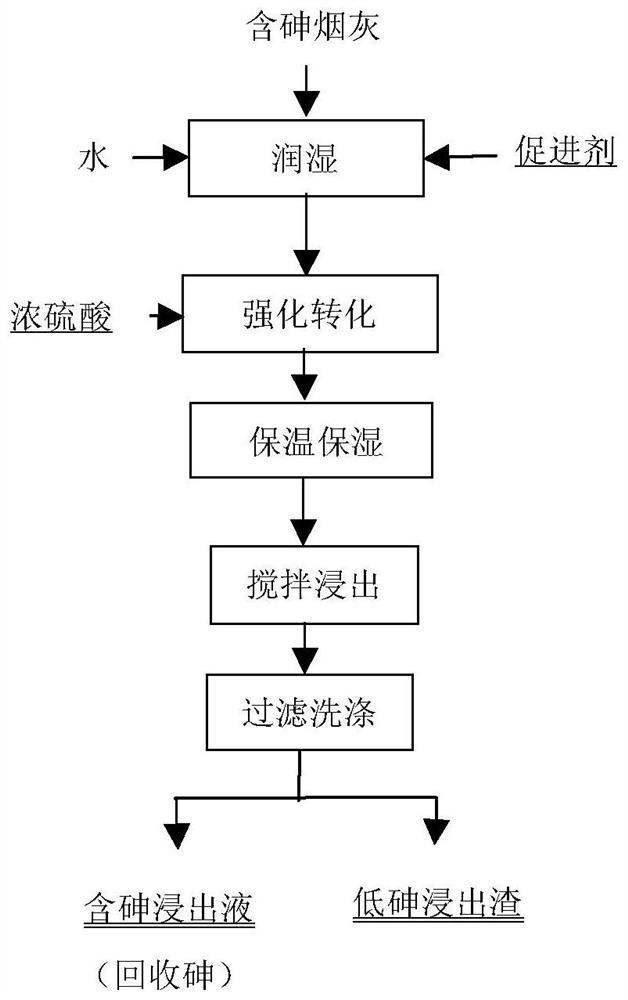

Process for removing arsenic by converting and leaching arsenic-containing soot produced by copper-lead pyrometallurgy

A technology of pyrometallurgy and lead fire method, which is applied in the field of conversion and leaching of arsenic-containing arsenic in copper-lead pyrometallurgy smelting, can solve the problems of high chemical cost, high arsenic removal rate, and difficulty in achieving it, and achieve simple equipment, The effect of simple processing and easy engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A copper smelting company in Hunan has electric dust collection. The chemical composition of raw materials mainly includes Cu 16.38%, As 12.8%, Zn 2.22%, Pb 11.10%, Fe 1.29%, S 11.15% and Bi 2.90%. The soot is used as raw material. Adopting the method of the present invention to process arsenic removal comprises the following steps:

[0039]The raw materials are crushed and mixed evenly with double rollers. Take 100g of the mixed material and put it in a ground jar, measure 8ml of tap water, add 20g of high iron sulfate, mix it into the soot, and mix it evenly with a spoon. Measure 14ml of concentrated sulfuric acid (36N), quickly drop it into the well-mixed and moistened soot, and quickly mix it evenly, cover it, and put it in an oven set at 120°C. After reaching the temperature, keep it for 4 hours , take out to cool slightly. Measure 500ml of tap water, add it to a jar, stir and leach for 2 hours at room temperature, filter with suction, and rinse to obtain 648ml of...

Embodiment 2

[0042] Copper smelting soot from a certain place in Henan, the main chemical composition of raw materials includes Cu 21.10%, As 7.02%, Zn2.72%, Pb3.15%, Fe 10.82%, S 12.03% and Bi 0.60%, using this soot as raw material, using this The inventive method for dealing with arsenic removal comprises the following steps:

[0043] The raw materials are crushed and mixed evenly with double rollers. Take 100g of the mixed material and put it in a ground jar, measure 12ml of tap water, add 10g of pyrolusite, mix it into the soot, and mix it evenly with a spoon. Measure 7ml of concentrated sulfuric acid (36N), quickly drop it into the well-mixed and moistened soot, and quickly mix it evenly, cover it, and put it in an oven set at 80°C, and keep it for 8 hours after reaching the temperature , take out to cool slightly. Measure 500ml of tap water, add it to a jar, stir and leach at 60°C for 1 hour, filter with suction, and rinse to obtain 688ml of leaching solution. Sampling and analyzing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com