Method for improving corner cracks and middle cracks of plate blank

A technology for corner cracks and slabs is applied in the field of improving the corner cracks and intermediate cracks of slabs based on dual-temperature process control at the corners of the slab, and can solve the increase of bending straightening reaction force. , reduce production efficiency, reduce equipment service life and other problems, to achieve the effect of improving intermediate crack control, optimizing positioning parameters, and improving stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A medium-high carbon steel billet is prepared by a continuous casting machine, and the composition of the medium-high carbon steel is:

[0078] steel type C(2) Si(2) Mn(2) P(3) S(3) Al S (3)

Medium and high carbon steel (wt%) ≤0.48 ≤0.30 0.50~1.30 ≤0.020 ≤0.010 ≤0.020

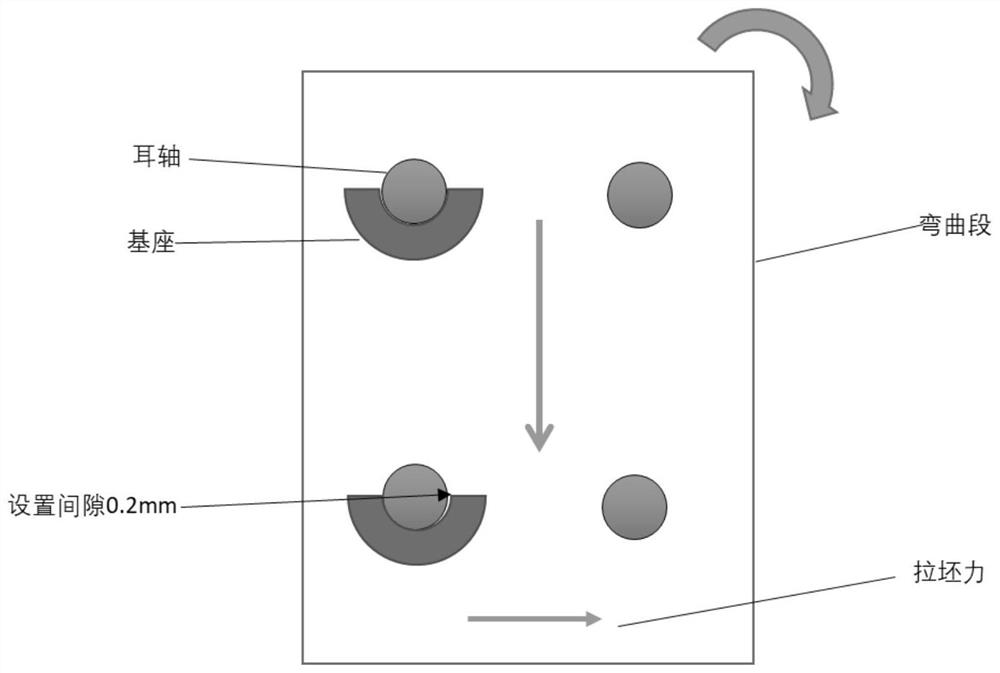

[0079] The setting of the continuous casting machine is: the gap between the trunnion on the east side of the bending section and the "U"-shaped seat is measured with a feeler gauge to be 0.2mm, and the gap between the trunnion on the west side and the "U"-shaped seat is measured to be 0.3mm with a feeler gauge;

[0080] Casting speed during pouring is 1.1m / min~1.4m / min, tundish temperature is 1535℃~1545℃;

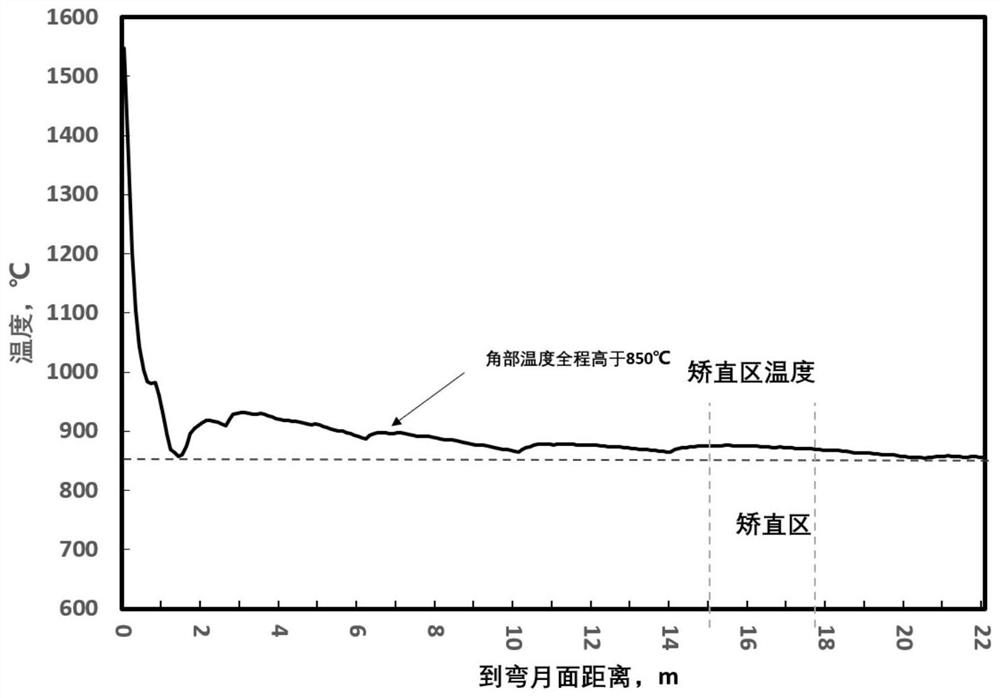

[0081] Set the target temperature at the corner of the billet in the bending area to 910°C, and use an infrared temperature measuring gun to measure the actual temperature at 900°C to 908°C; set the target temperature at the corner of the billet in the straightening...

Embodiment 2

[0090] A continuous casting machine is used to prepare a boron-containing steel billet, and the composition of the boron-containing steel is:

[0091] steel type C(2) Si(2) Mn(2) P(3) S(3) Al S (3)

B(4) Boron-containing steel (wt%) ≤0.20 ≤0.30 0.30~0.90 ≤0.020 ≤0.010 ≤0.025 ≤0.0020

[0092] The setting of the continuous casting machine is: the gap between the trunnion on the east side of the bending section and the "U"-shaped seat is measured with a feeler gauge to be 0.5mm, and the gap between the trunnion on the west side and the "U"-shaped seat is measured to be 0.6mm with a feeler gauge;

[0093] Casting speed during pouring is 1.1m / min~1.6m / min, tundish temperature is 1545℃~1555℃;

[0094] Set the target temperature at the corner of the billet in the bending area to 900°C, and use an infrared temperature measuring gun to measure the actual temperature at 902°C to 915°C; set the target temperature at the corner of the billet in the stra...

Embodiment 3

[0103]A continuous casting machine is used to prepare microalloyed steel slabs, and the composition of the microalloyed steel is:

[0104]

[0105] The setting of the continuous casting machine is: the gap between the trunnion on the east side of the bending section and the "U"-shaped seat is measured with a feeler gauge to be 0.3mm, and the gap between the trunnion on the west side and the "U"-shaped seat is measured to be 0.35mm with a feeler gauge;

[0106] Casting speed during pouring is 1.0m / min~1.3m / min, tundish temperature is 1540℃~1550℃;

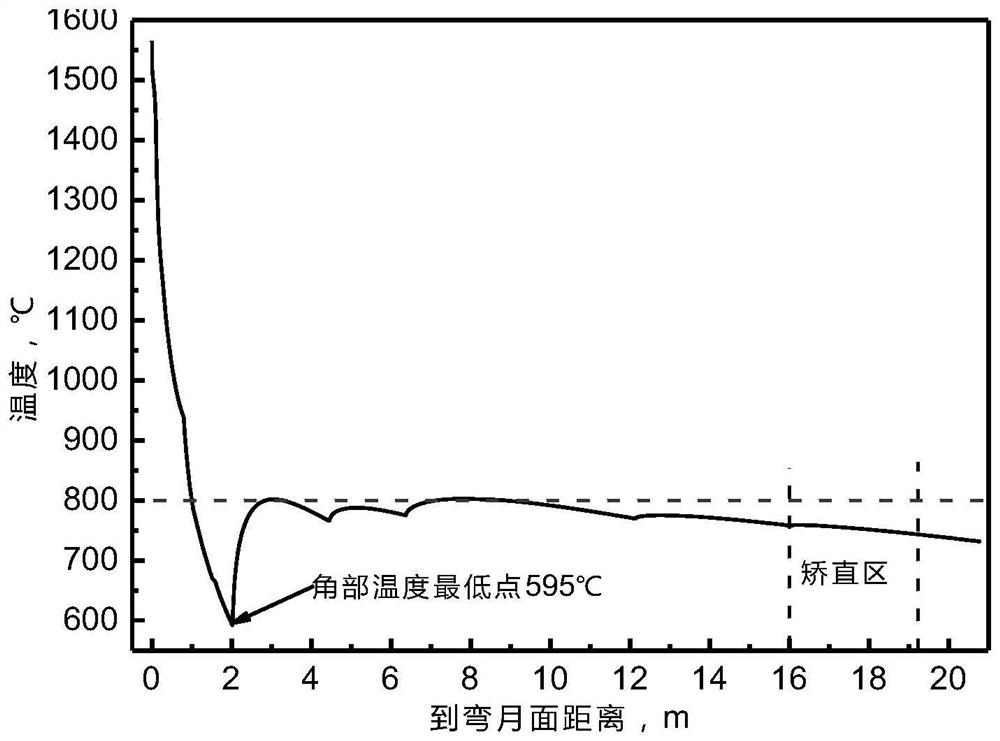

[0107] Set the target temperature at the corner of the billet in the bending area to 920°C, and use an infrared temperature measuring gun to measure the actual temperature at 925°C to 930°C; set the target temperature at the corner of the billet in the straightening area to 700°C, and use an infrared temperature measuring gun to measure the temperature at the entrance of the straightening area. The corner temperature of the slab i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com