Defoaming agent applied to thin-layer self-leveling mortar and preparation method of defoaming agent

A defoamer and self-leveling technology, which is applied in the field of fine chemical preparations, can solve the problems of cracking and hollowing on the surface of thin-layer self-leveling mortar, and achieve the effects of reducing the risk of oil floating, simple preparation method and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

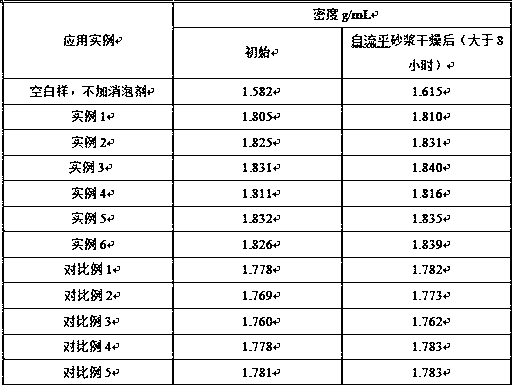

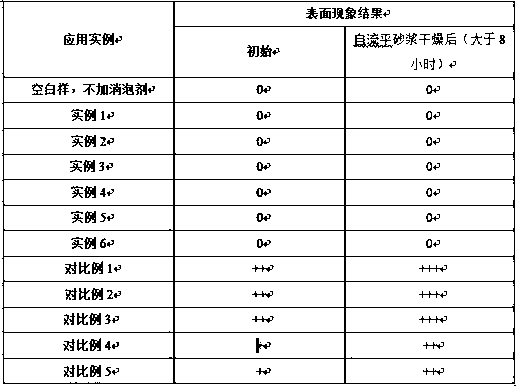

Examples

Embodiment 1

[0023] Take 25g 2-octyldodecanol and 4g vapor phase hydrophilic silica (specific surface area 50 m 2 / g), stirring at 120°C for 3 hours, it is dispersion M1-1.

[0024] Take 15.625g hydrogen-terminated silicone oil (0.1% hydrogen content), 9.375g acetylene alcohol ether (molecular weight 600), mix and heat, add 50ppm catalyst chloroplatinic acid isopropanol solution at a temperature of 50℃, and the reaction time is at 100℃ After 3 hours, the acetylene alcohol silicon polyether D-1 is obtained, and the dispersion M1-1 is added, 30 g of nonylphenol polyoxyethylene ether, the temperature is lowered at 80° C., and the temperature is kept for 1 hour, which is M2-1.

[0025] At a temperature of 60℃, a rotating speed of 1000rpm, and a time of 30s, spray M2-1 through a metering pump onto 16g of vapor-phase hydrophilic silica (specific surface area 50 m 2 / g), it becomes M3-1 after mixing. The prepared solid defoamer can be obtained by sieving the mixture M3-1.

Embodiment 2

[0027] Take 10g tetradecyl alcohol and 16g precipitation method hydrophilic silica (specific surface area 500m 2 / g), stirring for 2 hours at a temperature of 180°C, it is dispersion M1-2.

[0028] Take 4.68g side hydrogen silicone oil (hydrogen content 0.3%, molecular weight), 25.32g D2 molecular weight 1500 mixed and heated, add 15ppm catalyst platinum-alcohol complex at a temperature of 80℃, and a reaction time of 0.5 hours at a temperature of 160℃ to obtain Add the dispersion M1-2, 20g lauric acid polyoxyethylene ether, and keep the temperature at 100°C for 0.5 hours to obtain M2-2.

[0029] At a temperature of 100°C, a rotation speed of 500rpm, and a time of 10s, spray M2-2 through a metering pump onto 24g of precipitation hydrophilic silica (specific surface area of 500m 2 / g), it becomes M3-2 after mixing. The prepared solid defoamer can be obtained by sieving the mixture M3-2.

Embodiment 3

[0031] Take 25g cetyl alcohol and 16g vapor phase hydrophilic silica (specific surface area 200m 2 / g), stirring for 2.5 hours at a temperature of 160°C, it is dispersion M1-3.

[0032] Take 6.25g end-side hydrogen silicone oil (0.2% hydrogen content), 13.75g butynol ether (molecular weight 1000), mix and heat, add 3ppm catalyst platinum-olefin complex at 70℃, and react at 140℃. It is 2 hours to obtain acetylenic silicon polyether D-3, adding dispersion M1-3, 15g sorbitan monostearate, cooling at 90°C and keeping it for 1 hour, it is M2-3.

[0033] At a temperature of 80℃, a rotation speed of 800rpm, and a time of 20s, spray M2-3 through a metering pump onto 24g of vapor-phase hydrophilic silica (specific surface area 200m 2 / g), it becomes M3-3 after mixing. The prepared solid defoamer can be obtained by sieving the mixture M3-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com