Method for continuously preparing modified polyester

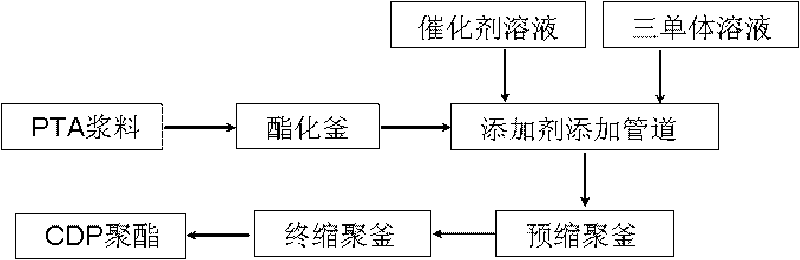

A technology for modifying polyester and polyester, which is applied in the direction of one-component polyester rayon and one-component copolyester rayon, etc., which can solve the problems of poor product uniformity, cost, quality, and output disadvantages. To achieve uniform dispersion, full and more even reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

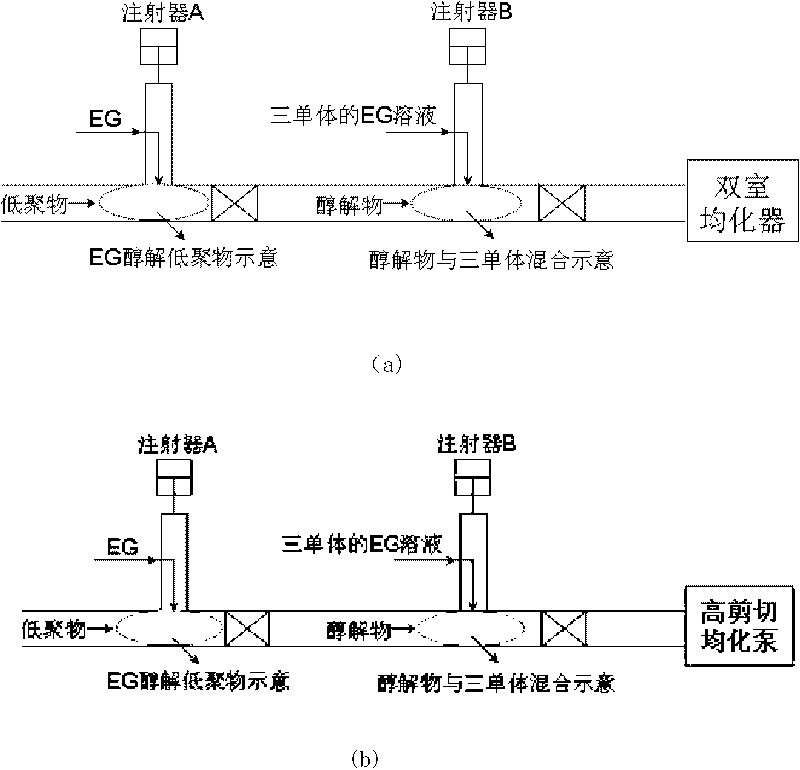

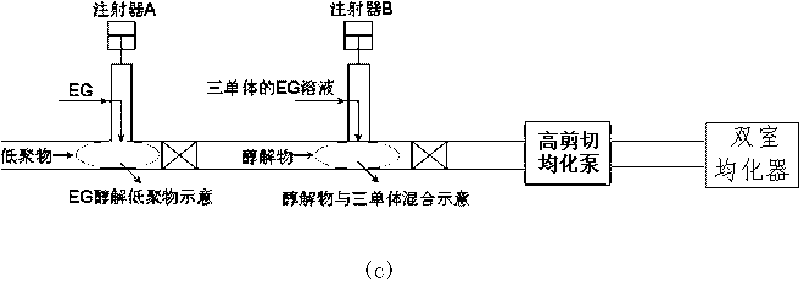

[0057] The raw materials terephthalic acid and ethylene glycol are added to the esterification tank at a flow rate of 6250kg / h and 3125kg / h respectively, and the esterification reaction or polymerization reaction is carried out at a temperature of 270 ° C. The average value of the esterification product The degree of polymerization reaches 3, and when the rate of esterification is 91%, the esterification product oligomer that the degree of polymerization is 3 is delivered to a pipeline with a flow rate of 7588kg / h. A flow rate of 455kg / h is injected into ethylene glycol at a temperature of 45°C, and a SIPE solution with a temperature of 100°C and a concentration of 25% is injected at a flow rate of 607kg / h from the pipeline that is closer to the precondensation tank, and the temperature of the pipeline is kept At 230°C and a pressure of 400KPa, the mixture in this pipeline enters the liquid homogenizer to make it evenly mixed, and then flows from the homogenizer to the preconde...

Embodiment 2

[0059] The raw materials terephthalic acid and ethylene glycol are added to the esterification tank at a flow rate of 6250kg / h and 4202kg / h respectively, and the esterification reaction or polymerization reaction is carried out at a temperature of 260°C. The average value of the esterification product When the degree of polymerization reaches 6, the acid value is 40mgKOH / g; The esterification product oligomer that the degree of polymerization is 6 is transported to a pipeline with a flow rate of 7588kg / h, and is passed through the near addition pipeline from this pipeline distance from the esterification kettle to A flow rate of 530kg / h is injected into ethylene glycol at a temperature of 50°C, and a SIPE solution with a temperature of 90°C and a concentration of 20% is injected at a flow rate of 675kg / h from the pipeline that is closer to the precondensation tank, and the temperature of the pipeline is kept At 230°C and a pressure of 500KPa, the mixture in this pipeline enters...

Embodiment 3

[0061] The raw materials terephthalic acid and ethylene glycol are added to the esterification tank at a flow rate of 6250kg / h and 1875kg / h respectively, and the esterification reaction or polymerization reaction is carried out at a temperature of 240°C. The average value of the esterification product The degree of polymerization reaches 8, and when the rate of esterification is 92%, the esterification product oligomer that the degree of polymerization is 8 is delivered to a pipeline with a flow rate of 7588kg / h. The flow rate of 379kg / h injects ethylene glycol with a temperature of 60°C, and the SIPE solution with a temperature of 80°C and a concentration of 15% is injected at a flow rate of 758kg / h from the pipeline that is closer to the precondensation tank, and the temperature of the pipeline is maintained. At 230°C and a pressure of 550KPa, the mixture in the pipeline enters the liquid homogenizer through a high-shear homogenizer pump to make it evenly mixed, and then flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com