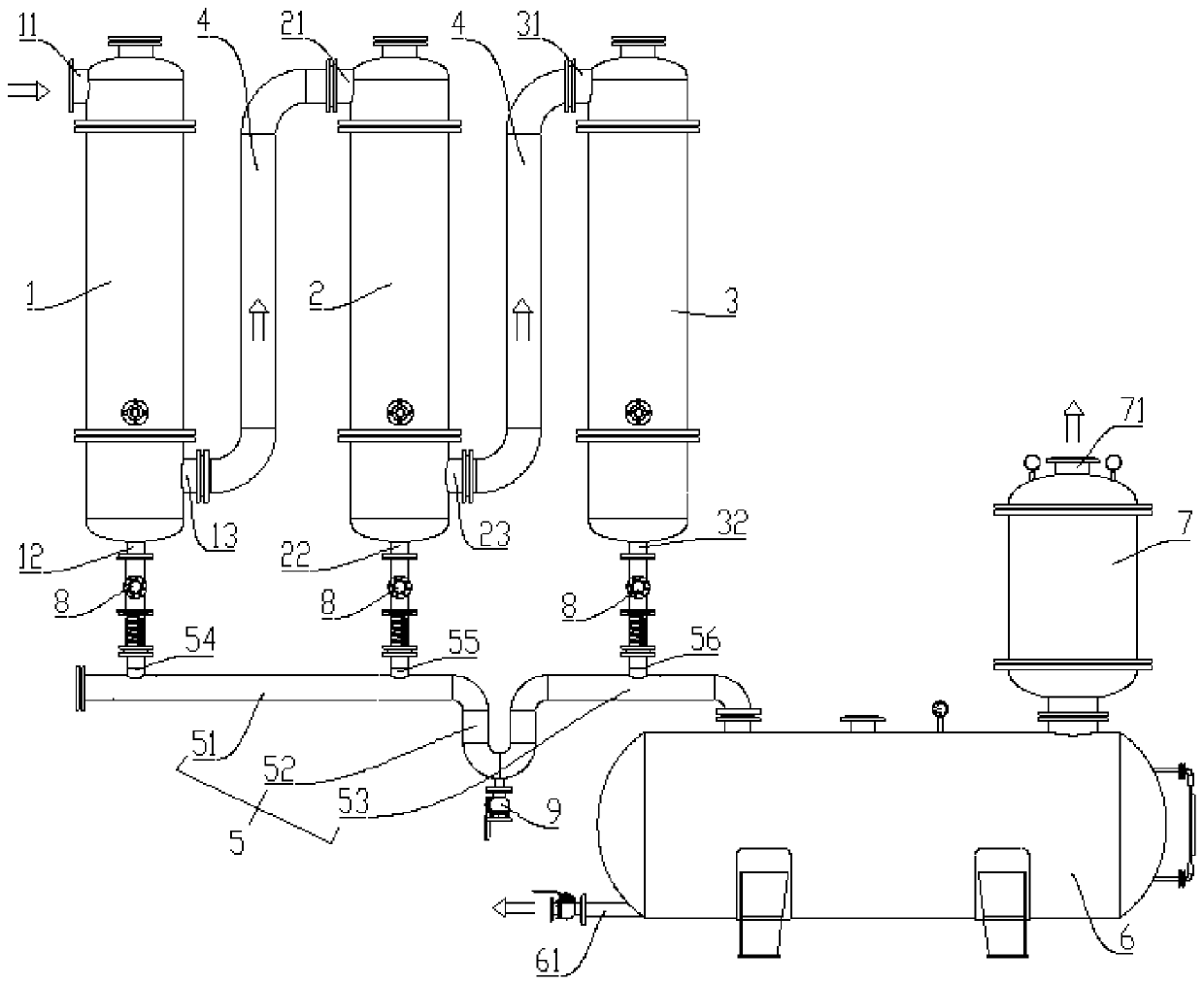

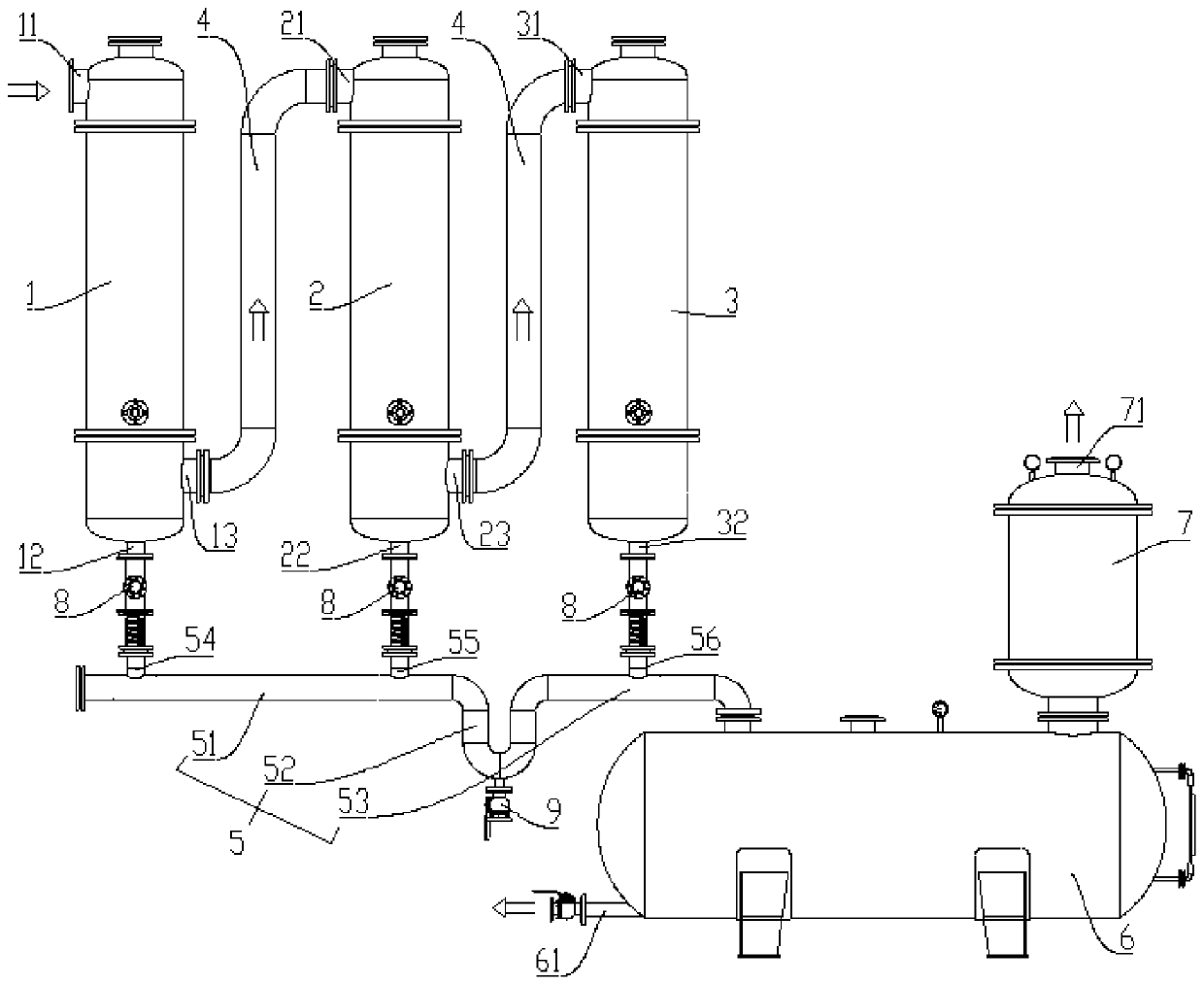

Oil seal condensation system for waste tire thermal cracking

PendingCN111151022ARecycle thoroughlyEasy to separateMultiple-effect/fractional condensationLiquid hydrocarbon mixture recoveryThermodynamicsStraight tube

The invention provides an oil seal condensation system for waste tire thermal cracking, which belongs to the technical field of waste tire thermal cracking, and can fully condense gas generated by waste tire thermal cracking. The oil seal condensation system comprises a first condenser, a second condenser and a third condenser, wherein a gas conveying pipeline is connected between a non-condensable gas outlet of the first condenser and a gas inlet of the second condenser, and a gas conveying pipeline is connected between a non-condensable gas outlet of the second condenser and a gas inlet of the third condenser. The oil seal condensation system further comprises an oil conveying pipeline. The oil conveying pipeline comprises a first straight pipe section, a U-shaped pipe section and a second straight pipe section. The first straight pipe section is provided with a first oil product inlet connected with a condensed oil outlet of the first condenser and a second oil product inlet connected with a condensed oil outlet of the second condenser, and the second straight pipe section is provided with a third oil product inlet connected with a condensed oil outlet of the third condenser. The second straight pipe section is connected with an oil product collecting tank, and a non-condensable gas distributing bag is arranged at the top of the oil product collecting tank.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

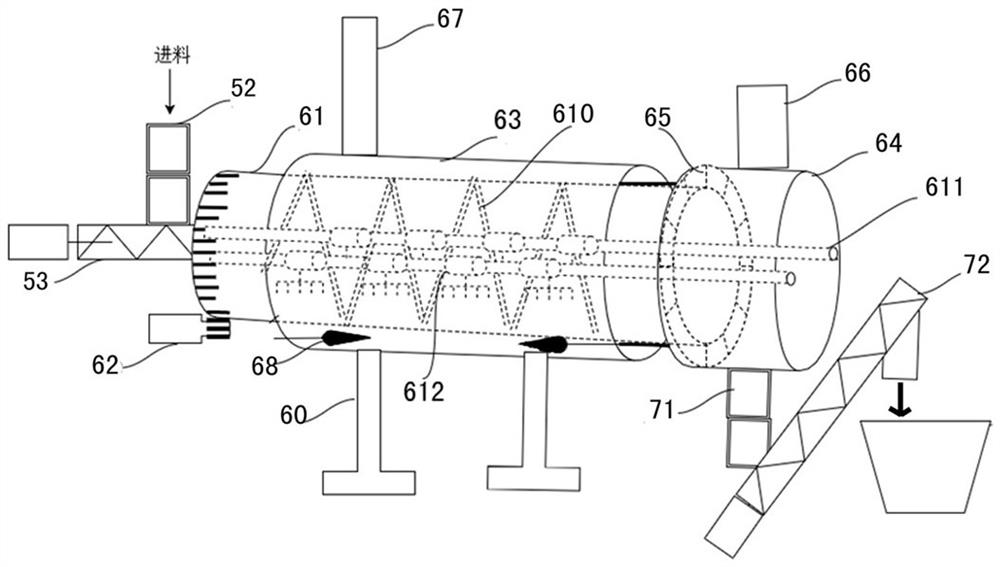

Production method and production system for extracting oil in oil sludge

ActiveCN111875208ARealize continuous industrial productionSuitable for harmless treatmentSludge treatment by pyrolysisByproduct vaporizationThermodynamicsCoke

The invention discloses a production method and a production system for extracting oil in oil sludge. An oil sludge pyrolysis device comprises a rotary drum, wherein the open end of the rotary drum iscommunicated with a fixed cylindrical discharge end socket, and the rotary drum is in rotary sealing fit with the discharge end socket; a spiral guide plate is fixedly arranged on the inner wall of the rotary drum, the rotary drum rotates, and the spiral guide plate pushes and throws oil sludge; oil steam and residues after pyrolysis are discharged from the discharging seal head; a decoking and crushing device in the rotary drum comprises a fixed shaft parallel to the axis of the rotary drum, a plurality of decoking tooth claws are arranged on the fixed shaft at intervals in the axial direction, the handle ends of the decoking tooth claws are rotatably arranged on the fixed shaft in a sleeving mode, the claw ends elastically press and contact the inner wall of the rotary drum through springs, and the rotating direction of the claw ends is opposite to that of the rotary drum under the action of the springs; the decoking tooth claws grab and dig the inner wall of the rotary drum along with the rotation of the rotary drum to remove inner wall cokes and crush oil sludge blocks. The method realizes continuous industrial production of extracting the oil in the oil sludge, and is high inpyrolysis efficiency, thorough in harmless treatment of the oil sludge and high in oil recovery rate.

Owner:舟山麦哲伦环保科技有限公司

Method for purifying and processing attapulgite clay mineral

InactiveCN100579903CRealize continuous industrial productionEnhanced interface propertiesEnergy inputSilicon compoundsSeparation factorClay minerals

The invention relates to a purifying and processing method of attapulgite clay minerals, which belongs to the technical field of the wet separating technique of minerals. The specific steps comprise utilizing spiral classifier for primary purification, utilizing cyclone classifier for secondary purification, employing gravity separation equipment for three-stage purification, concentration, drying and disintegration, thereby preparing ultrafine powders of the purified attapulgite clay minerals with the average particle size of 0.93-2.0 micron, and particle size of the largest particle is 3.5-5.0 micron. The method employs spiral classifier to remove the partly impure minerals with bigger particles in raw ores in advance, reinforcing the dispersion effect and the difference of suspension property of the attapulgites and impure minerals by means of surfactants, increasing separation factor, utilizing gravity separation equipment to separate the impure minerals and the attapulgite clay minerals efficiently, thereby overcoming the shortcomings that the prior art is difficult to achieve industrial production and obtain qualified purification products.

Owner:HEBEI UNIV OF TECH

Preparation method of hollow fiber composite nano-filtration membrane

InactiveCN108479433AMake up for the lack of sealing difficultiesLow mechanical strengthReverse osmosisWater/sewage treatment bu osmosis/dialysisFiberFiltration membrane

The invention relates to a preparation method of a hollow fiber composite nano-filtration membrane. According to the method, a polysulfone hollow fiber basic membrane is adopted and is subjected to dip-coating in a membrane forming solution, which takes acrylic resin, carboxyl type vinyl chloride-vinyl acetate resin and diphenylmethane diisocyanate as solutes and butyl acetate and dimethyl carbonate as solvents, to form a dense membrane, so as to prepare the hollow fiber composite nano-filtration membrane; the disadvantages that an organic hollow fiber composite nano-filtration membrane is easy to swell and has low mechanical strength, and an assembly is difficult to seal are overcome; meanwhile, the nano-filtration membrane has a good desalting rate and relatively high water flux and chemical stability, and can realize continuous industrial production.

Owner:北京享云智汇科技有限公司

Production device and method for continuously producing 2-bromo-3, 3, 3-trifluoropropene

ActiveCN111470939AWell mixedIncrease profitPreparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationAutomatic controlCirculator pump

The invention discloses a production device and method for continuously producing 2-bromo-3, 3, 3-trifluoropropene. The device comprises an addition reaction system, an elimination reaction system, acoarse separation system and a rectification purification system; the addition reaction system is a jet loop reaction system, an addition reaction product 1, 2-dibromo-3, 3, 3-trifluoropropane is adopted as a reaction circulating solvent, and an addition reaction circulating pump circulates to form a jet reaction loop; the addition reactor adopts a venturi jet reactor, and at least one light source is arranged in the reactor. The coarse separation system adopts a flash evaporation continuous separation mode. And the rectification purification system adopts a two-tower continuous pressurized rectification device. The method disclosed by the invention is realized through the production device, has the advantages of simple process, high preparation efficiency, high raw material recycling rate, low possibility of deterioration of the product, stable quality and the like, can realize automatic control of the whole process, saves labor, and is suitable for continuous industrial production of2-bromo-3, 3, 3-trifluoropropene products.

Owner:新元化学(山东)股份有限公司 +1

Method for producing granular rare earth chloride

InactiveCN108408755ARapid cooling and crystallizationCrystallize fastRare earth metal chloridesSolution crystallizationRare earthChloride

The invention discloses a method for producing granular rare earth chloride, and belongs to the field of production of rare earth products, and the method mainly comprises the steps such as adjustingof the pH value of a rare earth chloride solution, concentrating and cooling crystallization of the rare earth chloride solution under reduced pressure. The high temperature rare earth chloride solution is crystallized in a cooling crystallizer which has the function of cooling and destroying solidification and growth of the crystal. The cooling crystallizer comprises a heat transfer jacket, a liner, a rotating shaft, a scraping stirring paddle, a bracket, a tiltable power device, a stirring power device, and the like, and the cooling crystallizer rapidly cools the rare earth chloride throughthe heat transfer jacket and jet air. The coagulation of crystal particles is destroyed by the stirring action of the scraping stirring paddle. The method solves the following problems in the production process in prior art: the rare earth chloride which is condensed as a whole must be crushed; in the cooling crystallization process the rare earth chloride is exposed to the outside air for a longtime, the product is easily contaminated; the production cycle is long; the crushed rare earth chloride has irregular sharp corners, and is not conducive to long-term preservation. The continuous production of the granular rare earth chloride is realized.

Owner:鲍永平

Method for preparing dibutyl dithiocarbamate by aid of high-gravity reactor

The invention discloses a method for preparing dibutyl dithiocarbamate by the aid of a high-gravity reactor. The method includes preparing solution with a molar ratio of 1:0.5-2 from dibutylamine and alkali solution, adding the solution into a mixing tank A, preparing solution with a molar ratio of 1:0.1-1 from carbon disulfide and dichloromethane and adding the solution into a mixing tank B; allowing the temperature of the high-gravity reactor to range from 30 DEG C to 95 DEG C under the control, continuously pumping the solution in the tank A at the flow rate of 1-200 ml / min, simultaneously continuously pumping the solution in the tank B into a vaporizing tube at the speed of 1-200 ml / min, vaporizing the solution, then feeding the solution into the high-gravity reactor and carrying out gas-liquid counter-current reaction on the solution and the vaporized solution; condensing unreacted gas phases, feeding the unreacted gas phases into the tank B to be reused and allowing serous fluid with the dibutylamine and alkali to flow into the tank A to participate in cycling; pumping the serous fluid into a separator when the decreasing speed of the content of the dibutylamine in the tank A tends to be gentle, removing water phases, washing oil phases until the oil phases are neutral and then carrying out reduced pressure distillation under the condition of the vacuum degree ranging from -0.01 Mpa to -0.5 Mpa at the temperature of 50-90 DEG C to obtain the clear and transparent dibutyl dithiocarbamate.

Owner:CHINA PETROLEUM & CHEM CORP +1

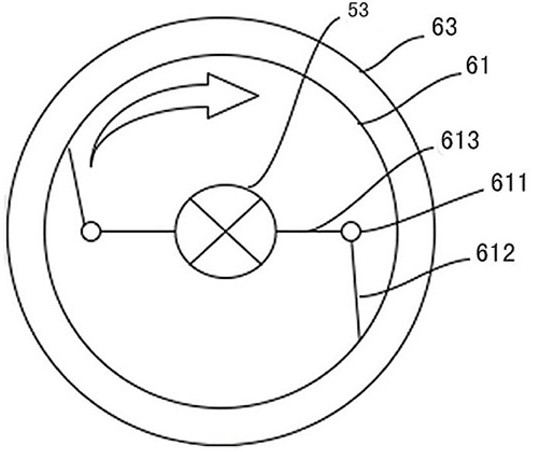

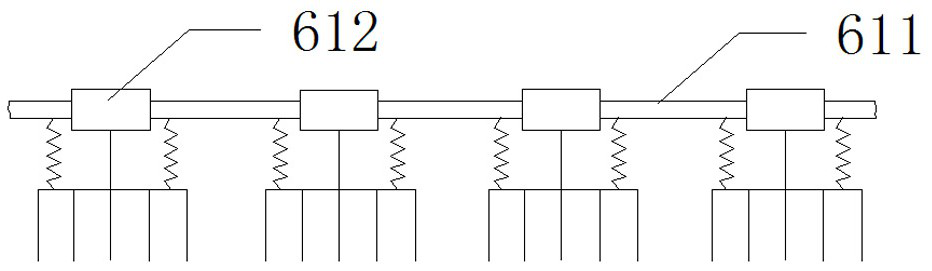

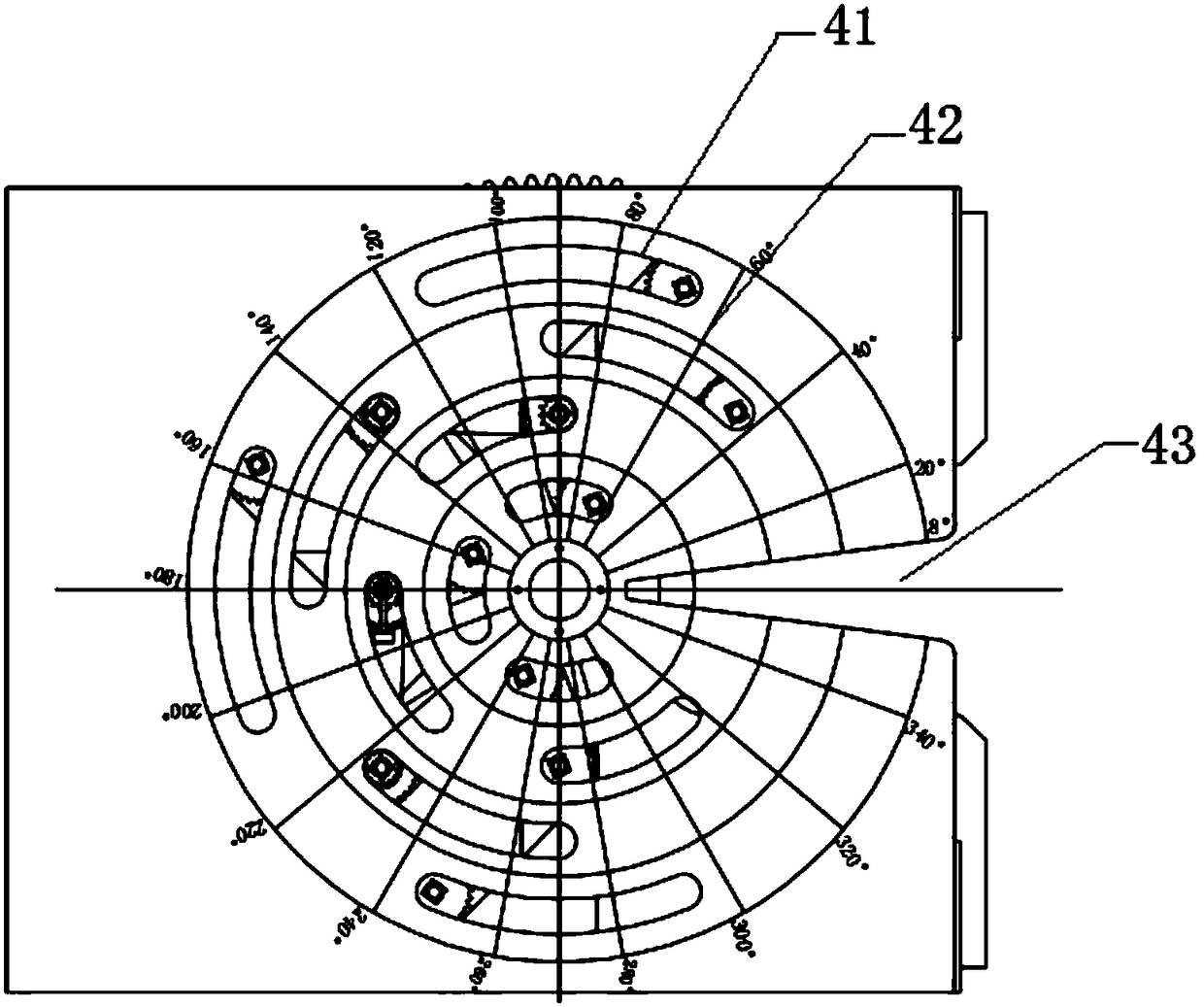

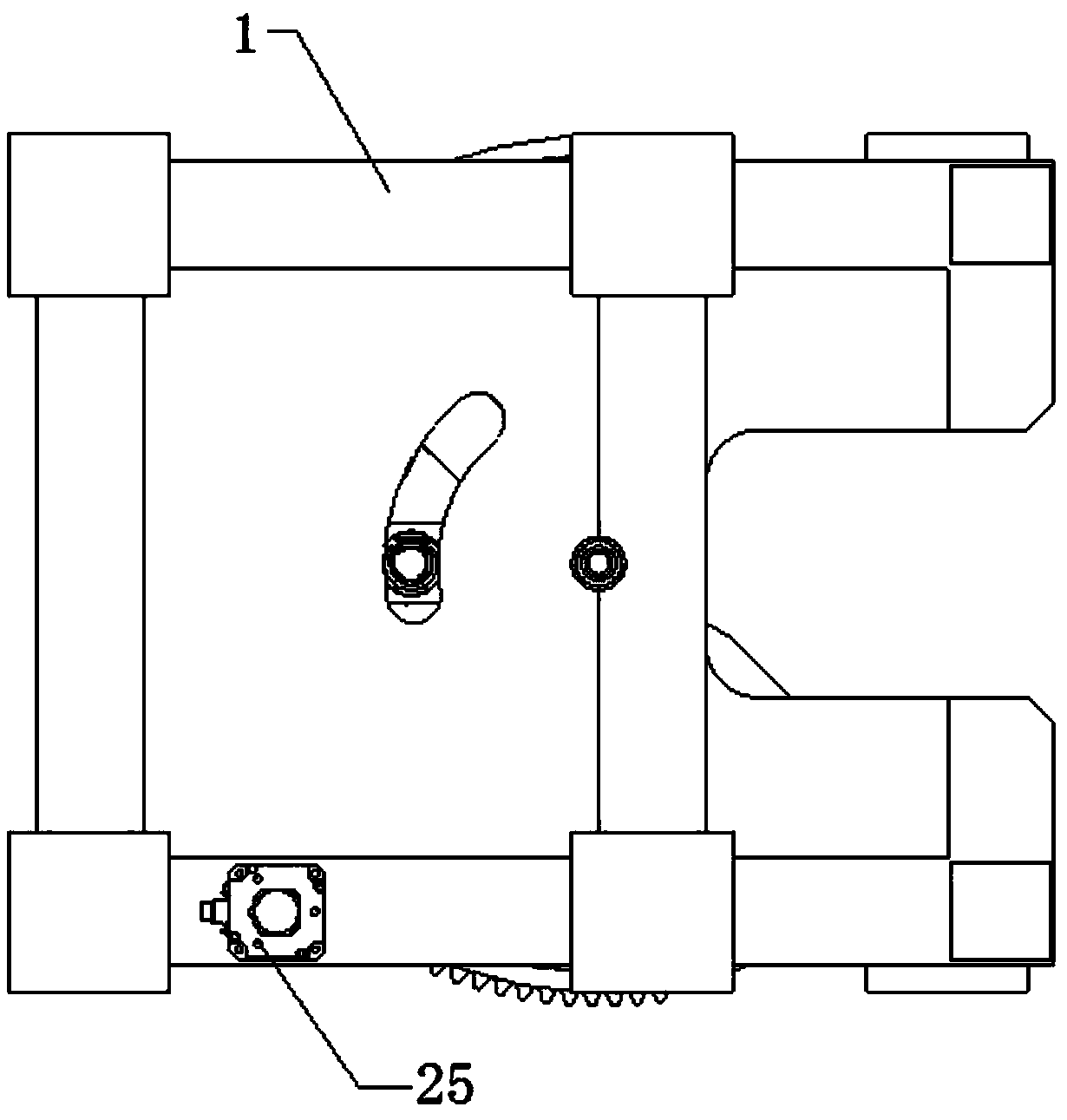

Rotation device used for tire cutting machine

PendingCN108544557ARealize continuous industrial productionHigh degree of automationPreparing sample for investigationMetal working apparatusEngineeringContinuous production

The invention discloses a rotation device used for a tire cutting machine. The rotation device comprises a base, a rotation mechanism, a supporting mechanism and a scale plate; the supporting mechanism comprises multiple supporting wheel sets, each supporting wheel set comprises multiple transmission wheel parts, one transmission wheel part is a driving wheel part, other transmission wheel parts are driven wheel parts, each driving wheel part comprises a lifting motor, a first driving transmission wheel, a second driving transmission wheel, a first supporting shaft and a locking rod, the lifting motors are connected with the first driving transmission wheels, the second driving transmission wheels are fixedly arranged above the first driving transmission wheels and are coaxial with the first driving transmission wheels, and the locking rods transversely penetrate the first supporting shafts. Through the device, continuous production of the tire cutting machine can be achieved.

Owner:青岛厚泽锦业技术有限公司

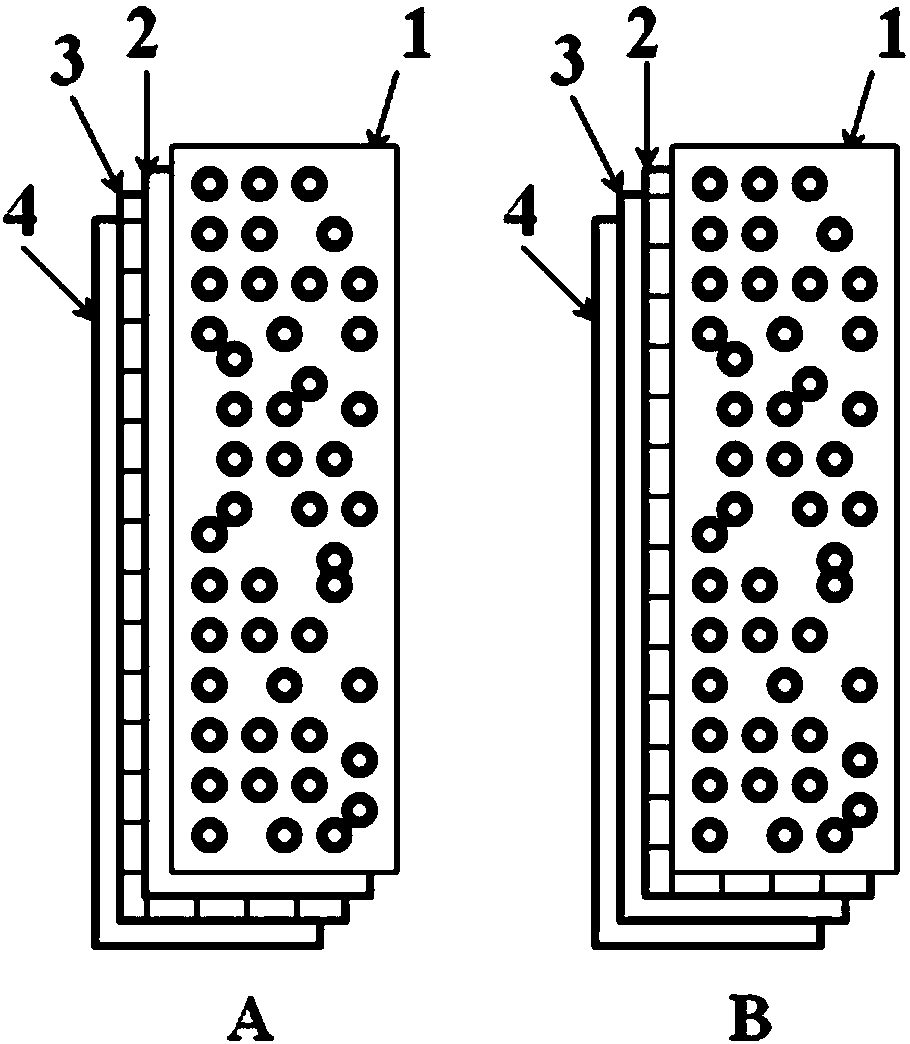

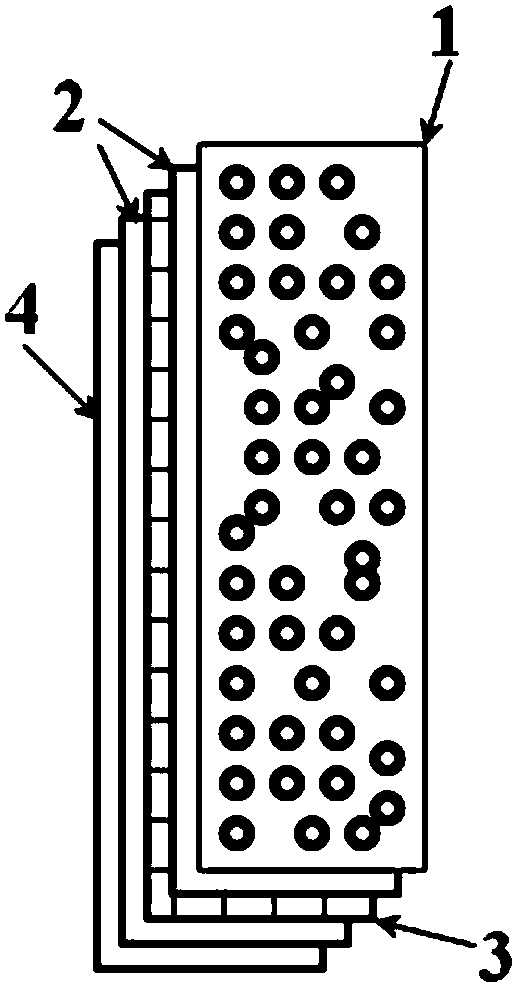

Gas diffusion electrode and preparation method thereof

The invention discloses a gas diffusion electrode. The gas diffusion electrode is low in manufacturing cost, high in production efficiency and long in service lifetime. The gas diffusion electrode comprises a catalytic layer, a transition layer, a current collection conductor and a waterproof ventilation layer, wherein the catalytic layer comprises a carrier material and an active constituent, thetransition layer is formed by pasting and laminating a binding agent and porous particles, the porous particles are conductive particles with high specific surface, the binding agent is a polytetrafluoroethylene, polyvinylidene fluoride or fluorinated ethylene-propylene copolymer, the current collection conductor is a carbon conductor in forms of copper, aluminum, nickel, silver, stainless steel,alloy, carbon fiber, carbon paper or carbon felt, the waterproof ventilation layer is a porous hydrophobic ventilation film, and the material of the waterproof ventilation layer is a polytetrafluoroethylene, polyvinylidene fluoride or fluorinated ethylene-propylene copolymer. The invention also discloses a method for preparing the gas diffusion electrode.

Owner:张树雄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com