Method for preparing chromium-based composite material for connecting plate

A composite material and connecting plate technology, which is applied in the preparation of chromium-based composite materials and in the field of powder metallurgy alumina dispersion-reinforced chromium-based composite materials, can solve the problem of preventing large grain size chromium oxide and reducing the forming of powder metallurgy formed parts Density and other issues, to achieve the effect of slowing down the high temperature oxidation of chromium, low cost, excellent high temperature resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

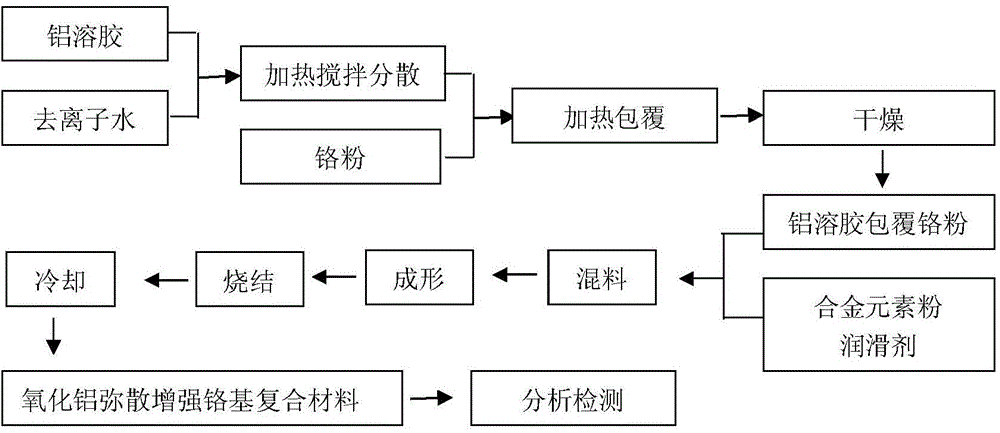

[0030] A method for preparing a chromium-based composite material for a connecting plate, the specific steps are as follows:

[0031] 1) Aluminum sol dispersion: Add alumina sol to deionized water at a ratio of 1:3.5, and disperse with magnetic stirring in a water bath at 85°C for 60 minutes until the aluminum sol is completely dispersed.

[0032] 2) Coating with chromium powder: Add the chromium powder to the dispersed aluminum sol after passing through a 100-mesh sieve, the ratio of chromium powder to alumina sol is 25:1, stir vigorously and slowly heat to 80°C, keep warm until the water evaporates completely.

[0033] 3) Drying of coated powder: transfer the above-mentioned aluminum sol coated powder to an oven at 100° C. for 2 hours for sufficient drying.

[0034] 4) Mixing: The dried aluminum sol is coated with chromium powder, iron powder and lubricant, and mixed in a double-cone or V-shaped mixer or other mixers according to the proportion. The specific ratio is as fol...

Embodiment 2

[0045] A method for preparing a chromium-based composite material for a connecting plate, the specific steps are as follows:

[0046] 1) Dispersion of aluminum sol: Add alumina sol to deionized water at a ratio of 1:10, and disperse with magnetic stirring in a water bath at 80°C for 30 minutes until the aluminum sol is completely dispersed.

[0047] 2) Coating with chromium powder: Add the chromium powder to the dispersed aluminum sol after passing through a 100-mesh sieve, the ratio of chromium powder to alumina sol is 50:1, stir vigorously and slowly heat to 80°C, keep warm until the water evaporates completely.

[0048] 3) Drying of coated powder: transfer the above-mentioned aluminum sol coated powder to an oven at 100° C. for 2 hours for sufficient drying.

[0049] 4) Mixing: The dried aluminum sol is coated with chromium powder, iron powder, tungsten powder, and lubricant, and mixed in a double-cone or V-shaped mixer or other mixers according to the ratio. The specific ...

Embodiment 3

[0059] A method for preparing a chromium-based composite material for a connecting plate, the specific steps are as follows:

[0060] 1) Dispersion of aluminum sol: Add alumina sol to deionized water at a ratio of 1:10, and disperse with magnetic stirring in a water bath at 80°C for 30 minutes until the aluminum sol is completely dispersed.

[0061] 2) Coating with chromium powder: Add chromium powder to the dispersed aluminum sol after passing through a 100-mesh sieve. The ratio of chromium powder to alumina sol is 100:1. Stir vigorously and slowly heat to 80°C, keep warm until the water evaporates completely.

[0062] 3) Drying of coated powder: transfer the above-mentioned aluminum sol coated powder to an oven at 100° C. for 2 hours for sufficient drying.

[0063] 4) Mixing: Add pure iron powder and lubricant to the dried coated chromium powder, and mix them in a V-shape mixer or other mixers. The added amount of pure iron powder and lubricant is preferably 5wt%, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com