Pipeline supporting and repairing device and pipeline repairing method

A technology of pipe support and support head, which is applied in the direction of pipes/pipe joints/fittings, pipe elements, mechanical equipment, etc., can solve the problems of cumbersome repair process and low construction efficiency, and achieve improved construction efficiency, reasonable design, sufficient heating and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

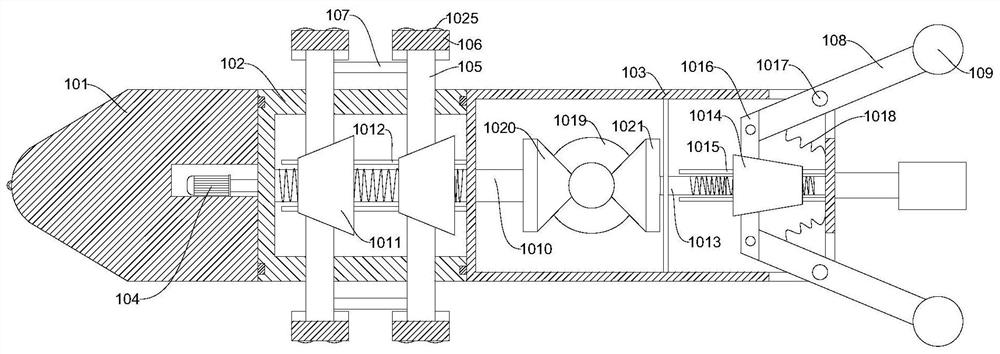

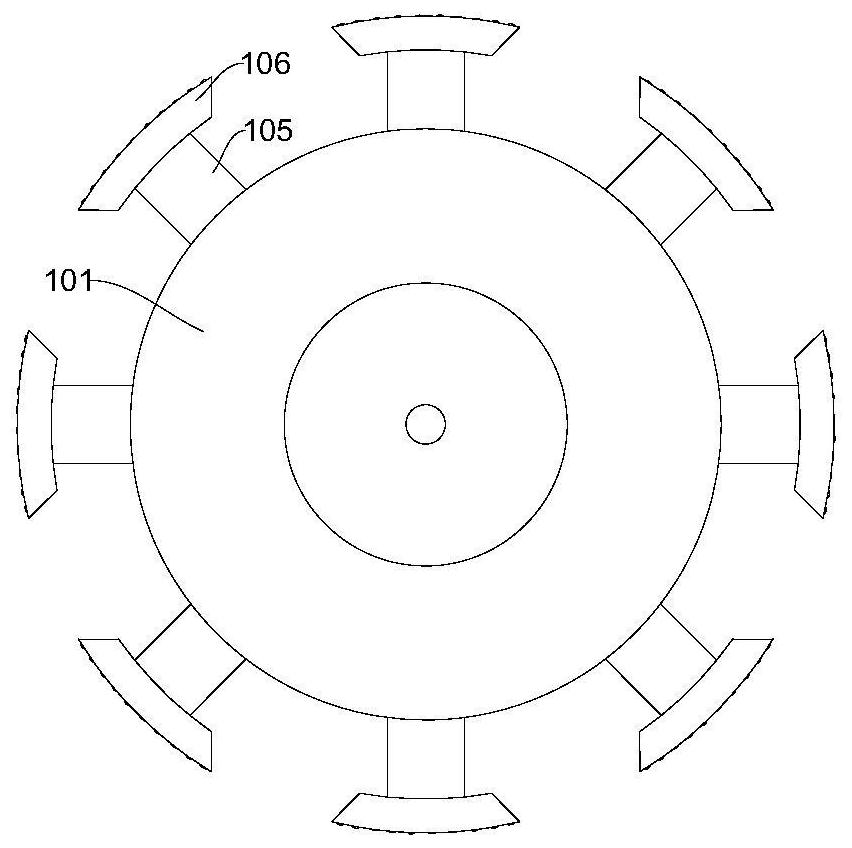

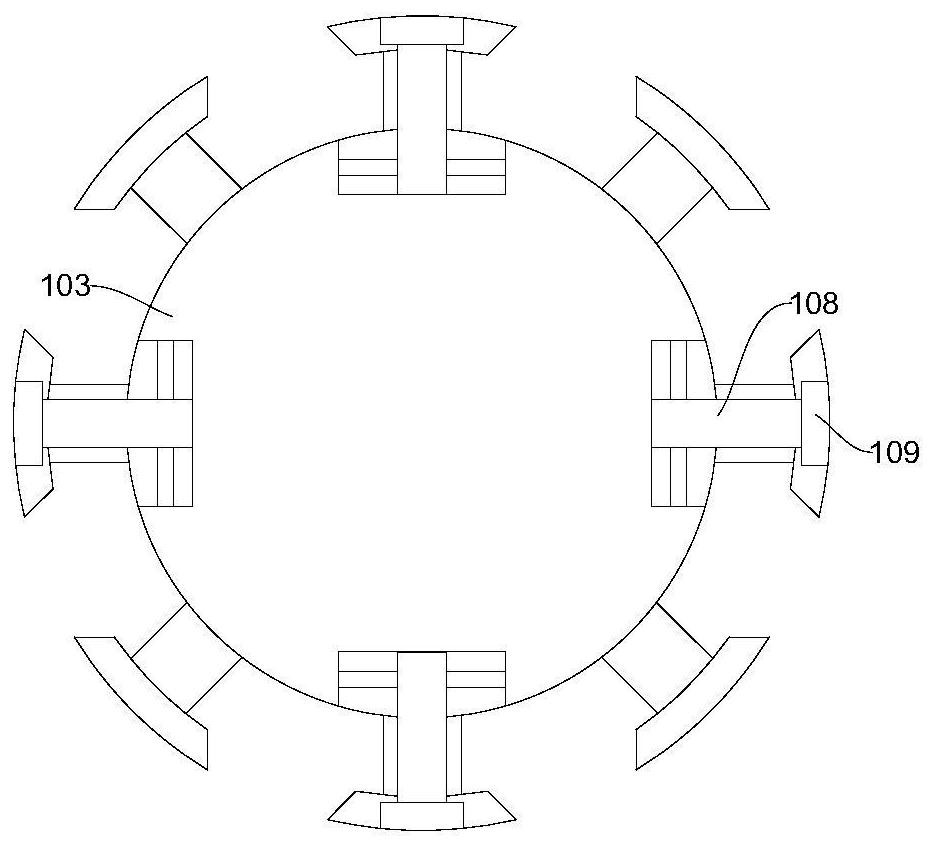

[0039] Please refer to Figure 1 to Figure 3 , a pipeline support repair device 100, used for heating and curing the repair hose 200 in the pipeline 300 to be repaired, the pipeline support repair device 100 includes a first fixed part 101, a rotating part 102 and a second fixed part 103 arranged in sequence, Wherein, the first fixing part 101, the rotating part 102 and the second fixing part 103 of this embodiment are all cylindrical structures, and the two sides of the rotating part 102 are respectively connected to the side of the first fixing part 101 and the side of the second fixing part 103 in rotation, The rotating part 102 can freely rotate between the first fixing part 101 and the second fixing part 103. The first fixing part 101 is provided with a first motor 104 for driving the rotating part 102 to rotate. The output end of the first motor 104 It is fixedly connected with the side wall of the rotating part 102 away from the second fixing part 103 .

[0040] At the...

Embodiment 2

[0050] A pipeline repair method, using the pipeline support repair device 100 described in the above-mentioned embodiment 1, please refer to Figure 5 , including the following steps:

[0051] S1. lay the repair hose 200 in the pipeline 300 to be repaired between the first shaft 400 and the second shaft 500, and install the traction mechanism at an appropriate position in the second shaft 500;

[0052] S2. Manually stretch the repair hose 200 near the end of the first shaft 400 to a certain extent, put the first fixed part 101 and the rotating part 102 into the repair hose 200 in sequence with the first fixed part 101 as the front end, and Connect the traction rope 1024 with the first fixing part 101;

[0053]S3. Start the second motor to drive the first rotating shaft 1010 and the second rotating shaft 1013 to rotate simultaneously, the first rotating shaft 1010 drives the first wedge-shaped block 1011 to move along the length direction of the first rotating shaft 1010, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com