Preparation method of ultrafine fibrous membrane-toughened prepreg of thermoplastic resin

A technology of thermoplastic resin and ultrafine fiber, which is applied in the field of prepreg preparation of composite materials, can solve the problems of affecting the process performance of composite materials, cumbersome process, poor paving performance, etc. good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

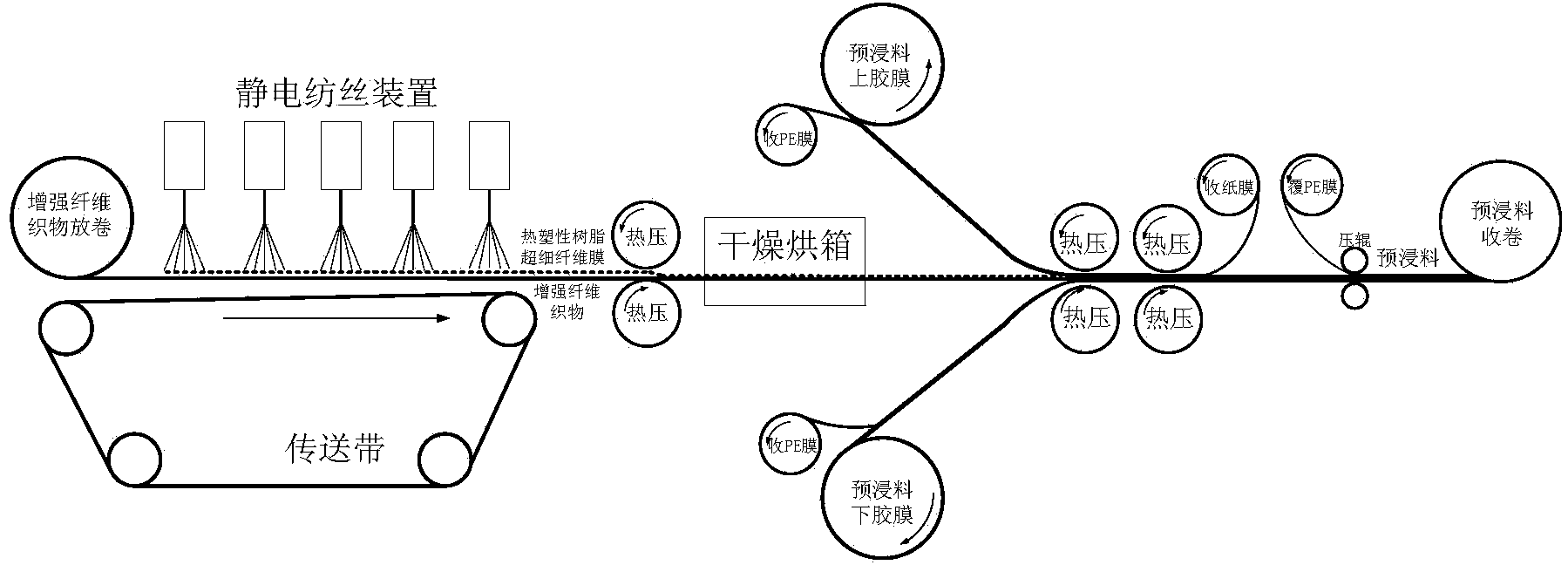

[0024] A preparation method of a thermoplastic resin superfine fiber film toughened composite material prepreg, the specific steps are as follows:

[0025] (1) Select a thermoplastic resin as a toughening agent, slice or crush the thermoplastic resin, then place it in a drying oven, and dry it at 80-100°C for 1-2 hours to remove the moisture therein;

[0026] (2) adding a good solvent to the dried thermoplastic resin to prepare a thermoplastic resin solution;

[0027] (3) Spray the thermoplastic resin solution on the surface of the reinforcing fiber fabric 1 by electrospinning to form a thermoplastic resin superfine fiber toughening layer 2 with random distribution and uniform surface density;

[0028] (4) The reinforced fiber fabric 1 with the superfine fiber toughening layer 2 loaded on the surface is hot-pressed by a hot roll to make the toughening layer 2 and the fiber fabric 1 form a whole, that is, the toughened fabric;

[0029] (5) The reinforced fiber fabric 1 loaded ...

Embodiment 1

[0033] Polyamide PA6 is selected as the toughening agent, the PA6 resin is sliced or crushed, then placed in a drying oven, dried at 100°C for 2 hours, and after removing the moisture, the PA6 pellets are dissolved in formic acid. The dissolved resin solution is added to the electrospinning equipment, and the PA6 resin is sprayed on the surface of the carbon fiber unidirectional fabric U3160 by the electrospinning method to form a thermoplastic resin fiber toughening layer with random distribution and uniform surface density; the surface is loaded The U3160 carbon fiber fabric with the ultrafine PA6 fiber toughening layer is hot-pressed by a hot roll at 80°C so that the PA6 ultrafine fiber toughening layer and the U3160 reinforced fiber fabric form a whole, and the toughened carbon fiber unidirectional fabric is dried in an oven. After the solvent in the toughening layer is completely evaporated, the U3160 toughened fiber fabric is combined with the epoxy resin-based prepreg ...

Embodiment 2

[0035]Polyethersulfone PES is selected as the toughening agent, the PES resin is sliced or crushed, then placed in a drying oven, dried at 100°C for 2 hours, and the water is removed, and the PES pellets are dissolved in DMF solvent. The dissolved resin solution is added to the electrospinning equipment, and the PES resin is sprayed on the surface of T700 carbon fiber unidirectional fabric U7192 by electrospinning method to form a thermoplastic resin fiber toughening layer with random distribution and uniform surface density; The U7192 carbon fiber fabric loaded with the ultrafine PES fiber toughening layer is hot-pressed by a hot roller at 150°C to form a whole with the PES ultrafine fiber toughening layer and the U7192 reinforced fiber fabric, and the toughened carbon fiber unidirectional fabric is dried in an oven. After the solvent in the toughening layer is completely volatilized, the U7192 toughened fiber fabric is combined with the Shuangma resin-based prepreg film, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com