Preparation method of solid welding wire for welding of nickel-based superalloys resistant to molten salt corrosion

A technology of nickel-based superalloy and solid welding wire, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problem of unusability, and achieve the effect of reducing loss, reducing content, and restoring the plasticity of welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

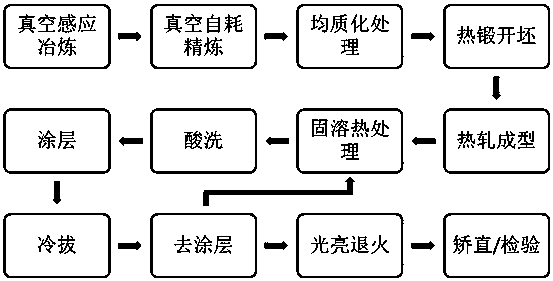

[0042] Aiming at the problem that the existing nickel-based alloy solid welding wire preparation process is difficult to produce solid welding wires for molten salt corrosion resistant nickel-based superalloy welding, the present invention provides a practical method for molten salt corrosion resistant nickel-based superalloy welding. The cored welding wire preparation method can mass-produce high-quality solid welding wires of various diameters for the welding of nickel-based superalloys resistant to molten salt corrosion at a high yield rate. The method includes the following steps:

[0043] 1) Vacuum smelting: Solder is configured and melted by vacuum induction and poured into electrode rods;

[0044] The solder can adopt existing or future formulations suitable for welding of nickel-based superalloys resistant to molten salt corrosion. In order to improve the welding quality, the present invention further proposes a preferred solder formula, the components of which are calcula...

Embodiment 1

[0062] The composition (mass percentage) of the solder in this embodiment is: C: 0.06%, Mn: 0.65%, Fe: 4.06%, Si: 0.44%, P: 0.0028%, S: 0.002%, Cu: 0.002%, Co : 0.14%, Cr: 6.89%, Mo: 17.2%, Re (rare earth element): 0.05%, Al: 0.03%, Ti: 0.01%, Nb: 1.5, and the rest is Ni.

[0063] The preparation process of the solid wire in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0064] 1)Vacuum smelting: according to the components of the solder, all pure metals are used, and Fe, Ni, Cr, Mo are directly placed in the crucible; while the rest of the active and volatile Mn, Si, C, Re and other elements are placed In the feeder, after the charging is completed, vacuum is started. When the vacuum degree is below 10 to 2 Torr, it starts to send electricity to heat the charge. Due to the skin effect of the induced current, the charge is melted layer by layer, which is very conducive to degassing and degassing. Unless metal inclusions, usually maintain a h...

Embodiment 2

[0077] The composition (mass percentage) of the solder in this embodiment is: C: 0.053%, Mn: 0.69%, Fe: 4.25%, Si: 0.35%, P: 0.002%, S: 0.003%, Cu: 0.0022%, Co : 0.12%, Cr: 6.50%, Mo: 16.7%, Re: 0.045%, Al: 0.003%, Ti: 0.02%, Nb: 1.5, and the rest is Ni.

[0078] The preparation method of the solid welding wire of this embodiment is the same as that of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com