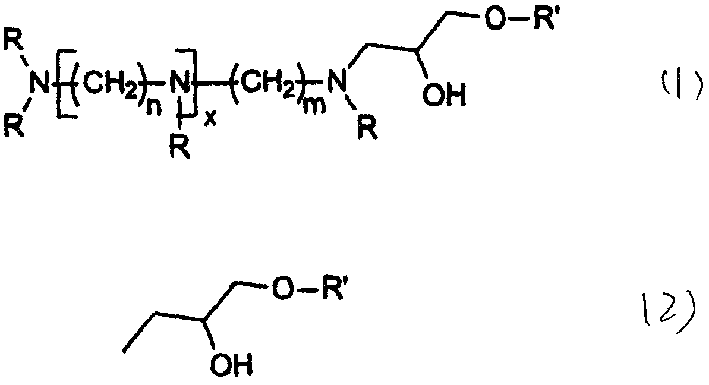

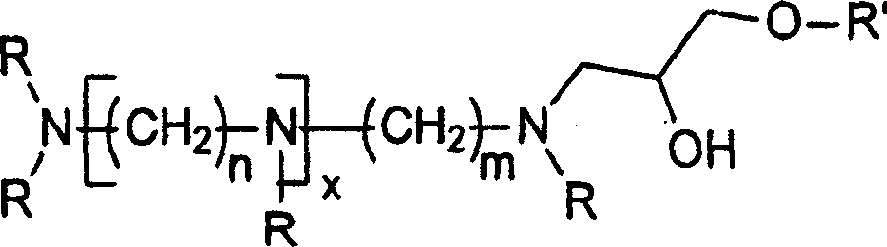

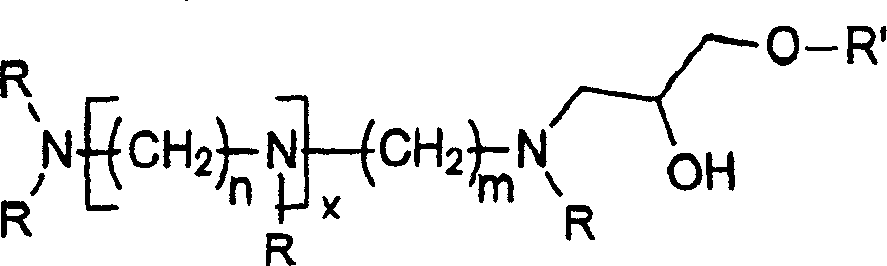

Alkyl glycidyl ether capped polyamine foam controlling agent

A polyamine and alkyl technology, which is applied in the field of the reaction product of polyamine and alkyl glycidyl ether as a foam control agent, can solve the problems of foam generation and air removal, improve storage stability, reduce coating or Effect of printing defects, good substrate surface wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0067] 1:1, 1:2, 1:3, 1:4 addition products of diethylenetriamine (DETA) and n-butyl glycidyl ether (BGE) were prepared by reacting pure DETA with appropriate equivalents of BGE . DETA (40.00 g) was added to a three-necked flask equipped with addition funnel, reflux condenser, thermocouple and magnetic stirring bar. The amine was heated to 100°C under nitrogen. At this point, the heat was turned off, and the BGE was added to the amine at such a rate that the reaction temperature was maintained at 90-120°C. After adding 1 equivalent of BGE (50.92 g), the reaction solution was heated to 100° C. for 40 minutes, and then a sample (Example 1, 15.01 g, 1:1 DETA / BGE adduct, pale yellow oil) was taken out. Then 2-4 equivalents of BGE were added to the reaction mixture at 85-120°C. After adding each equivalent, the reaction solution was heated to 100° C. for at least 20 minutes, and the following samples were successively removed from the reactor: Example 2 (20.00 g, 1:2 DETA / BGE, l...

Embodiment 5

[0069] A 1:5 addition product of diethylenetriamine (DETA) and n-butyl glycidyl ether (BGE) was prepared by reacting pure amine with 5 equivalents of BGE. DETA (53.89 g) was added to a three-necked flask equipped with addition funnel, reflux condenser, thermocouple and magnetic stirring bar. DETA was heated to 80°C under nitrogen. At this point, the heat was turned off, and the BGE was added to the DETA at such a rate that the reaction temperature was maintained at 80-115°C. After addition of BGE (342.53 g), the reaction was heated to 100-102° C. for 40 minutes to give a pale yellow oil (394.1 g, 1:5 DETA / BGE adduct). This sample was used without further purification.

Embodiment 6-10

[0071] Prepared 1: 1, 1: 2, 1: 3, 1: 4 and 1: 5 diethylenetriamine (DETA) by pure DETA and the EHGE reaction of appropriate equivalent number with the similar step of embodiment 1-5 and 2-ethylhexyl glycidyl ether (EHGE) adduct. The obtained adducts were Example 6 (100g, 1:1 DETA / EHGE, dark yellow syrup), Example 7 (100g, 1:2DETA / EHGE, very light yellow oil), Example 8 (100g , 1:3DETA / EHGE, very light yellow oil), Example 9 (100g, 1:4DETA / EHGE, very light yellow oil) and Example 10 (100g, 1:5DETA / EHGE, very light yellow oil yellow oil). These materials were used without further purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com