Equipment and process for industrially producing graphene by microwaves

A graphene and microwave technology, applied in the field of graphene new material preparation, can solve the problems of graphene being flammable, safety threats, fire hazards, etc., to prolong the service life, improve product quality, and prevent acid gas corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

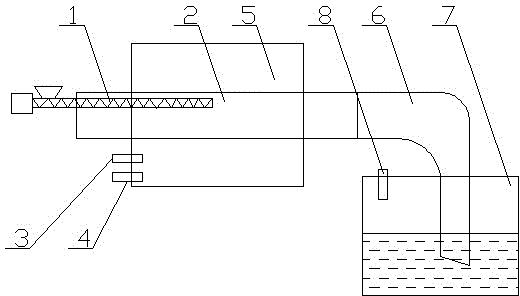

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] figure 1 As shown, a kind of equipment that can industrially utilize microwave to produce graphene includes screw feeder 1, furnace tube 2, inert gas inlet 3, compressed air inlet 4, microwave cavity 5, discharge pipe 6, product collector 7 and pump Vacuum port 8. The furnace tube 2 is connected in the microwave cavity 5, the input end of the furnace tube 2 is connected with a screw feeder 1, the screw feeder 1 is made of polytetrafluoroethylene, and the output end of the furnace tube 2 is The product collector 7 is connected through the discharge pipe 6, and the furnace pipe 2 and the discharge pipe 6 are made of PTFE-lined stainless steel; the inner wall of the microwave cavity 5 is evenly equipped with a plurality of microwave transmitters, and the microwave cavity The body 5 is made of high borosilicate glass, corundum or quartz; the input end of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com