Thin pancake machine

A pancake and rack technology, applied in the field of pancake machines, can solve the problems of unfavorable automation and large-scale production, high frequency of contact between human hands and dough, poor hygiene, etc., and achieves the realization of industrialized production line operation, novel structure, automation and hygiene. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

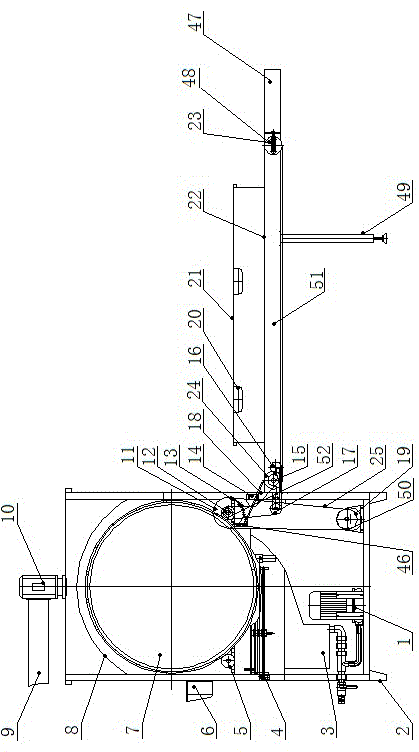

[0022] figure 1 Shown is the structural representation of the present invention.

[0023] The invention provides a pancake machine, which includes a frame 2, a roller mold 7, a spraying mechanism, a transmission mechanism, a conveying mechanism and an electrical control part 6.

[0024] Described drum mold 7 is arranged on the top of frame 2, and the top of described drum mold 7 is provided with arc-shaped insulation board 8, and its front is provided with scraper 46 and along material tray 18, and its below is provided with material spraying mechanism.

[0025] The top of described frame 2 is provided with blower fan 10, and the air inlet of blower blower 10 and air outlet are provided with connecting pipe and exhaust pipe 9, and the form and length of exhaust pipe 9 can be determined 9 according to actual production site.

[0026] The transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com