Acicular ferrite/bulk ferrite marine steel plate and manufacturing method thereof

A technology of acicular ferrite and massive ferrite, applied in the field of iron and steel metallurgy, can solve the problems of high alloy cost, not conforming to the development trend of ship plate steel to reduce cost and increase efficiency, and add more alloys, etc. Nucleation point, inhibiting the formation of pearlite, reducing the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

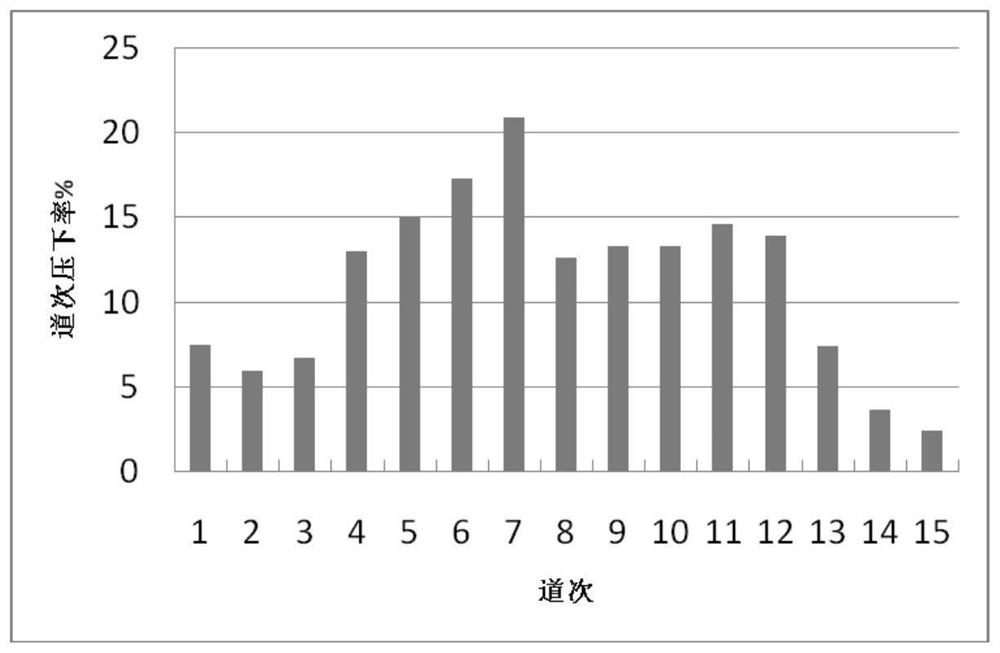

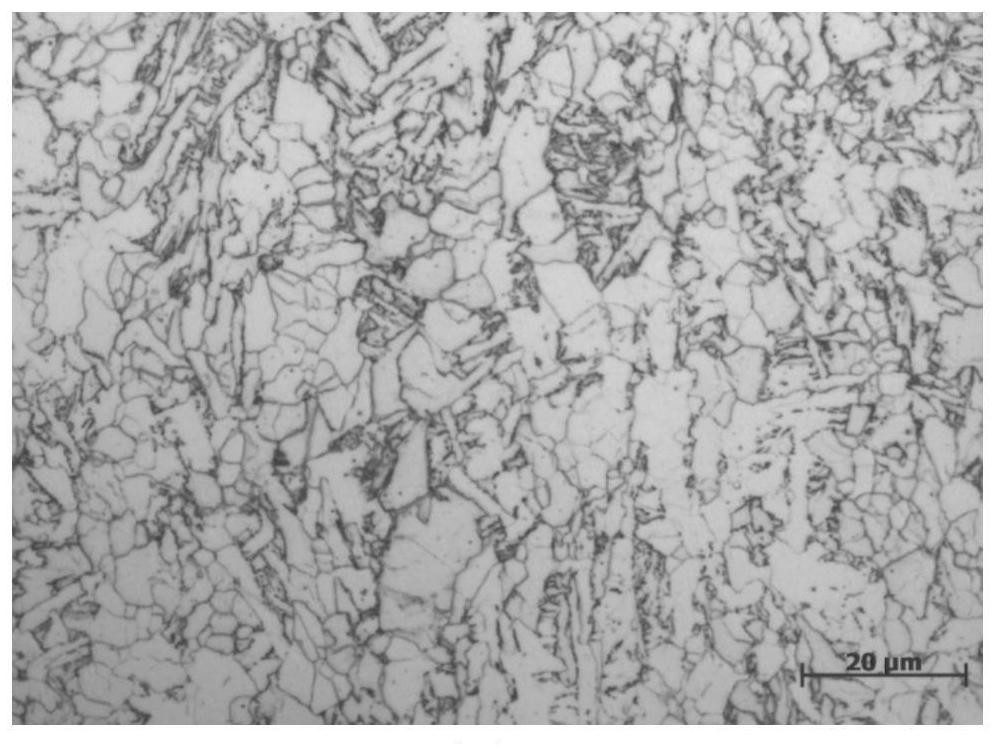

Embodiment Construction

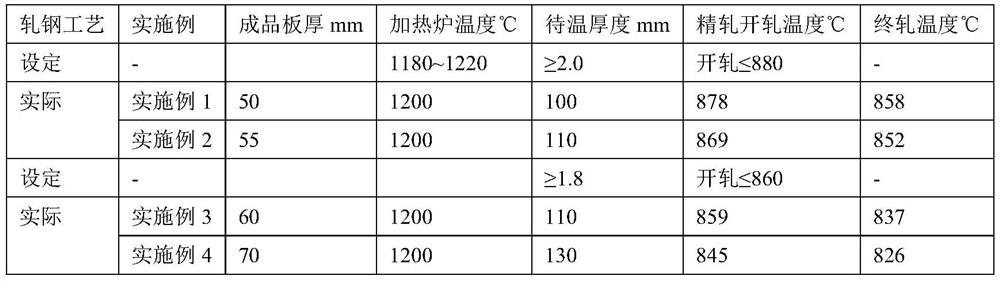

[0034] The present invention will be further described in detail below with reference to the embodiments, which are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0035] The chemical compositions of the acicular ferrite / mass ferrite marine steel sheets corresponding to each embodiment are shown in Table 1. The data in the table are the mass percentage contents of each element, and the remainder are Fe and inevitable impurity elements.

[0036] Table 1

[0037] Example Heat number C Si Mn P S Cr Ca Al Ti N Nb Example 1 S22007231 0.03 0.36 1.58 0.004 0.0014 0.10 0.0010 0.014 0.016 0.0035 0.047 Example 2 S22004775 0.04 0.48 1.46 0.003 0.0007 0.18 0.0012 0.008 0.012 0.0045 0.050 Example 3 S11904874 0.05 0.40 1.53 0.005 0.0013 0.22 0.0020 0.018 0.015 0.0050 0.048 Example 4 S11904883 0.04 0.45 1.56 0.003 0.0016 0.15 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com