Technique for hypercritical continuous preparation of biological diesel oil and equipment thereof

A biodiesel and supercritical technology, applied in the petroleum industry, biological raw materials, biofuels, etc., can solve the problems of slow heterogeneous reaction rate, expensive enzyme catalyst, waste acid and waste alkali discharge, etc., and save reaction time. , to avoid the discharge of waste acid or waste lye, the effect of mass transfer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

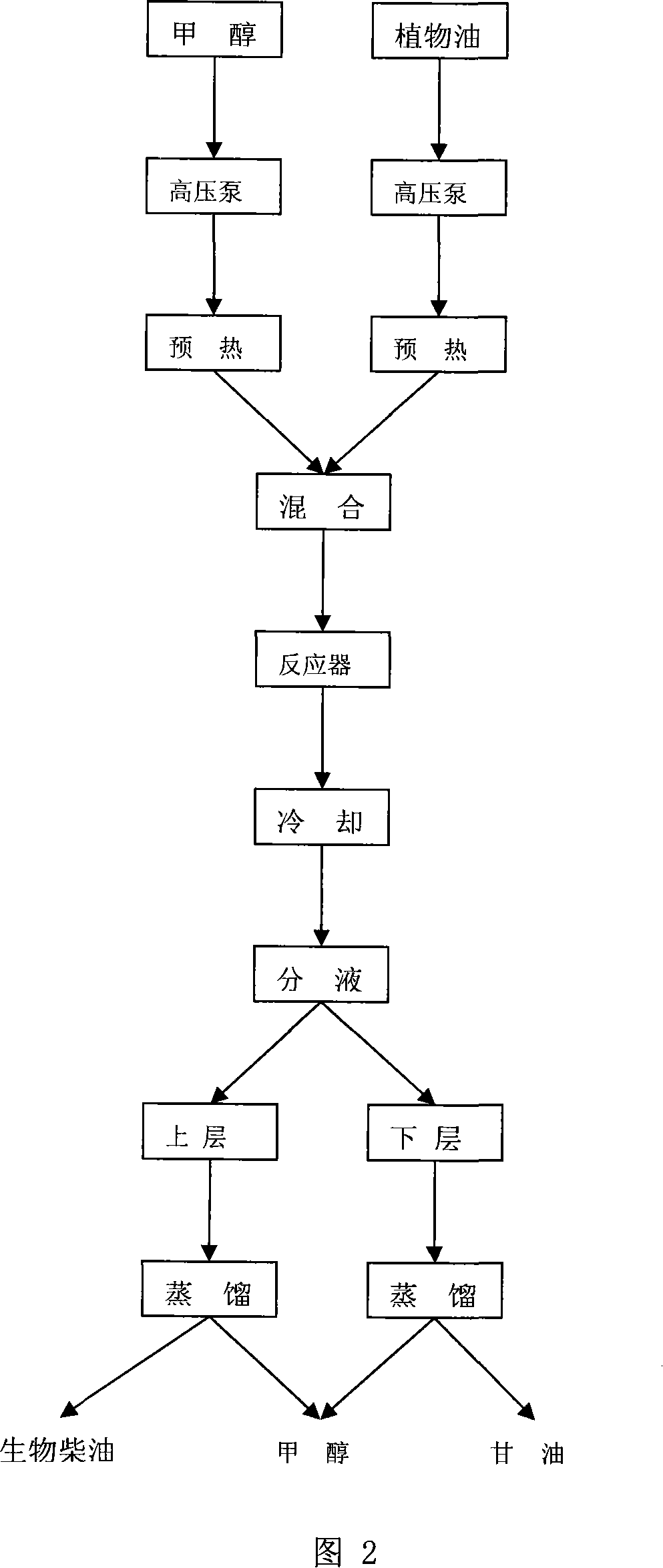

[0035] As shown in Figure 2, the supercritical continuous biodiesel preparation process comprises the following steps:

[0036] 1) Select methanol [analytical pure methanol] and vegetable oil [edible soybean oil (Hubei Zhongchang Company)] according to the molar ratio of methanol and vegetable oil as 42:1, and reserve;

[0037] 2) Put methanol and vegetable oil into their respective preheaters with high-pressure pumps, methanol is preheated at a constant temperature of 200°C, and vegetable oil is preheated at a constant temperature of 250°C, and then mixed in a mixer;

[0038] 3) After mixing well, enter into a constant temperature tubular reactor, the reaction temperature is 300°C, the pressure is 18MPa, and the reaction time is 8min;

[0039] 4) After the reaction is completed, it enters the preliminary separator. The preliminary separator adopts a flash tower, and the system pressure drops from 18Mpa to 6-10Mpa. At this time, most of the methanol enters the gas phase becaus...

Embodiment 2

[0041] As shown in Figure 2, the supercritical continuous biodiesel preparation process comprises the following steps:

[0042] 1) Select methanol [analytical pure methanol] and vegetable oil [edible soybean oil (Hubei Zhongchang Company)] according to the molar ratio of methanol and vegetable oil as 42:1, and reserve;

[0043] 2) Put methanol and vegetable oil into their respective preheaters with high-pressure pumps, methanol is preheated at a constant temperature of 200°C, and vegetable oil is preheated at a constant temperature of 250°C, and then mixed in a mixer;

[0044] 3) After mixing fully, enter into a constant temperature tubular reactor, the reaction temperature is 350°C, the pressure is 20MPa, and the reaction time is 10min;

[0045] 4) After the reaction is completed, it enters the preliminary separator. The preliminary separator adopts a flash tower, and the system pressure drops from 20Mpa to 6-10Mpa. At this time, most of the methanol enters the gas phase beca...

Embodiment 3

[0047] As shown in Figure 2, the supercritical continuous biodiesel preparation process comprises the following steps:

[0048] 1) Select methanol [analytical pure methanol] and vegetable oil [edible soybean oil (Hubei Zhongchang Company)] according to the molar ratio of methanol and vegetable oil as 42:1, and reserve;

[0049] 2) Put methanol and vegetable oil into their respective preheaters with high-pressure pumps, methanol is preheated at a constant temperature of 200°C, and vegetable oil is preheated at a constant temperature of 250°C, and then mixed in a mixer;

[0050] 3) After mixing fully, enter into a constant temperature tubular reactor, the reaction temperature is 350°C, the pressure is 20MPa, and the reaction time is 10min;

[0051] 4) After the reaction is completed, it enters the preliminary separator, which adopts a gas-liquid separator. The system pressure drops from 20Mpa to 6-10Mpa, and the temperature drops from 350°C to 150-200°C. The methanol in biodiese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com