Pipelined continuous preparation method and device of triisoamyl phosphate for spent fuel post-treatment

A technology for preparing triisoamyl phosphate and a device, which is applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, and pressure vessels used in chemical processes, which can solve problems such as high process risk and achieve Improve the reaction yield, the process is less dangerous, and realize the effect of continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

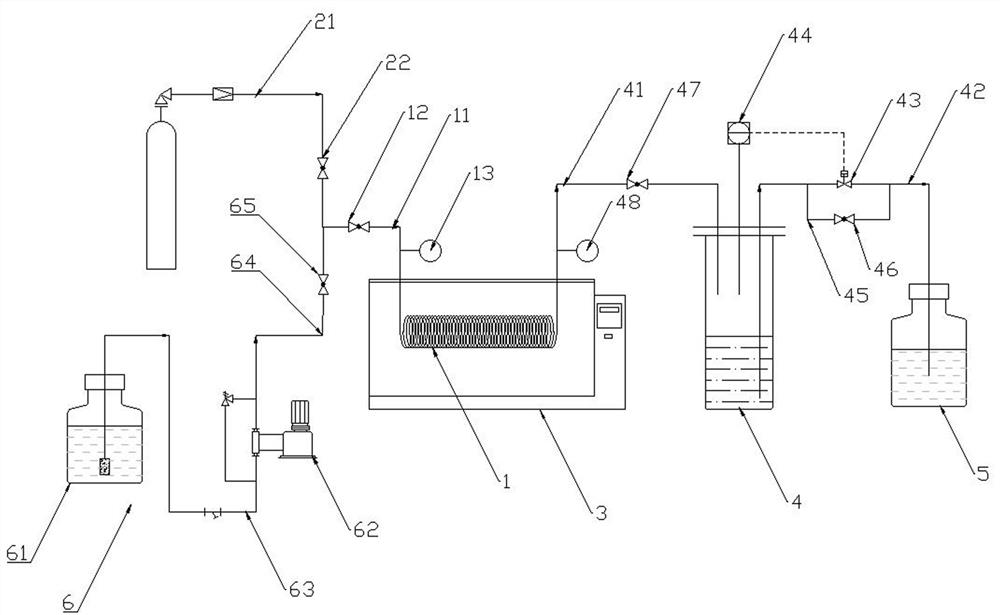

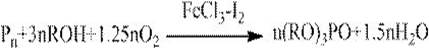

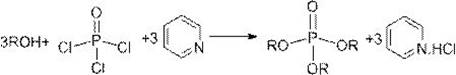

[0060] The embodiment of the present invention proposes a method for preparing triisoamyl phosphate for spent fuel reprocessing, comprising the following steps:

[0061] S1. Mix trimethyl phosphate and isoamyl alcohol evenly to obtain a mixed solution.

[0062] Specifically, trimethyl phosphate and isoamyl alcohol are mixed evenly at a molar ratio of 1:3~6.

[0063] S2. Heating the mixed solution under a protective gas environment of 2.5-10 MPa to obtain a reaction solution; wherein the heating temperature is 150-250° C.

[0064] Specifically, the heating time is 60-150 minutes.

[0065] S3. Distilling the reaction solution under reduced pressure to obtain triisoamyl phosphate.

[0066] Compared with the prior art, in the preparation method of triisoamyl phosphate used in the reprocessing of spent fuel provided by the embodiment of the present invention, the by-product methanol will not react with triisoamyl phosphate, and no solvent is needed during the reaction With the p...

Embodiment 1

[0095] S1. Preparation before preparation: Mix trimethyl phosphate and isoamyl alcohol evenly according to the molar ratio of 1:3 and then add the mixed liquid storage tank; close the first liquid outlet switch, open the intake switch, and fill the reaction coil with nitrogen to When the first pressure gauge shows that the pressure is 4MPa, close the intake switch; adjust the temperature of the constant temperature oil bath to 150°C, and wait for the temperature indication to stop changing.

[0096] S2. Preparation of triisoamyl phosphate: turn on the feed switch, the plunger metering pump pumps the mixed solution into the reaction coil at 0.5mL / min, and the transesterification reaction of trimethyl phosphate and isoamyl alcohol occurs in the reaction coil , to obtain the reaction solution. Then the reaction solution enters the high-pressure buffer tank from the upper part of the inner space of the high-pressure buffer tank for temporary storage.

[0097] S3. Continuous produ...

Embodiment 2

[0102] S1. Preparation before preparation: mix trimethyl phosphate and isoamyl alcohol evenly according to the molar ratio of 1:4, and then add the mixed liquid storage tank; close the first liquid outlet switch, open the intake switch, and fill the reaction coil with nitrogen to When the first pressure gauge shows that the pressure is 3.5MPa, close the intake switch; adjust the temperature of the constant temperature oil bath to 180°C, and wait for the temperature indication to stop changing.

[0103] S2. Preparation of triisoamyl phosphate: Turn on the feed switch, and the plunger metering pump pumps the mixed solution into the reaction coil at 0.8mL / min, and the transesterification reaction of trimethyl phosphate and isoamyl alcohol occurs in the reaction coil , to obtain the reaction solution. Then the reaction solution enters the high-pressure buffer tank from the upper part of the inner space of the high-pressure buffer tank for temporary storage.

[0104] S3. Continuou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com