Continuous production process and apparatus of honeycomb card board with stuffing

A filling material and production process technology, applied in the field of continuous production process and production equipment, can solve the problems of poor sound insulation performance, poor thermal insulation performance, honeycomb panels can not meet the needs of modern engineering, etc., achieve excellent thermal insulation performance and sound insulation performance, simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

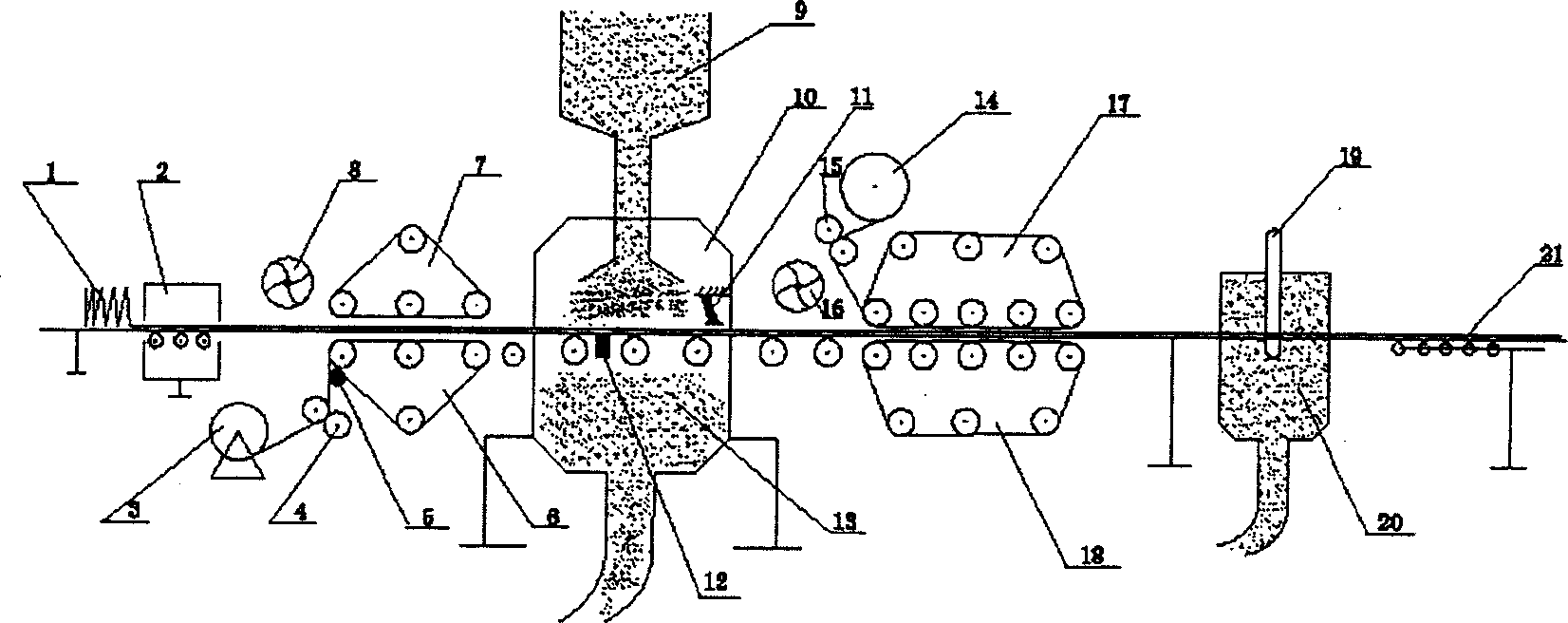

Method used

Image

Examples

Embodiment 1

[0028] The composite wall body of fire-retardant paper honeycomb board and gypsum panel filled with expanded perlite produced by the present invention has the following properties:

[0029] The honeycomb paper core is made of 175 grams of flame-retardant cardboard, the honeycomb aperture is 10mm; the thickness of the gypsum board is 10mm, and the wall thickness is 100mm, filled with expanded perlite.

[0030] Core material (honeycomb paper core with filling material) thermal conductivity: 0.03W / M.K

[0031] Sound insulation: 55dB, GBJ75-1984

[0032] Fire resistance limit: 102min, GB9978-88

[0033] Bending load: 4.75KN / Z JG / T 3029

[0034] Compression resistance: 4.25Mpa

[0035] Filling material density: 55kg / m 3

[0036] The maximum diameter of filler particles: 1.2mm, moisture content: <3%.

Embodiment 2

[0038] The composite plate of paper honeycomb plate and color steel plate filled with flame-retardant polystyrene foam particles produced by the present invention has the following properties:

[0039] Honeycomb paper core made of flame-retardant cardboard weighing 175 grams, with a honeycomb aperture of 10mm;

[0040] Color steel plate thickness: 0.5mm

[0041] Total thickness of the board: 60mm

[0042] Thermal conductivity of core material: 0.04W / M.K

[0043] Sound insulation: 35dB, GBJ75-1984

[0044] Flame retardant: B1 level

[0045] Compressive strength: 4.5M.Pa

[0046] Filling material density: 15kg / m 3

[0047] Filling material particle diameter: 1-2.5mm.

Embodiment 3

[0049] Be filled with the composite partition wall board of the paper honeycomb board and the magnesia panel of vermiculite powder and polystyrene foam particle mixed material (volume ratio 1: 1) produced by the present invention, performance is as follows:

[0050] Honeycomb paper core made of flame-retardant cardboard weighing 175 grams, with a honeycomb aperture of 10mm;

[0051]MgO plate thickness: 10mm

[0052] Total wall thickness: 100mm

[0053] Thermal conductivity of core material: 0.55W / M.K

[0054] Sound insulation: 57dB, GBJ75-1984

[0055] Fire resistance limit: 123min, GB9978-88

[0056] Bending load: 5.8KN / Z JG / T 3029

[0057] Compression resistance: 4.20Mpa

[0058] Filling material density: 40kg / m 3

[0059] Filling material Polystyrene particle diameter: 1-2.5mm; vermiculite powder diameter 1.5mm, water content <3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com