Method for recycling phosphorus from sewage through bioelectrochemical struvite crystallization

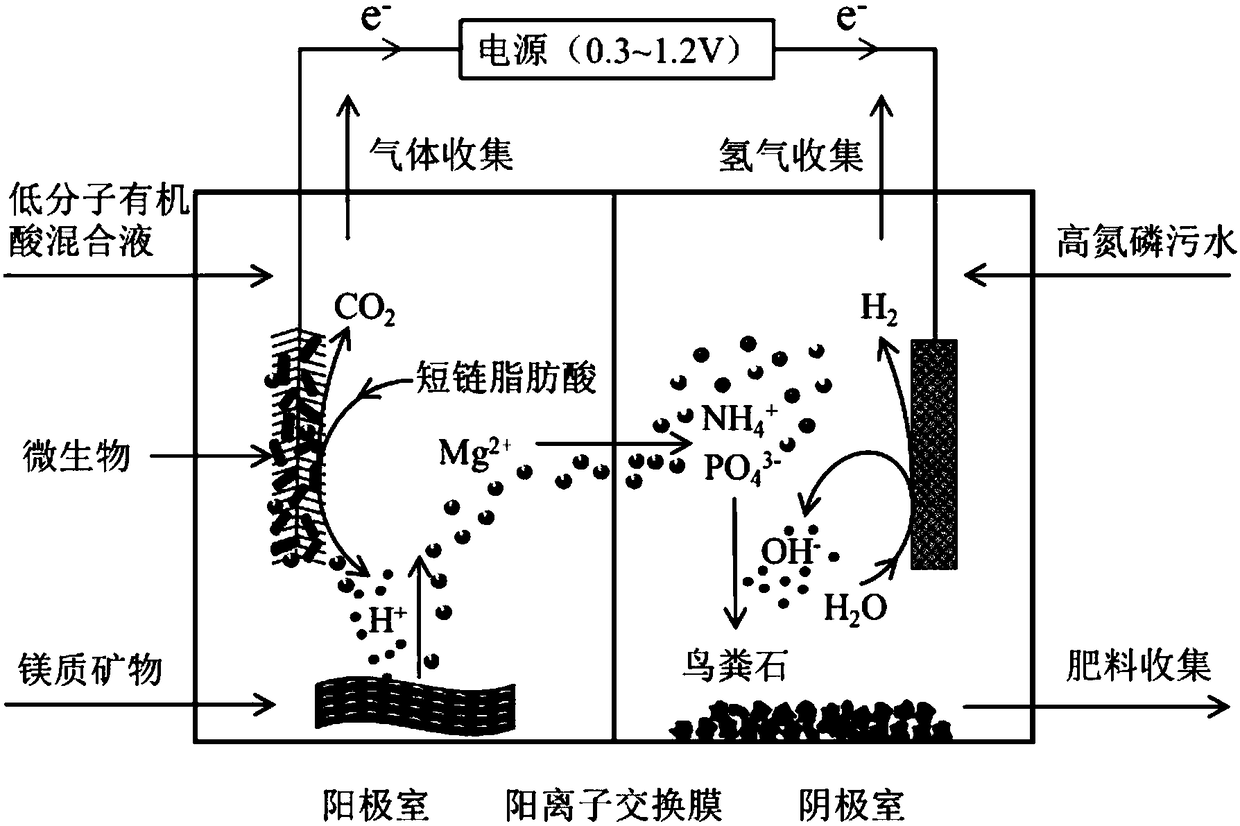

A bioelectrochemical and struvite technology, applied in chemical instruments and methods, biological water/sewage treatment, electrochemical biocombination treatment, etc., can solve problems such as system performance degradation, damage to the activity of electrogenic bacteria, and potential increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

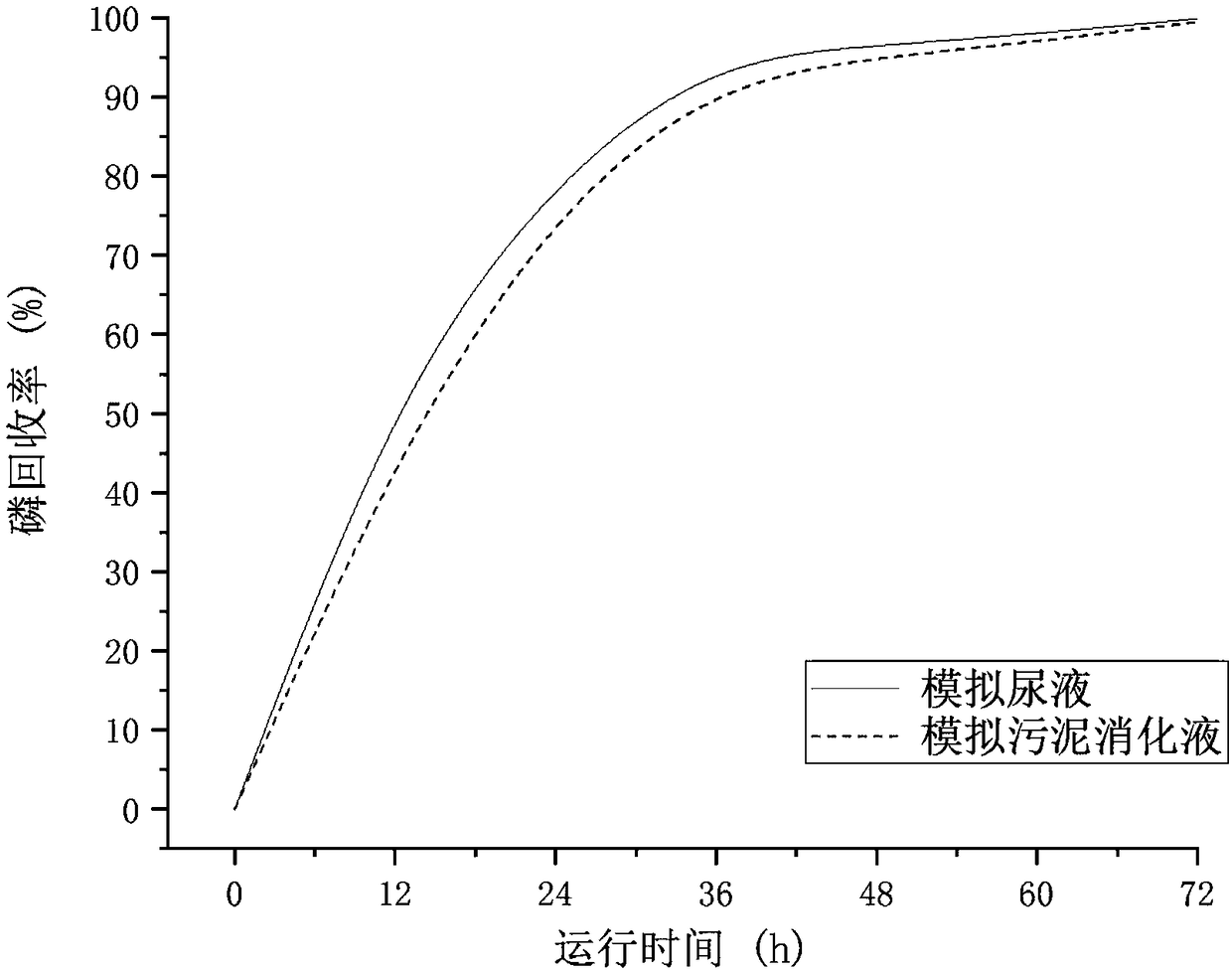

Embodiment 1

[0032] Applied to sludge digestion liquid, the process flow is as follows:

[0033] 1. Construction of double-chamber microbial electrolytic cell:

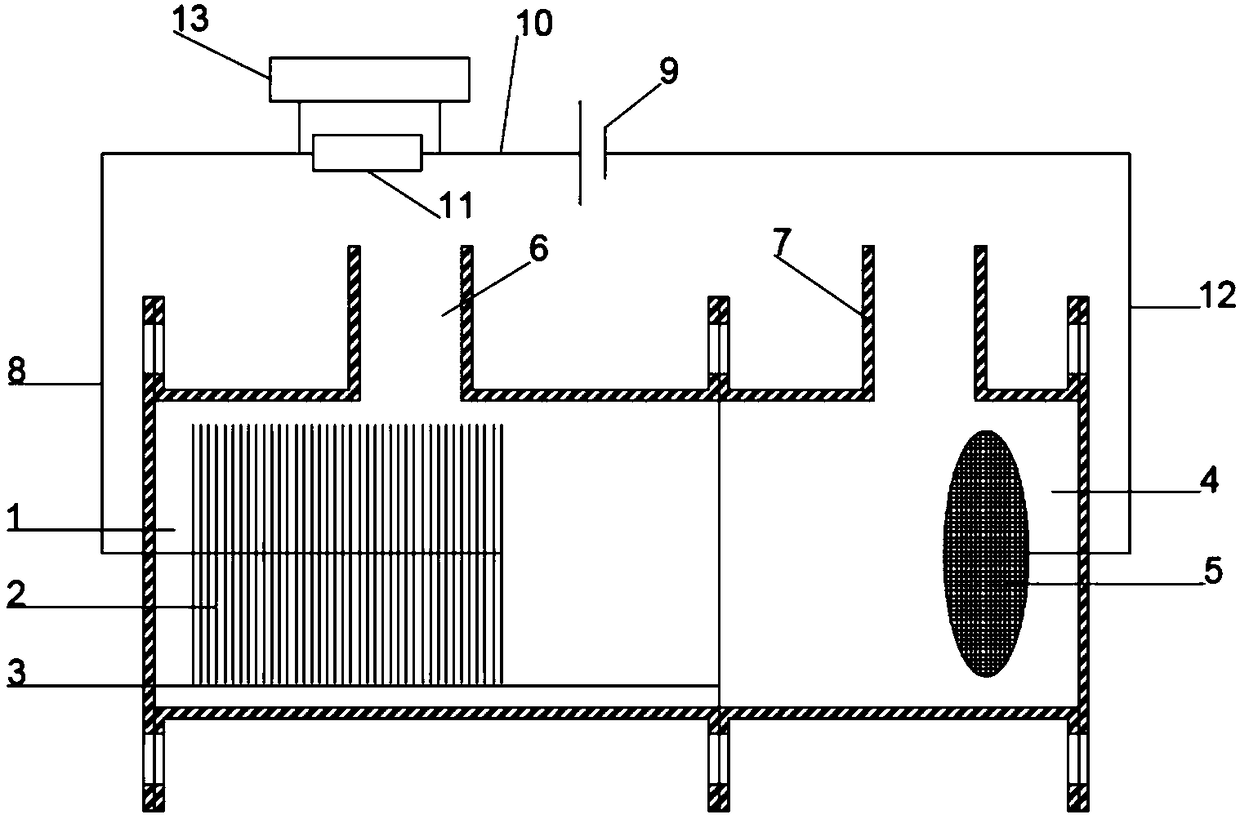

[0034] The structure of the double-chamber microbial electrolytic cell is as follows: figure 2 As shown, including: 1 anode chamber, 2 carbon brush anode electrode, 3 cation exchange membrane, 4 cathode chamber, 5 stainless steel mesh cathode electrode, 6 anode chamber inlet, 7 cathode chamber inlet / gas collection port, 8 wires, 9 potentiostat, 10 wire, 11 high-precision resistor, 12 titanium wire, 13 data acquisition system.

[0035] The anode chamber 1 and the cathode chamber 4 of the dual-chamber microbial electrolysis cell are separated by a cation exchange membrane 3 (CMI-7000, Membrane International). Before the carbon brush anode is used, clean the impurities on the carbon fiber with deionized water, and heat it at 450°C for 30 minutes in a muffle furnace to facilitate the attachment of microorganisms. Before using the ...

Embodiment 2

[0042] Applied to urine, the technological process is as follows:

[0043] 1. Construction of double-chamber microbial electrolytic cell:

[0044] The structure of the double-chamber microbial electrolytic cell is as follows: figure 2 As shown, including: 1 anode chamber, 2 carbon brush anode electrode, 3 cation exchange membrane, 4 cathode chamber, 5 stainless steel mesh cathode electrode, 6 anode chamber inlet, 7 cathode chamber inlet / gas collection port, 8 wires, 9 potentiostat, 10 wire, 11 high-precision resistor, 12 titanium wire, 13 data acquisition system.

[0045] The anode chamber 1 and the cathode chamber 4 of the dual-chamber microbial electrolysis cell are separated by a cation exchange membrane 3 (CMI-7000, Membrane International). Before the carbon brush anode is used, clean the impurities on the carbon fiber with deionized water, and heat it at 450°C for 30 minutes in a muffle furnace to facilitate the attachment of microorganisms. Before using the stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com