Preparation method and application for iron oxyhydroxide

An iron oxyhydroxide, reaction technology, applied in chemical instruments and methods, iron oxide/iron hydroxide, metal/metal oxide/metal hydroxide catalyst, etc. Uniform, large particle size and other problems, to achieve the effect of inhibiting the growth of crystal nucleus, shortening the contact time, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

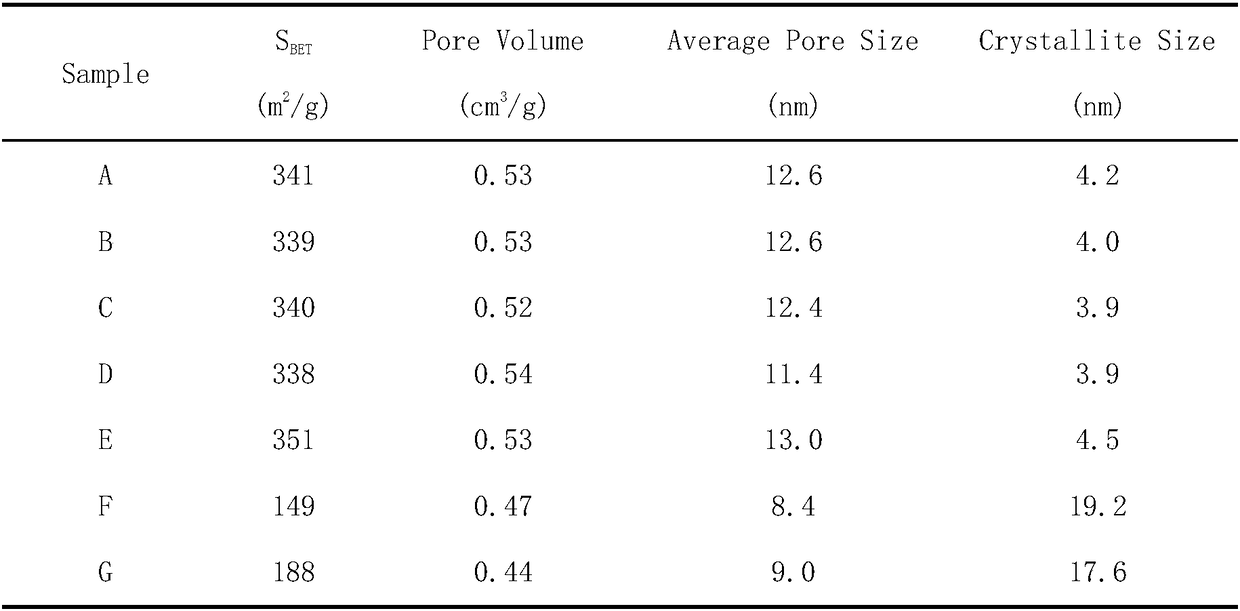

Embodiment 1

[0028] Configure 0.5mol / L FeCl 2 solution and 2.0mol / L NaOH solution. A rotating packed bed supergravity reactor using wire mesh as filler, with a rotational speed of 1000 revolutions per minute. Oxygen-containing gas is sprayed into the rotating bed from the bottom of the reactor through a gas distributor. Regulated Fe 2+ The relative flow of the solution and the lye is such that the pH of the slurry at the outlet of the reactor is 9.0. The outlet slurry is pumped into the aging tank via a sampling pump. The heating temperature of the aging tank is 20°C, stirring, bubbling and oxidation with oxygen-containing gas, and the aging time is 30 minutes. After aging, the slurry was subjected to routine operations such as separation, washing, and drying to obtain sample A.

Embodiment 2

[0030] Configure 1.0mol / L FeSO 4 solution and 2.8mol / L NaCO 3 and NaHCO 3 Mixed alkaline solution in which NaCO 3 and NaHCO 3 The molar ratio is 1:1. A rotating packed bed supergravity reactor using wire mesh as filler, with a rotational speed of 1500 revolutions per minute. Oxygen-containing gas is sprayed into the rotating bed from the bottom of the reactor through a gas distributor. Regulated Fe 2+ The relative flow of the solution and the lye makes the pH of the slurry at the outlet of the reactor 8.0. The outlet slurry is pumped into the aging tank via a sampling pump. The heating temperature of the aging tank is 40°C, stirring, bubbling and oxidation with oxygen-containing gas, and the aging time is 10 minutes. After aging, the slurry was subjected to routine operations such as separation, washing, and drying to obtain sample B.

Embodiment 3

[0032] Configure 1.5mol / L Fe(NO 3 ) 2 solution and 3.4mol / L NH 4 OH and NH 4 HCO 3 Mix the alkaline solution. A rotating packed bed supergravity reactor using wire mesh as filler, with a rotational speed of 2000 revolutions per minute. Oxygen-containing gas is sprayed into the rotating bed from the bottom of the reactor through a gas distributor. Regulated Fe 2+ The relative flow of the solution and the lye makes the pH of the slurry at the outlet of the reactor 7. The outlet slurry is pumped into the aging tank via a sampling pump. The heating temperature of the aging tank is 45° C., stirring, bubbling and oxidation with oxygen-containing gas, and the aging time is 90 minutes. After aging, the slurry was subjected to routine operations such as separation, washing, and drying to obtain sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com