Method for producing granular rare earth chloride

A technology of rare earth chloride and production method, applied in chemical instruments and methods, rare earth metal compounds, rare earth metal halides, etc., can solve the problem of irregular sharp edges and corners of rare earth chloride, unfavorable long-term storage and transportation, and the need for rare earth chloride. crushing and other problems, to achieve the effect of continuous industrial production, long cooling waiting time and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for producing granular rare earth chloride. The rare earth chloride used is a cerium chloride solution with a mass concentration of 280g / l. Place 3 liters of cerium chloride solution in a 5 liter glass, adjust the pH to 3.5, and heat it on a heating furnace Evaporate and concentrate to a rare earth content of about 43-45% (based on REO). Stir while cooling, the stirring speed is controlled at 50 r / min, the stirring time is 10 min, the temperature is lowered to room temperature, the rare earth chloride is completely cooled and crystallized, and the particle size of the granular solid cerium chloride is mostly less than 5 mm and a small amount of adhesion.

Embodiment 2

[0021] A method for producing granular rare earth chloride, the rare earth chloride used is a lanthanum cerium chloride solution with a mass concentration of 283g / l, taking 3m 3 The lanthanum cerium chloride solution is placed in a reduced pressure concentration reactor, the pH value is adjusted to 3.5, the heating temperature is controlled at 100-110 ℃, the pressure is 40-50 Kpa, the water in the lanthanum cerium chloride solution is evaporated, and the rare earth content is concentrated to about 43 Between -45% (based on REO). Then release the lanthanum and cerium chloride solution in 3 times, place it in the crystallizer, start the stirring power while adding the lanthanum and cerium chloride solution, and let the scraping paddle perform continuous stirring, and the stirring speed is controlled at 30-50r / min. While adding high-temperature rare earth chloride, cooling water is introduced into the cooling jacket of the crystallizer. According to the outside room temperature, t...

Embodiment 3

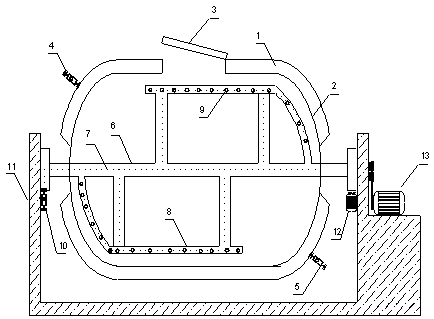

[0023] Rare earth chloride cooling crystallizer, such as figure 1 It is equipped with a cooling device and a device for destroying the solidification and growth of crystal particles. The device for destroying the solidification and growth of crystal particles is a mechanical rotating stirring device. In the laboratory, a small amount of rare earth chloride is cooled and crystallized, and only continuous stirring is required to obtain Granular rare earth chloride. In the continuous industrial production, due to the large amount of rare earth chloride, a large amount of heat needs to be released, which requires a cooling device and a special stirrer.

[0024] The industrial cooling crystallizer is composed of heat transfer jacket 1, inner liner 2, rotating shaft 6, scraping stirring paddle 8, bracket 11, stirring power device 13, etc., rotating shaft 6 is fixed on the bracket, and rotating shaft 6 is fixed with scraping and stirring The paddle 13, the rotating shaft 6 and the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com