Crystallizer capable of preventing continuous casting slab defects

A technology of mold and cooling water tank, applied in the field of slab, billet continuous casting mold and mold, can solve the problems of cracks, uneven heat conduction, uncontrollable flow, etc., achieve uniform heat conduction, reduce continuous casting defects, reduce The effect of cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

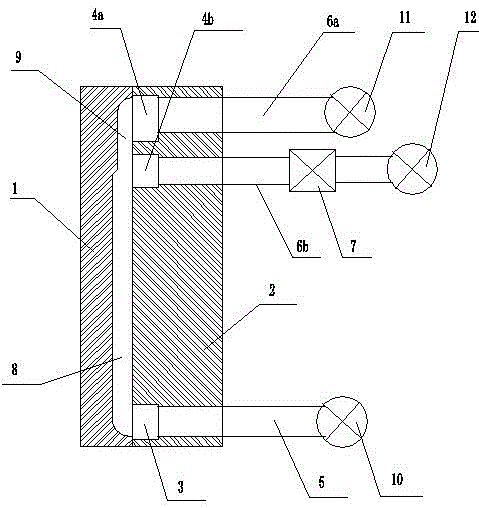

[0032] Embodiment one: as figure 1 As shown, a crystallizer for preventing defects includes a crystallizer copper plate 1 and a crystallizer water tank 2 that supports the mold copper plate and cools water through it. The crystallizer water tank is provided with a water inlet chamber 3 and two water outlets chamber, water outlet chamber one 4a and water outlet chamber two 4b, the water inlet chamber 3 is in communication with the water inlet pipe 5, the water outlet chamber one 4a is in communication with the water outlet pipe one 6a, and the water outlet chamber two 4b is in communication with the water outlet pipe two 6b, A valve 7 is set on the second water outlet pipe 6b, the second water outlet pipe 6b communicates with the valve 7, and a plurality of evenly distributed cooling water tanks are arranged on the copper plate of the crystallizer, and the cooling water tank is divided into two parts, the first part is normal Cooling water tank one 8, the second part is the coo...

Embodiment 2

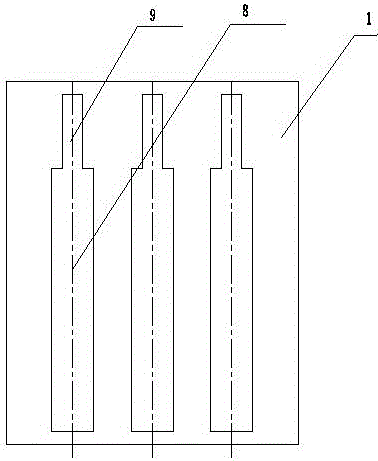

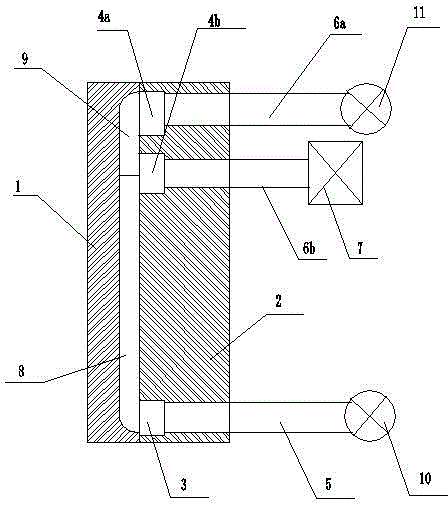

[0033] Embodiment two: as figure 2 , image 3As shown, a mold for preventing continuous casting slab defects includes a mold copper plate 1 and a mold water tank 2 that supports the mold copper plate and cools water through it. The mold water tank is provided with a water inlet chamber 3 and Two water outlet chambers, water outlet chamber one 4a and water outlet chamber two 4b, the water inlet chamber 3 communicates with the water inlet pipe 5, the water outlet chamber one 4a communicates with the water outlet pipe one 6a, and the water outlet chamber two 4b communicates with the water outlet pipe two 6b is connected, and a valve 7 is set on the second outlet pipe 6b, and the second outlet pipe 6b is connected to the valve 7. The copper plate of the crystallizer is provided with a plurality of evenly distributed cooling water tanks, and the cooling water tanks are divided into two parts, the first part It is a normal cooling water tank one 8, and the second part is a cooling...

Embodiment 3

[0034] Embodiment three: as Figure 4 As shown, a mold for preventing continuous casting slab defects includes a mold copper plate 1 and a mold water tank that supports the mold copper plate and cools water through it. The mold water tank includes a water tank 2a and a water tank and a crystal The water tank back plate 2b that can be quickly replaced is increased between the copper plates of the water tank. The water inlet chamber 3, the water outlet chamber one 4a, and the water outlet chamber two 4b are arranged on the water tank back plate. The water inlet chamber 3 communicates with the water inlet pipe 5. Outlet chamber one 4a communicates with the corresponding passage of water tank 2a and outlet pipe one 6a, and described outlet chamber two 4b communicates with water tank 2a corresponding passage and outlet pipe two 6b, and valve 7 is set on the described outlet pipe one 6a, and described outlet pipe one 6a communicates with the valve 7, the crystallizer copper plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com