Patents

Literature

45results about How to "Avoid warming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

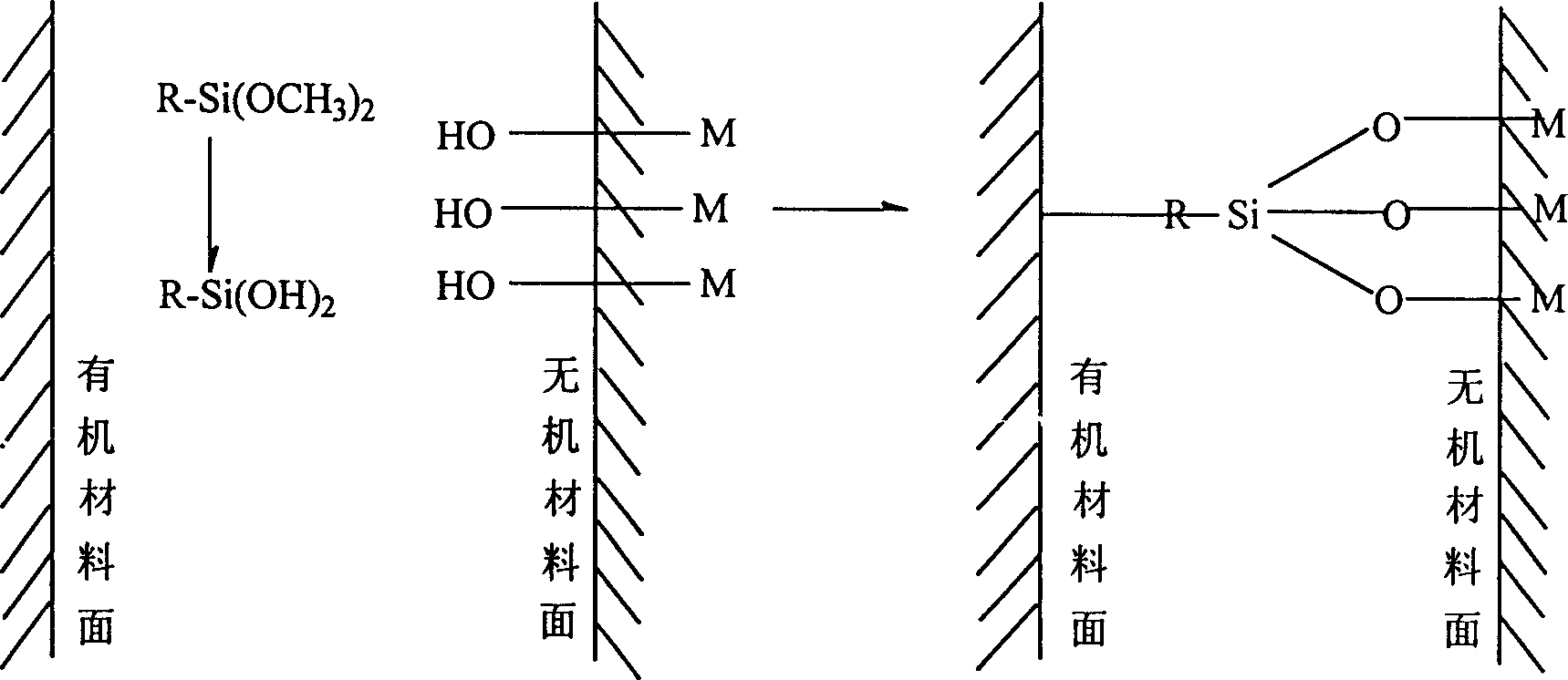

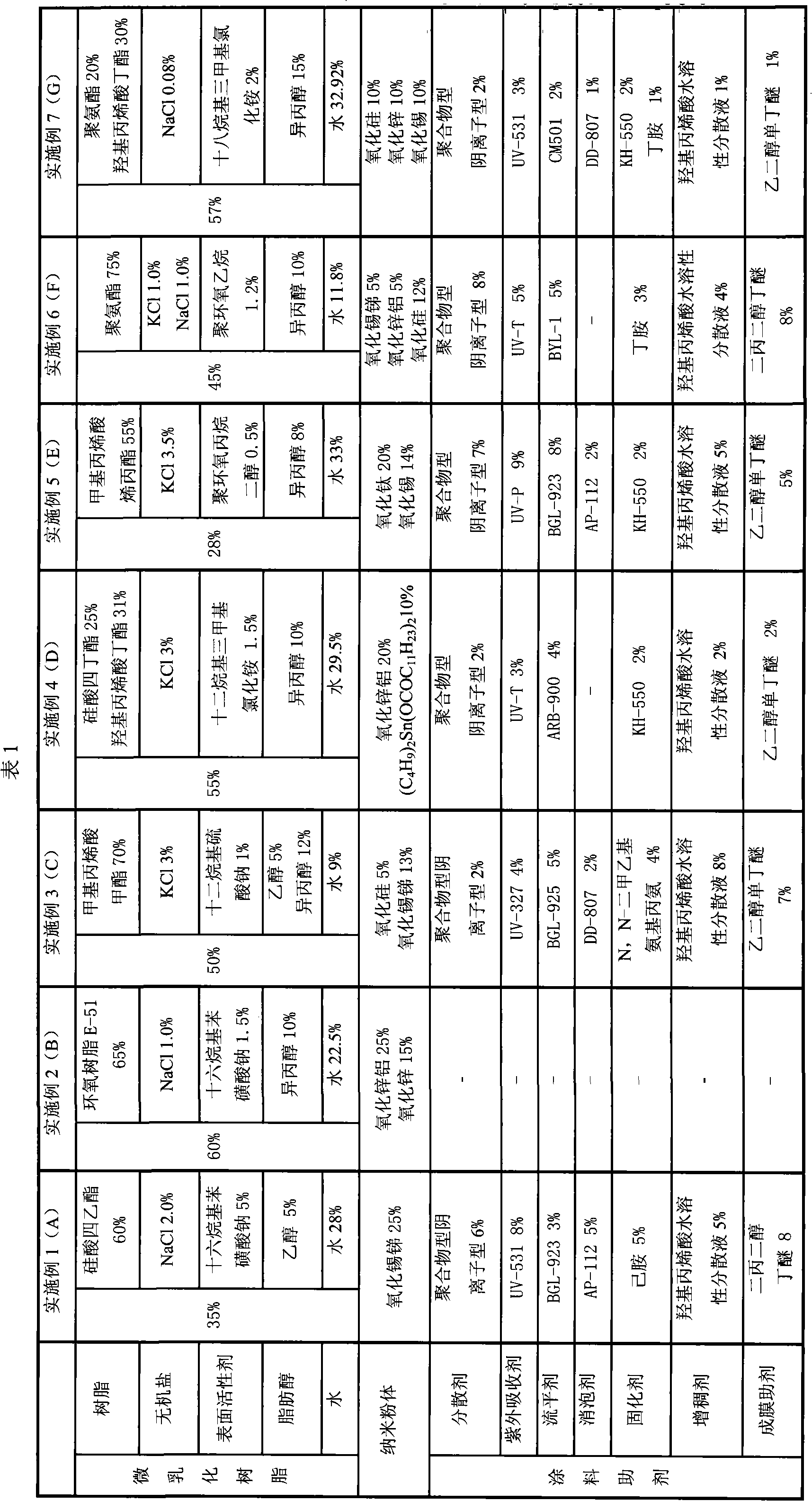

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

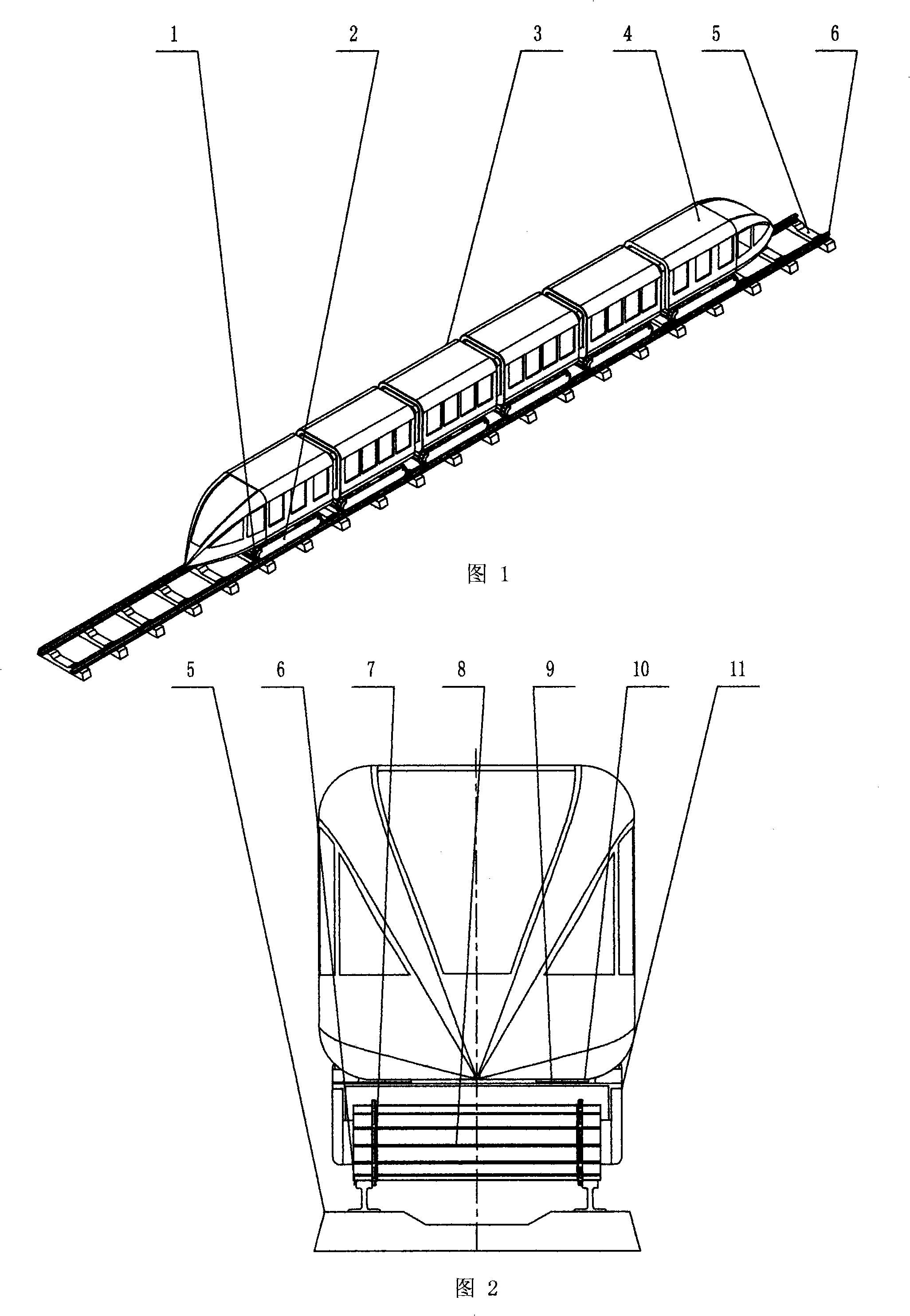

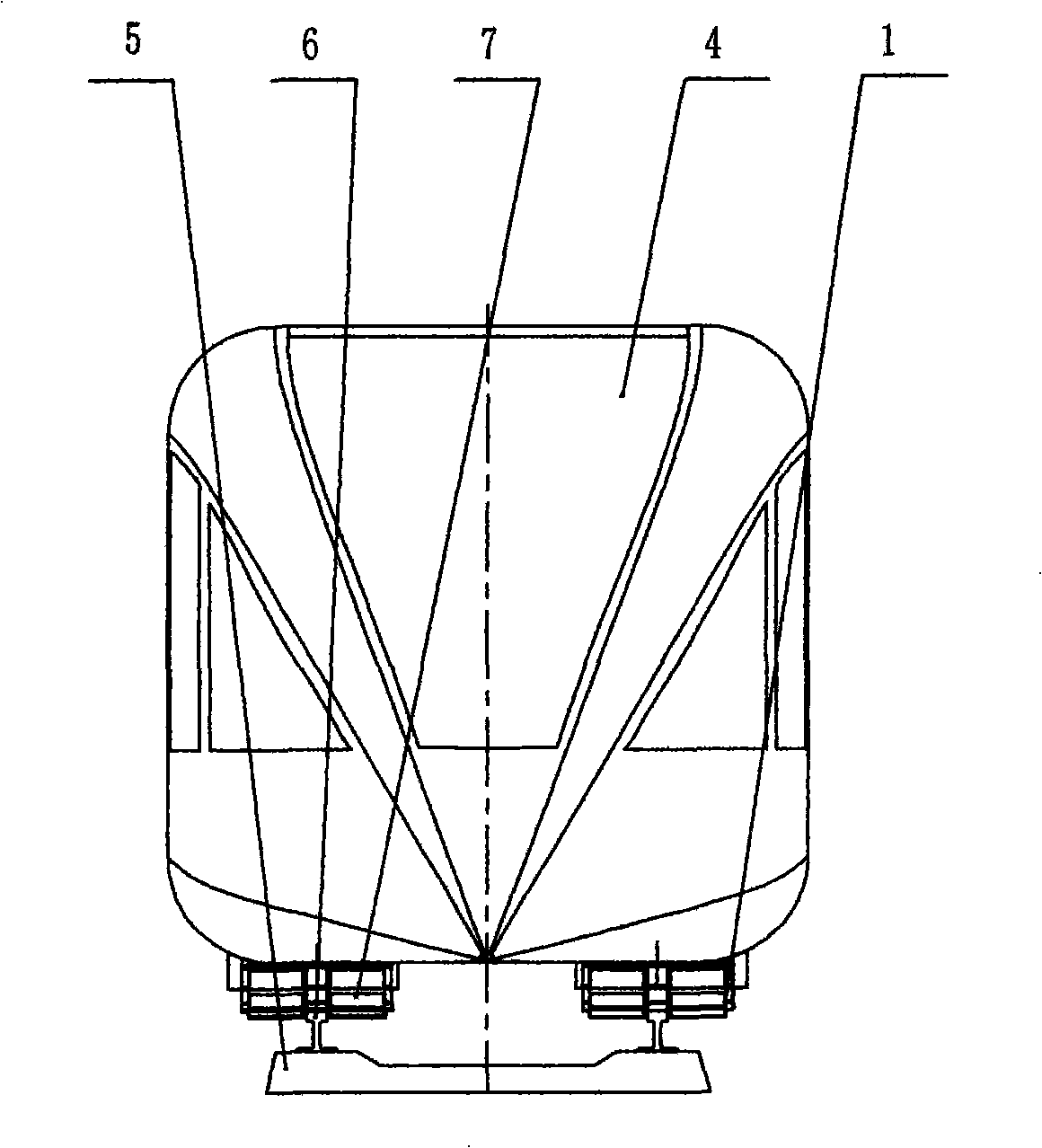

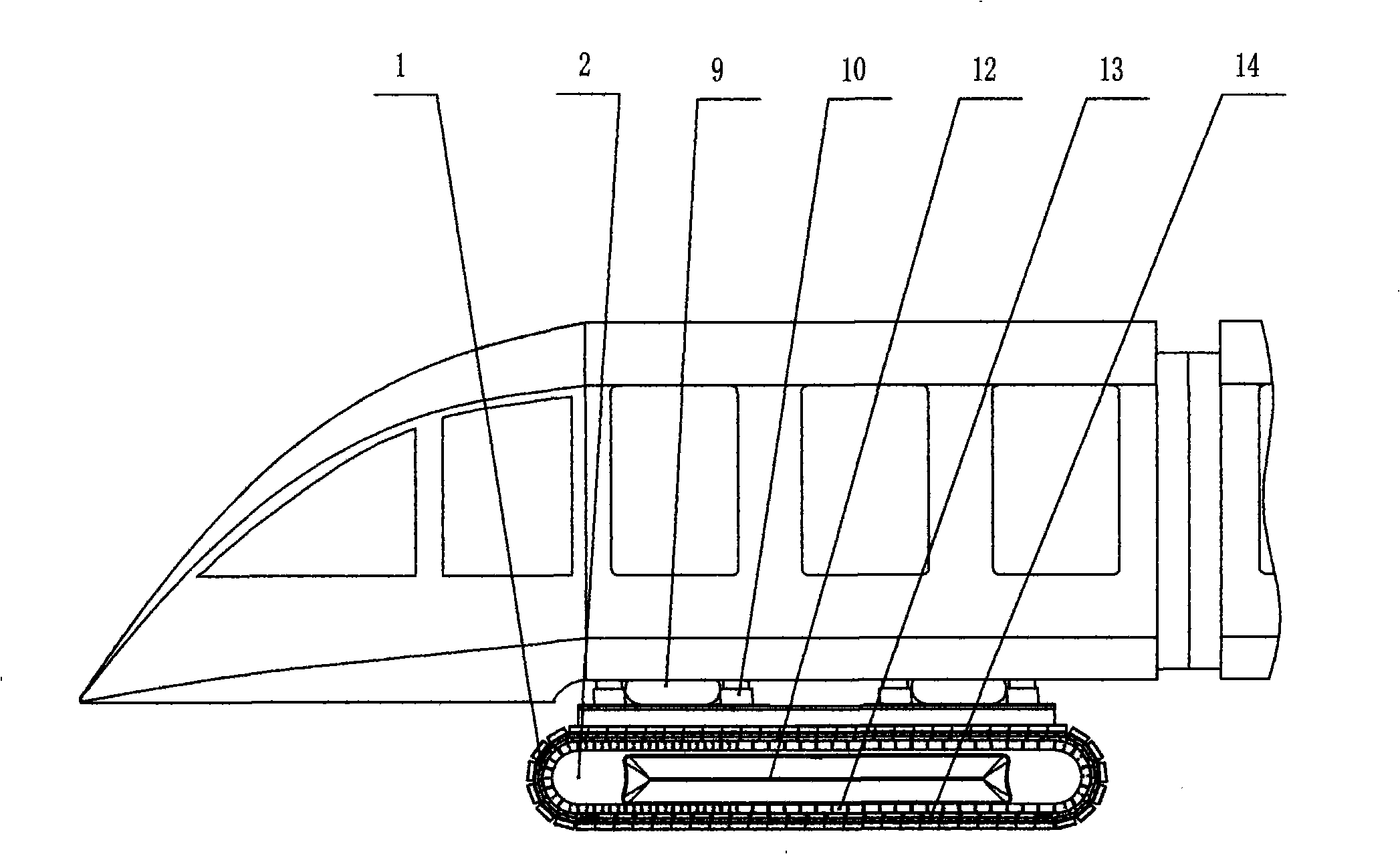

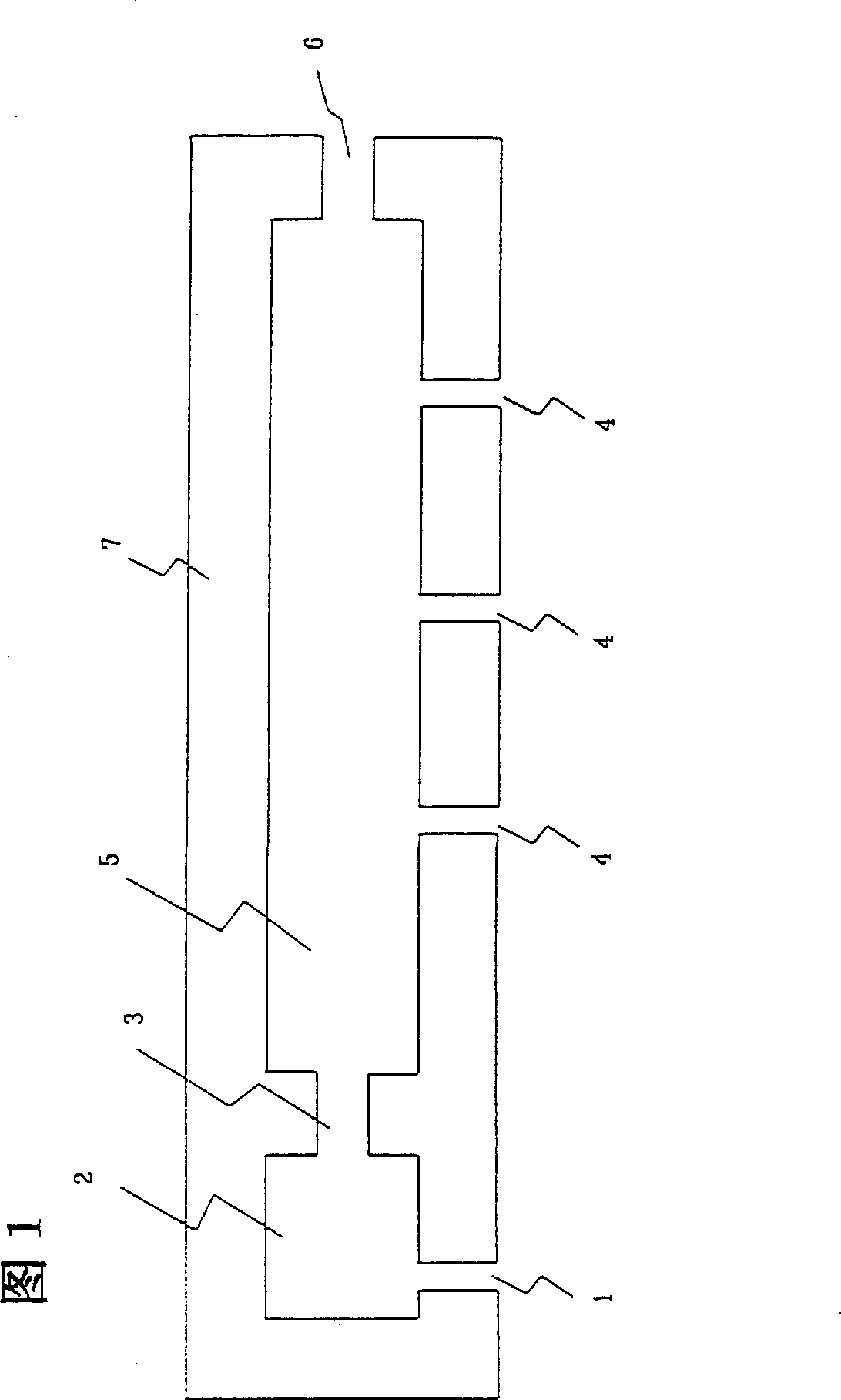

Crawler maglev vehicle and conveyor

InactiveCN101407181ASimple structureLow costEndless track vehiclesElectric propulsionDrive wheelFriction force

The invention provides a tracked magnetic suspension vehicle / a conveyer, which comprise a track, permanent magnets, a suspension seat and a driving wheel. The track is fixedly connected with the permanent magnet or a magnetizer, the suspension seat is fixedly connected with the permanent magnet, and the permanent magnet on the track and the permanent magnet on the suspension seat have homopolarity (or heteropolarity) and are arranged oppositely, generate magnetic suspension repulsive force (or attractive force) opposite to gravitational attraction, reduce or eliminate friction force when a vehicle runs, and reduce energy dissipation. The tracked magnetic suspension vehicle has the advantages of no energy consumption during suspension, low energy consumption during running, and energy saving. The tracked magnetic suspension vehicle achieves trackless magnetic suspension, also can run on a road, and is not limited by railway track any more. The tracked magnetic suspension vehicle also can be used as a magnetic suspension conveyer, and is energy-saving, clean and dustless.

Owner:刘忠臣

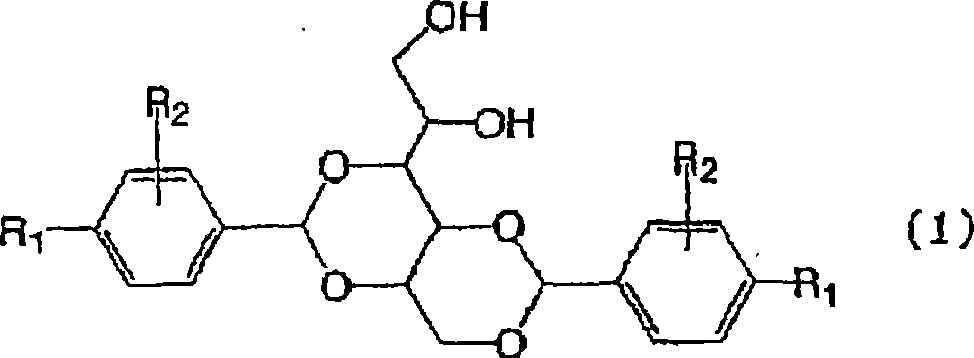

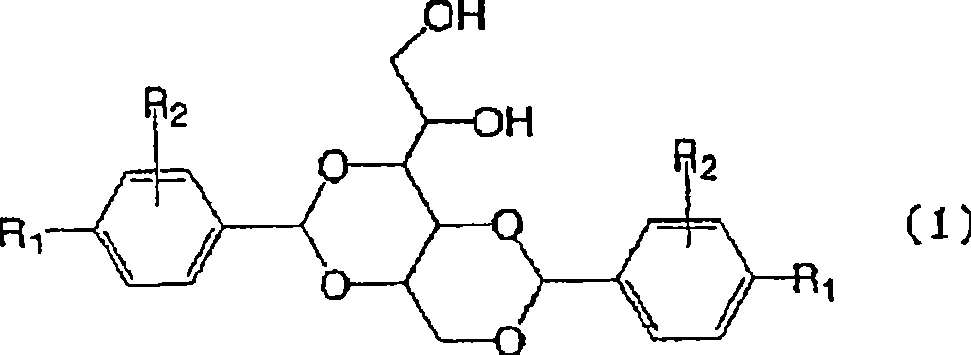

Biodegradable resin compositions and molded objects thereof

The present invention has its object to provide a resin composition excellent in impact resistance, tensile properties and transparency using a plant-derived biodegradable polymer obtained by positive fixation of carbon dioxide on the earth and, moldings thereof, and, further, provide a resin composition and moldings thereof improved in processability and thermal stability. The present invention relates to a resin composition which comprises (A), an aliphatic polyester type biodegradable polymer and (B) at least one copolymer selected from the group consisting of composite rubber graft copolymers (b1) and core-shell type graft copolymers (b2); or, a resin composition which comprises (A) an aliphatic polyester type biodegradable polymer and (C) at least one compound selected from the group consisting of sorbitol compounds (c1) having a particular chemical structure and urea bond-containing substituted urea compounds (c2).

Owner:KANEKA CORP +1

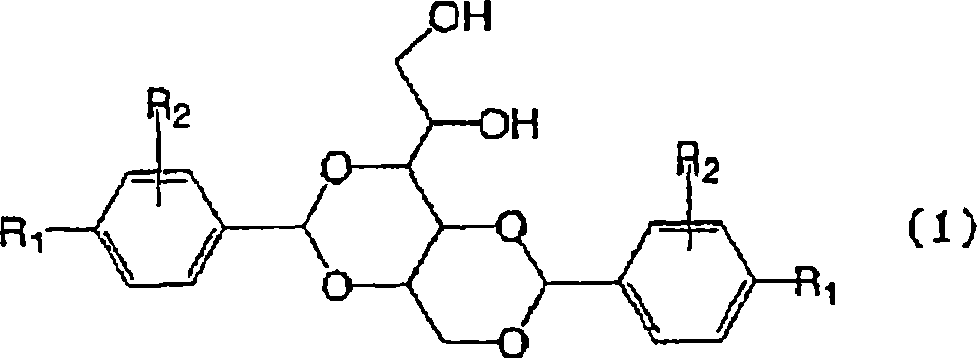

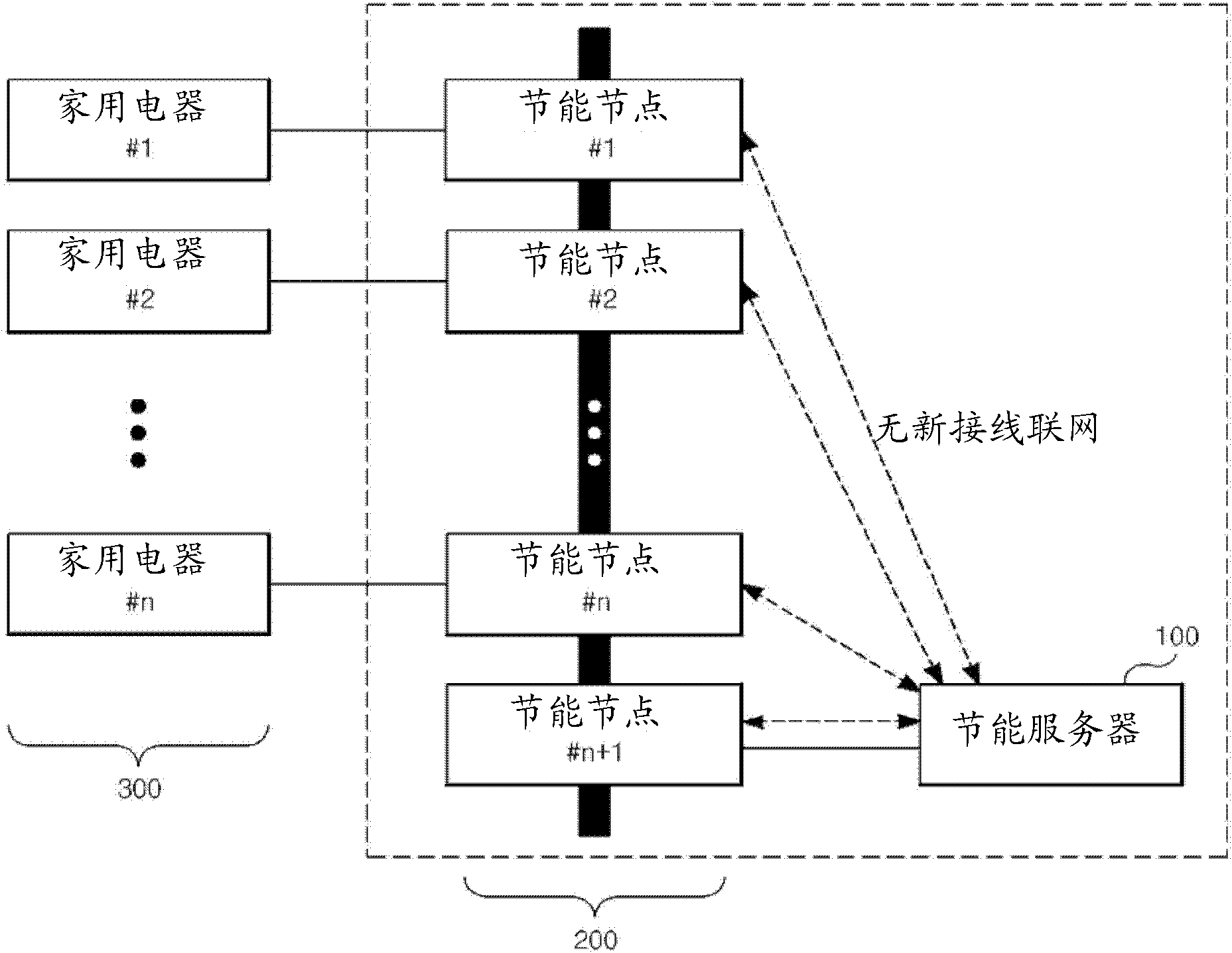

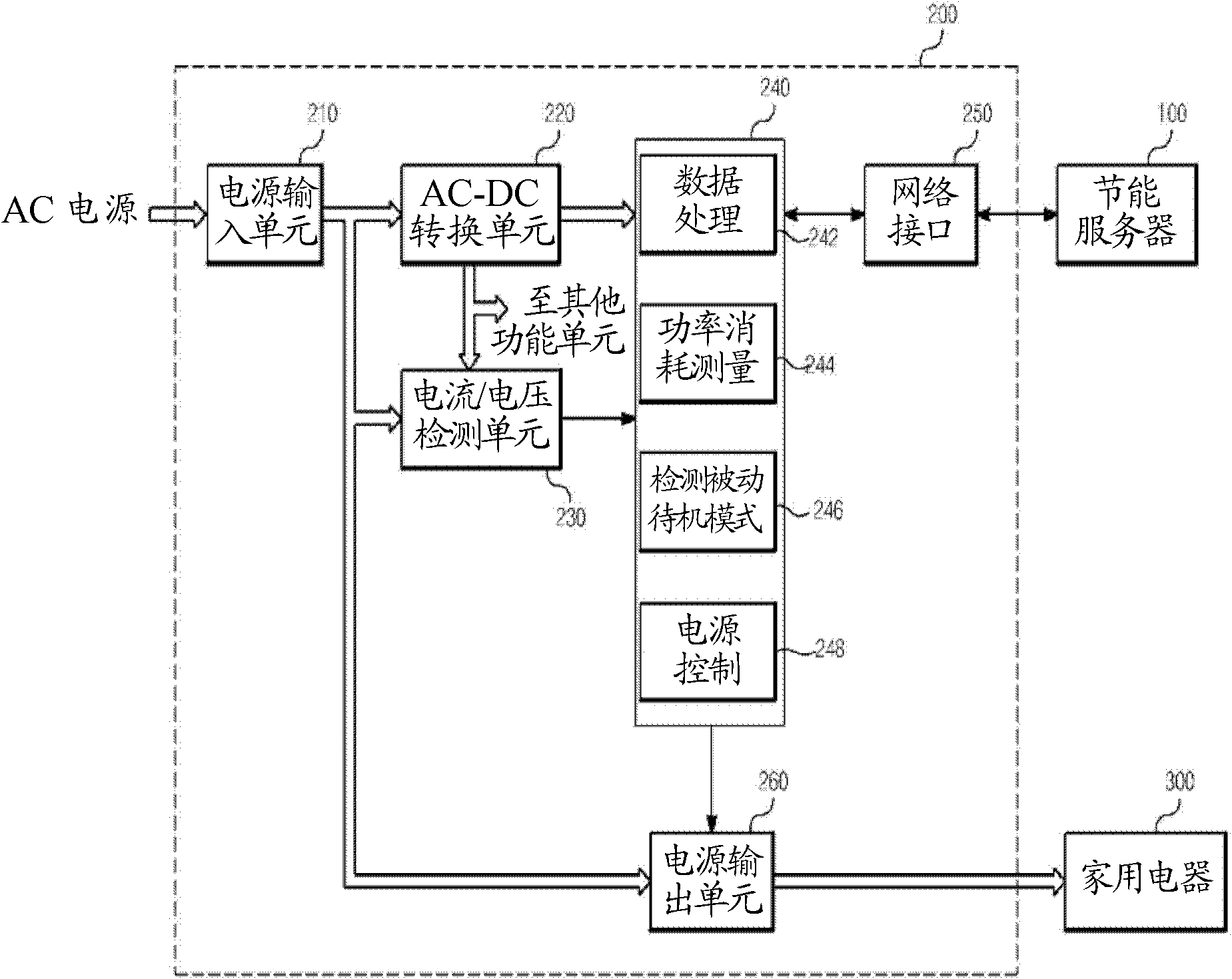

System and method for reducing standby power consumption and monitoring power consumption of household appliances and home network equipment

ActiveCN102292895ASave electricityCommunication standby power cut offEnergy efficient ICTPower distribution line transmissionEngineeringEnergy depletion

This invention relates to an energy consumption monitoring and standby power saving system and methods for the home appliances and home network devices that is capable of; automatically shutting off not only passive standby power but also active standby power which is unnecessarily consumed in the residential environment including homes and offices; realtime monitoring of the amount of consumed electrical energy of a specific appliance for a specific period; and providing various power related additional services through transmission of the collected data to power suppliers and service providers. According to one feature of the present invention, it provides an energy consumption monitoring and standby power saving system which is connected to home appliances and detects the amount of the power consumption of corresponding home appliances, and includes more than two energy saving nodes which approve application or shut-off power to corresponding home appliances, and an energy saving server which is connected to each of said energy saving nodes and collecting various status information of corresponding home appliances including said amount of power consumption from said nodes.

Owner:KOREA ELECTRONICS TECH INST

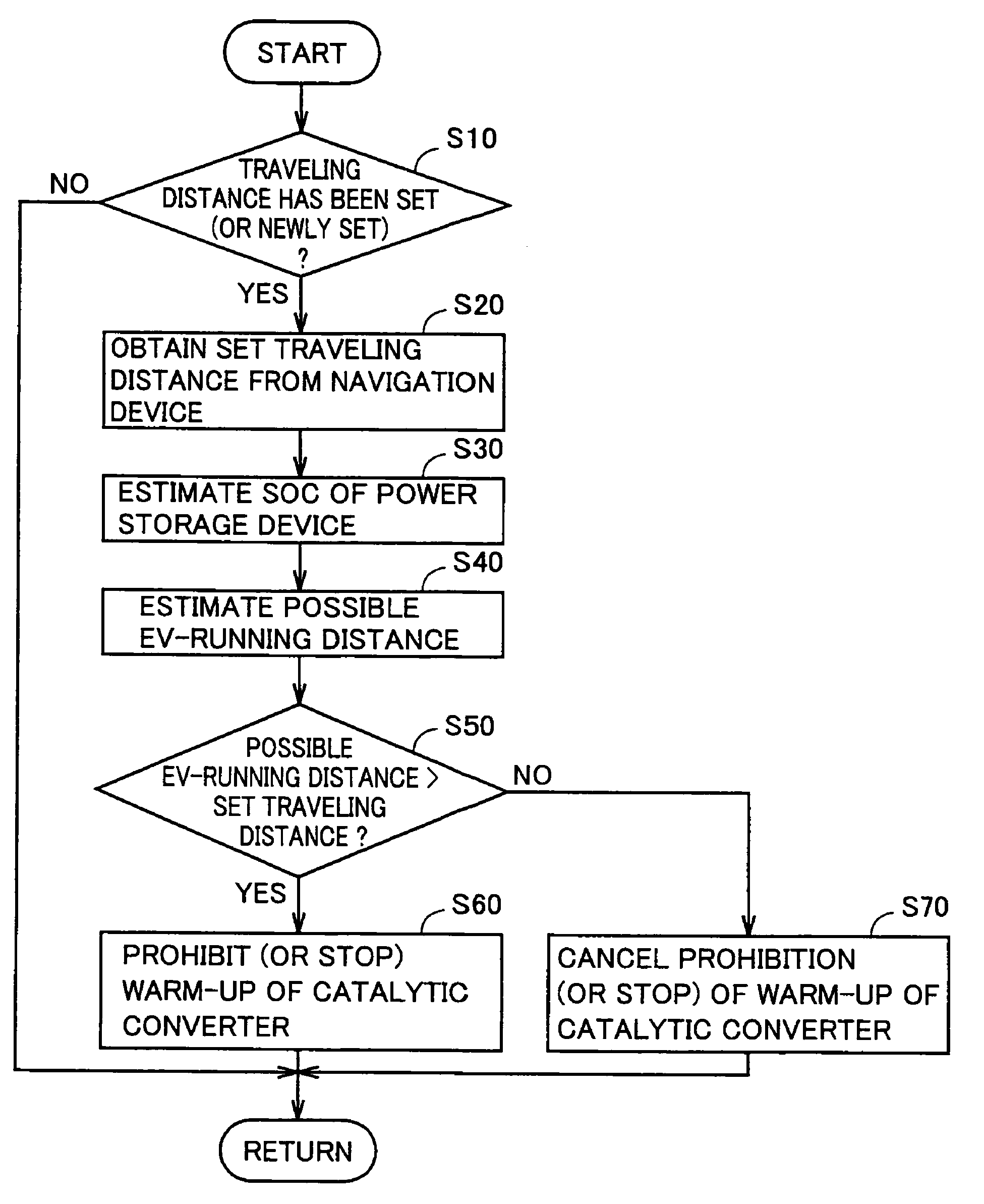

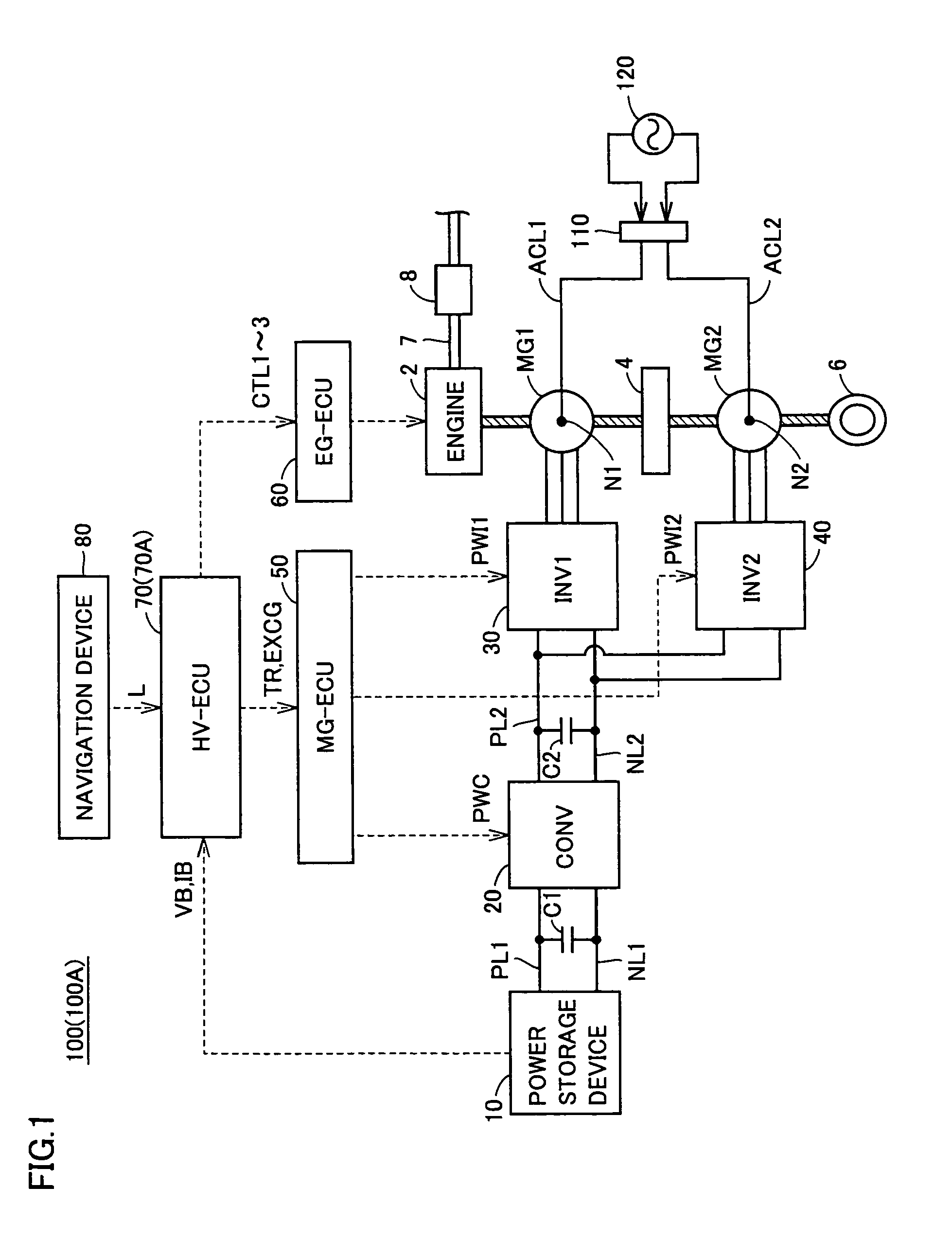

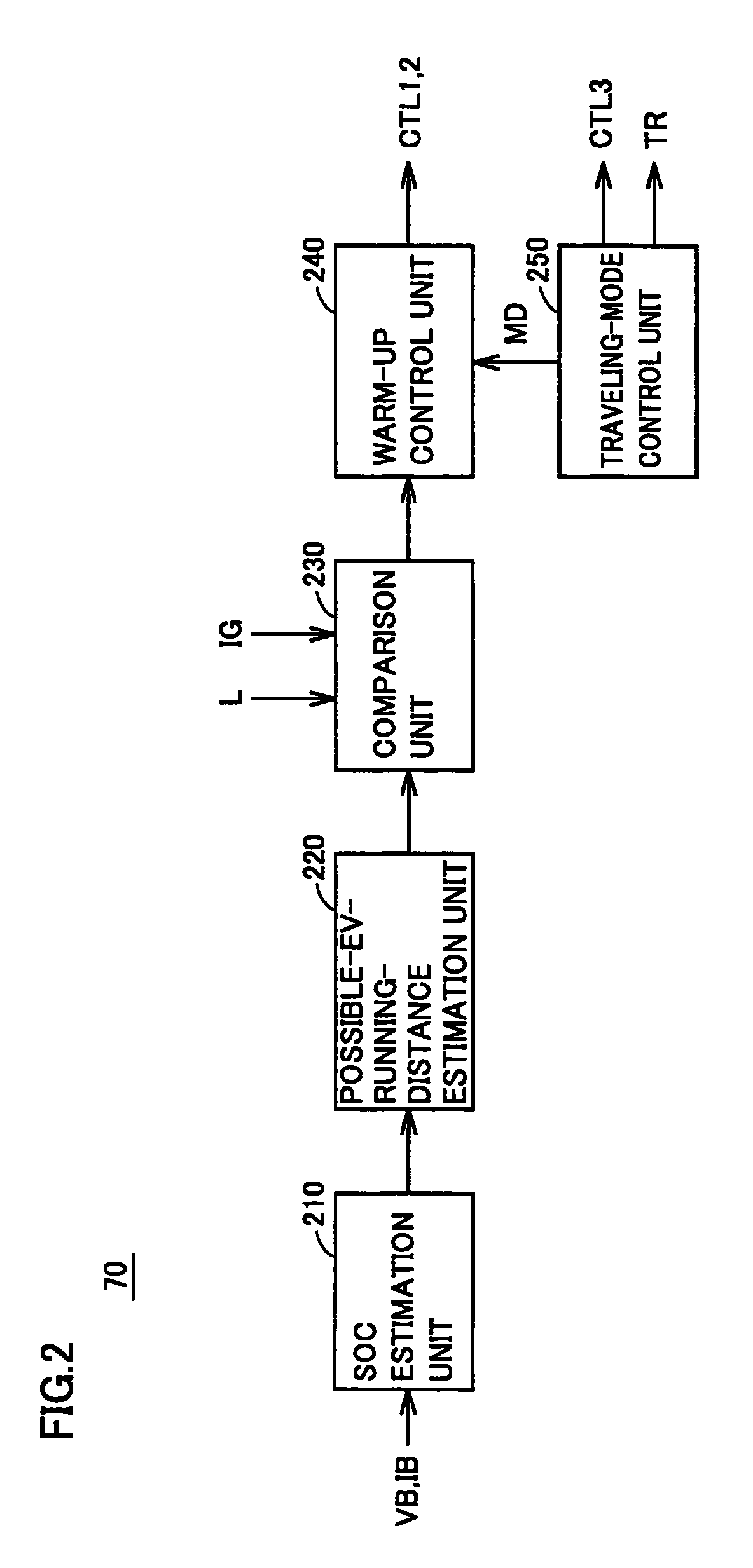

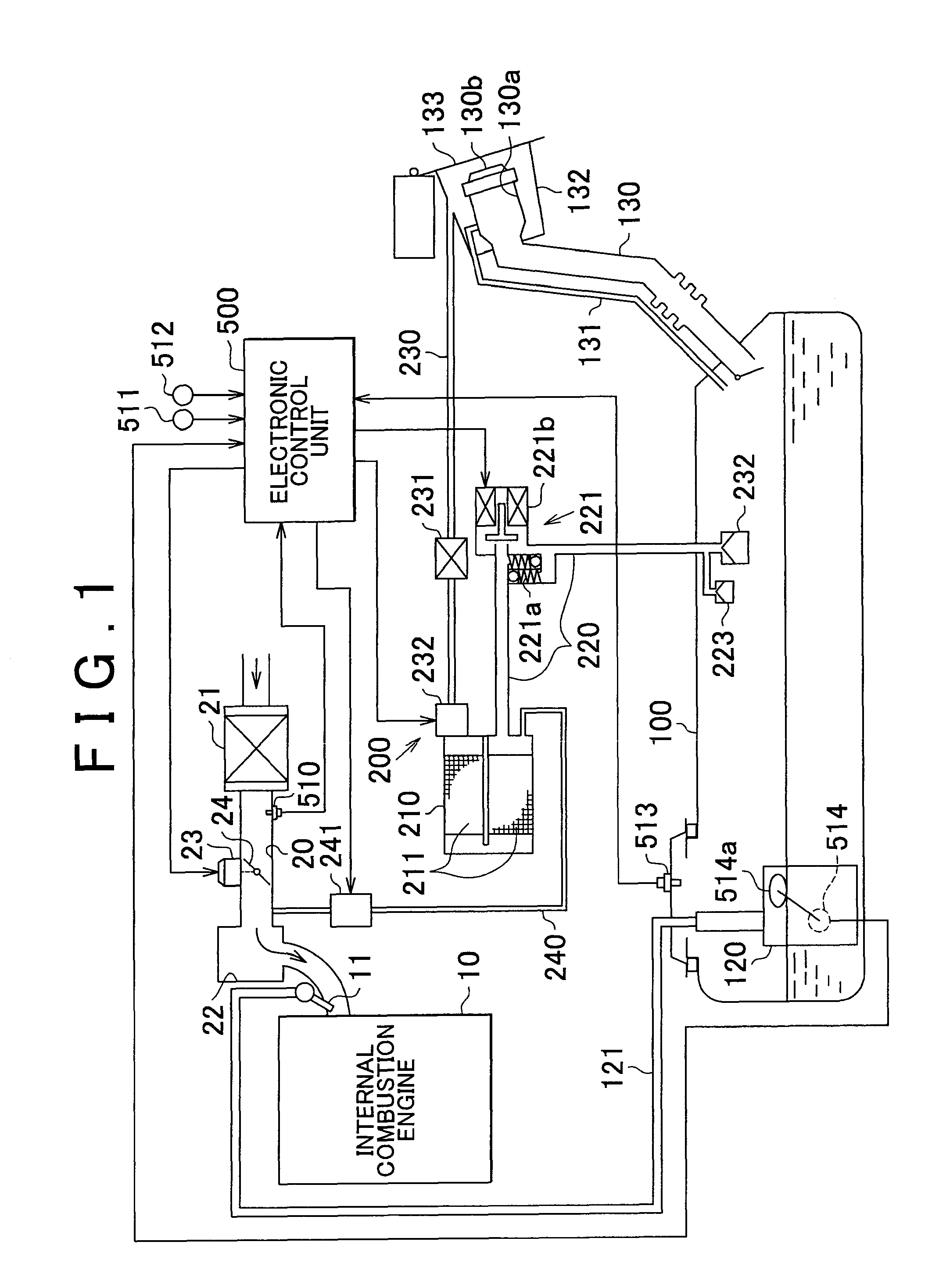

Hybrid vehicle and method of controlling the same

ActiveUS8774993B2Prevents unnecessary warm-upReduce fuel consumptionHybrid vehiclesInstruments for road network navigationControl signalHybrid vehicle

A hybrid vehicle is equipped with an engine and a motor generator (MG2) serving as a power source for driving the vehicle. A catalytic converter is provided in an exhaust pipe of the engine. An HV-ECU estimates a possible EV-running distance based on an SOC of a power storage device for comparison with a traveling distance (L) to a destination set by a navigation device. When the possible EV-running distance is longer than the traveling distance (L), the HV-ECU outputs a control signal (CTL2) instructing prohibition of warm-up of the catalytic converter, to an EG-ECU.

Owner:TOYOTA JIDOSHA KK

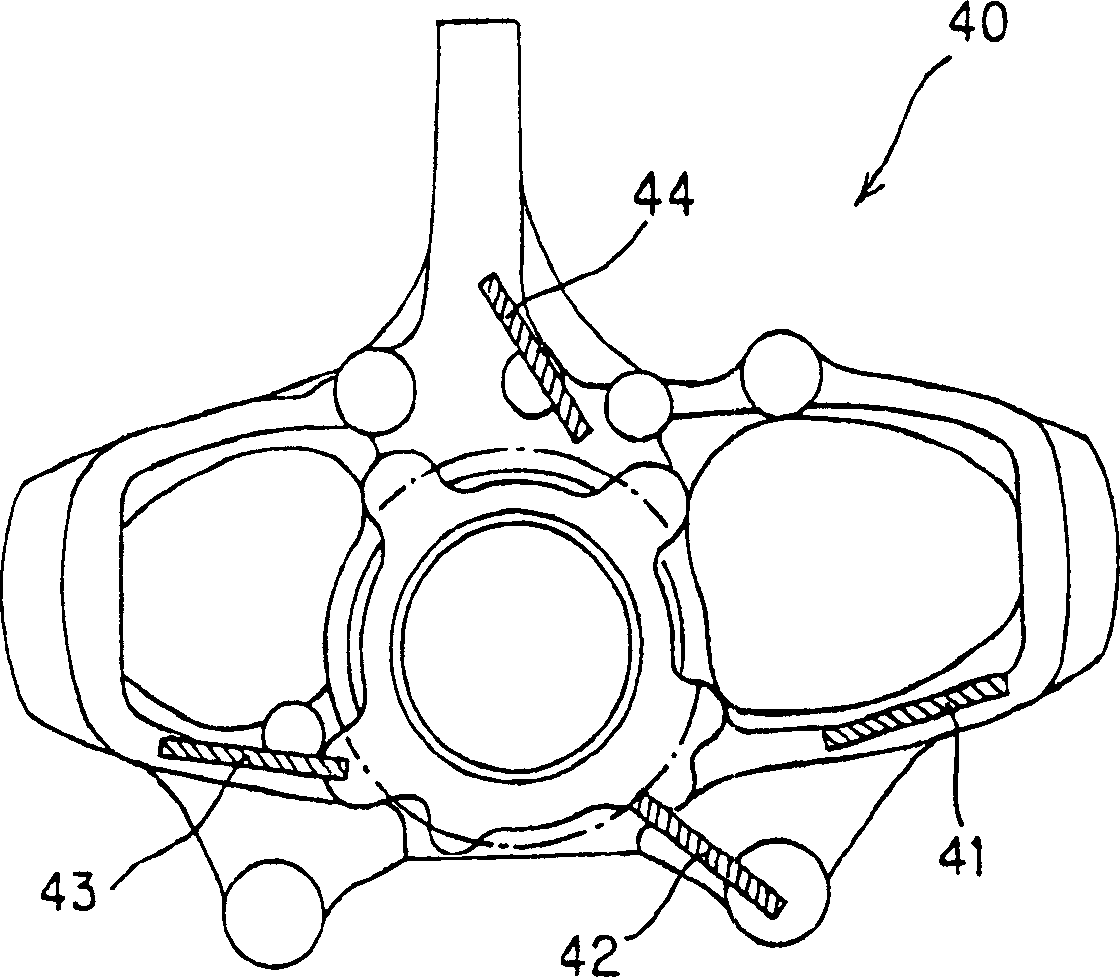

Aluminium allloy for casting/forging, aluminium alloy cast/forged product and producing methods

InactiveCN1529763AHigh tensile strengthHigh yield strengthSuspensionsSteering linkagesManganeseCastability

Owner:ASAHI TEC CORP +1

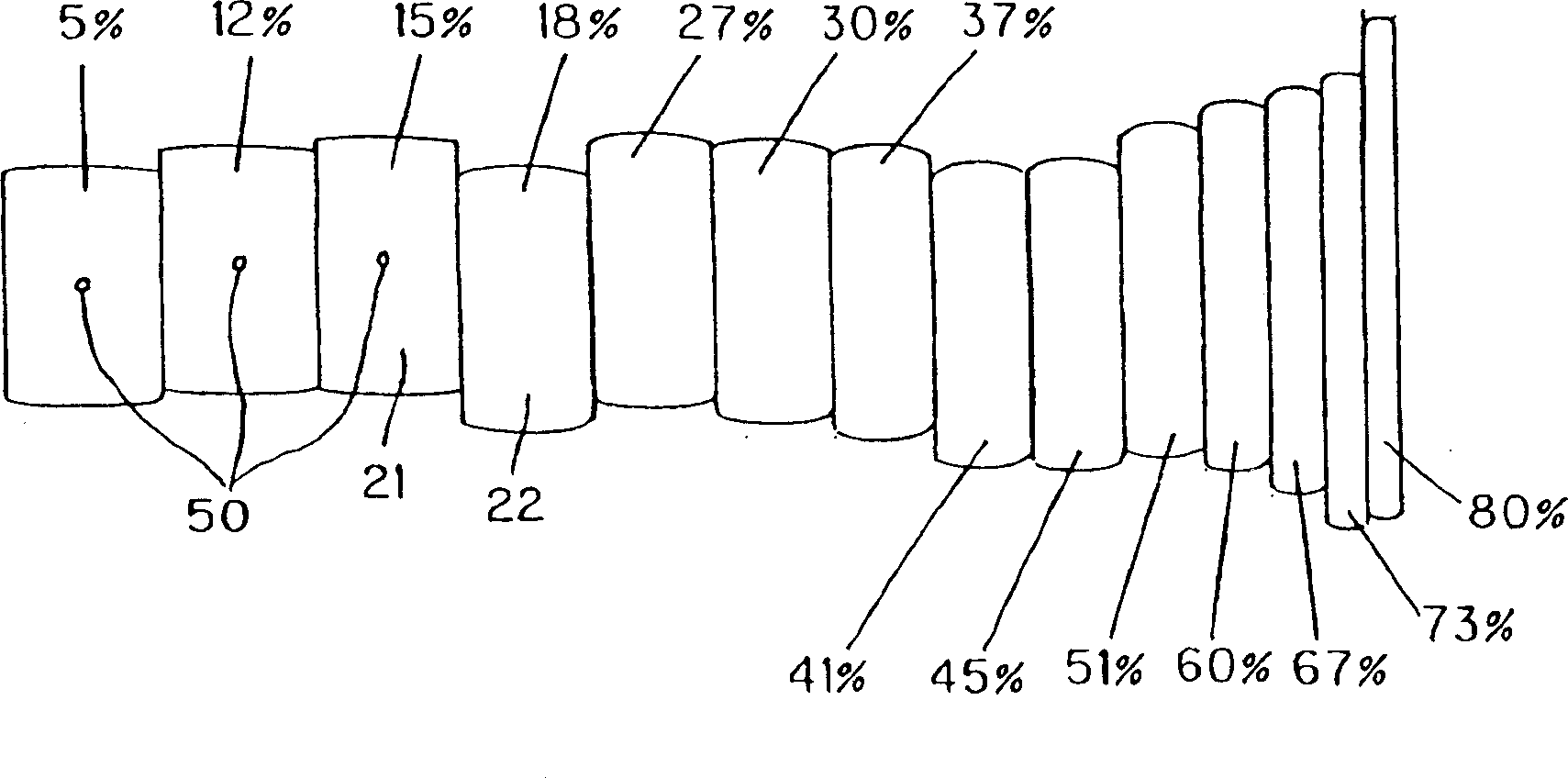

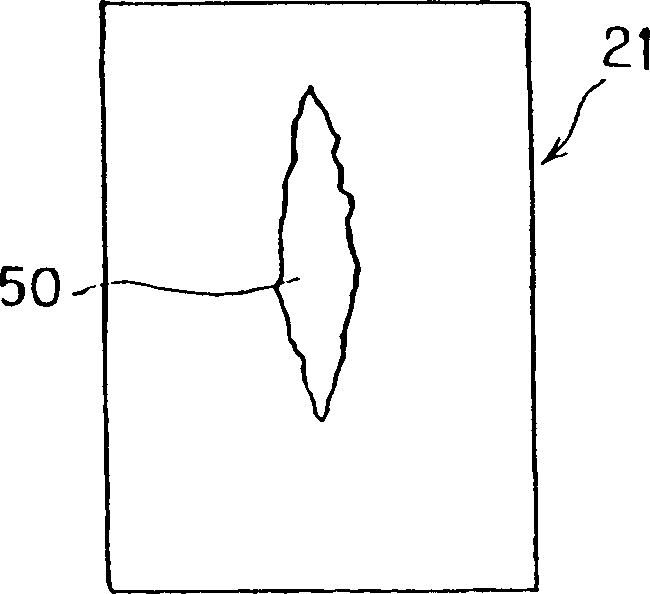

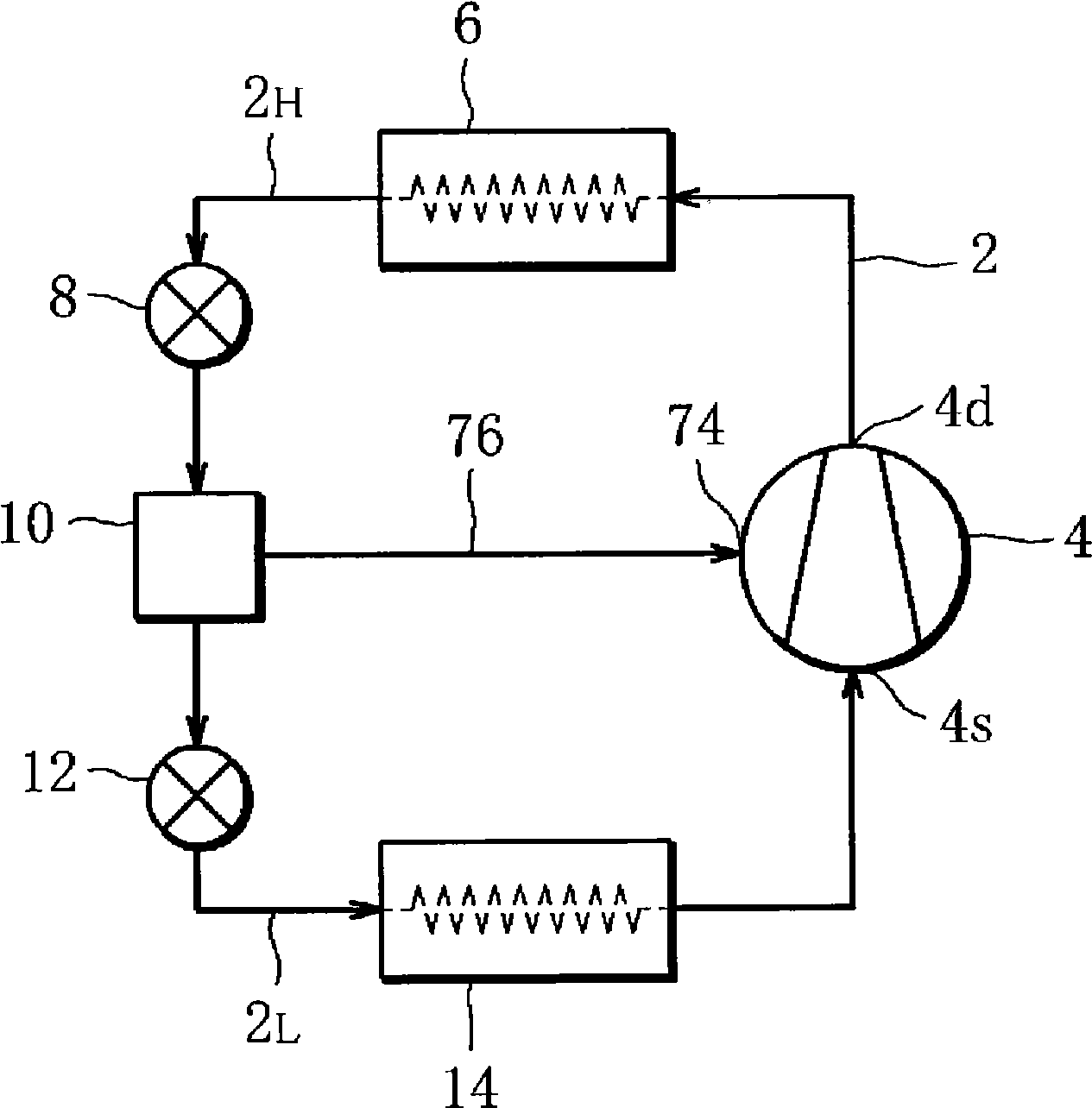

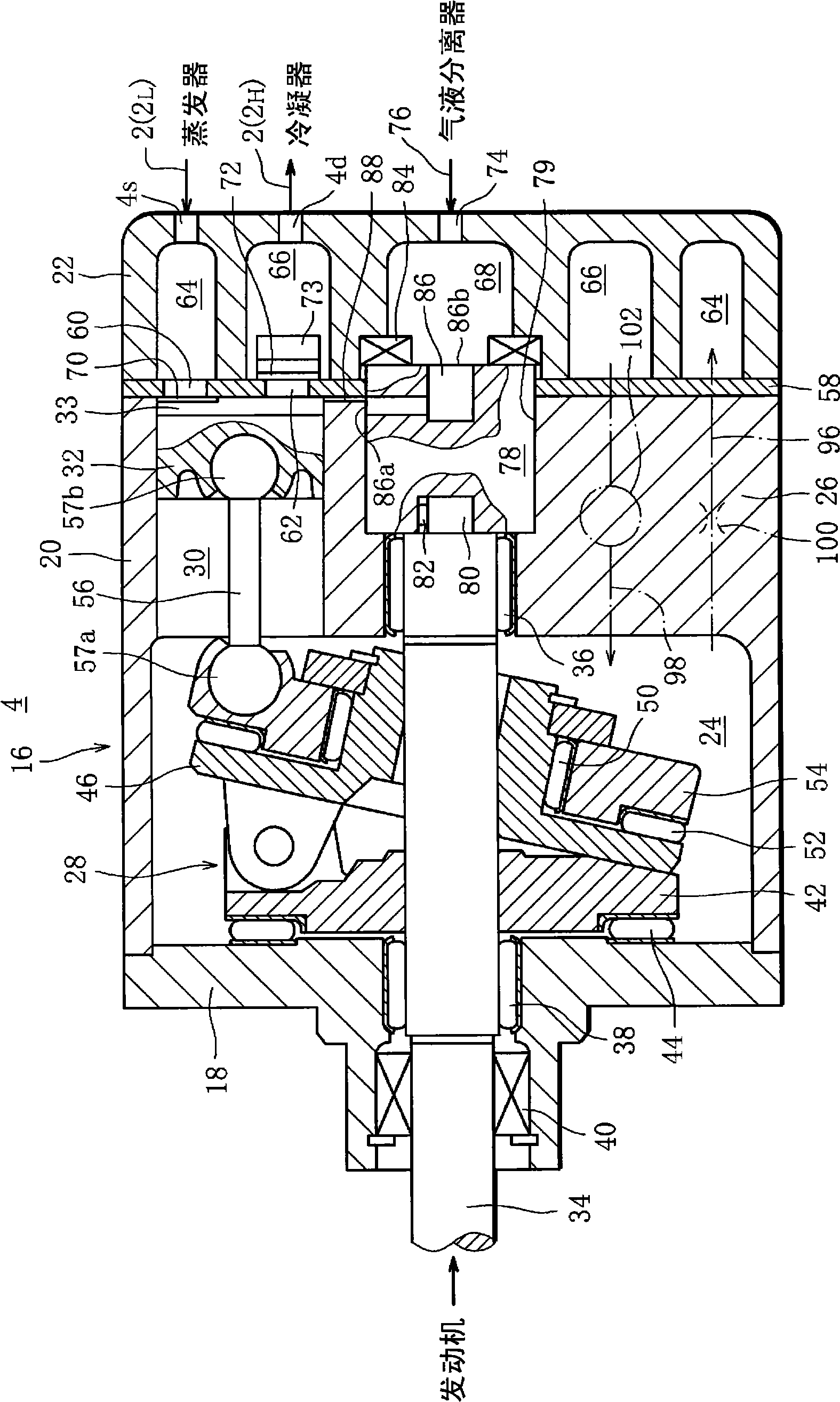

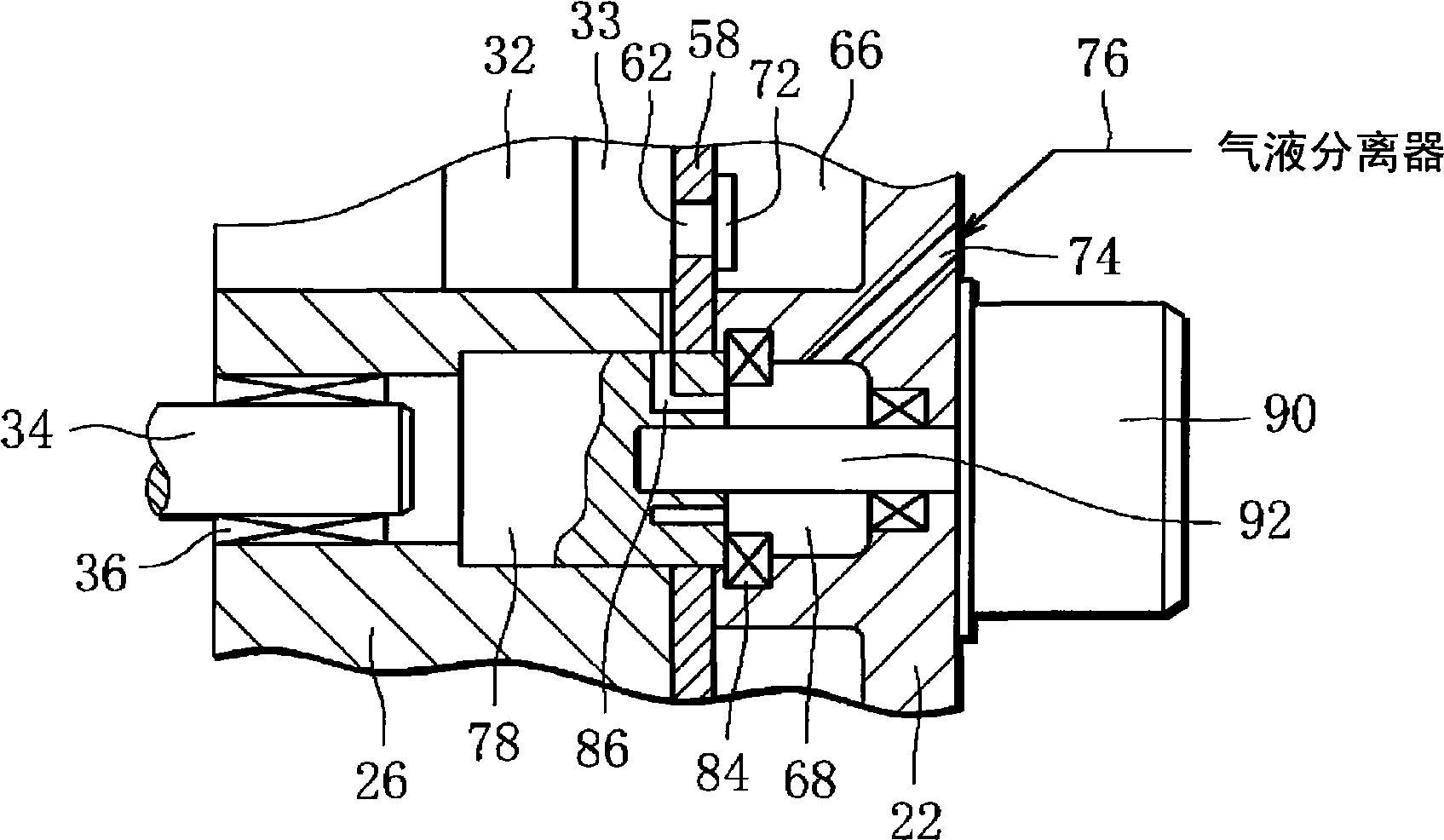

Reciprocating compressor of refrigerating machine

InactiveCN101535646AAvoid temperature riseImprove energy efficiencyPositive displacement pump componentsCompression machines with non-reversible cycleVapor–liquid separatorReciprocating motion

A reciprocating compressor of refrigerating machine that realizes inhibition of any temperature increase of discharged refrigerant and enhancing of refrigerant compression efficiency. The reciprocating compressor of refrigerating machine is one comprising housing (16) with cylinder bore (30); piston (32) capable of reciprocating motion in the cylinder bore (30), fitted in the cylinder bore (30); intermediate pressure chamber (68) disposed within the housing (16), into which a low-temperature refrigerant is led from gas-liquid separator (10) of refrigerating machine; and rotary valve (78) disposed between compression chamber (33) and the intermediate pressure chamber (68), wherein the rotary valve (78) rotates in conjunction with main shaft (34) of the compressor and, when the refrigerant is in the stage of compression within the compression chamber (33), opens so as to jet the low-temperature refrigerant from the intermediate pressure chamber (68) into the compression chamber (33).

Owner:SANDEN CORP

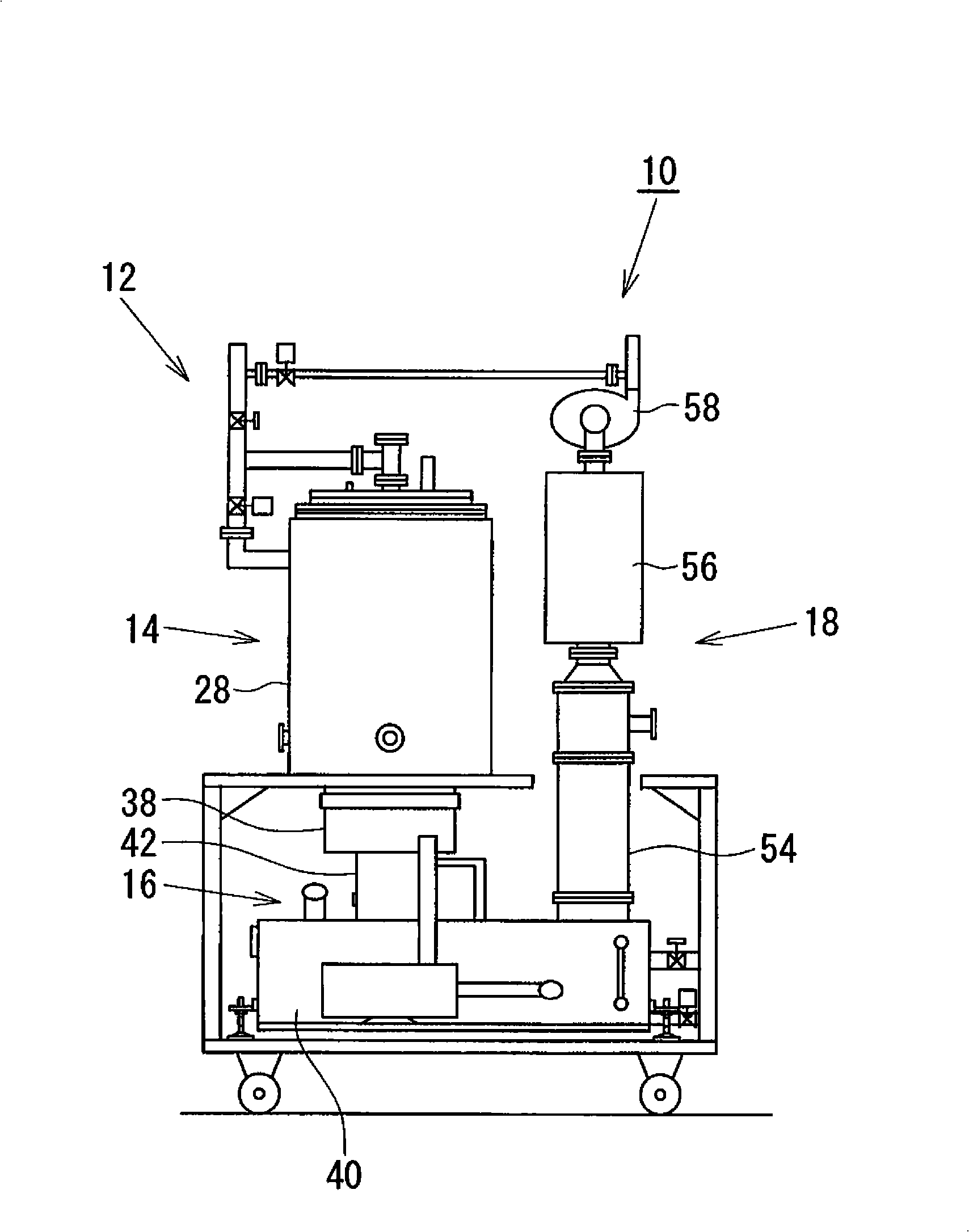

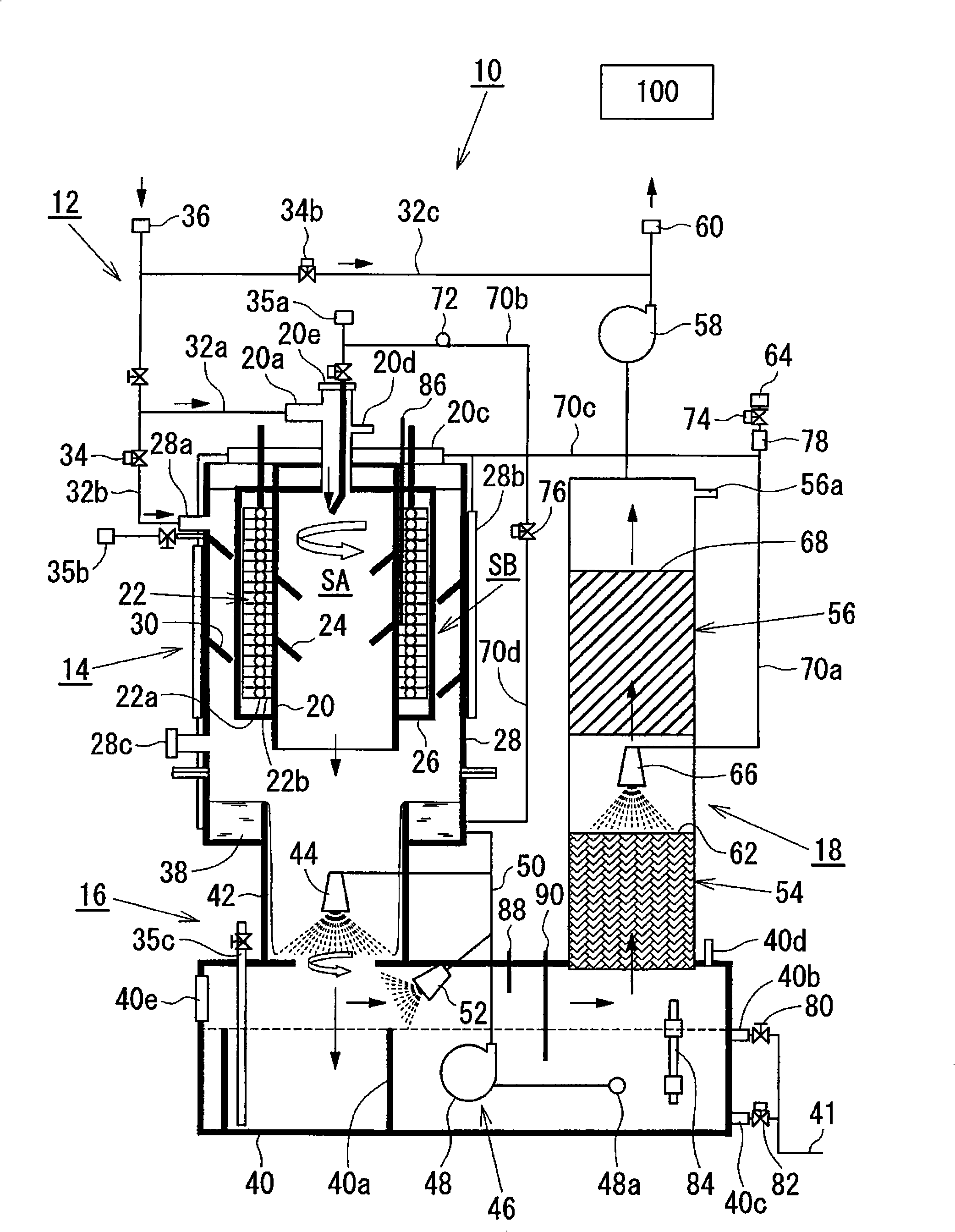

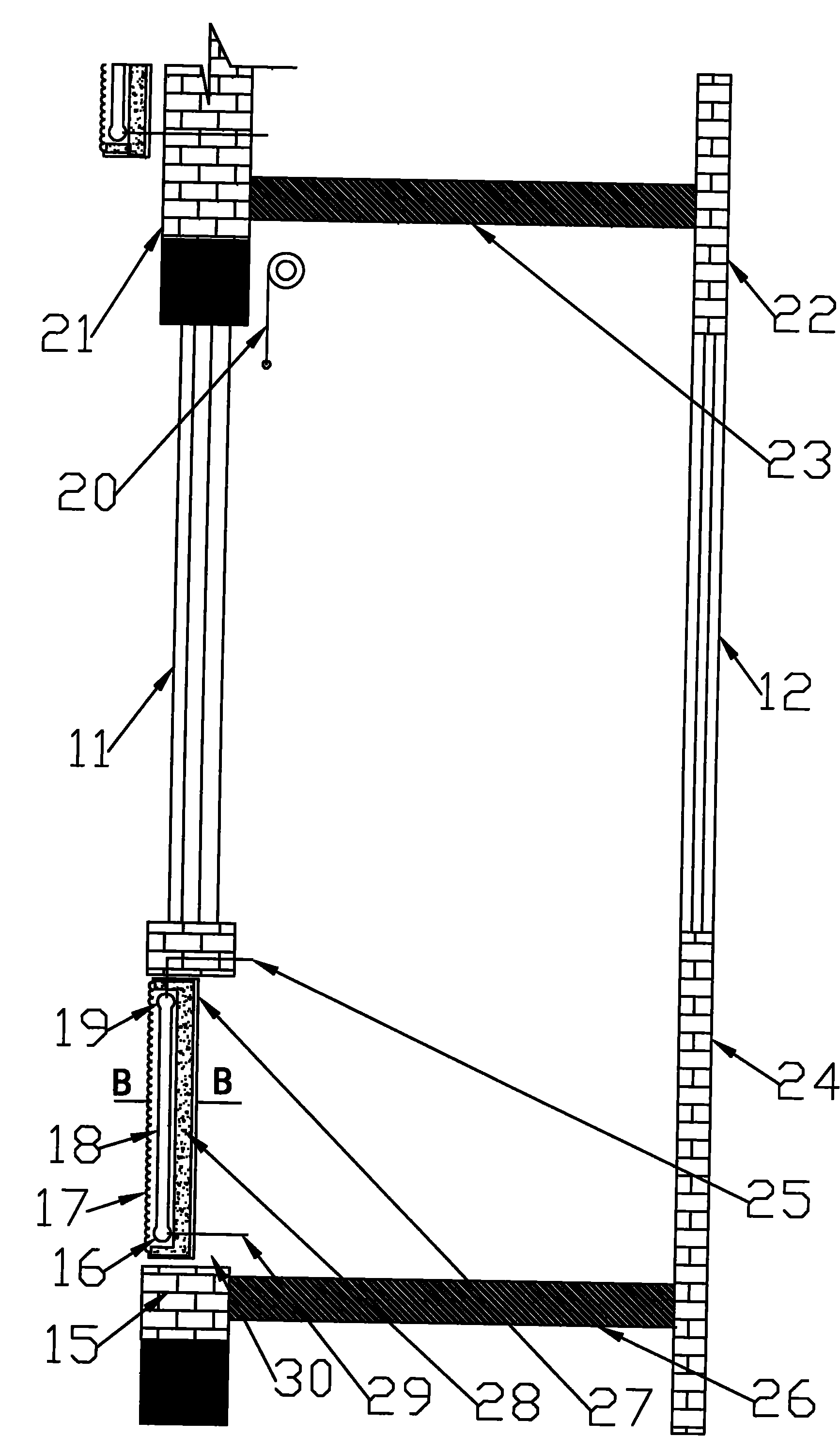

Water gas treatment device

InactiveCN101332405AExcellent temperature correction capabilityAvoid warmingFinal product manufactureDispersed particle separationHeating timeDecomposition

The invention provides a waste gas treating apparatus for effectively executing heat treatment for waste gas containing warm gas. The waste gas is introduced from a waste gas introducing section (12) into a heating treatment section (14). The waste gas is pyrolyzed mainly by radiation heat heated with an electromagnetic induction heating unit (22) and coming from a circular cylinder tube (20), in process of one-way pass from its base end section to end section in a circular cylinder tube of the heating treatment section. At this time, heating time for waste gas is adequately secured because waste gas becomes rotational flow via a commutation unit (24) to pass through the circular cylinder tube (20). As a result, even in condition that introduced waste gas from the waste gas introducing section (12) rapidly increases, desired capacity of decomposition is secured. In addition, power and gas generated by heating waste gas is cooled and decomposed in a water treating section (16) to remove residual mist in a final treating section (18).

Owner:NISSEI SANGYO

Method and device for global warming prevention

InactiveCN1280519AAvoid warmingGood effectNitrous oxide captureProductsGlobal-warming potentialChemistry

A low-cost and practically useful method for preventing global warming by decomposing N2O wherein N2O contained in an N2O-containing gas to be treated can be decomposed at a relatively low temperature; and an apparatus therefor. That is, a method for preventing global warming comprising, in a process of thermally or catalytically decomposing N2O in an N2O-containing gas to be treated, dividing the N2O-containing gas stream to be treated in portions, preheating a portion thereof so as to exothermally decompose N2O in said gas stream to form a hot gas stream, and supplying the remainder of the divided gas stream to be treated into said hot gas stream to thereby continuously decompose N2O.

Owner:ASAHI KASEI KK

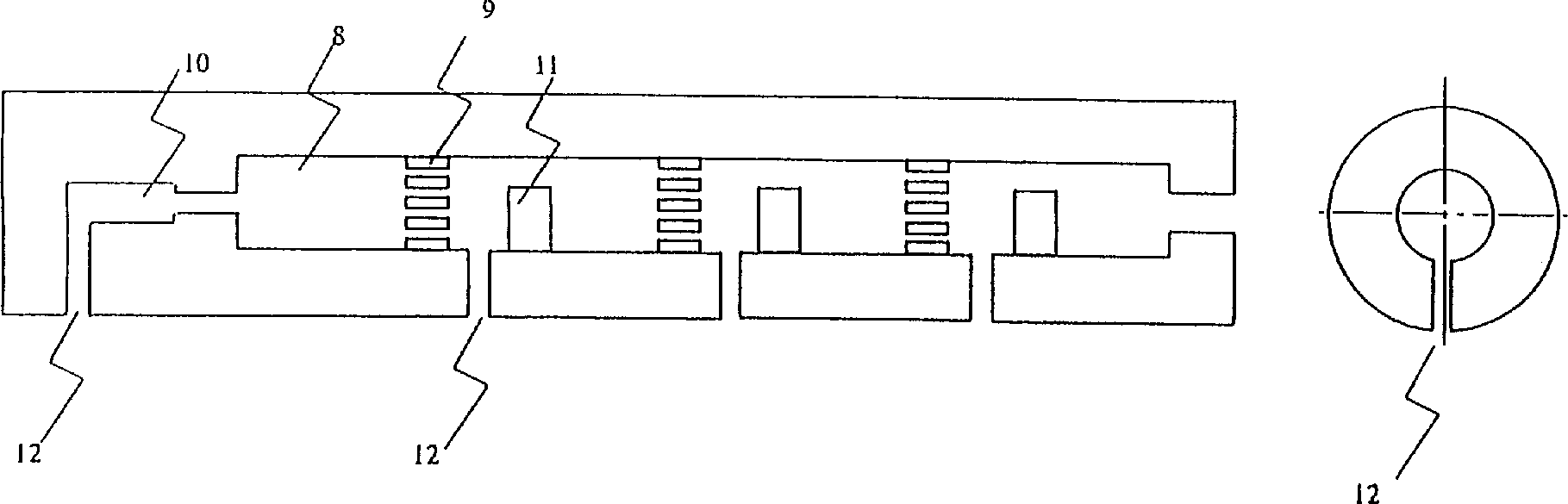

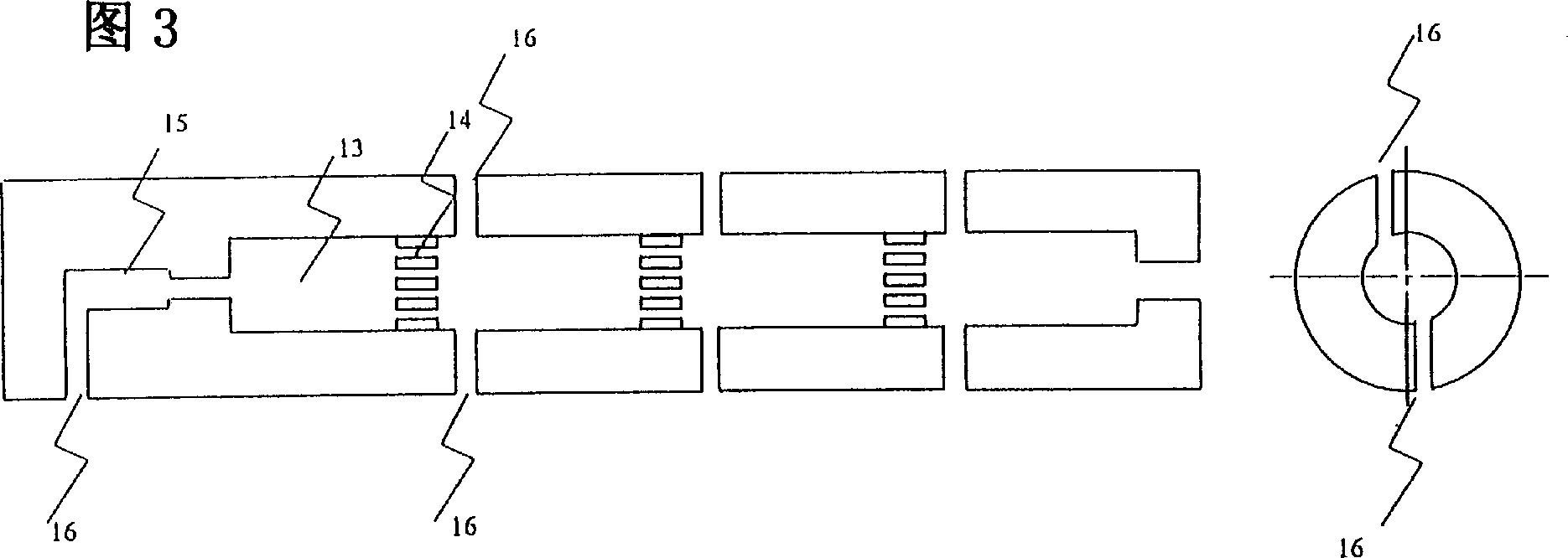

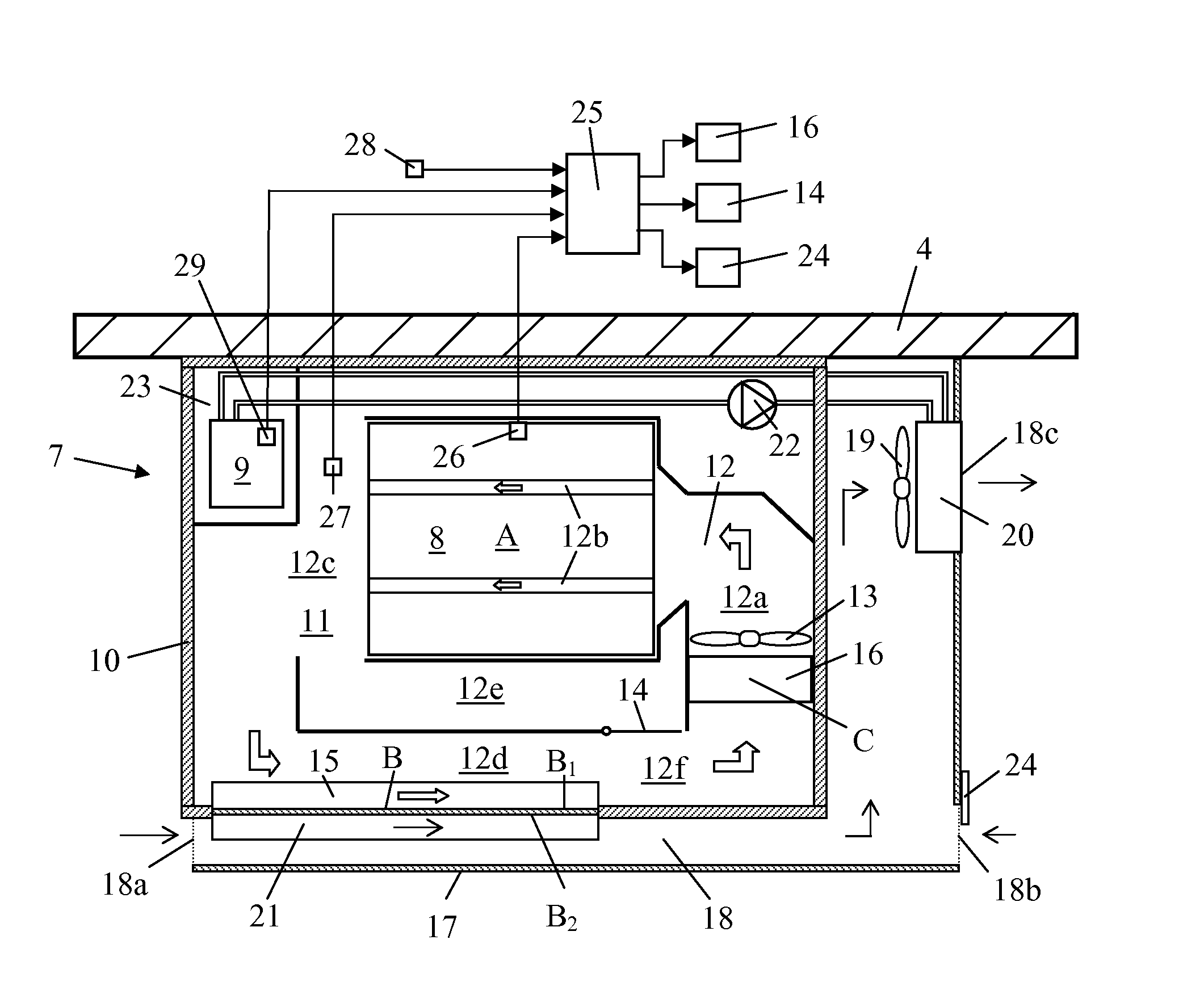

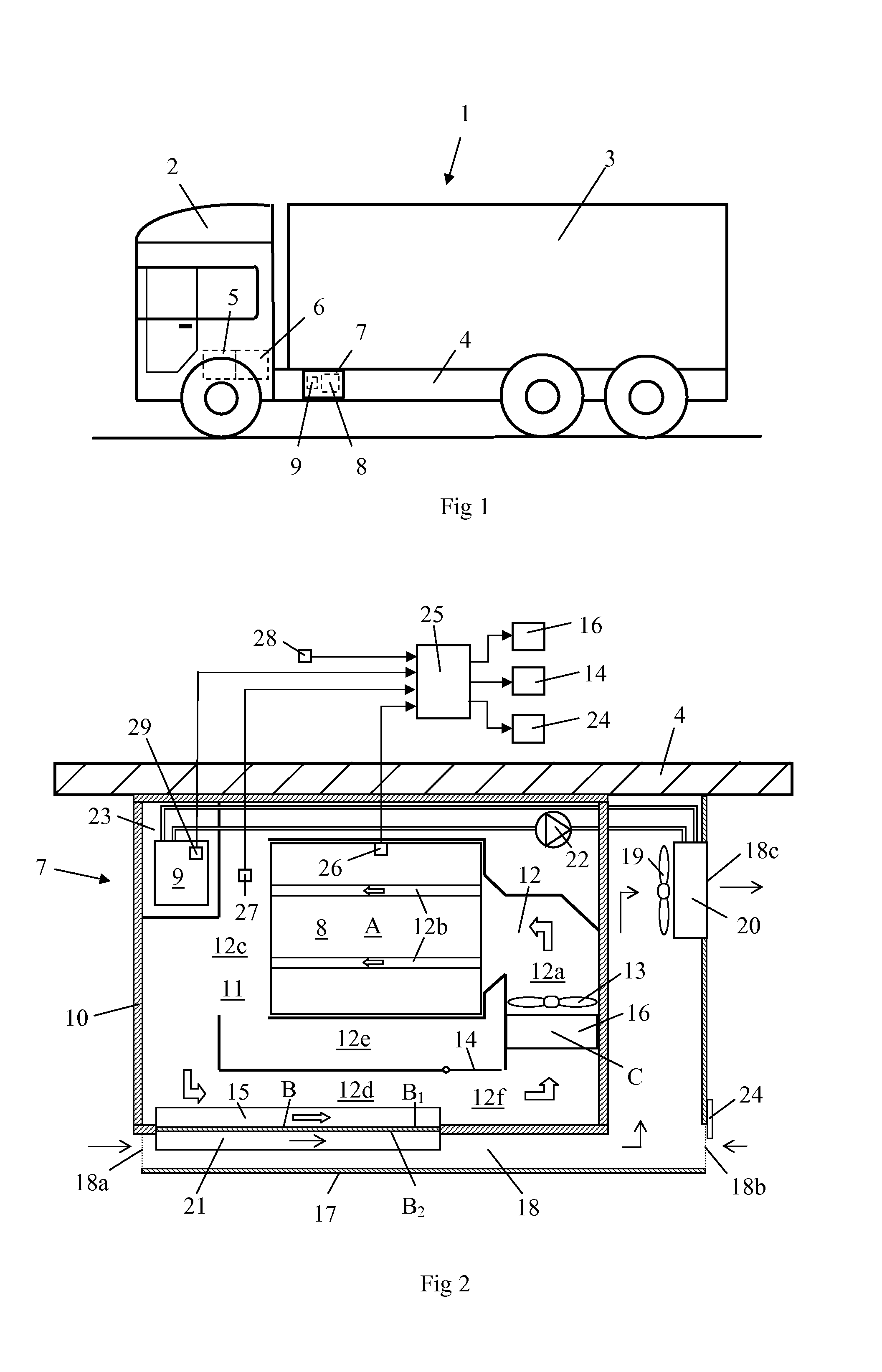

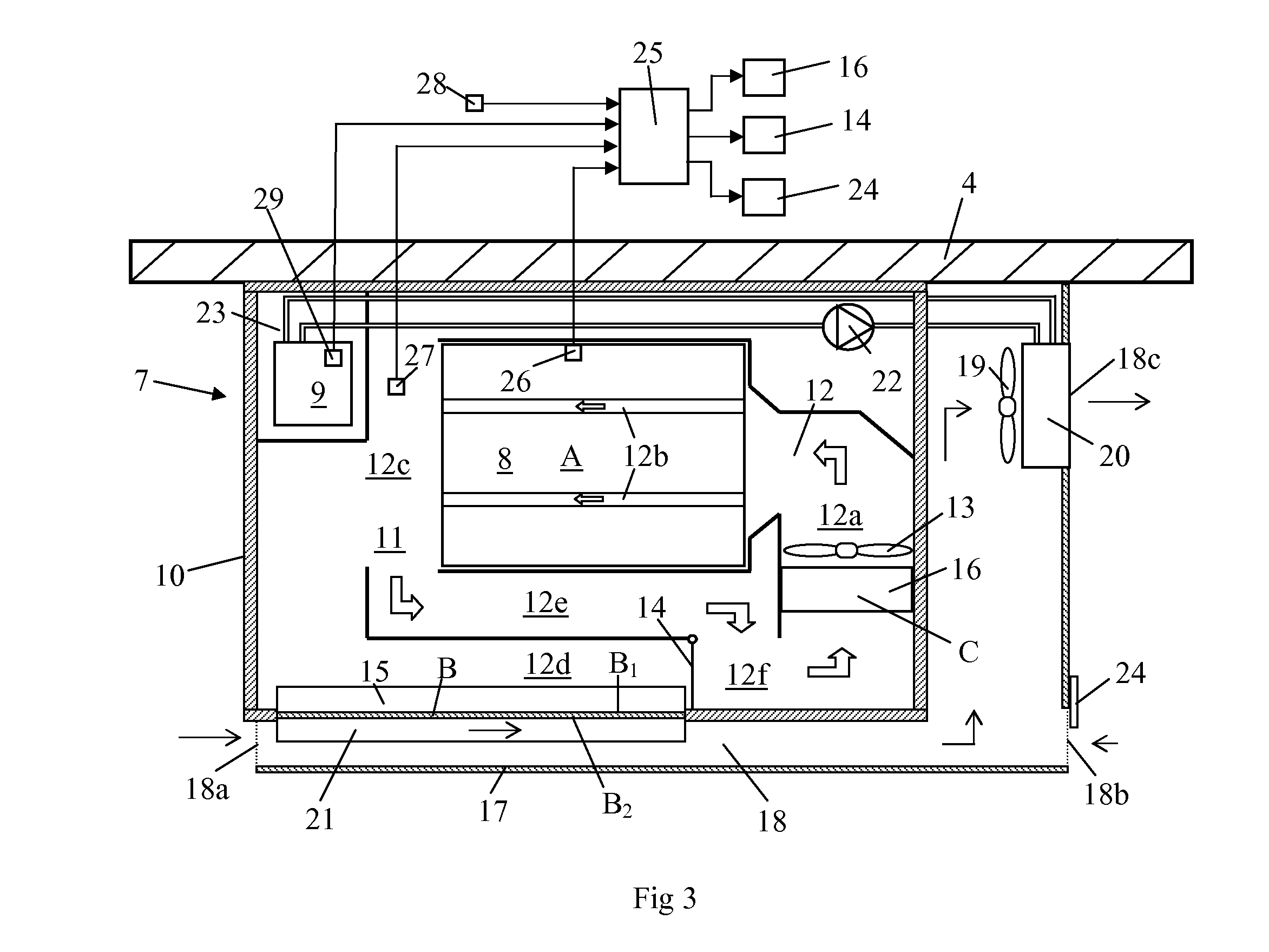

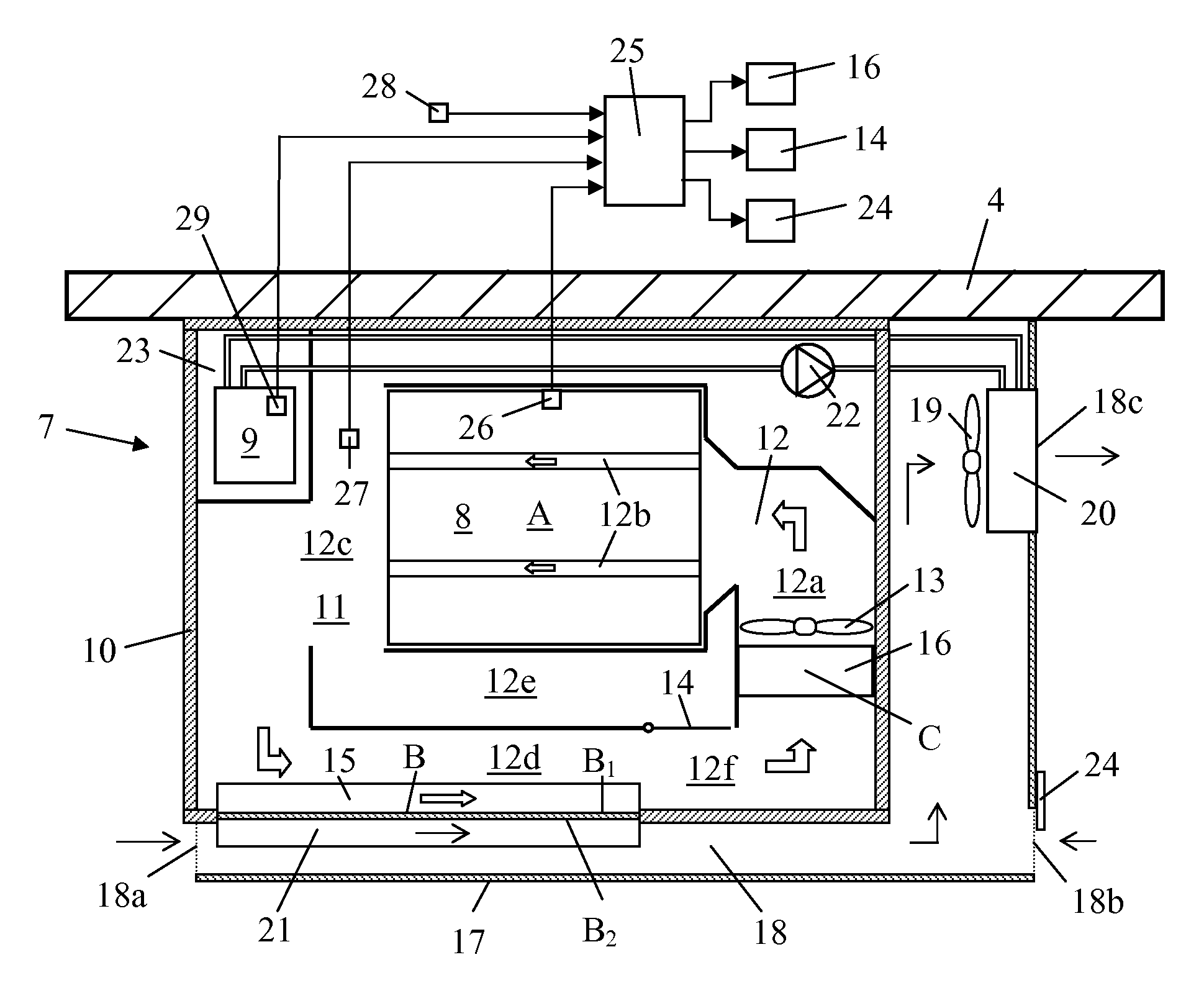

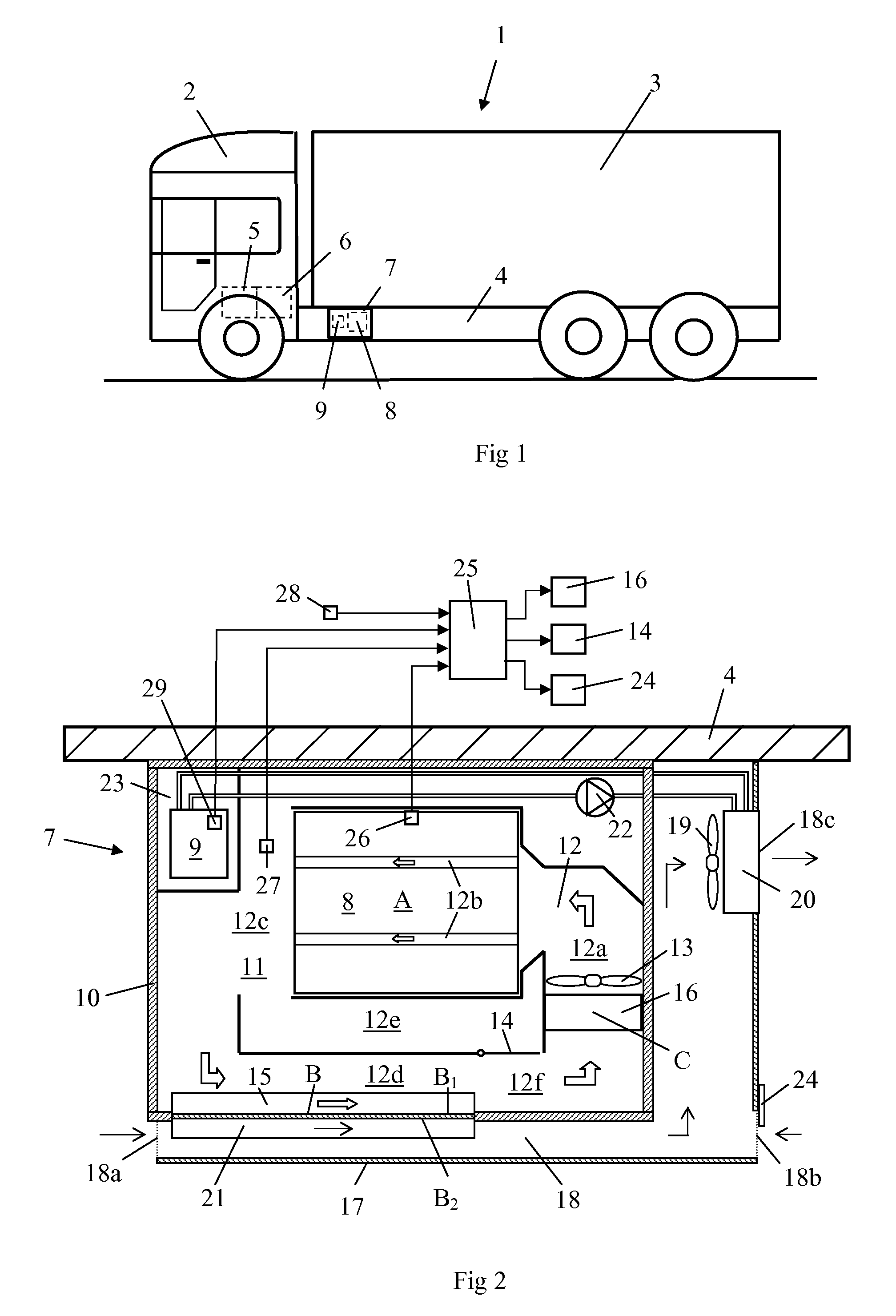

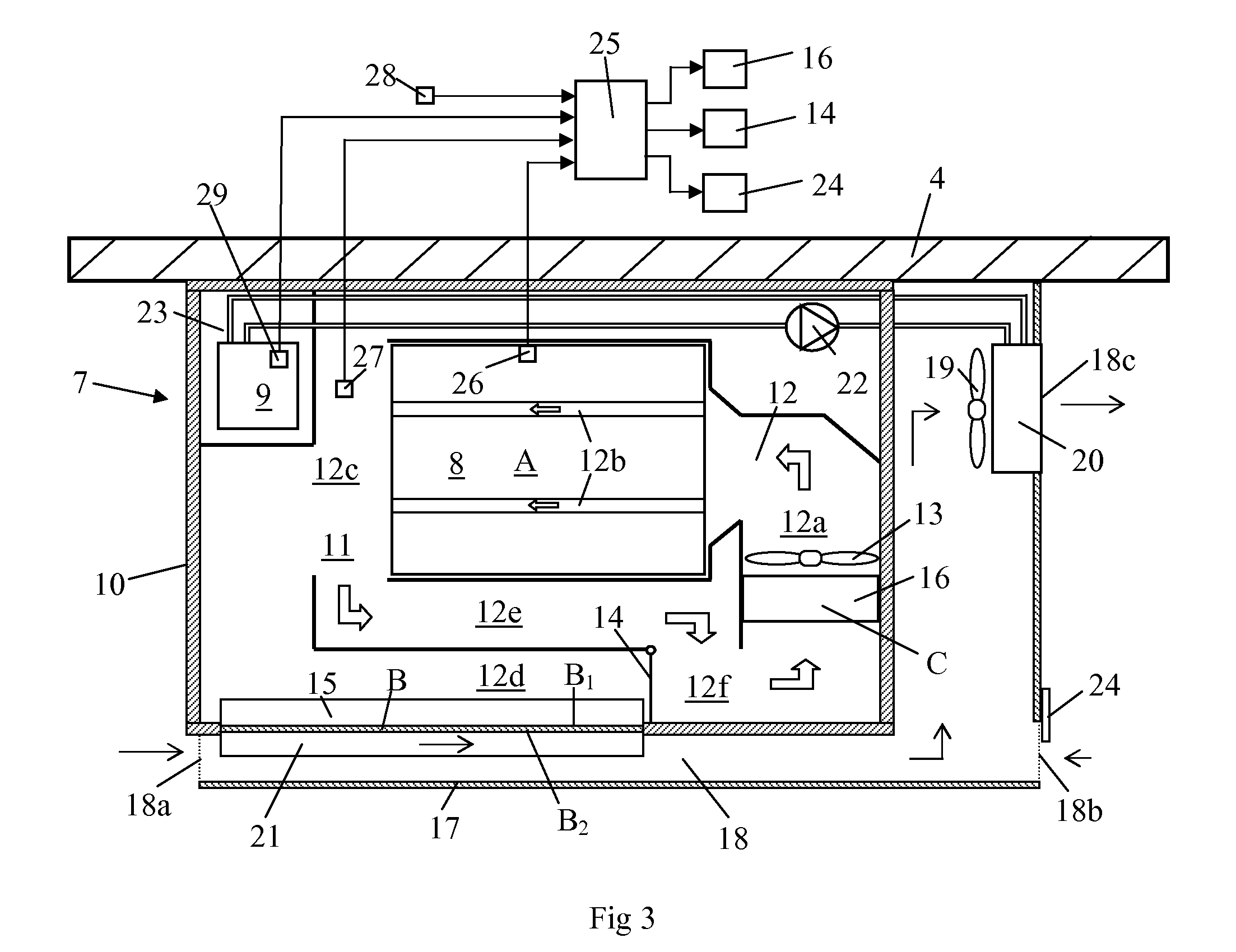

Cooling arrangement for at least one battery in a vehicle

InactiveUS20120267080A1Improve cooling effectMinimum energy consumptionElectric devicesCell temperature controlInterior spaceElectrical battery

A cooler arrangement for at least one battery (8) in a vehicle (1) includes a cooling circuit (12a-f) with a circulating cooling medium, a circulator (13) to circulate the cooling medium in the cooling circuit (12a-f), and a cooling region (A) where the cooling medium cools the battery (8). The cooler arrangement includes a container (10) with an enclosed internal space (11), in which the battery (8) and the cooling circuit (12a-f) with the circulating cooling medium are situated, and the container (10) includes a heat release region (B) where cooling medium is intended to release heat to surrounding air.

Owner:SCANIA CV AB

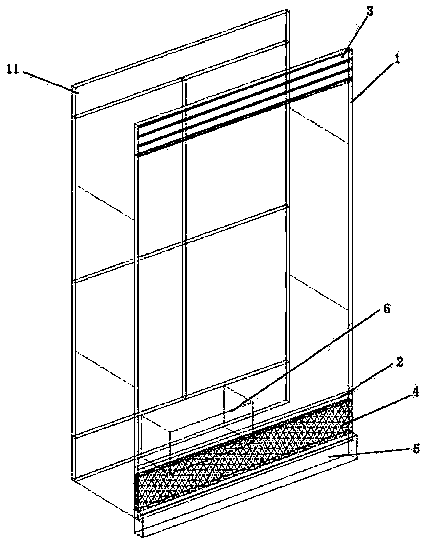

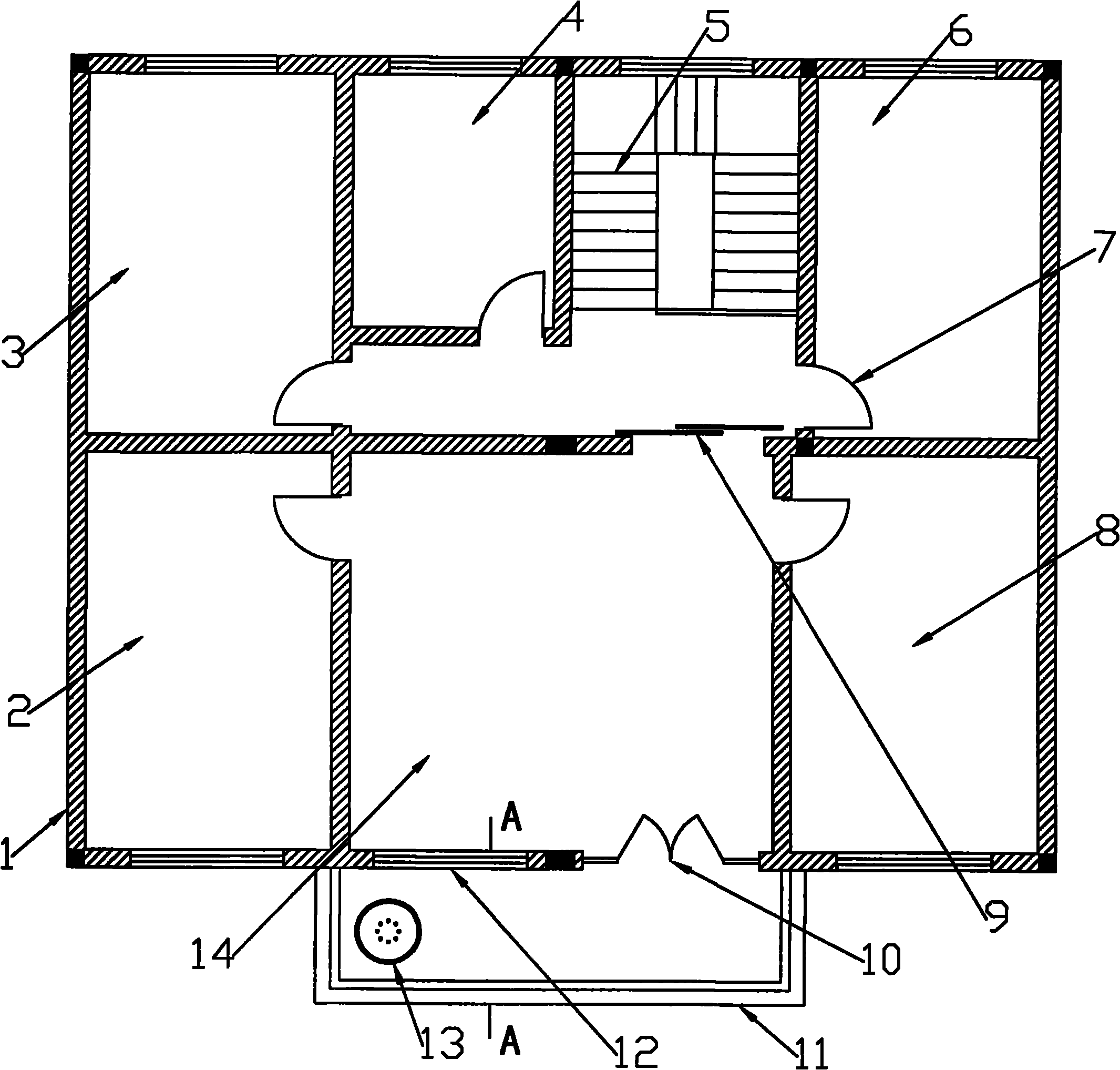

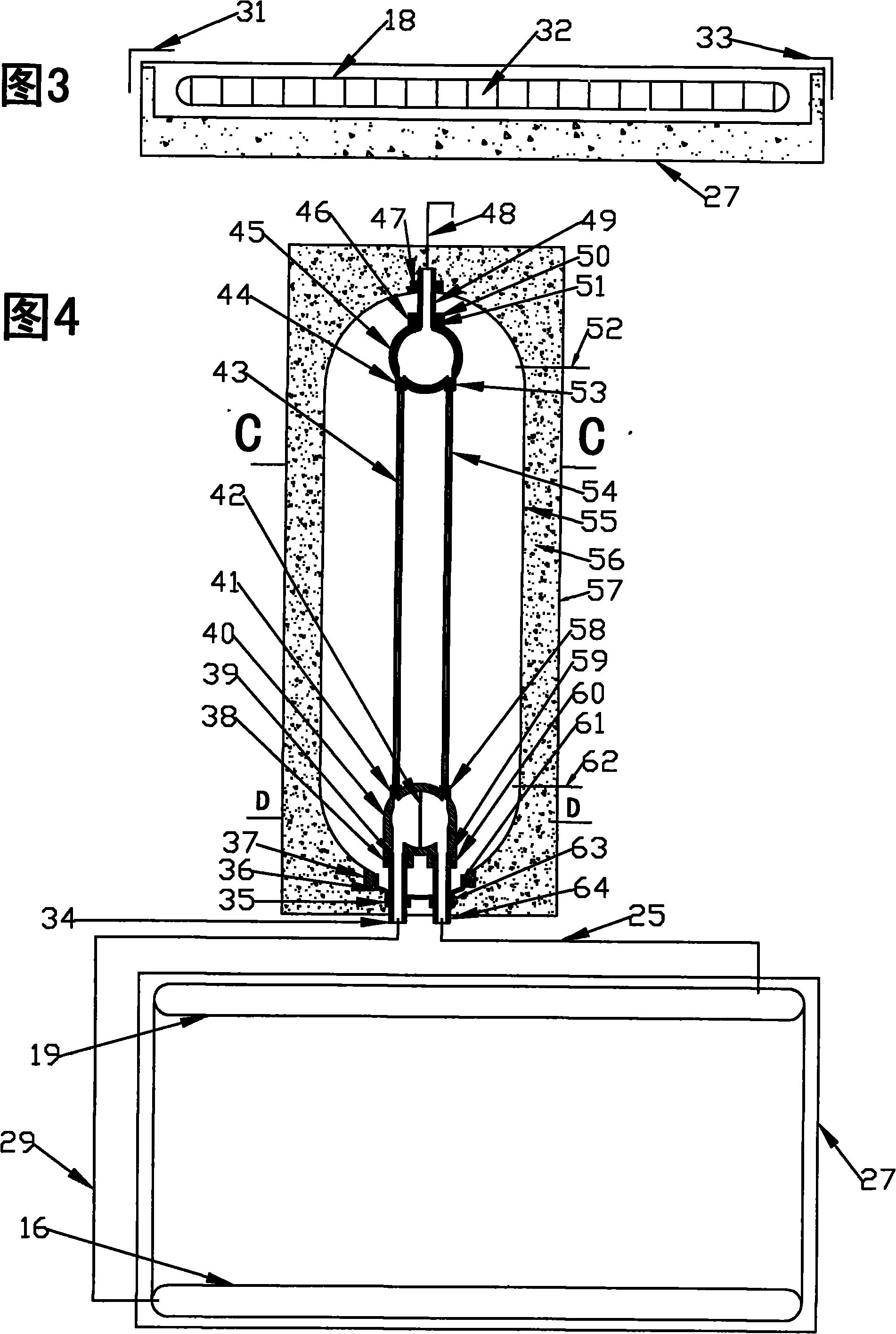

Vacuum glass breathing curtain wall unit with self-cleaning filter device

InactiveCN103883047AComfortable feelingFeel comfortableWallsLighting and heating apparatusMegasonic cleaningGeothermal heat pump

The invention discloses a vacuum glass breathing curtain wall unit with a self-cleaning filter device. The vacuum glass breathing curtain wall unit comprises a curtain wall body, an air inlet located in the lower portion of the curtain wall body and an air outlet located in the upper portion of the curtain wall body. The curtain wall body is composed of vacuum glass. The filter device and a temperature adjusting device are arranged at the position of the air inlet. The filter device is provided with a self-cleaning cleaner which is a high-pressure air flow cleaner or ultrasonic cleaner. The temperature adjusting device is a ground source heat pump system. The vacuum glass breathing curtain wall unit can effectively isolate heat conduction and reduce energy loss, and has a self-cleaning function of the filter device. The ground source heat pump system is adopted as the temperature adjusting device and ground heat is used as energy, so that the vacuum glass breathing curtain wall unit is efficient and energy saving and remarkable in benefit of environmental protection, and is of great significance to energy conservation and emission reduction, resource conservation and prevention of global climate warming by further popularization.

Owner:江苏瑞节安科技有限公司

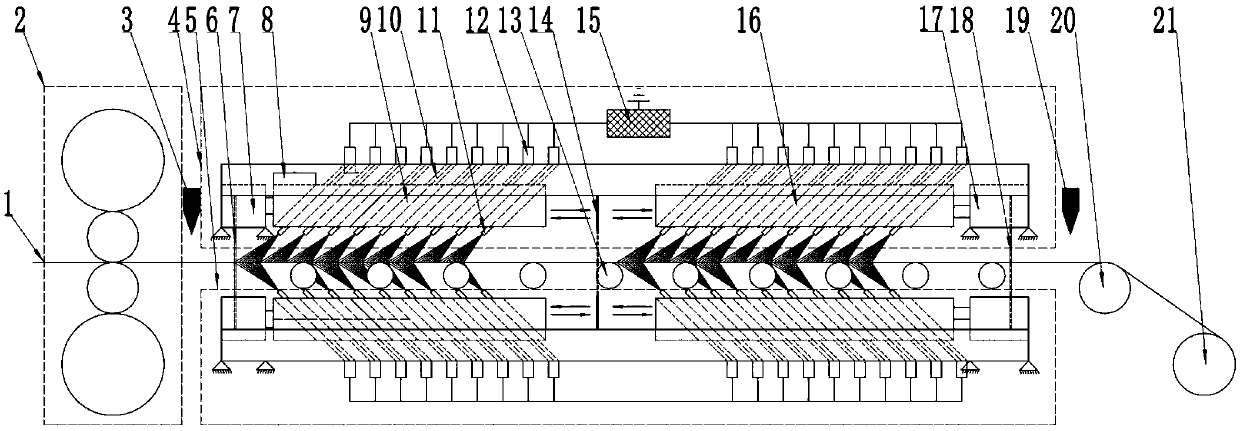

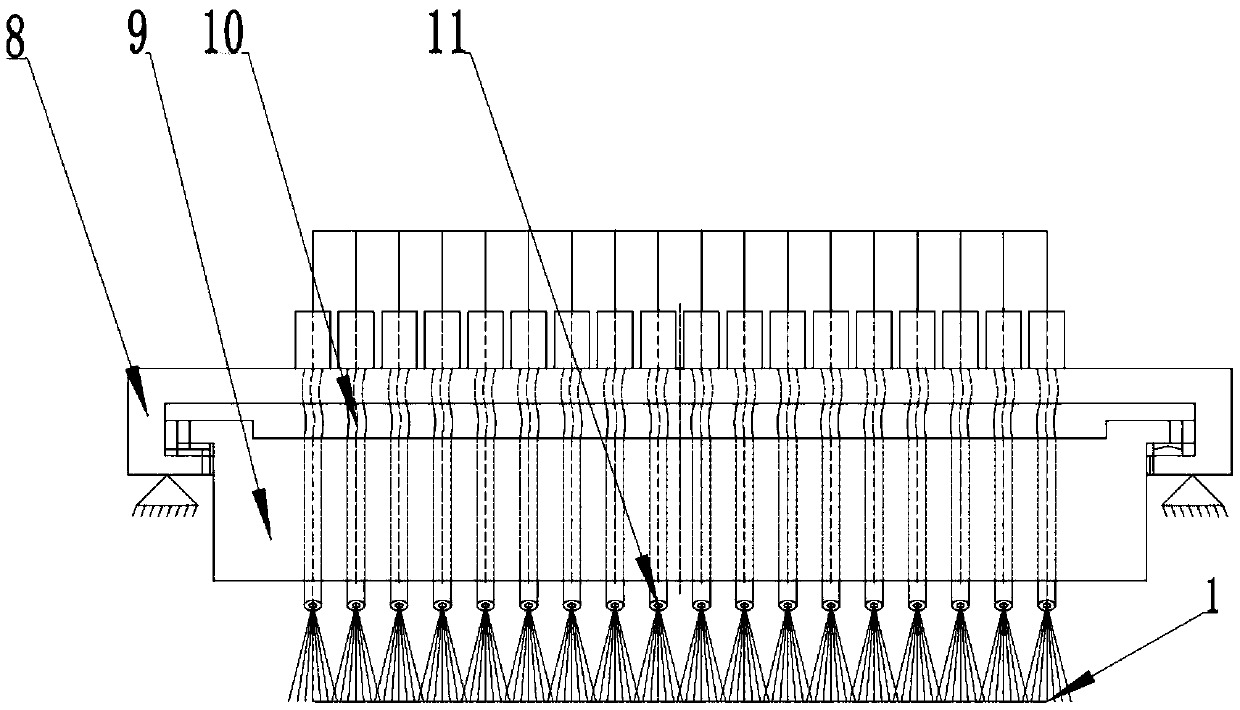

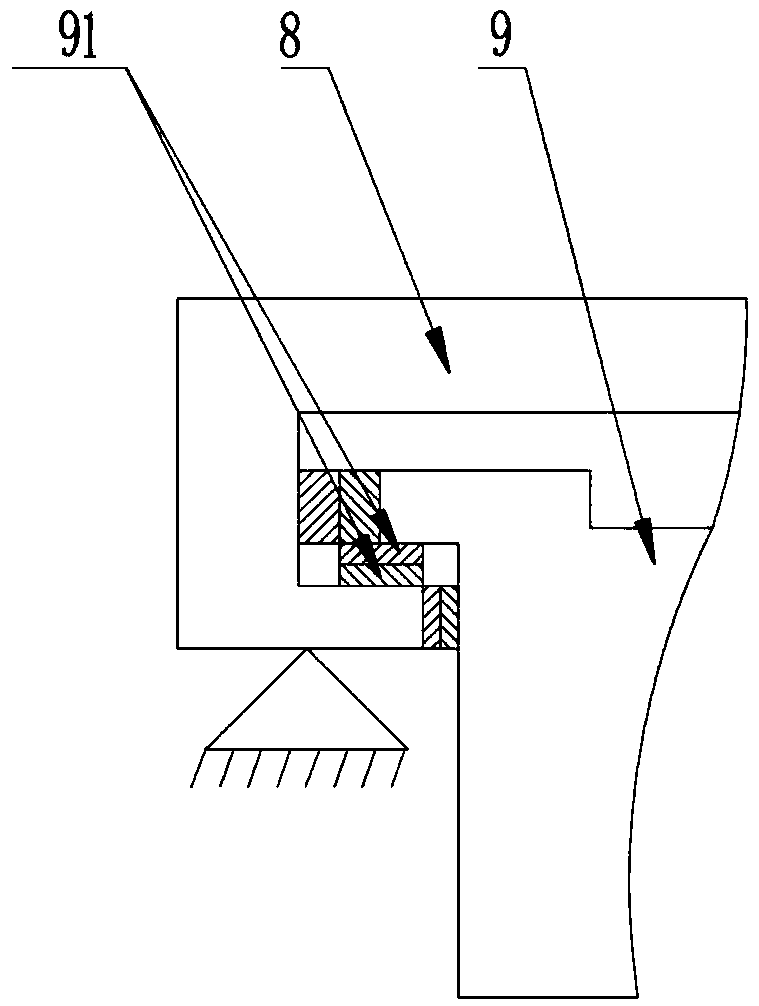

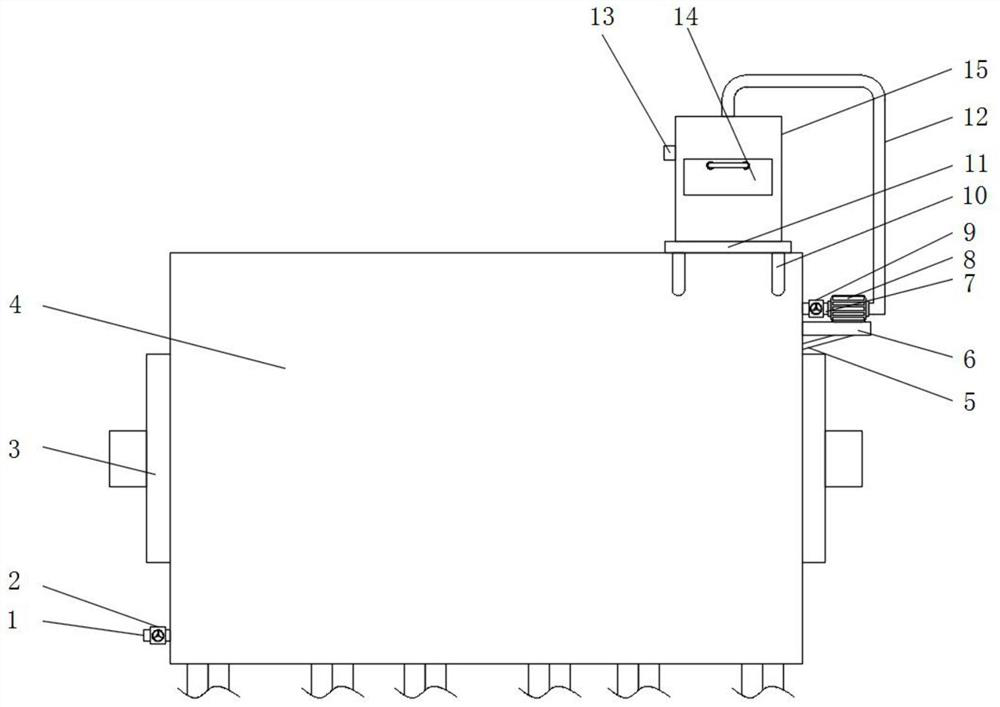

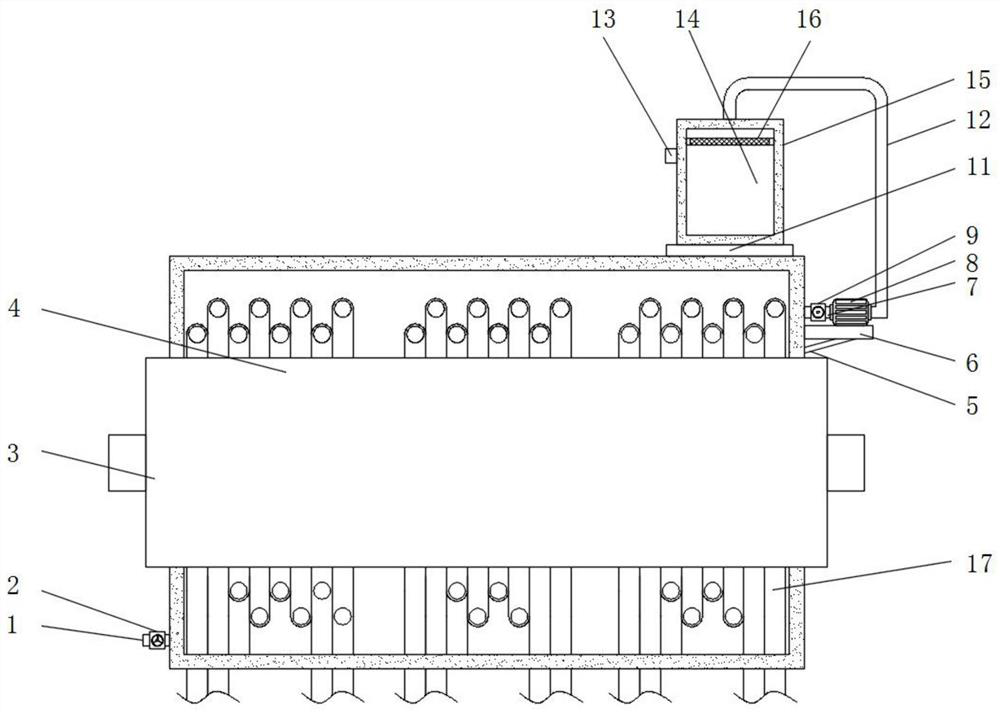

Hot rolled sheet strip liquid nitrogen ultrafast cooling device

ActiveCN109647914APrevent oxidationAvoid warmingTemperature control deviceMeasuring devicesWinding machineLiquid nitrogen container

The invention relates to a hot rolled sheet strip liquid nitrogen ultrafast cooling device. The hot rolled sheet strip liquid nitrogen ultrafast cooling device comprises thermo detectors, a controllerand a plurality of cooling sections connected between a finishing mill and a winding machine in series; the thermo detectors are located before an outlet of the finishing mill and the winding machine; each cooling section comprises an upper controlled cooling device and a lower controlled cooling device which are arranged on the two sides of a sheet strip, and the upper controlled cooling deviceand the lower controlled cooling device each comprise a controlled cooling transverse beam guide rail, a guide rail type supporting frame, slice nozzle assemblies, pressure nozzles, a displacement cylinder, a liquid nitrogen container, an infrared temperature measurement device and solenoid valves; the guide rail type supporting frames are slidably connected with the controlled cooling transversebeam guide rails and pushed by the displacement cylinders to move in the rolling direction; the multiple slice nozzle assemblies are fixed to the guide rail type supporting frames in the rolling direction, a plurality of pressure nozzles are fixed to the slice nozzle assemblies, inclined angles are formed between the nozzles and the rolling direction of the sheet strip, and the nozzles are connected with the liquid nitrogen containers through powder heat insulated pipes; the solenoid valves are arranged on the pressure nozzles and connected with the controller; and the two ends of the coolingsections are provided with the infrared temperature measurement devices.

Owner:北京秦冶众智科技有限公司

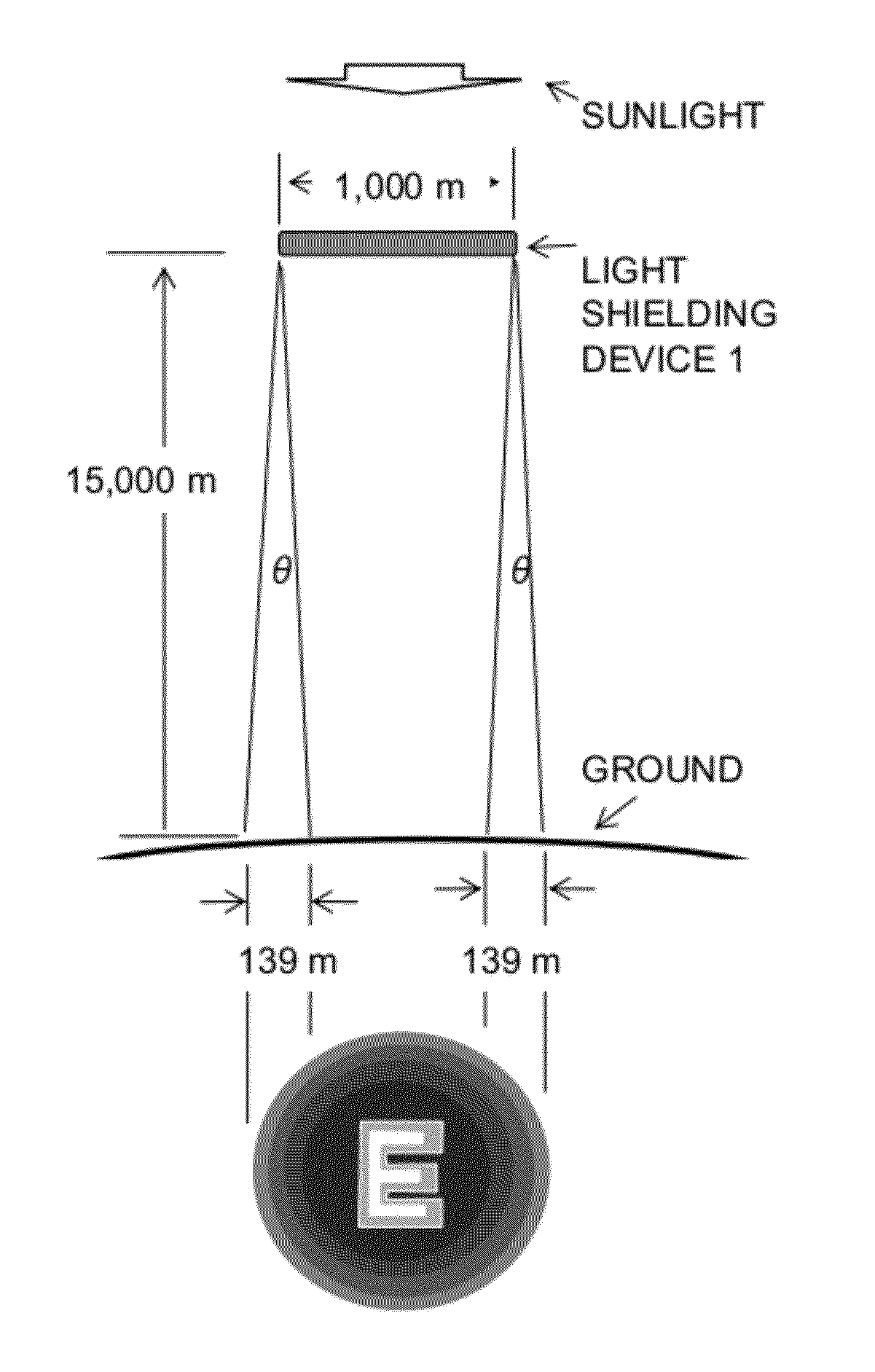

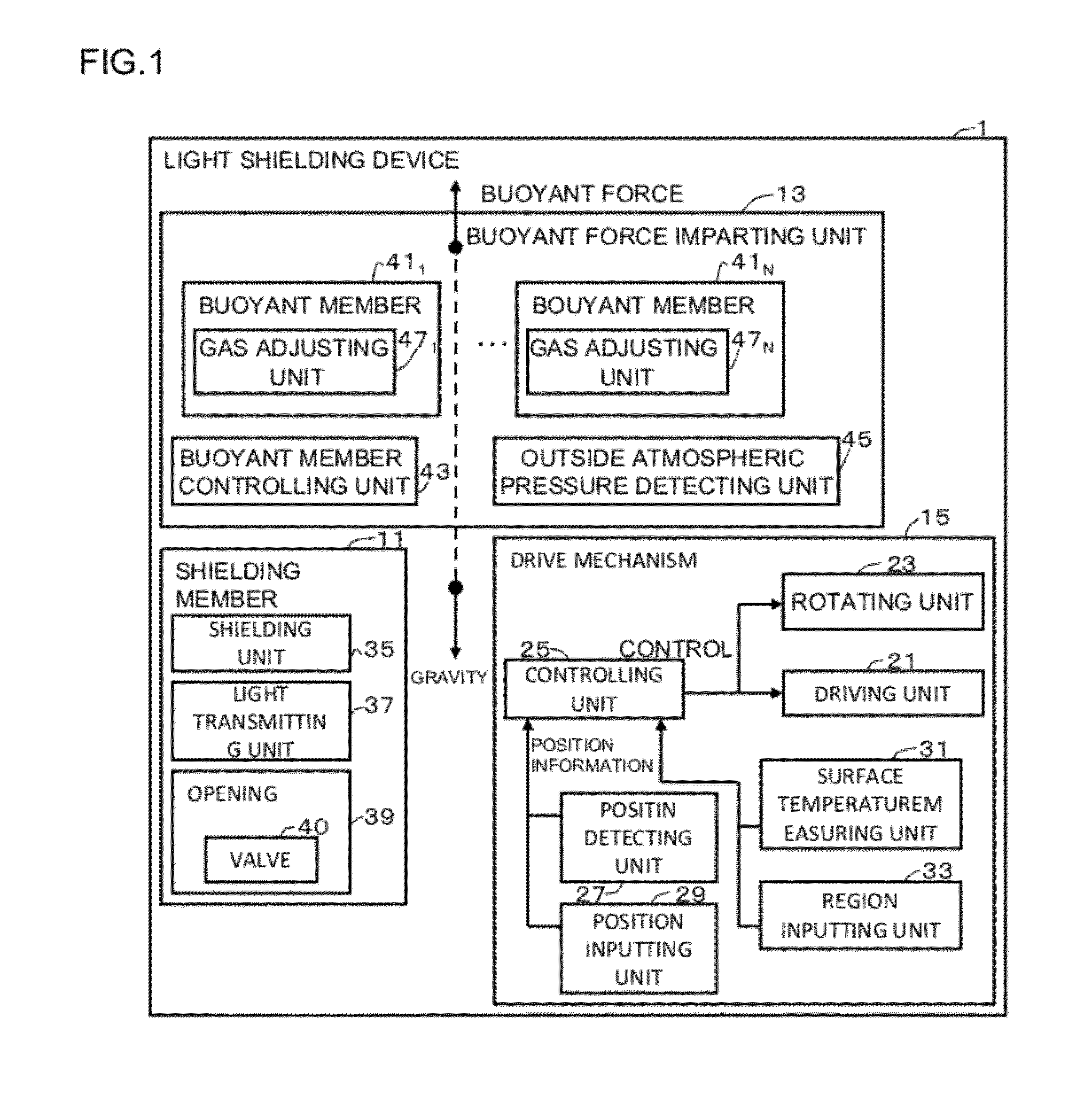

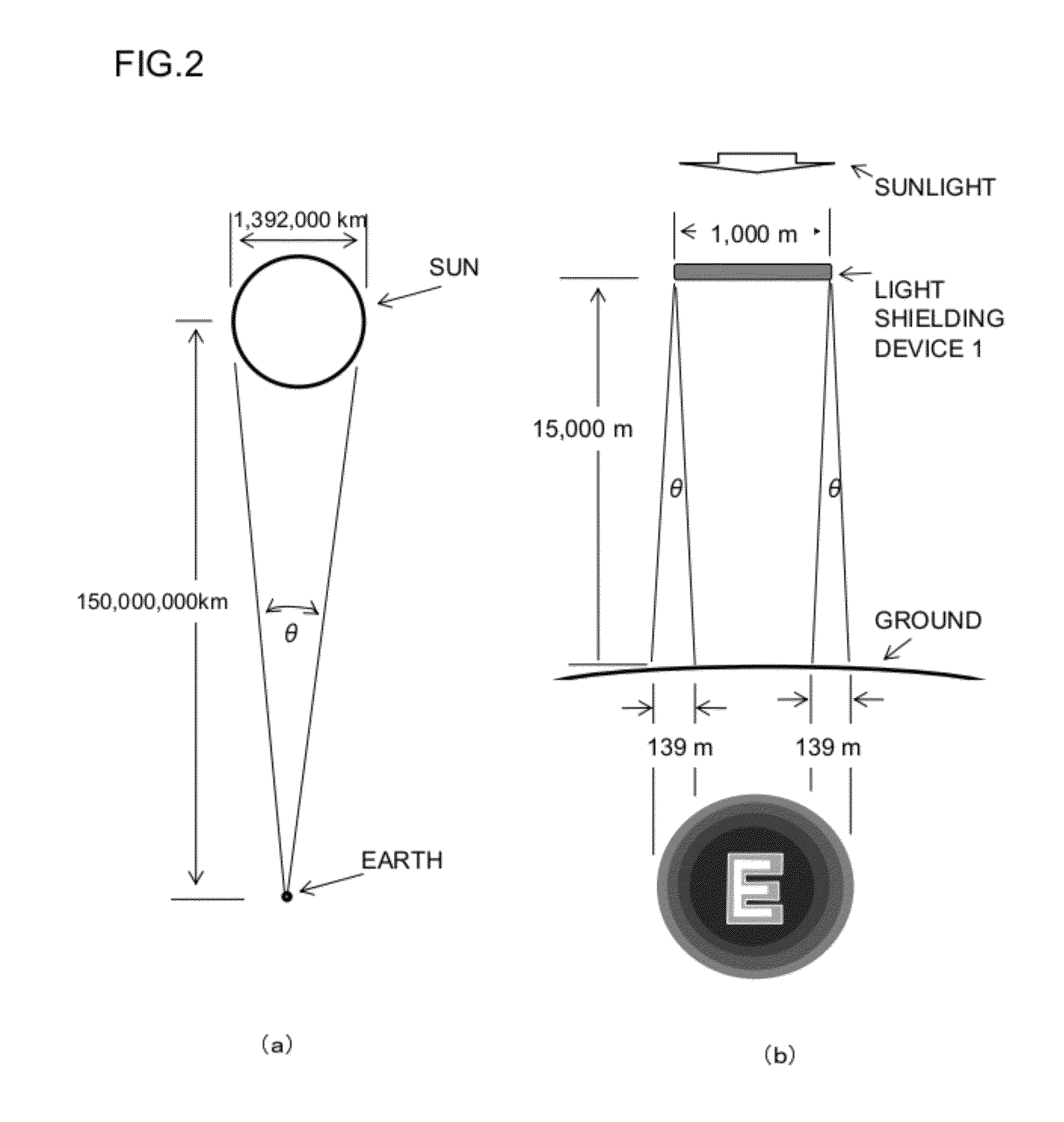

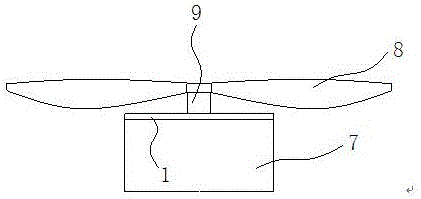

Light shielding device and light shielding method

InactiveUS20120069464A1Preventing global warmingReduce the temperatureWalking sticksMirrorsEngineeringGravitation

Owner:MURAKAMI HIDEYO

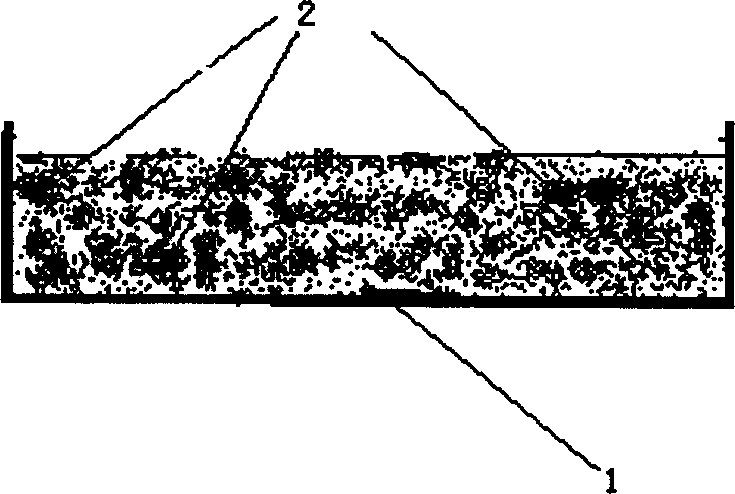

Weathering-resistant and permeable adhesive for paving a road and its constitutional body

InactiveCN1566248AImprove water resistanceExcellent soundproof performancePolyureas/polyurethane adhesivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses a weathering-resistant and permeable adhesive for paving a road and its constitutional body, wherein the bonding agent comprises weatherability fibrosis epoxy resin and weatherability modified ring form polyamine. The bonding agent possesses high strength, ductility, and yellow / white conversion resistance.

Owner:赵 立民

Biodegradable resin composition and molded article produced from the same

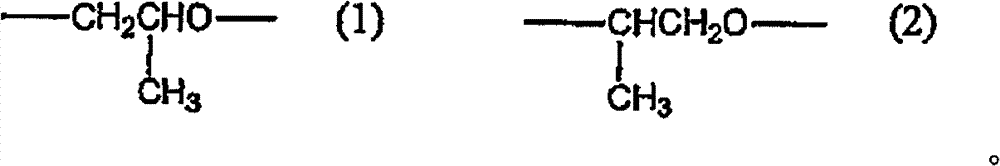

Disclosed is a resin composition excellent in molding processability which comprises a plant-derived biodegradable plastic produced by actively fixing carbon dioxide present in the earth. A resin composition excellent in molding processability, comprising (A) a biodegradable (3-hydroxyalkanoate) copolymer having a repeated unit represented by the formula (1): [-CHR-CH2-CO-O-] (wherein R represents an alkyl group represented by the formula CnH2n+1 and n is an integer of 1 to 15) and (B) 0.1 to 100 parts by weight, based on 100 parts by weight of the biodegradable (3-hydroxyalkanoate) copolymer (A), of an acrylic modifier having a weight average molecular weight (Mw) of 500,000 to 10,000,000.

Owner:KANEKA CORP

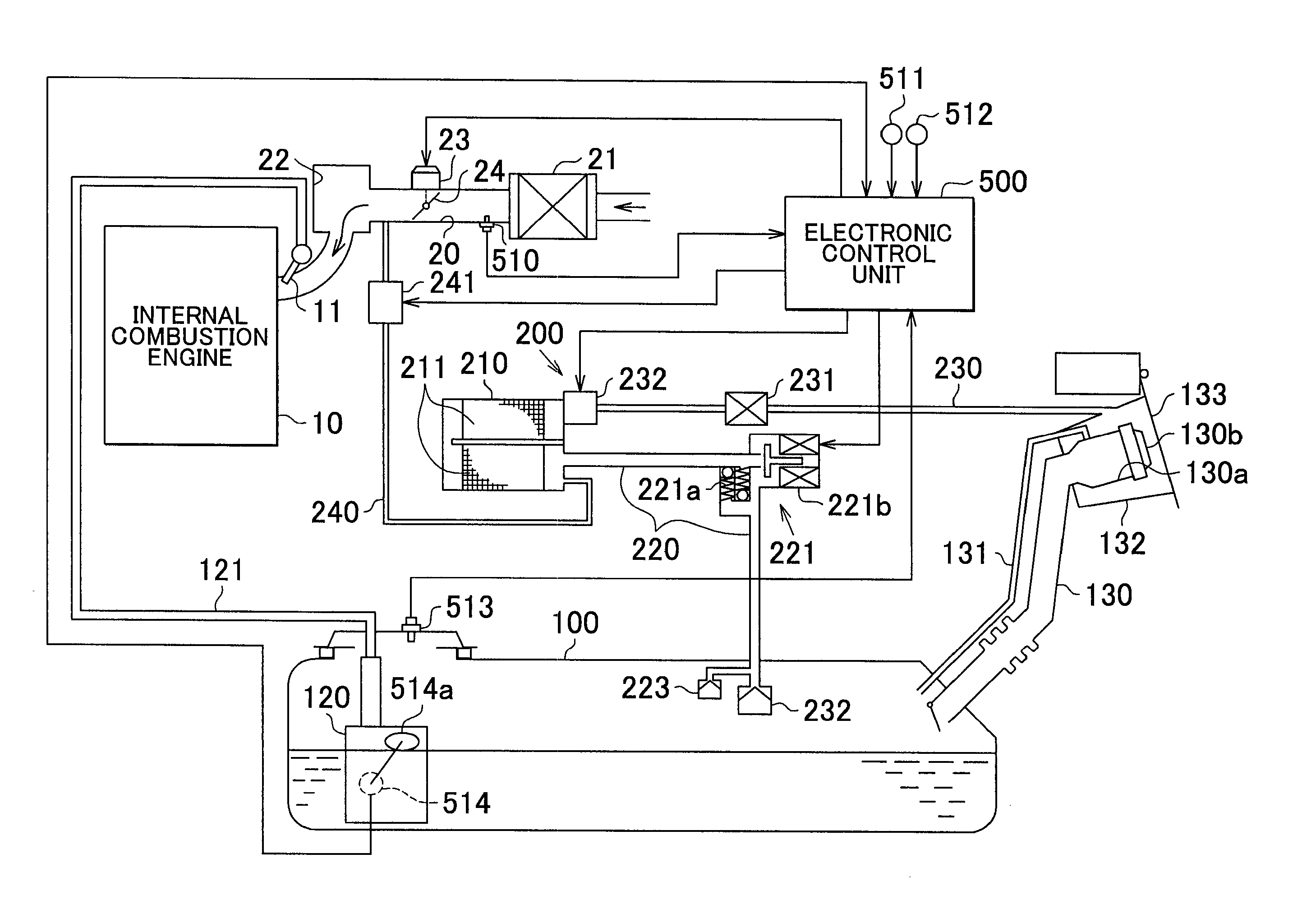

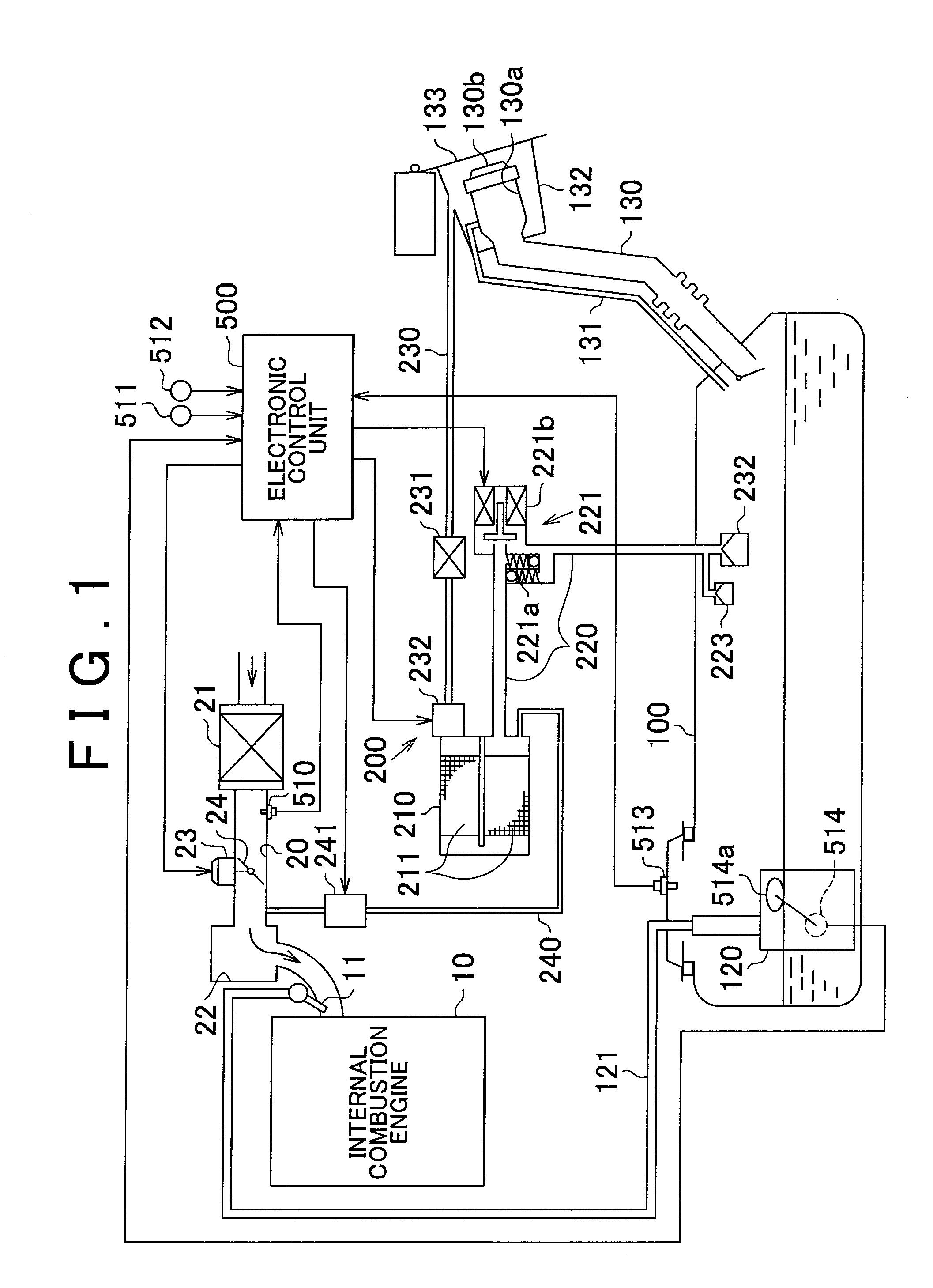

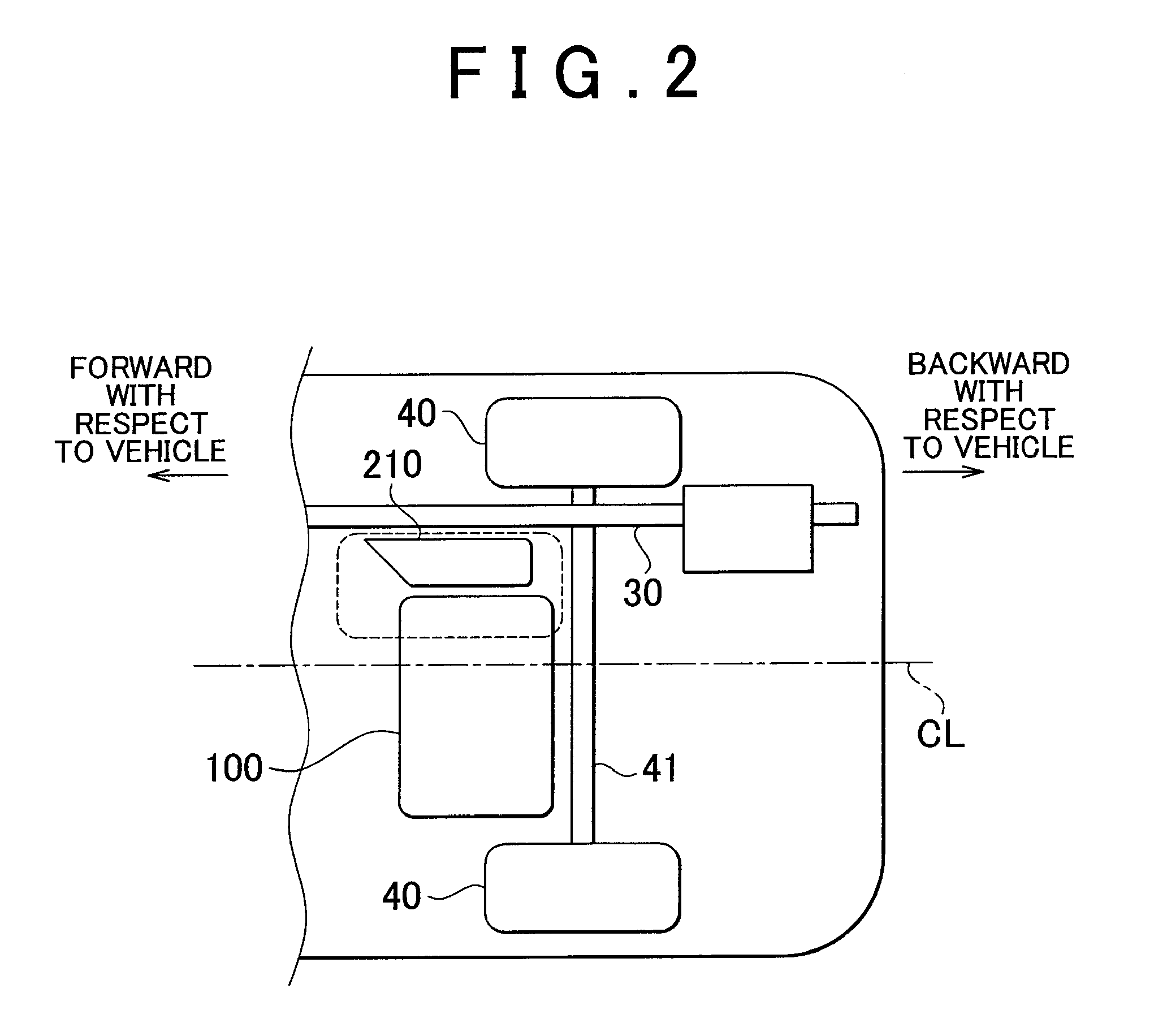

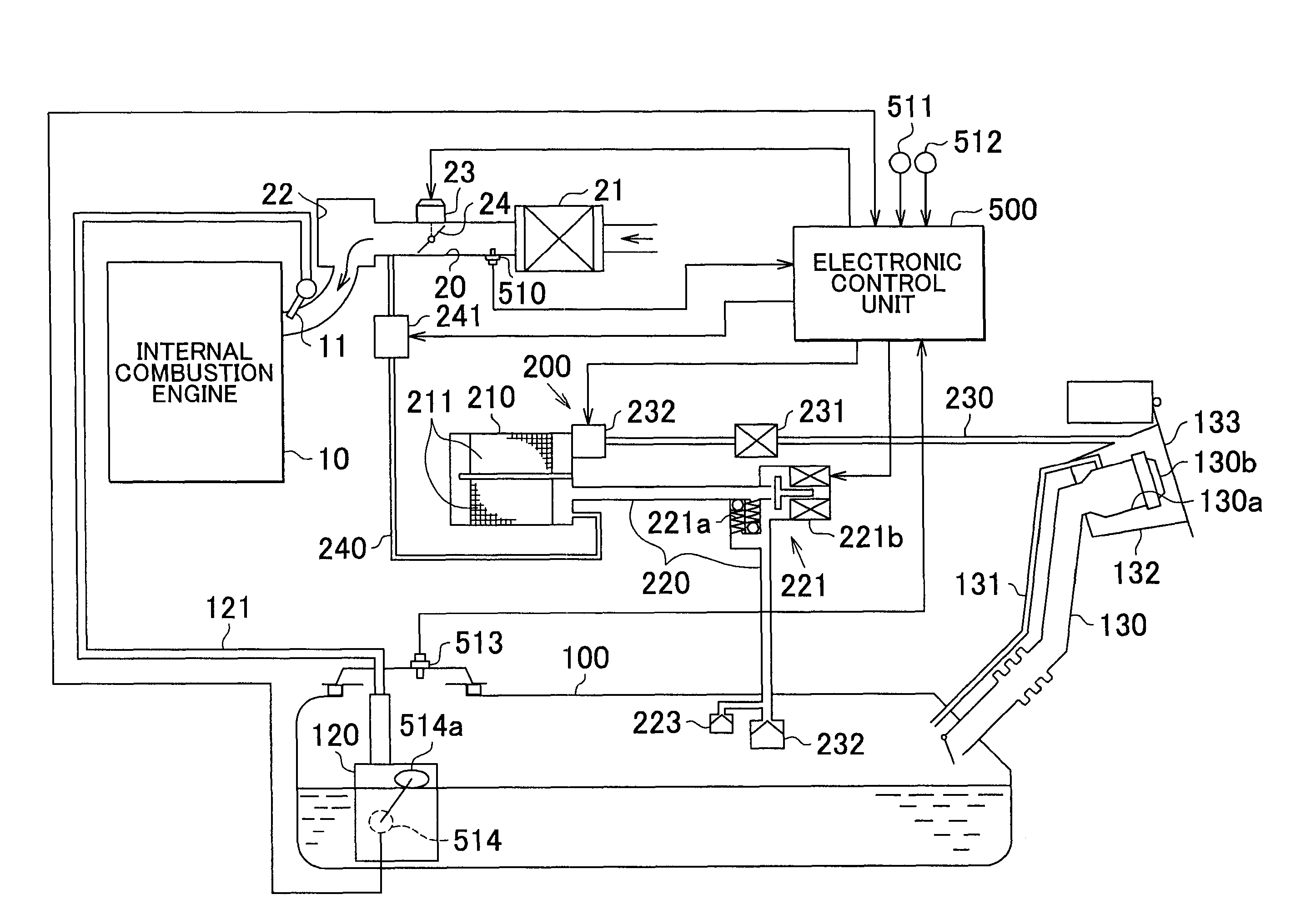

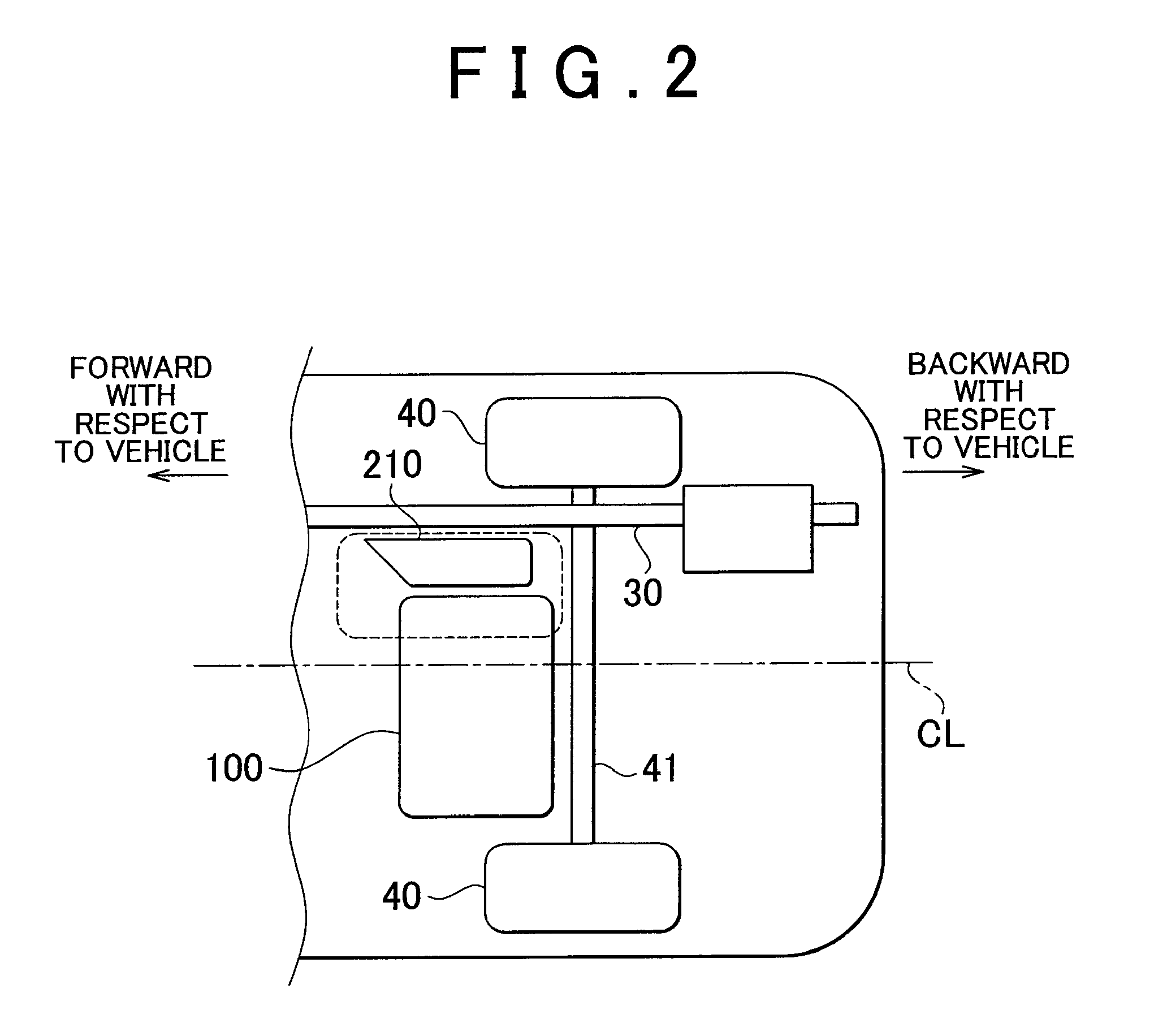

Canister arrangement structure, fuel vapor recovery device, and vehicle equipped with fuel vapor recovery device

ActiveUS20110252972A1Avoid warmingFuel tank can be restrainedNon-fuel substance addition to fuelExhaust apparatusInternal combustion engineExhaust pipe

A canister arrangement structure in a fuel vapor recovery device includes a canister that has built therein an adsorbent for adsorbing fuel and temporarily collects fuel vapor generated in a fuel tank of an internal combustion engine, the canister is arranged between an exhaust pipe of the internal combustion engine and the fuel tank.

Owner:TOYOTA JIDOSHA KK

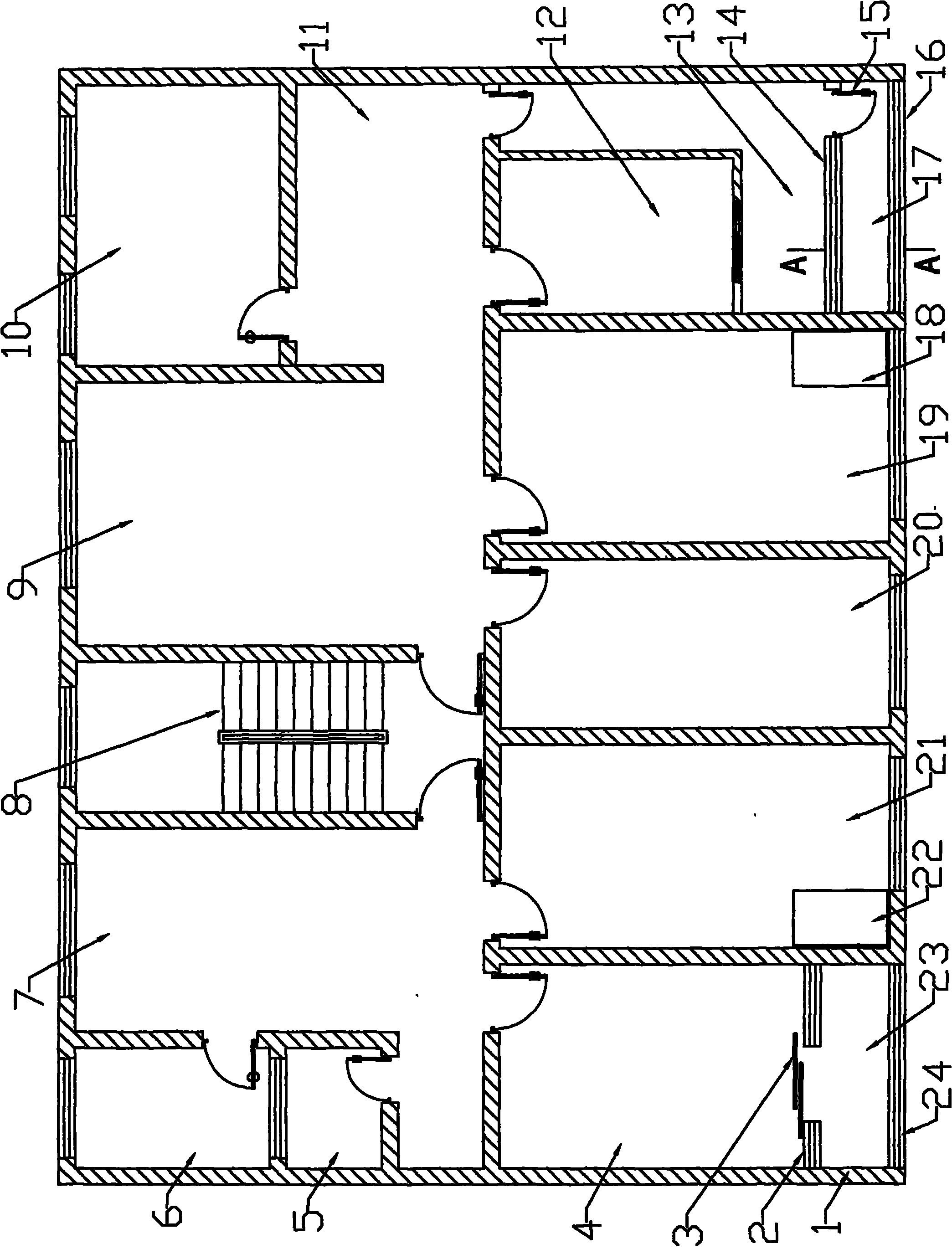

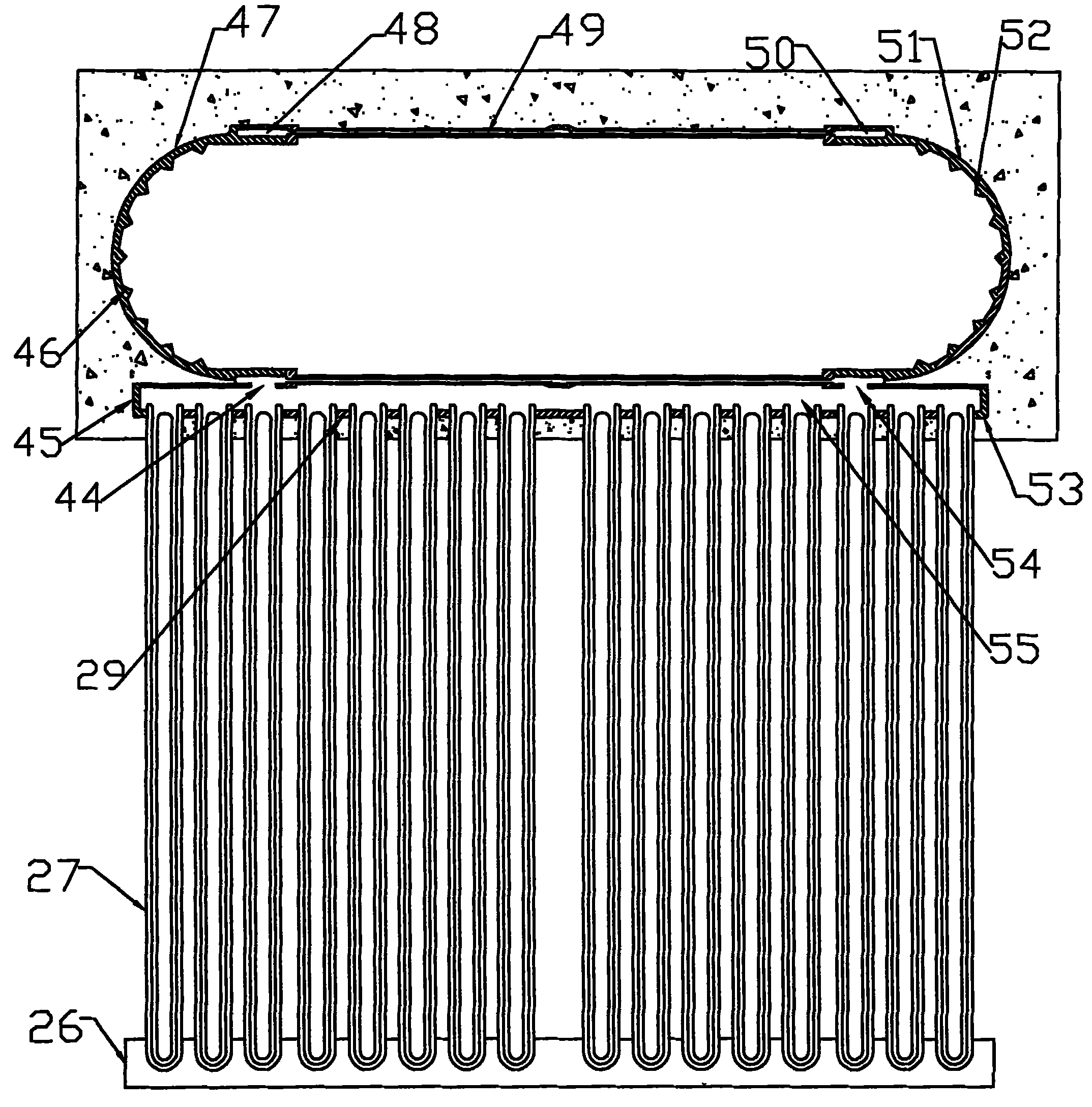

Flat-plate type solar balcony bathroom

InactiveCN101988335AImprove heating efficiencyImprove heat transfer efficiencySolar heating energySolar heat devicesSolar waterMature technology

A flat-plate type solar balcony bathroom consists of a passive solar house, a pressure-bearing dual-cycling solar water heater and a connecting pipe thereof. The passive solar house is enclosed by walls, a window, a door, a roof and a base of the balcony. A heat exchanger consists of a spherical shell, a pipe on the spherical shell, and a heat exchange tube. Both the heat exchanger and a solar collector have an all-plastic structure, and scale is never formed on the heat exchanger and a solar collector. Therefore, the heat exchanger and the solar collector can keep higher efficiency of heat collection and heat exchange. The flat-plate type solar balcony bathroom is in an internal thermal type heating mode, and the system has higher heating efficiency. The flat-plate type solar balcony bathroom is fully integrated with the building body into a whole, can supply a large quantity of hot water for living and provide a warm bathing space, is practical in living, is environmentally-friendly and has mature technology and wide market space.

Owner:侯国山

Bio-electronic system

InactiveUS20110184256A1Safe humiditySafe vibrationAnimal reproductionDiagnostic recording/measuringNotification ReceiverElectronic systems

The bio-informatics system of the present invention serves to identify by electronic means, in body fluids of domestic and / or wild mammals, the metabolic changes that occur in each of the physiological moments of economic, scientific, and technological importance, associated with the female reproduction and with the health of animals in general. The system encrypts the information, analyzes it, memorizes when each one of the metabolic variables reach a predetermined level, and informs a receiver of the event.

Owner:BARCELO ROJAS CARLOS ALBERTO

Cooling arrangement for at least one battery in a vehicle

InactiveUS9118092B2Improve cooling effectMinimum consumptionBatteries circuit arrangementsElectric devicesEngineeringCooling medium

A cooler arrangement for at least one battery (8) in a vehicle (1) includes a cooling circuit (12a-f) with a circulating cooling medium, a circulator (13) to circulate the cooling medium in the cooling circuit (12a-f), and a cooling region (A) where the cooling medium cools the battery (8). The cooler arrangement includes a container (10) with an enclosed internal space (11), in which the battery (8) and the cooling circuit (12a-f) with the circulating cooling medium are situated, and the container (10) includes a heat release region (B) where cooling medium is intended to release heat to surrounding air.

Owner:SCANIA CV AB

Poly(3-hydroxyalkanoate) composition and molded object thereof

The present invention has for its object to obtain a composition and a molded product thereof excellent in processability, strength, impact resistance, heat resistance and water resistance and, when discarded, are biodegradable under the action of microorganisms and the like in an aerobic or anaerobic environment and, further, a plant origin composition and a molded product thereof, which can positively fix carbon dioxide on the earth. Such characteristics can hardly be attained with the above-mentioned chemically synthesized aliphatic polyesters or natural polymers such as starch. The present invention relates to a composition which comprises kenaf fibers and a poly(3-hydroxyalkanoate) produced by microorganisms and comprising a repeating unit represented by the formula (1): [-O-CHR-CH 2 -CO-] in the formula, R represents an alkyl group represented by C n H 2n+1 with n representing an integer of 1 to 15, and a molded product thereof.

Owner:KANEKA CORP

Waste heat recovery device of industrial kiln

InactiveCN112781386AHigh utilization rate of waste heat recoveryFast coolingIncreasing energy efficiencyWaste heat treatmentClimatic warmingProcess engineering

The invention discloses a waste heat recovery device of an industrial kiln, and relates to the technical field of industrial kiln equipment. The device specifically comprises a kiln body. When the device is used, a heat insulation box, a heat preservation coating outside the heat insulation box and a heat absorption pipe are arranged, in a using process of the kiln body, heat dissipated by the kiln body through surface radiation can be effectively recycled, a waste heat recovery rate of the kiln body is increased, the cost is saved, the situation that the heat is directly scattered into the atmosphere to cause climate warming is prevented, environmental protection is facilitated, after firing is completed, a first control valve and a second control valve are opened, a fan is started, and the fan introduces external airflow into the heat insulation box via an air conveying pipe and then introduces the external airflow out of the heat insulation box via an air outlet pipe, so that the cooling speed of the kiln body can be increased, collection of fired objects in the kiln body and next-time material distribution of the kiln body are facilitated, and the production efficiency of the kiln body is improved.

Owner:HUBEI XISHUI KEMEI MACHINERY

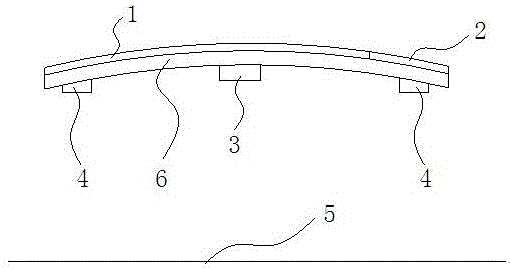

Air suspension type manual meteorological umbrella

ActiveCN105775097AAvoid meltingSlow down the melting rateLighter-than-air aircraftHybrid airshipsThermal energyStratosphere

An air suspension type manual meteorological umbrella comprises an inflation unit body. The inflation unit body comprises a bag skin and gas, wherein the bag skin is filled with the gas. At least one face of the inflation unit body is provided with a connector. The inflation unit body is connected through the connector, so that the meteorological umbrella is obtained. The inflation unit body is provided with a power source and a power drive part matched with the power source and used for adjusting the position of the inflation unit body. By the adoption of the meteorological umbrella, global warming can be stopped, and a glacier melting preventing function is achieved; the meteorological umbrella suspended in the stratosphere can effectively shade a thermal light source, and perpendicular incidence of the sunlight to the surface of the earth is reduced, so that solar thermal energy is effectively absorbed, the temperature of the surface of the earth is reduced, a glacier covered with the meteorological umbrella is prevented from melting, and the glacier melting speed is reduced.

Owner:山东鼎瑞泰沣环保科技有限公司

Canister arrangement structure, fuel vapor recovery device, and vehicle equipped with fuel vapor recovery device

ActiveUS8961660B2Fuel tank can be restrainedAvoid warmingNon-fuel substance addition to fuelIsotope separationInternal combustion engineExhaust pipe

A canister arrangement structure in a fuel vapor recovery device includes a canister that has built therein an adsorbent for adsorbing fuel and temporarily collects fuel vapor generated in a fuel tank of an internal combustion engine, the canister is arranged between an exhaust pipe of the internal combustion engine and the fuel tank.

Owner:TOYOTA JIDOSHA KK

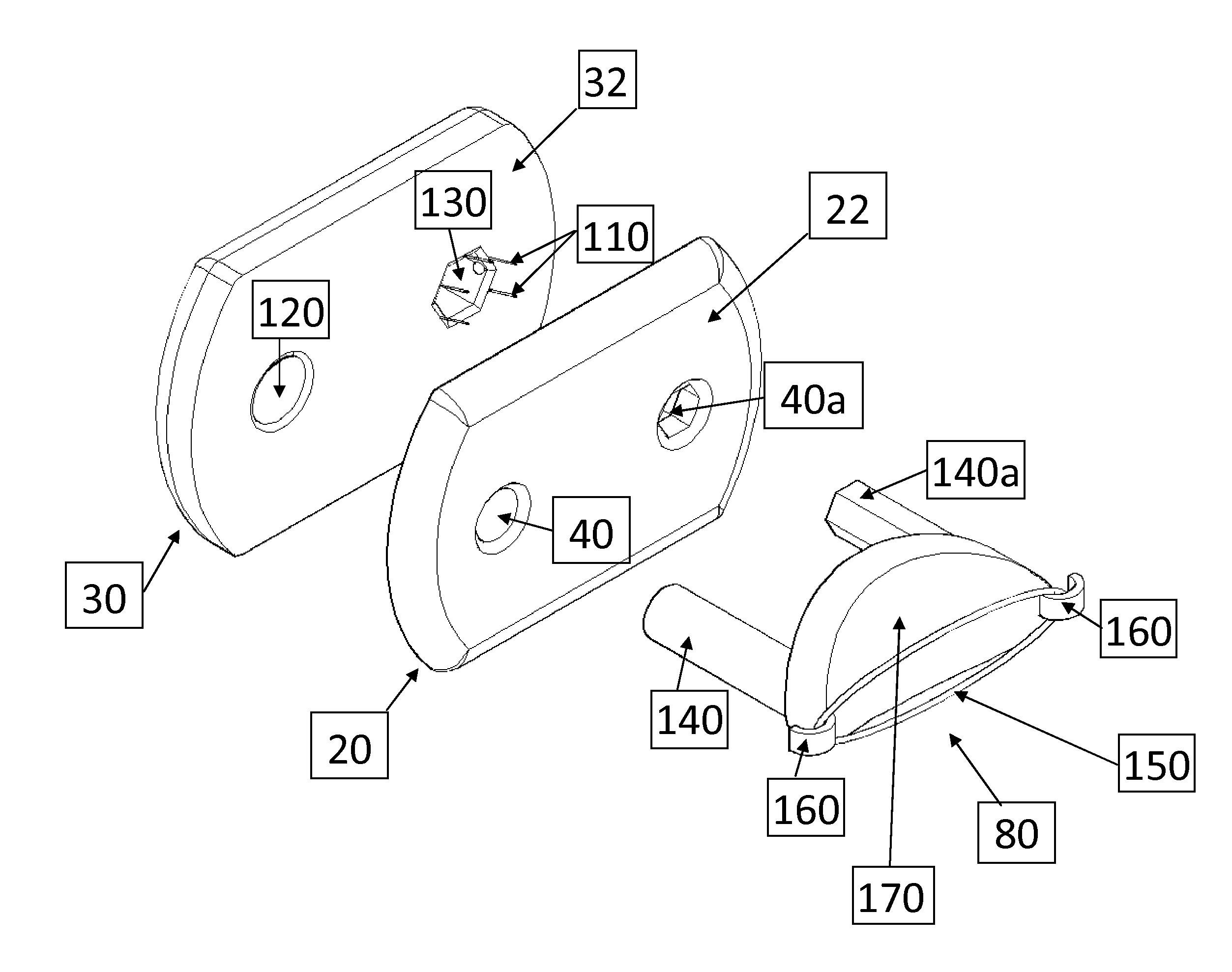

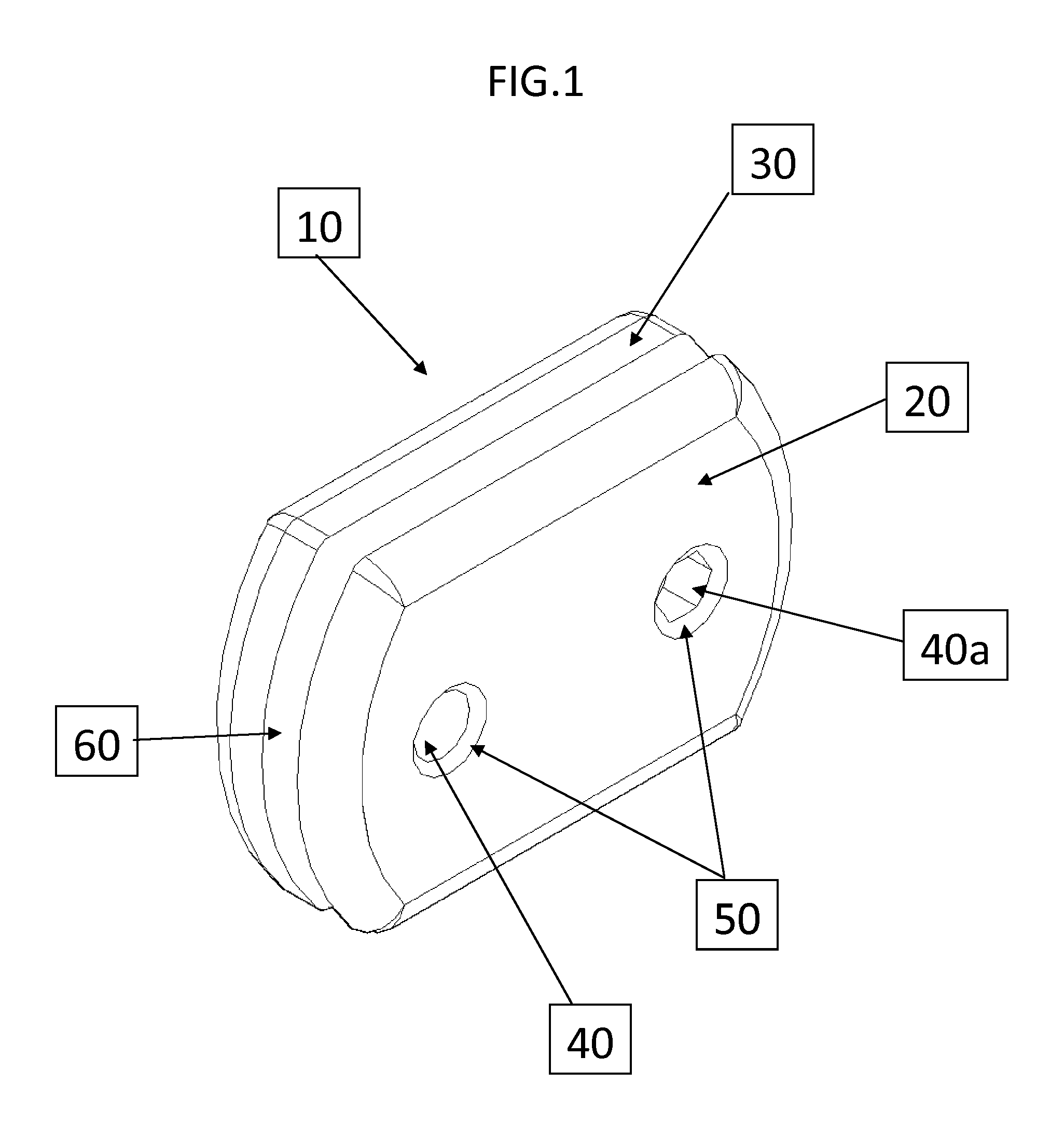

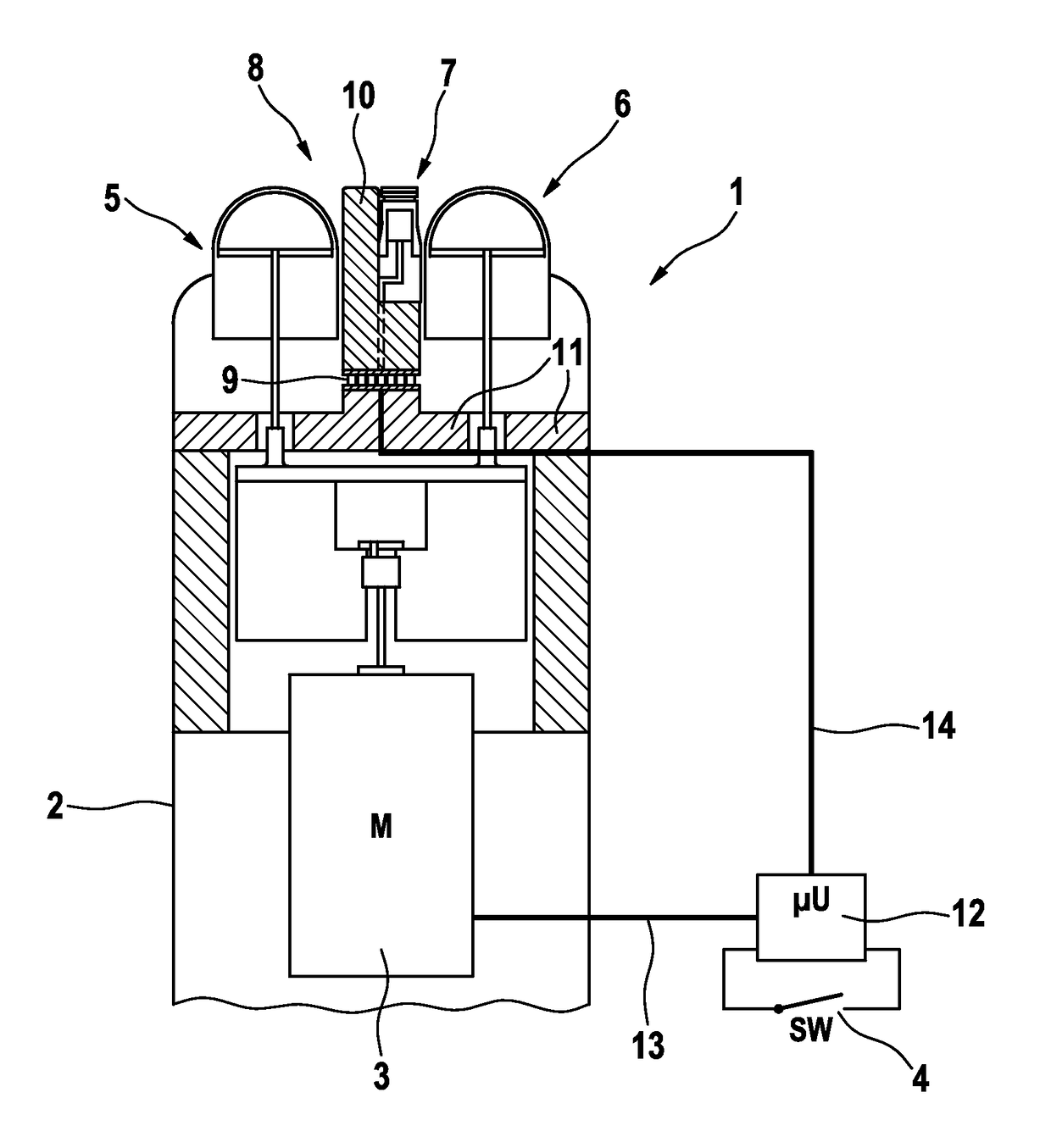

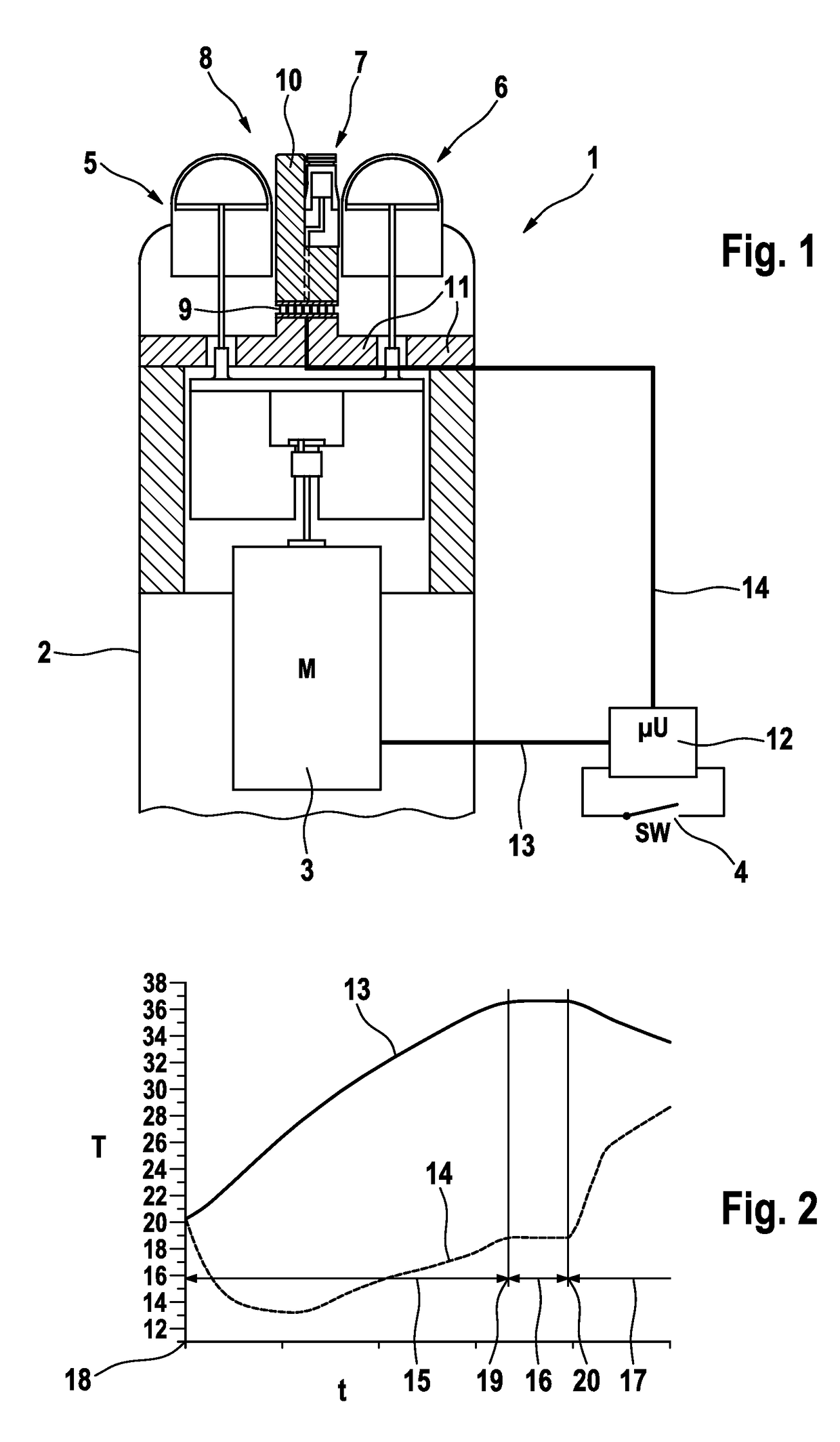

Male dry shaver

An electrically driven shaver comprises a housing and at least one hair cutting element that is driven by an electromotor. A thermoelectric skin cooling element and the electromotor are electrically operable by a microcontroller and an on / off switch which is electrically connected with the microcontroller. The microcontroller is adapted to activate and deactivate operation of both the electromotor and the skin cooling element. The skin cooling element is located adjacent to the hair cutting element. The microcontroller is adapted to immediately deactivate operation of the electromotor and relative to that to deactivate operation of the skin cooling element at later point of time, both in response to the “off” actuation of the same on / off switch.

Owner:BRAUN GMBH

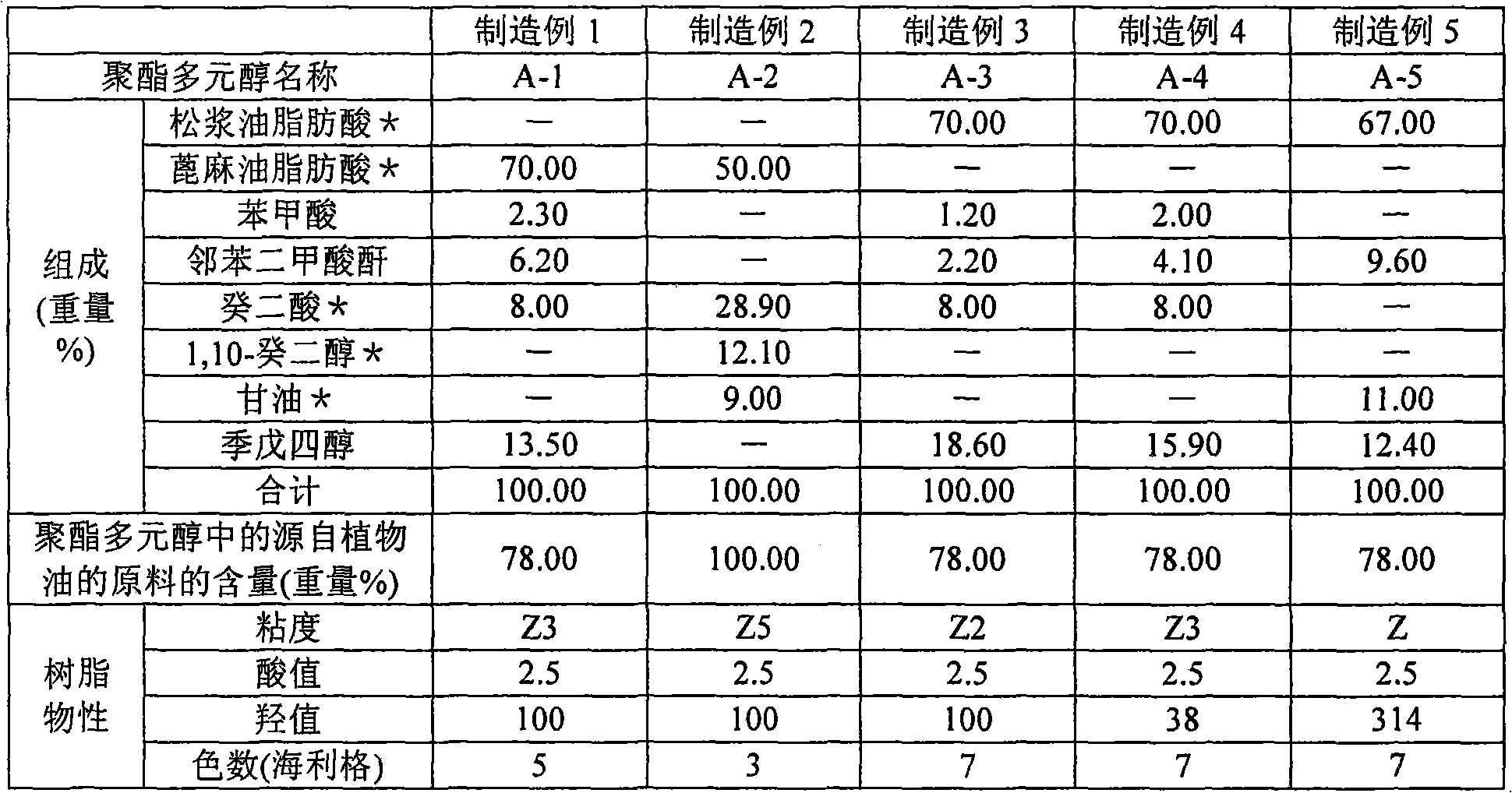

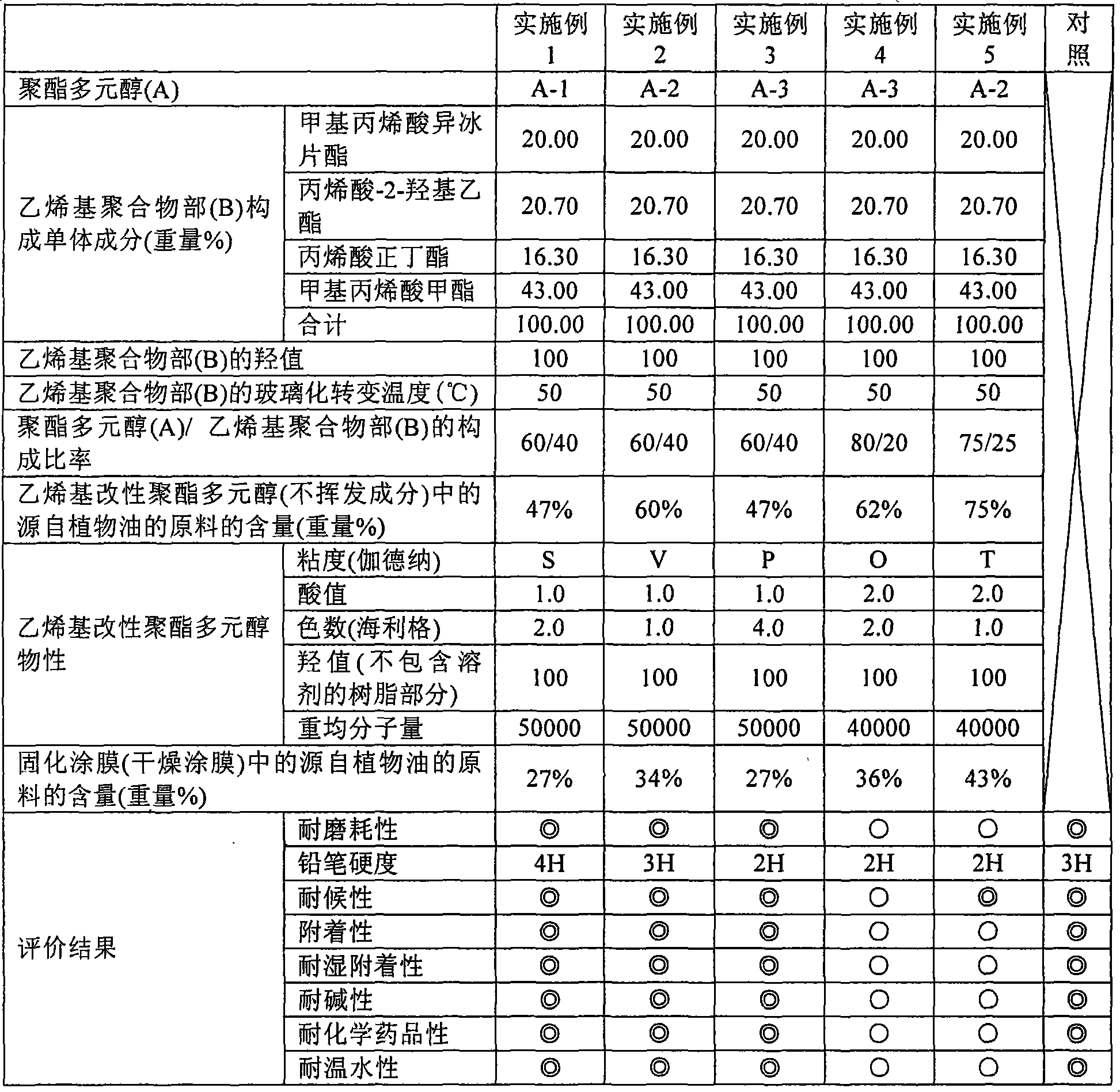

Vinyl modified polyester polyatomic alcohol, two-part curable paint composition and condensate

ActiveCN101993531AExcellent abrasion resistanceHigh hardnessPolyurea/polyurethane coatingsPolyesterAlcohol

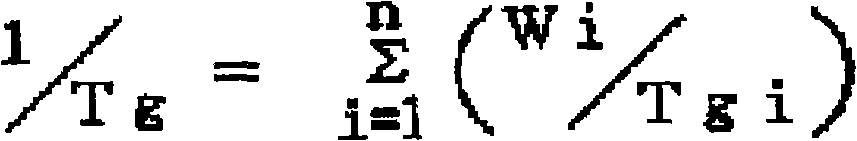

The present invention provides a vinyl modified polyester polyatomic alcohol, a two-part curable paint composition and condensate. The vinyl modified polyester polyatomic alcohol is that a polyester polyol (A) obtained from seed fat is combined with a vinyl polymer part (B), wherein a component ratio of the polyester polyol (A) and the vinyl polymer part (B) is from 20:80 to 80:20 by weight, a rate of raw material from the seed fat is 20-80 wt% relative to a non-volatilization component in the vinyl modified polyester polyatomic alcohol, a hydroxyl value of the polyester polyol (A) is from 40 to 300, a hydroxyl value of the vinyl polymer part (B) is from 10 to 300, and a glassivation transition temperature of the vinyl polymer part (B) is from 20 to 150 DEG C.

Owner:武蔵涂料株式会社 +1

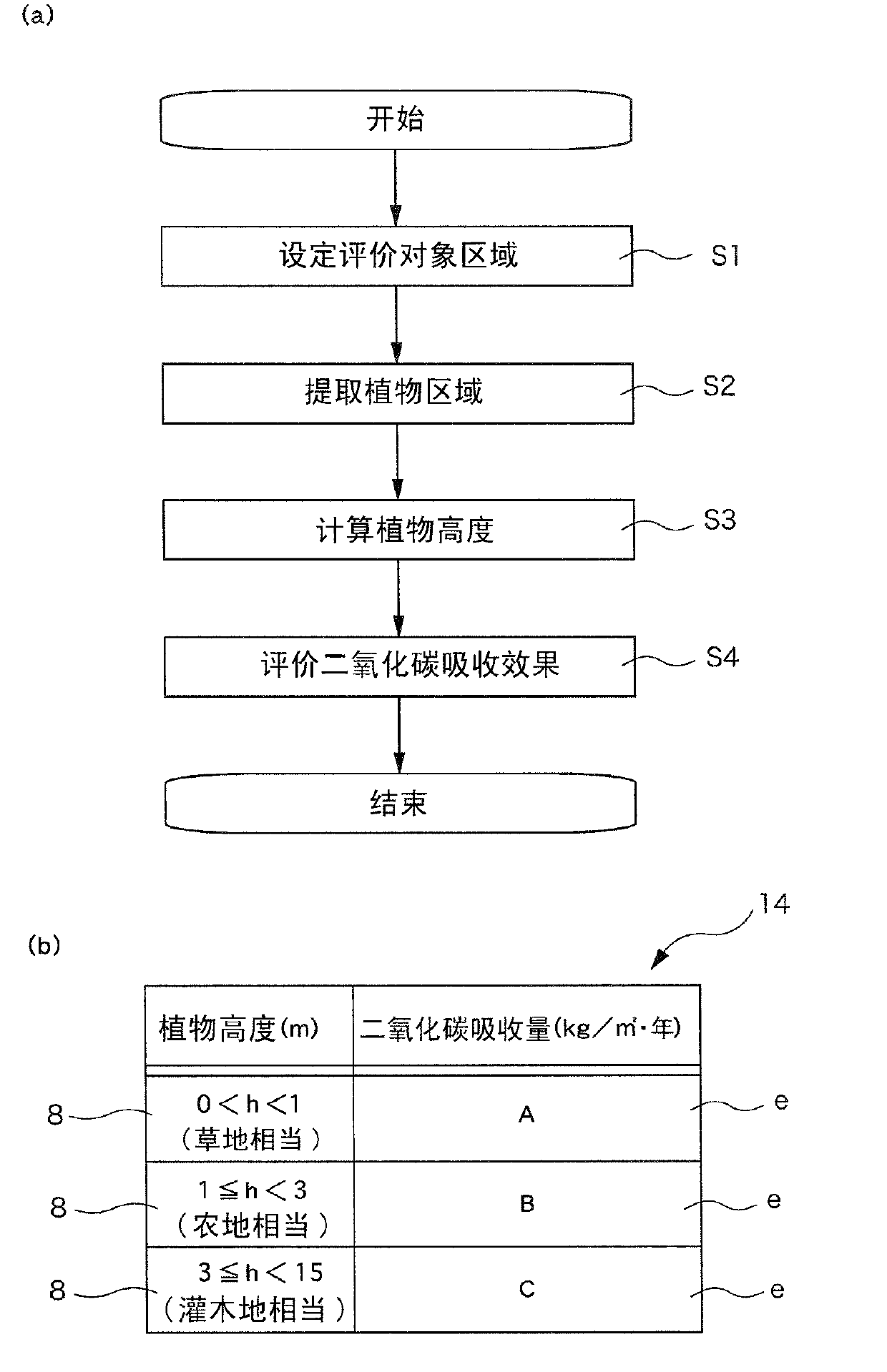

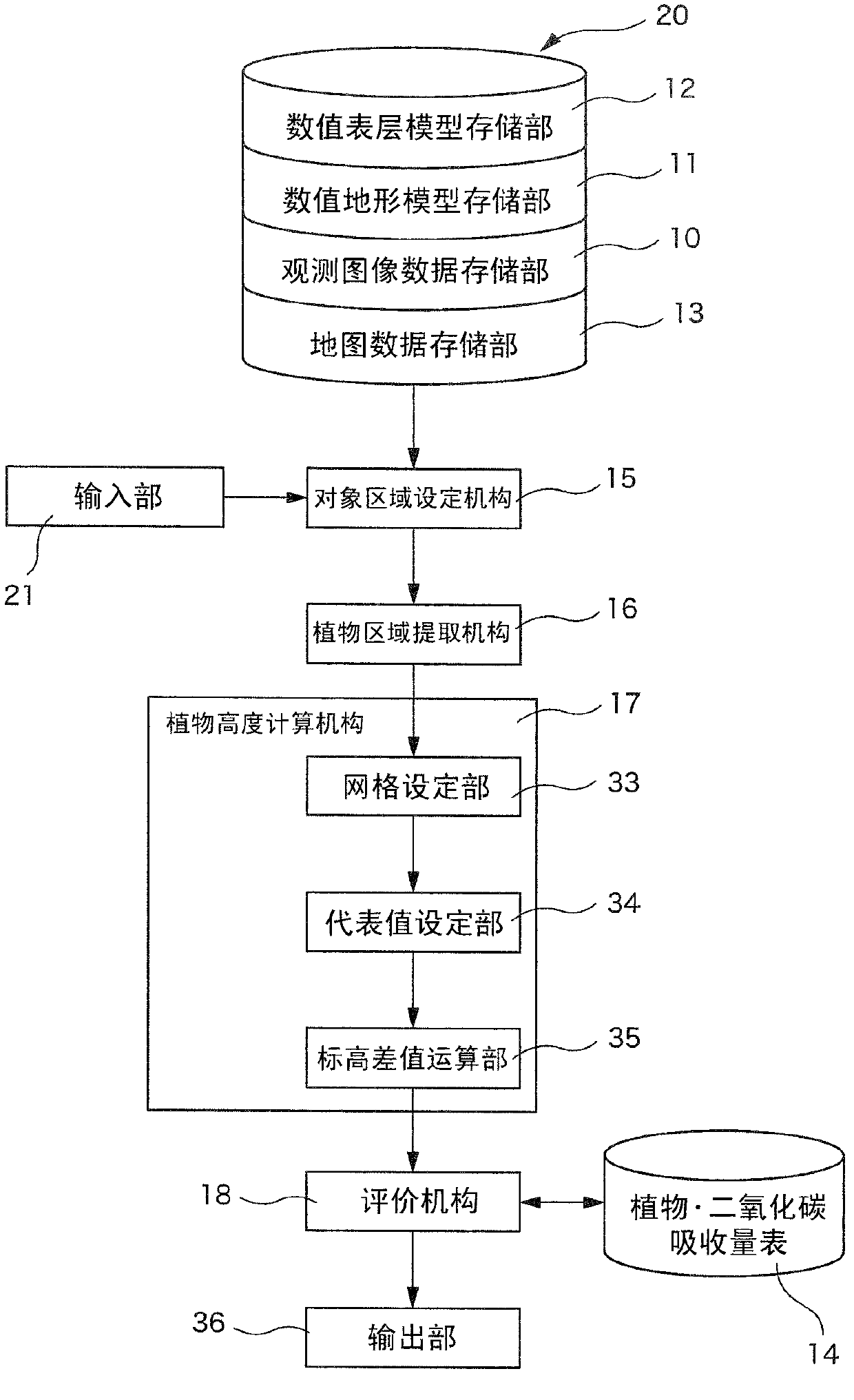

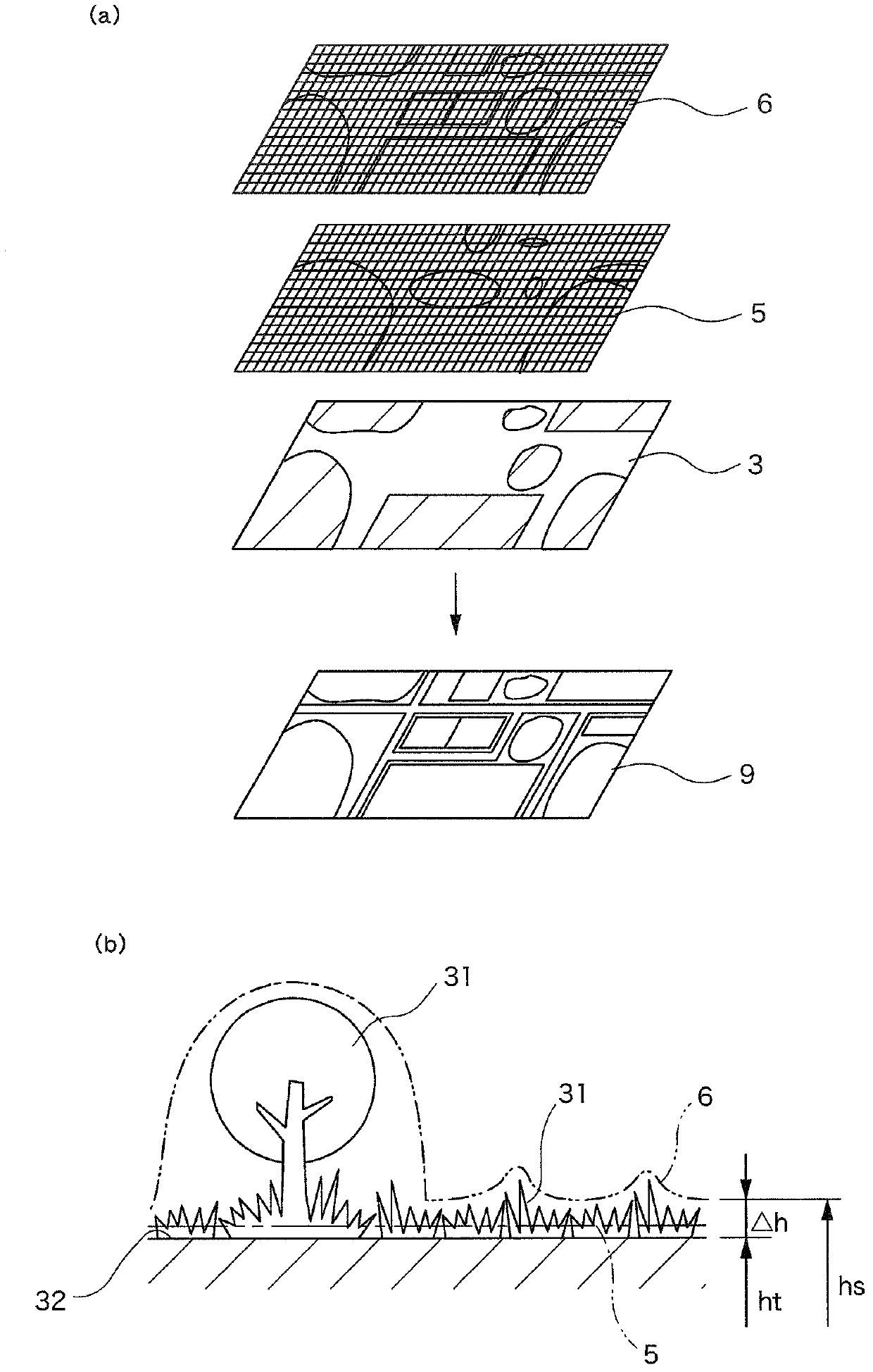

Evaluation device and evaluation method for carbon dioxide absorbing effectiveness

Disclosed is a method for the evaluation of carbon dioxide absorbing effectiveness which can carry out analysis suited to reducing carbon dioxide. The disclosed method comprises: a step wherein a plant region (4) is extracted from a region (2) to be evaluated in accordance with the pixel distribution of observation image data (3), wherein the region (2) to be evaluated has been observed from the air above by means of a specified wavelength region which can distinguish a plant group (1); a step wherein the difference between the ground surface elevation and the stratum layer elevation of the plant region (4) is calculated as the height of the plant group (1) for each partition unit (7) wherein the plant region (4) is partitioned into specified surface area units, said calculation being on the basis of a numerical terrain model (5) and a numerical stratum mode (6) coordinated and orientated to the observation image data (3); and a step wherein a carbon dioxide absorption amount (e) is allocated to a plant group (1) which is below a previously-set height corresponding to a forest, the carbon dioxide absorption amount (e) being for a specified unit surface area set according to the causal relationship with the carbon dioxide absorption amount (e), and the carbon dioxide absorbing effectiveness of the non-forest region under the cover of the surface area within the plant region (4) of the partition unit (7) comprising the plant group (1) is evaluated.

Owner:PASUKO KK

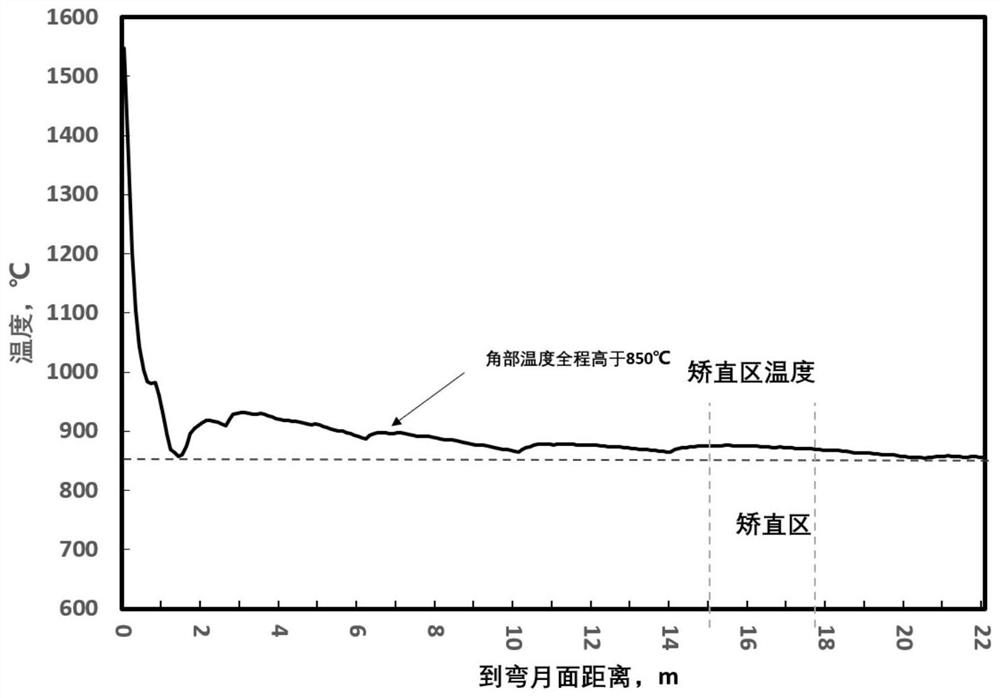

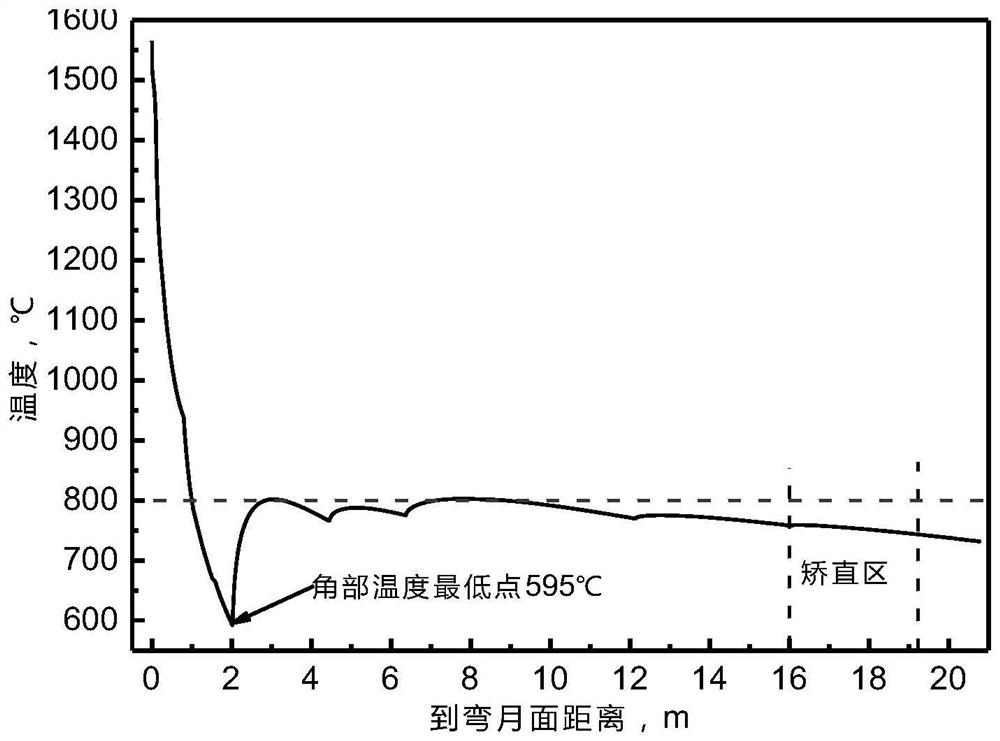

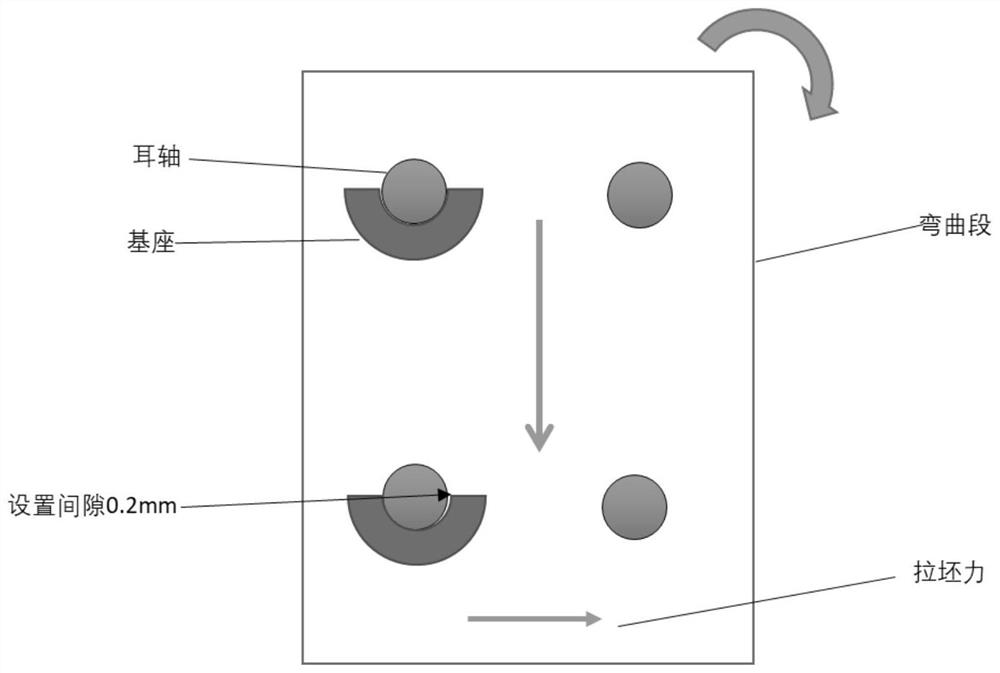

Method for improving corner cracks and middle cracks of plate blank

The invention provides a method for improving corner cracks and middle cracks of a plate blank. The method comprises the step of setting two temperature control intervals for the corner temperature of a casting blank. According to the method, the distance between the rollers in the bending section of the casting blank is small, the bulging stress of the casting blank is relatively small, the cooling strength is reduced in the area, the temperature of the bending section of the corner of the casting blank is in a high-temperature section, and corner cracks and middle cracks caused by the influence of bending stress in the bending area are avoided; the cooling strength of the arc-shaped section is increased, so that the temperature of the arc-shaped section entering the straightening area enters the low-temperature area, the middle cracks of the casting blank are effectively reduced, the corners of the casting blank are prevented from entering the brittle area of steel in the straightening area, and corner cracks are avoided; and meanwhile, in cooperation with bending section positioning parameter optimization, straightening area cooling partition and nozzle parameter optimization, the corner temperature of the casting blank is more uniform, corner temperature fluctuation is reduced, and the method has the obvious improvement effect on control over corner cracks and middle cracks of the casting blank.

Owner:吉林建龙钢铁有限责任公司

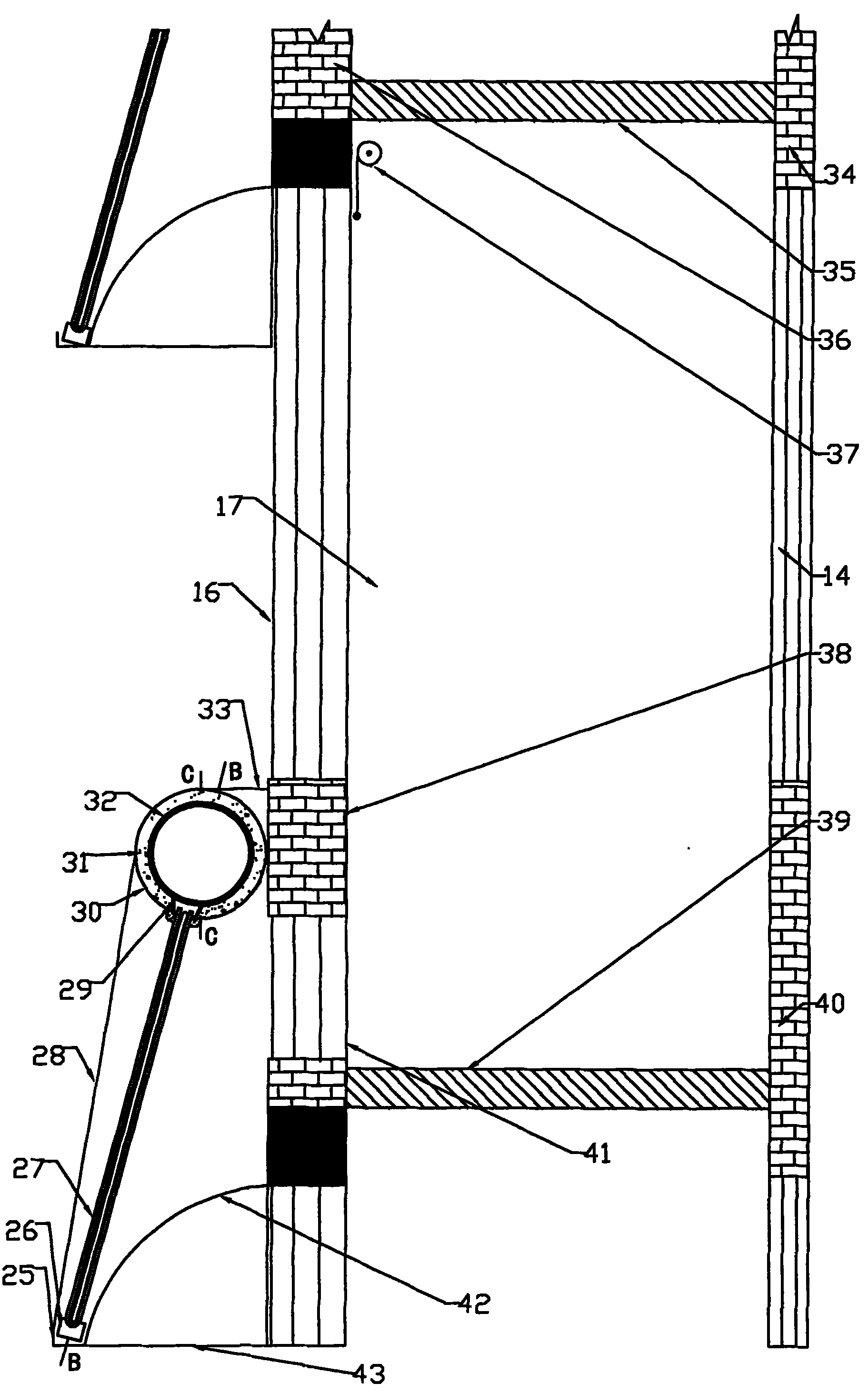

Straight-insertion type pressure-bearing dual-circulation solar balcony bathroom

InactiveCN101988344ALow circulation resistanceLow cycle heat lossSolar heating energySolar heat devicesSolar waterEngineering

The invention relates to a straight-insertion type pressure-bearing dual-circulation solar balcony bathroom which comprises a passive solar house, a pressure-bearing dual-circulation solar water heater and a connecting tube thereof. A wall, a window, a door, a roof and a bottom surface of a balcony are enclosed into the passive solar house; and a water tank, a hole in the wall of the water tank, an end cover and an annular hole together form a heat exchanger. The heat exchanger is in a full-plastic structure and never scales, which can ensure that the heat exchanger keeps higher heat exchange efficiency for a long time. The pressure-bearing dual-circulation solar water heater and the passive solar house are integrally designed, which can provide a large quantity of life hot water and provide a showing space with a room temperature of reaching 25-45 DEG C, thus even in a winter night with roaring north wind, hot water in the water tank can be used to ensure that the bathroom rapidly increases the temperature and keeps constant. The balcony has all functions of the balcony and can be used as the bathroom and a toilet as well as can also be used as a ventilation channel of an adjacent room.

Owner:侯国山

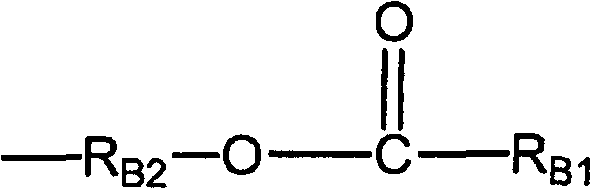

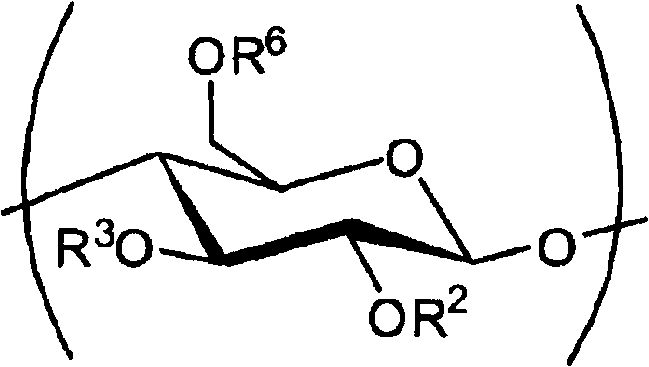

Cellulose derivative, thermoformed material, molded body, production method therefor, and casing for electrical and electronic equipment

A thermo-molding material contains a water-insoluble cellulose derivative, wherein the water-insoluble cellulose derivative comprises: A) a hydrocarbon group; B) a group containing an acyl group: -CO-R B1 and an alkyleneoxy group: -R B2 -O- (R B1 represents a hydrocarbon group, and R B2 represents an alkylene group having 3 carbon atoms); and C) an acyl group: -CO-R C (R C represents a hydrocarbon group).

Owner:FUJIFILM CORP

Coating Composition of insulating heat for glass, and preparation method

InactiveCN101050065BCurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyInorganic salts

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com