Multi-strand stranded welding wire for 3D printing wire material

A multi-strand welding wire and 3D printing technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high cost, oxidation, redundant equipment, etc., and achieve short production cycle, high efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

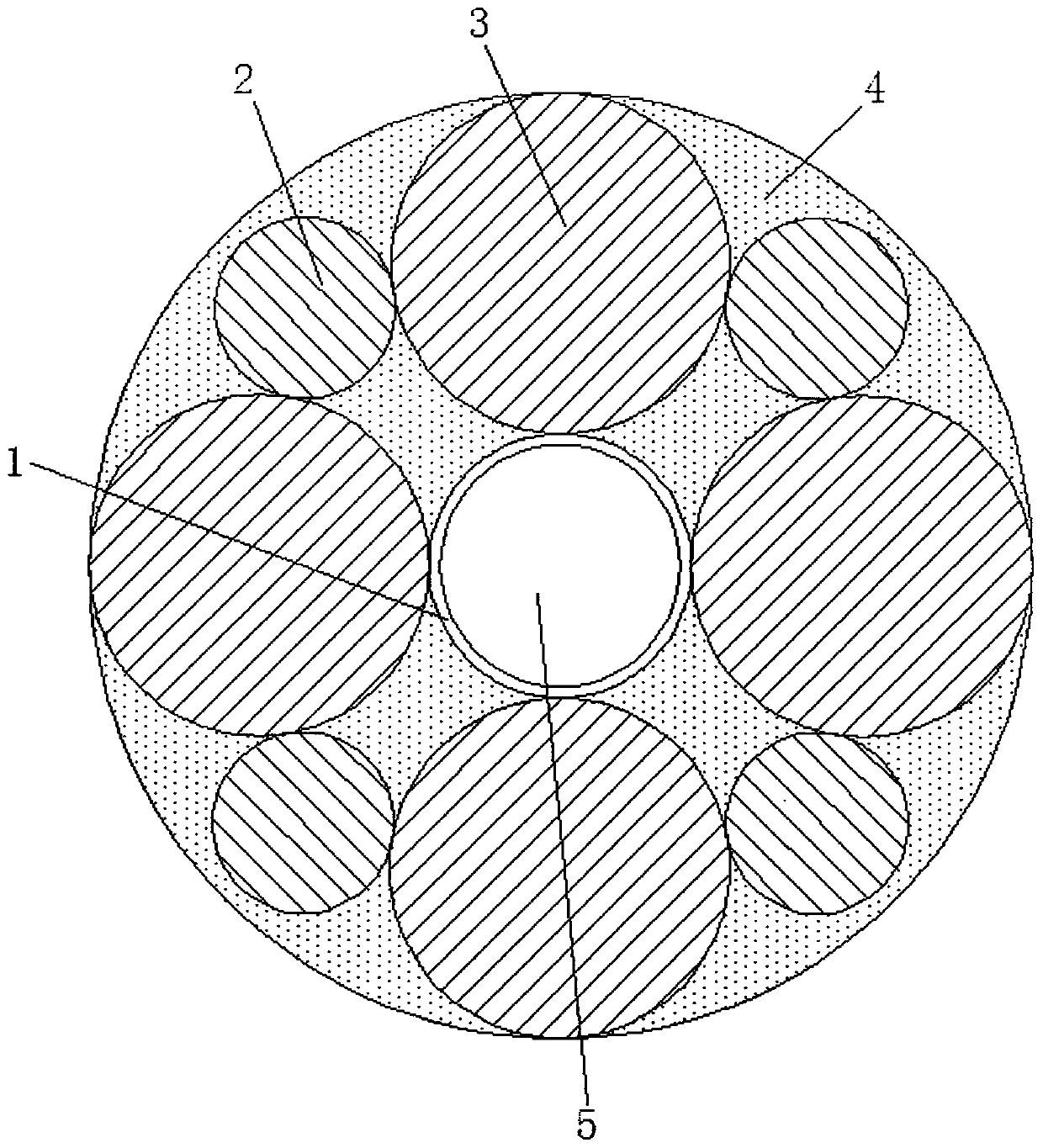

[0022] A 3D printing wire multi-strand stranded welding wire, the components and mass percentages of the welding wire are Ni: 13.6%, Mn: 9.7%, P: 0.01%, S: 0.02%, Cr: 24.3%, C : 0.07%, N: 0.50%, Mo: 2.7%, Si: 0.5%, Cu: 0.20%, and the balance is Fe.

Embodiment 2

[0024] A 3D printing wire multi-strand stranded welding wire, the components and mass percentages of the welding wire are Ni: 10.5%, Mn: 8.7%, P: 0.01%, S: 0.02%, Cr: 22.3%, C : 0.05%, N: 0.55%, Mo: 3.8%, Si: 0.7%, Cu: 0.35%, and the balance is Fe.

Embodiment 3

[0026] A 3D printing wire multi-strand stranded welding wire, each component and mass percentage of the welding wire are Ni: 11.0%, Mn: 8.3%, P: 0.01%, S: 0.02%, Cr: 22.3%, C : 0.07%, N: 0.60%, Mo: 3.8%, Si: 0.6%, Cu: 0.38%, and the balance is Fe.

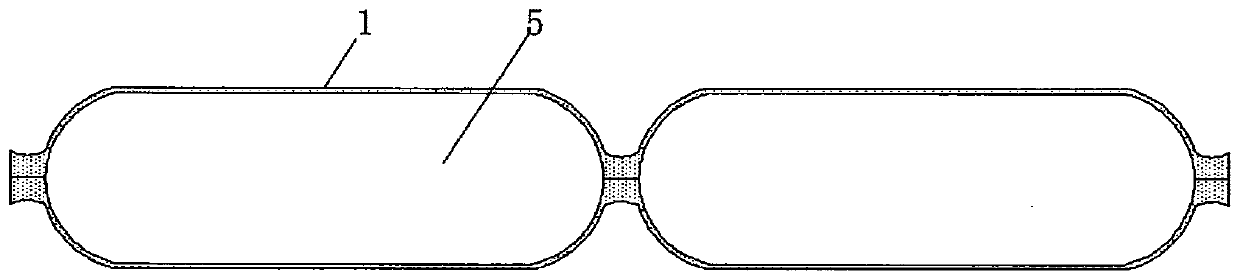

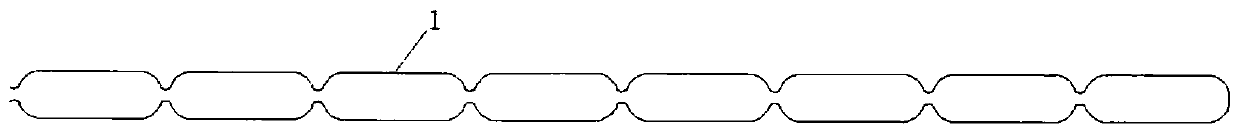

[0027] Manufacturing method of carbon dioxide storage tube 1: Fill the long and straight carbon dioxide storage tube with gas and seal both ends, and squeeze each section of the tube body through the extrusion device, so that the carbon dioxide storage tube 1 is formed as follows: image 3 shown structure.

[0028]

[0029] The second embodiment is the best test group by performing the welding test and the post-welding tensile resistance test on the three groups of welding wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com