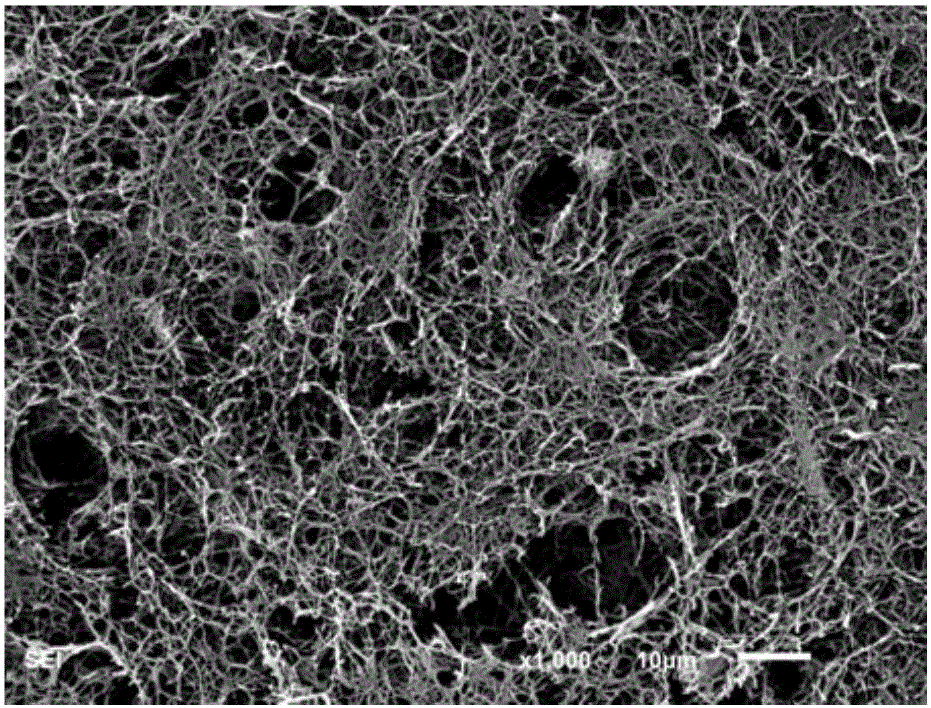

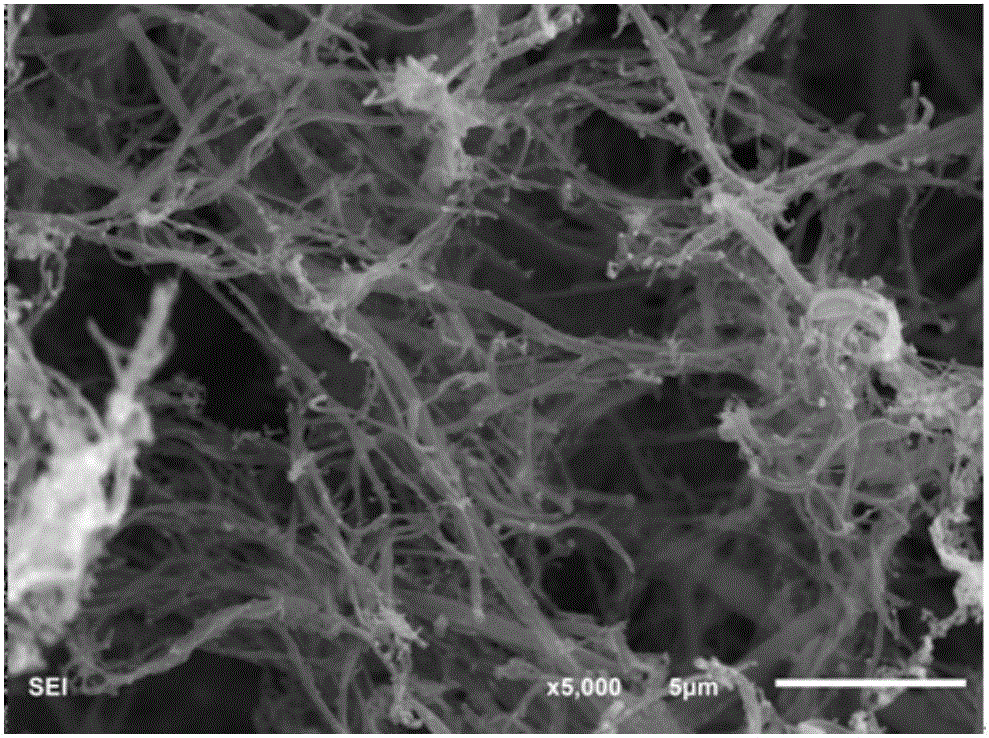

Preparation method of nanofiber aerogel material with hard magnetism

A technology of nanofibers and magnetic nanoparticles, which is applied in the field of preparation of hard magnetic nanofiber airgel materials, can solve the problems such as the preparation method of hard magnetic nanofiber airgel materials, and achieve smooth fibers and strong adsorption , the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment discloses a method for preparing an airgel material with hard magnetic nanofibers, comprising the following steps:

[0029] 1) Preparation of composite particles: SrFe with a particle size of 30nm 12 o 19 Nanoparticles were placed in a quartz crucible, gradually heated to 650°C in a vacuum furnace, then kept for 2 hours, and then naturally cooled to room temperature to obtain magnetic nanoparticles in a demagnetized state; 5g of sodium dodecylbenzenesulfonate was dissolved at 20°C In 60g of isopropanol solution, get 10g of demagnetized state magnetic nanoparticles and disperse them in the isopropanol solution of sodium dodecylbenzenesulfonate, ultrasonic 2h, obtain the demagnetized state magnetic nano particle dispersion B that mixes uniformly; The ethylene-vinyl alcohol copolymer masterbatch is placed in 270g of isopropanol, stirred and heated at 80°C to dissolve, and the polymer solution C is prepared; then the magnetic nanoparticle dispersion B in th...

Embodiment 2

[0036] This embodiment discloses a method for preparing an airgel material with hard magnetic nanofibers, comprising the following steps:

[0037] 1) Preparation of composite particles: the particle size is 50nm Nd 2 Fe 14 B nanoparticles were placed in a quartz crucible, gradually heated to 800°C in a vacuum furnace, then kept for 3 hours, and then naturally cooled to room temperature to obtain magnetic nanoparticles in a demagnetized state; Dissolve in 60g of isopropanol solution, take 10g of demagnetized state magnetic nanoparticles and disperse them in the isopropanol solution of sodium dodecylbenzene sulfonate, ultrasonic 2h, obtain demagnetized state magnetic nano particle dispersion B which is mixed uniformly; Put 90g of ethylene-vinyl alcohol copolymer masterbatch in 300g of isopropanol, stir and heat at 85°C to dissolve, and prepare polymer solution C; then dissolve and disperse demagnetized magnetic nanoparticle dispersion B to the polymerization solution C, and th...

Embodiment 3

[0043] This embodiment discloses a method for preparing an airgel material with hard magnetic nanofibers, comprising the following steps:

[0044] 1) Preparation of composite particles: SrFe with a particle size of 30nm 12 o 19 Nanoparticles were placed in a quartz crucible, gradually heated to 650°C in a vacuum furnace, then kept for 2 hours, and then naturally cooled to room temperature to obtain magnetic nanoparticles in a demagnetized state; 5g of sodium dodecylbenzenesulfonate was dissolved at 20°C In 60g of isopropanol solution, get 10g of demagnetized state magnetic nanoparticles and disperse them in the isopropanol solution of sodium dodecylbenzenesulfonate, ultrasonic 2h, obtain the demagnetized state magnetic nano particle dispersion B that mixes uniformly; The ethylene-vinyl alcohol copolymer masterbatch is placed in 270g of isopropanol, stirred and heated at 80°C to dissolve, and the polymer solution C is prepared; then the magnetic nanoparticle dispersion B in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com