Three-phase controllable polar direct-current electric arc furnace power supply device

A technology of DC electric arc furnace and power supply device, which is applied in the direction of output power conversion device, climate sustainability, high-efficiency power electronic conversion, etc. It can solve the problems of shortened smelting time, easy damage of furnace wall, increased thermal shutdown, etc., and achieves And the effect of convenient operation, novel and reasonable design, and reduced loss of short network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

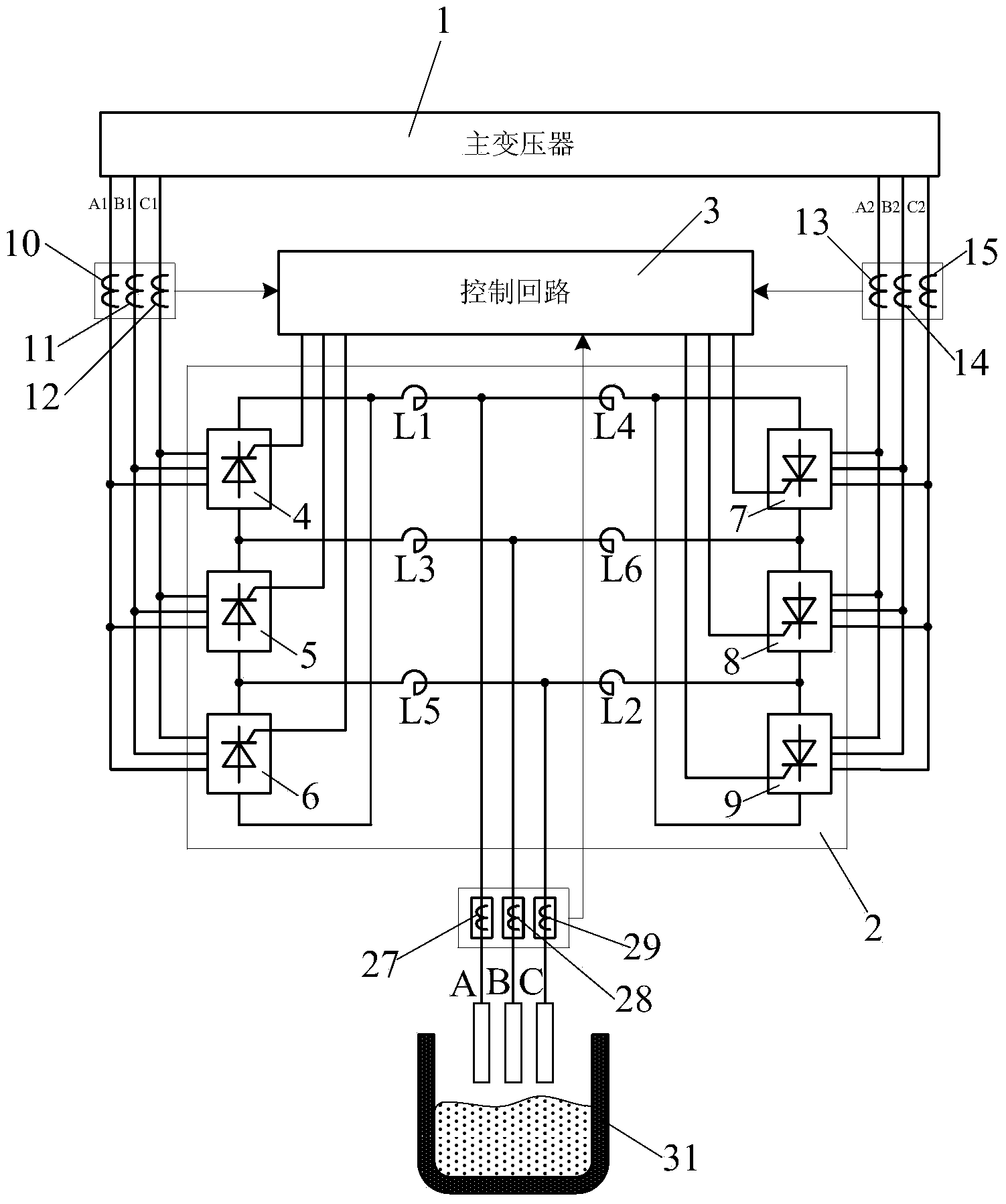

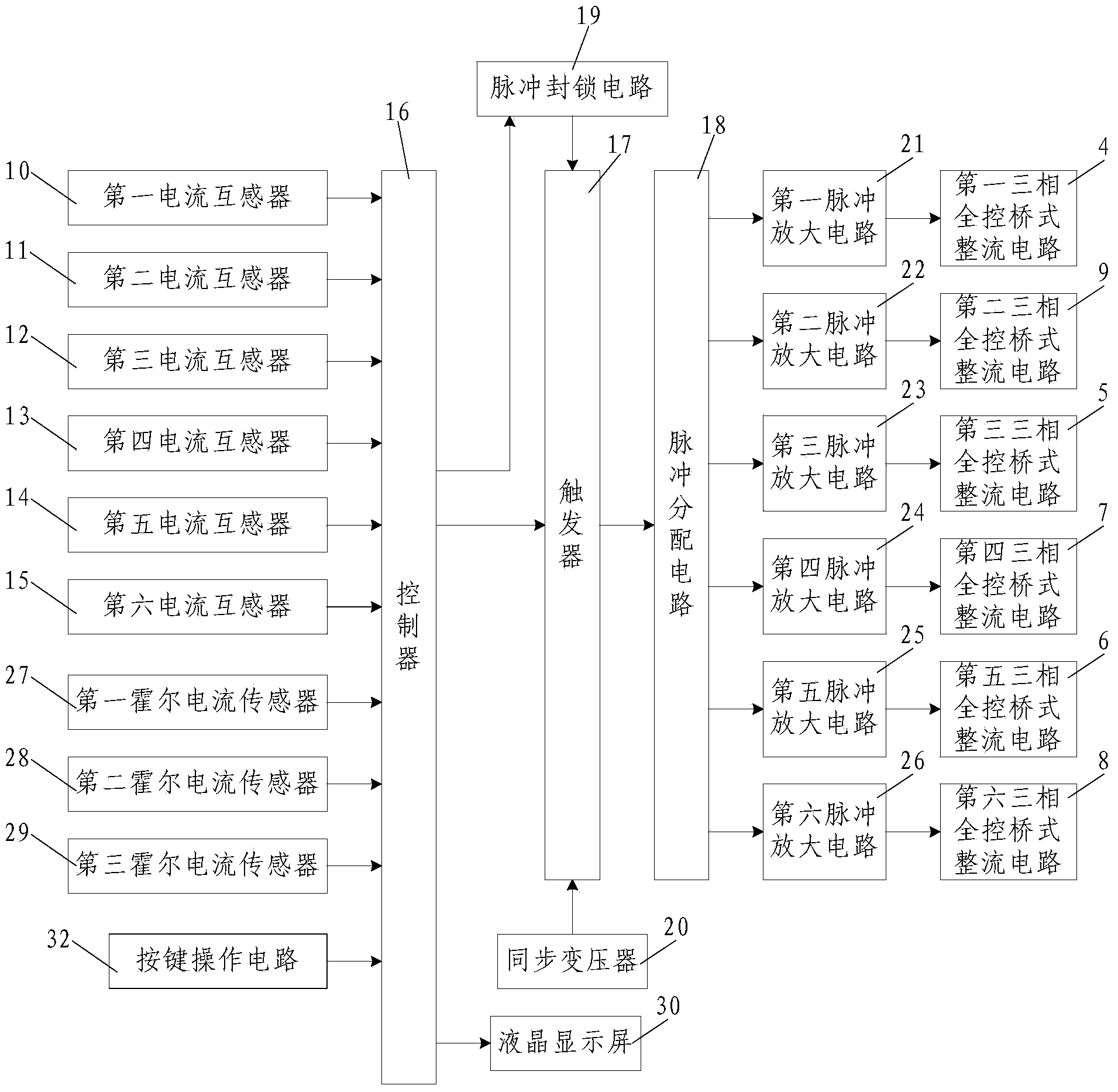

[0039] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a main transformer 1, a main circuit 2 and a control circuit 3 for controlling the main circuit 2, the secondary side winding of the main transformer 1 is composed of a first winding and a second winding, and the main Loop 2 comprises the first three-phase fully-controlled bridge rectifier circuit 4 connected with the first winding, the third three-phase fully-controlled bridge rectifier circuit 5 and the fifth three-phase fully-controlled bridge rectifier circuit 6, and the second The second three-phase fully-controlled bridge rectifier circuit 9, the fourth three-phase fully-controlled bridge rectifier circuit 7, and the sixth three-phase fully-controlled bridge rectifier circuit 8 connected by windings; the first three-phase fully-controlled bridge rectifier circuit The output end of the rectifier circuit 4 is connected to the input end of the fifth three-phase fully-controlled bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com