Method for producing cyclohexenyl anone from continuous condensating anone

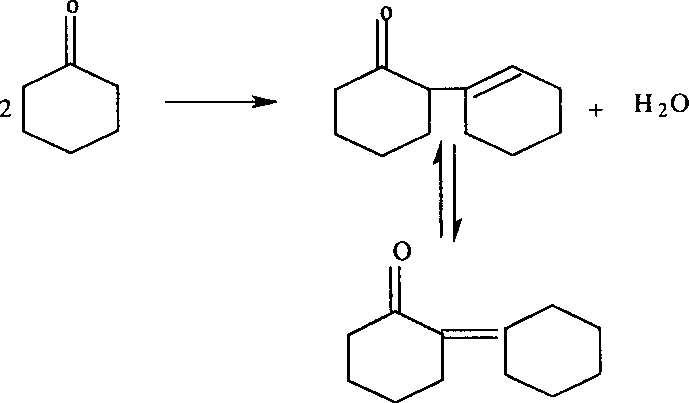

A technology of cyclohexenyl cyclohexanone and cyclohexanone is applied in the field of continuous condensation production of cyclohexenyl cyclohexanone, and can solve the problem of low cyclohexanone selectivity, high cyclohexanone consumption quota, many by-products, etc. problem, to achieve the effect of reducing waste water discharge and reducing the amount of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

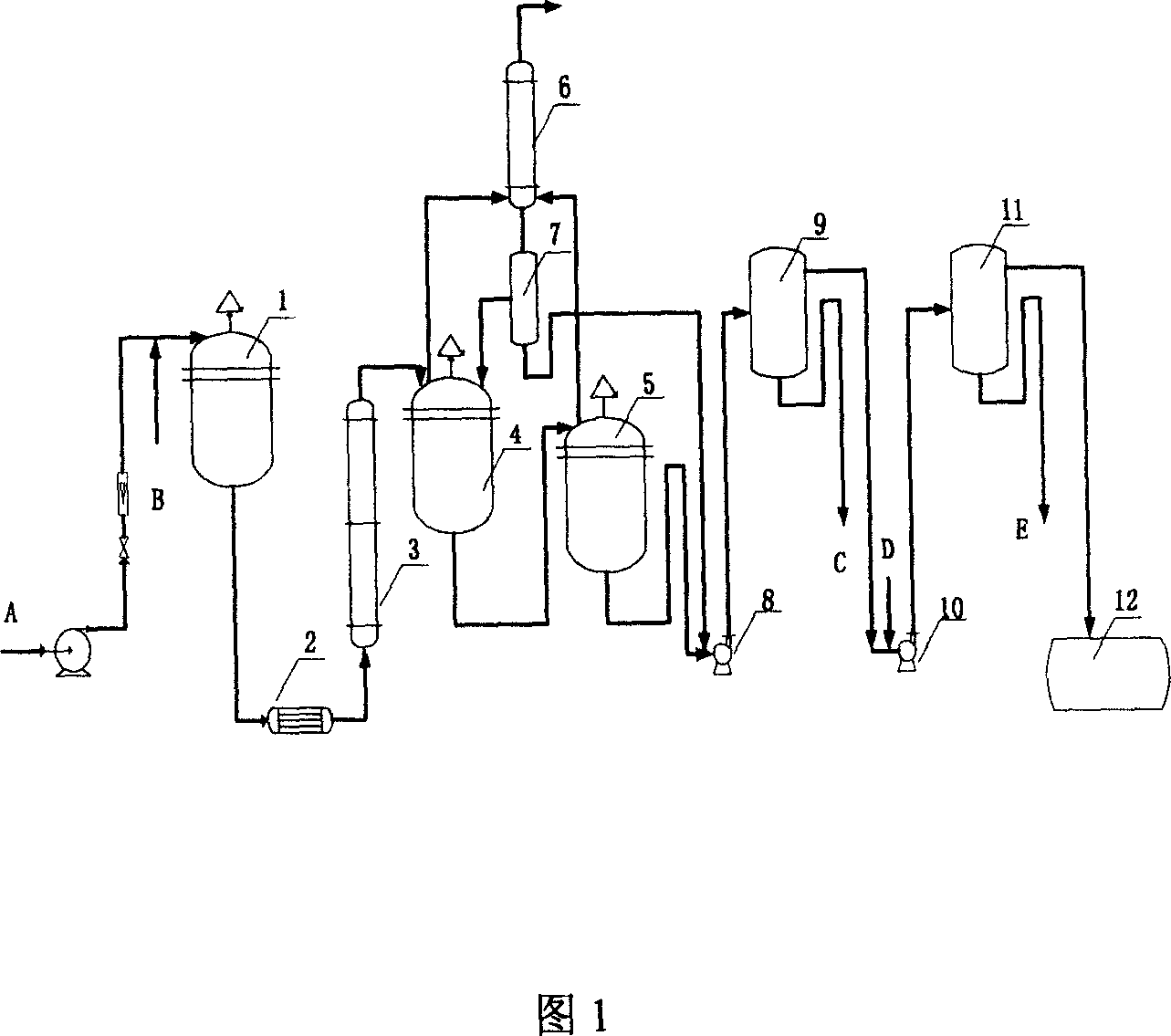

[0029] 4000kg of cyclohexanone and 100kg of phosphotungstic acid catalyst are mixed evenly in the 5000L stirring mixing tank 1, and then continuously enter the preheater 2 at a rate of 1000kg / h, preheat to 90°C with water steam, and then enter the jacketed Ф500× React in 4000 glass-lined tower reactor 3, control the outlet temperature of the tower reactor to 100°C, then enter the first 1000L stirred reactor 4, control the temperature in the kettle to 110°C, and then flow from the bottom of the kettle to the second one 1000L stirring reaction kettle 5, control the temperature in the second kettle to 125°C, the water generated by the reaction is steamed out together with cyclohexanone, condensed by the reflux condenser 6, and then enters the oil-water separator 7, the cyclohexanone is in the upper layer, overflows Back to the reactor 4; the water is in the lower layer, enters the water washing pump 8 for water washing, and the rest goes to the treatment device. The reaction prod...

Embodiment 2

[0031] The continuous condensation reaction of cyclohexanone was carried out in the same apparatus as in Example 1. 4000kg cyclohexanone and 100kgFeCl 3 / SiO 2After the solid superacid catalyst is mixed evenly in the 5000L stirring mixing tank 1, it enters the preheater 2 continuously at a rate of 1500kg / h, is preheated to 85°C with water steam, and then enters the jacketed Ф500×4000 glass-lined tower React in the reactor 3, control the outlet temperature of the tower reactor to be 95°C, then enter the first stirred 1000L reactor 4, control the temperature in the still to be 115°C, and then flow from the bottom of the still to the second stirred 1000L reactor 5, Control the temperature in the second kettle to be 120°C, and the water generated by the reaction will be steamed out together with cyclohexanone, and after being condensed by the reflux condenser 6, it will enter the oil-water separator 7, and the cyclohexanone will overflow back to the reaction kettle 4 in the upper...

Embodiment 3

[0033] The continuous condensation reaction of cyclohexanone was carried out in the same apparatus as in Example 1. 4000kg cyclohexanone and 100kg phosphotungstic acid are mixed evenly in the 5000L glass-lined mixing kettle 1 with agitation, and then enter the preheater 2 continuously at a rate of 700kg / h, preheat to 85°C with water steam, and then enter the jacketed Ф500 React in the tower reactor 3 of ×4000, control the outlet temperature of the tower reactor to 95°C, then enter the first stirring 1000L reactor 4, control the temperature in the kettle to 110°C, and then flow from the bottom of the kettle to the second 1000L Stir the reactor 5, control the temperature in the second stirred reactor to be 125°C, the water generated by the reaction is steamed out together with cyclohexanone, and enters the oil-water separator 7 after being condensed by the reflux condenser 6, and the cyclohexanone is in the upper layer, overflowing Flow back to the reaction kettle 4, the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com