Alkynol modified fluorine-containing polyester compound, preparation method thereof, anti-oil stain auxiliary agent and application of anti-oil stain auxiliary agent

A fluorine-containing polyester and compound technology, which is applied in the directions of repelling fibers to liquids, textiles and papermaking, fiber processing, etc., to achieve the effects of good oil resistance, good oil resistance and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

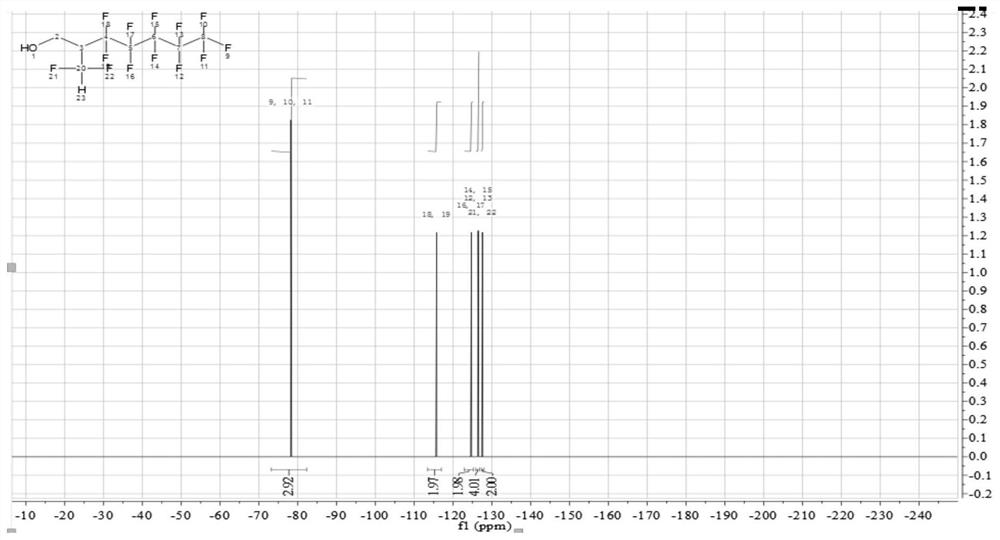

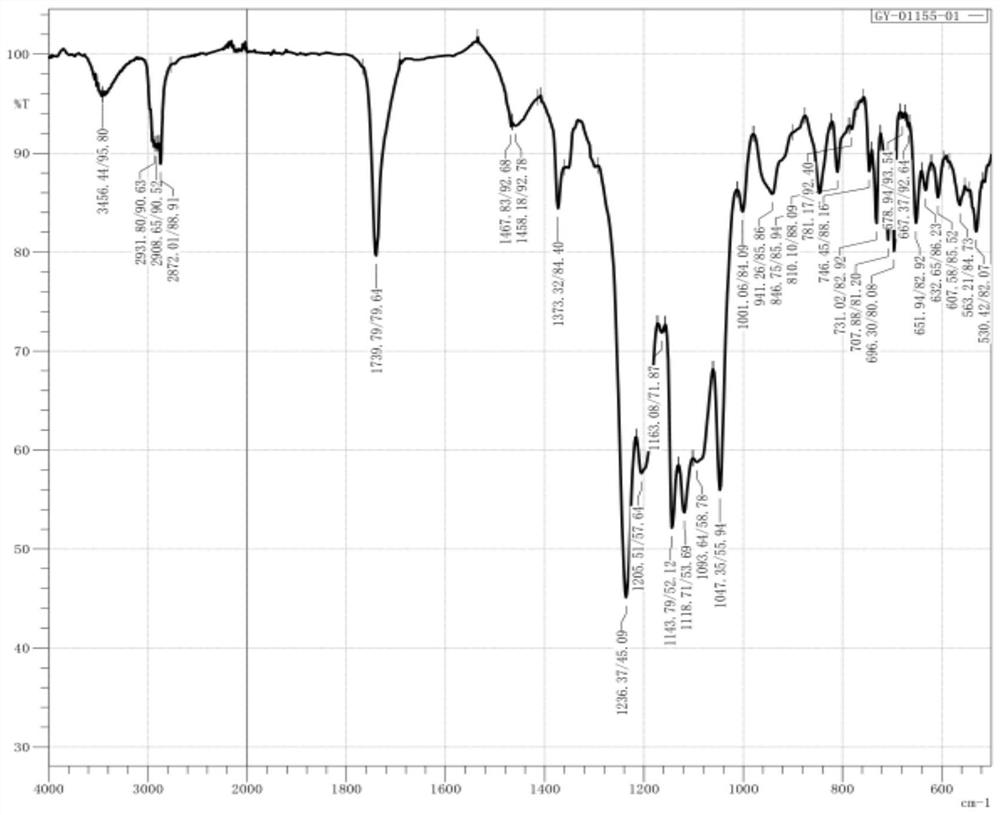

[0058] Get 0.2g sulfuric acid as catalyzer and the perfluoroisooctanol of 25.28g of sebacic acid, 45.61g (its fluorine spectrum such as figure 1 shown) as a raw material, mixed evenly with 141.59g of xylene, placed in a closed reaction vessel equipped with a water separation device, and stirred for 6 hours under the condition of heating in an oil bath at 150°C for water separation reaction to obtain a fluorine-containing polyester prepolymer.

[0059] Fix the total molar ratio of fluorine-containing unit alcohols and acetylene alcohols to be 1:1, add 106.29 g of fluorine-containing polyester prepolymer xylene solution (solid content 33.3%) in a closed reaction vessel equipped with a water separator, add 40.625g of polyether-modified acetylenic diol (molecular weight 650), stirring and heating up to solvent reflux, water separation reaction 10h, vacuum (-0.1Mpa) suction filtration after the completion of the reaction, use 76g propylene glycol monomethyl ether to dilute (solid co...

Embodiment 2

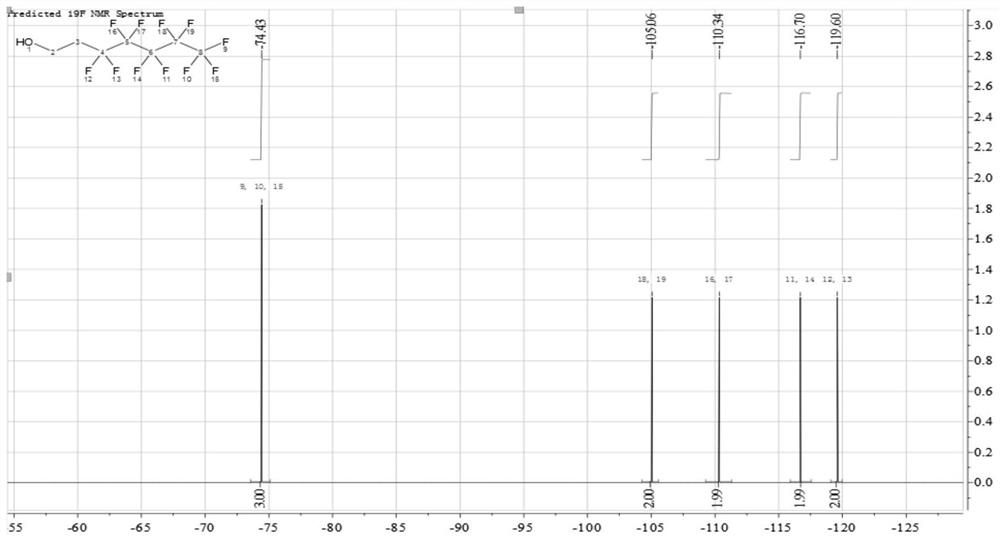

[0071] Get 0.2g sulfuric acid as catalyst and the 1H of 18.3g adipic acid, 33.11g, 1H, 2H, 2H-perfluorohexanol (its fluorine spectrum such as image 3 Shown) as a raw material, mixed evenly with 127.82g xylene, added to a closed reaction vessel equipped with a water separation device, stirred and water separation reaction was carried out at 150°C under oil bath heating conditions for 6 hours, and a fluorine-containing polyester prepolymer was obtained.

[0072] Fix the total molar ratio of fluorine-containing unit alcohols and acetylenic alcohols to be 1:1, add 95.86 g of fluorine-containing polyester prepolymer xylene solution (solid content 33.3%) in a closed reaction vessel equipped with a water separator, add 40.625g of polyether-modified acetylenic diol (molecular weight 650), stirred and heated up to 150-200°C, water separation reaction for 10h, vacuum (-0.1Mpa) suction filtration after the reaction, dilute with 72.57g propylene glycol monomethyl ether ( solid content of...

Embodiment 3

[0081] Get 0.2g sulfuric acid as catalyzer and the perfluorohexanepropanol of the sebacic acid of 25.28g, 47.26g (its fluorine spectrum such as Figure 4 shown) as a raw material, mixed evenly with 145.08g of xylene, placed in a closed reaction vessel equipped with a water separation device, and stirred for 6 hours under the condition of heating in an oil bath at 150°C for water separation reaction to obtain a fluorine-containing polyester prepolymer.

[0082] Fix the total molar ratio of fluorine-containing unit alcohols and acetylenic alcohols to be 1:1, add 108.81 g of fluorine-containing polyester prepolymer xylene solution (solid content 33.3%) in a closed reaction vessel equipped with a water separator, add 40.625g of polyether-modified acetylenic diol (molecular weight 650), stirring and heating up to solvent reflux, water separation reaction for 8-10h, vacuum (-0.1Mpa) suction filtration after the reaction, dilute with propylene glycol monomethyl ether (solid content 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com