Gas diffusion electrode and preparation method thereof

A gas diffusion electrode and one-sided technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of electrode performance attenuation, gas diffusion layer damage, attenuation, etc., and achieve low manufacturing cost, long service life, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

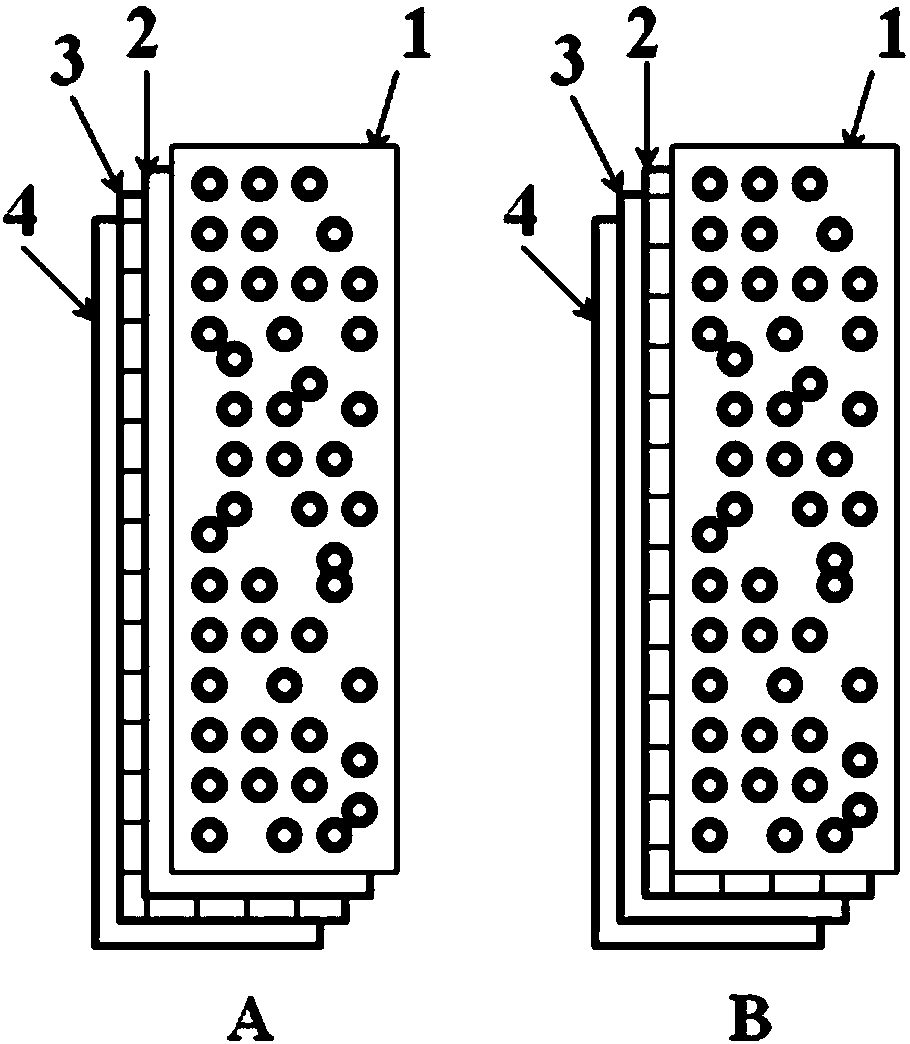

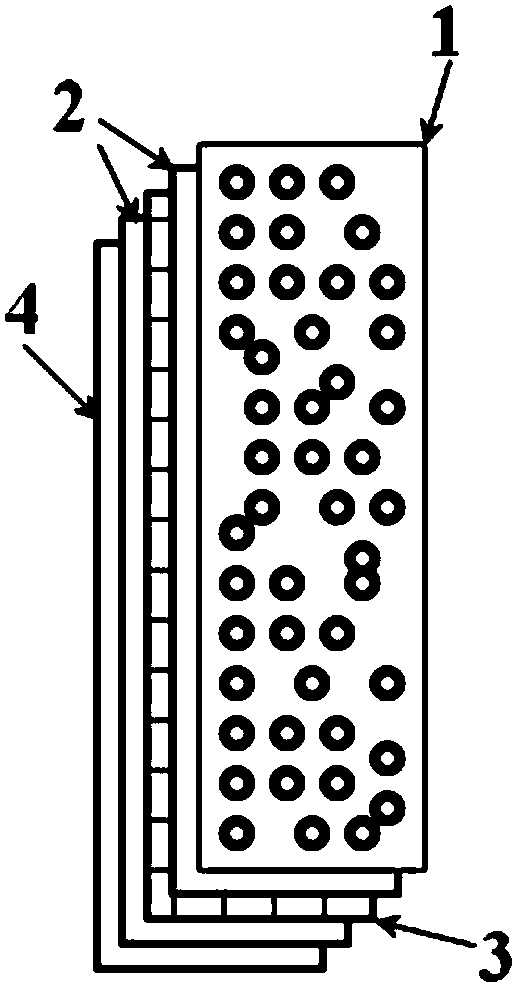

[0038] A method for preparing the gas diffusion electrode is also provided, and the method includes the following steps:

[0039] (4) Cold pressing the current collector conductor with a certain size and a thickness of 0.1-2mm and the transition layer with a thickness of 0.5-3mm;

[0040] (5) One side of the transition layer is sprayed with a catalytic layer slurry with a thickness of 0.005-0.5mm, dried at 10-100°C and hot-pressed at 20-80°C;

[0041] (6) Cold press the other side of the transition layer in step (2) and the waterproof and breathable layer with a thickness of 0.05-0.5mm to form an electrode sheet with a thickness of 0.5-2mm, and hot press at 30-400°C to form a gas diffusion electrode.

[0042] Another preparation method of the gas diffusion electrode is also provided, the method includes the following steps:

[0043] (1) at certain size, one side of the transition layer with a thickness of 0.5-3mm is sprayed with catalytic layer slurry, and the thickness is 0....

Embodiment 1

[0063] A method for manufacturing an air electrode, comprising a catalytic layer, a transition layer, a current-collecting conductive layer, and a waterproof and breathable layer.

[0064] The manufacturing method of the above-mentioned air electrode: cold-press a copper mesh with a certain size and a thickness of 0.2 and a transition layer with a thickness of 0.5 mm; Hot pressed at 30°C. Finally, spray the adhesive on the other side of the sheet and cold press it with a waterproof and breathable layer with a thickness of 0.18 mm to form an electrode sheet with a thickness of 1 mm. Finally, the electrode sheet was fired at 350°C to form a gas diffusion electrode.

[0065] The method for making the transition layer of the above-mentioned air electrode: 40% by mass of acetylene black and 60% by mass of polytetrafluoroethylene emulsion are uniformly mixed with absolute ethanol. The prepared transition layer raw material is finally made into a transition layer material with a th...

Embodiment 2

[0070] A method for manufacturing an air electrode, comprising a catalytic layer, a transition layer, a current-collecting conductive layer, and a waterproof and breathable layer.

[0071] The manufacturing method of the above-mentioned air electrode: cold-press a copper mesh with a certain size and a thickness of 0.3 and a transition layer with a thickness of 0.6 mm; then spray a catalytic slurry with a thickness of 0.06 mm on the copper mesh surface, dry it at 50 ° C and Hot pressed at 30°C. Finally, the other side of the sheet body is sprayed with an adhesive and cold-pressed with a waterproof and breathable layer with a thickness of 0.2mm to form a 1.2mm thick electrode sheet. Finally, the electrode sheet was fired at 350°C to form a gas diffusion electrode.

[0072] The method for making the transition layer of the above-mentioned air electrode: 45% by mass of acetylene black and 55% by mass of polytetrafluoroethylene emulsion are uniformly mixed with absolute ethanol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com