Patents

Literature

81results about How to "Reduce cooling intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

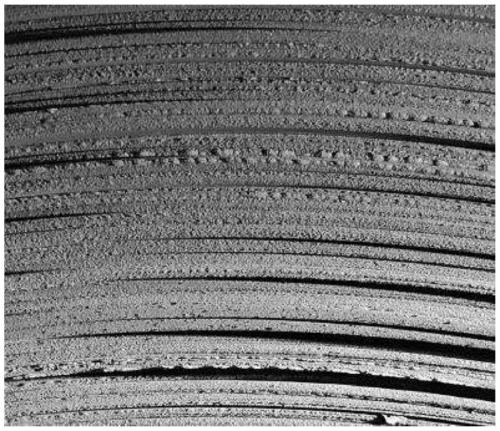

Steel for processing movement limiting core stick of continuous tube grimper and its producing process

The present invention belongs to the field of steel-smelting technology. The steel consists of C 0.30-0.43 wt%, Mn less than 0.60 wt%, Si 0.70-1.00 wt%, P less than 0.010 wt%, S less than 0.007 wt%, Cr 4.50-5.50 wt%, Mo 1.00-1.50 wt%, V 0.7-1.00 wt%, Nb 0-0.25 wt%, Al less than 0.015 wt%, Ni 0.10-0.75 wt%, Cu less than 0.10 wt%, O less than 30 ppm and H less than 2 ppm, except Fe. It may contain one or several of RE, W, B, Ca, Mg, Zr and Ti. The steel of the present invention has reasonable production process, high performance and long service life of the core rod therewith.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Semi-high speed steel break-down (BD) roller and manufacturing method thereof

ActiveCN105695873AHigh hardnessHigh hardness is controlled at HSD50~70, wear resistanceFurnace typesRollsManufacturing technologyAlloy

The invention discloses a semi-high speed steel break-down (BD) roller and a manufacturing method thereof, particularly relates to a roller applied to a profile steel rail beam BD rolling mill and belongs to the technical field of roller manufacturing. The whole roller is made of semi-high speed steel. The alloy components of the roller comprise, by weight, 0.3-1.5% of C, 0.2-1.4% of Si, 0.2-1.0% of Mn, 1.5-5.0% of Cr, 0-1.0% of Ni, 0.5-2% of Mo, 0.5-1.5% of W, 0-1.5% of V, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of raw material smelting, integral casting, heat preservation and demolding, heat pretreatment and heat treatment. According to the heat treatment, the high-temperature quenching technique and the high-temperature tempering technique are adopted. According to the structure of the roller, 3% or less of granular carbides are distributed on tempered sorbite, the macro-hardness of the roller is controlled to be HSD50-70, the abrasion resistance is high, the tensile strength is equal to or higher than 800 MPa, the crack extension resistance is high, and the roller is good in roller surface quality under the off-machine condition and small in abrasion under the on-machine condition; and the requirements of rail beam rolling can be well met, and especially the requirements for high strength, high abrasion resistance, high impact resistance and high hot cracking resistance of the roller in the rail beam rolling process can be well met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

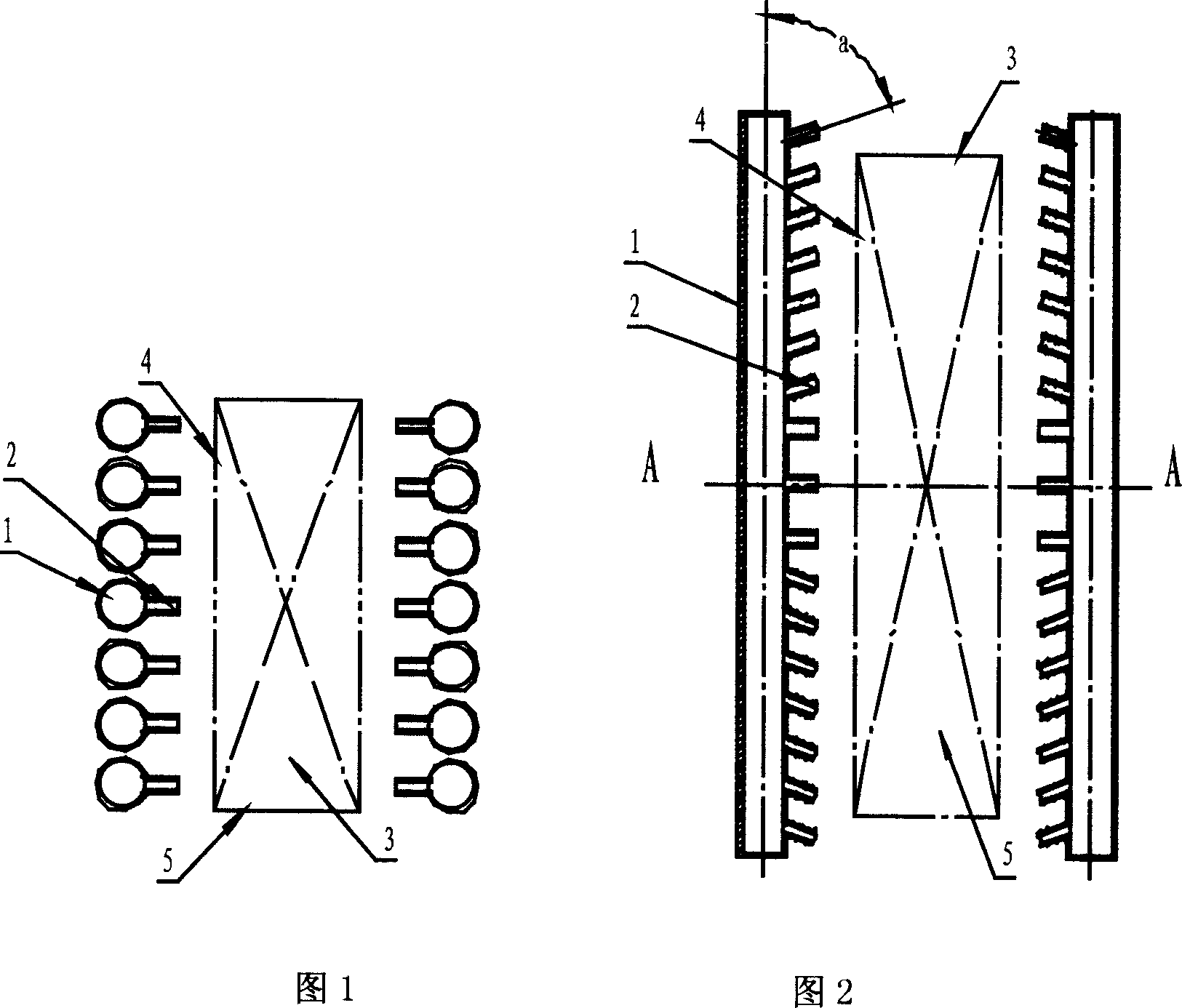

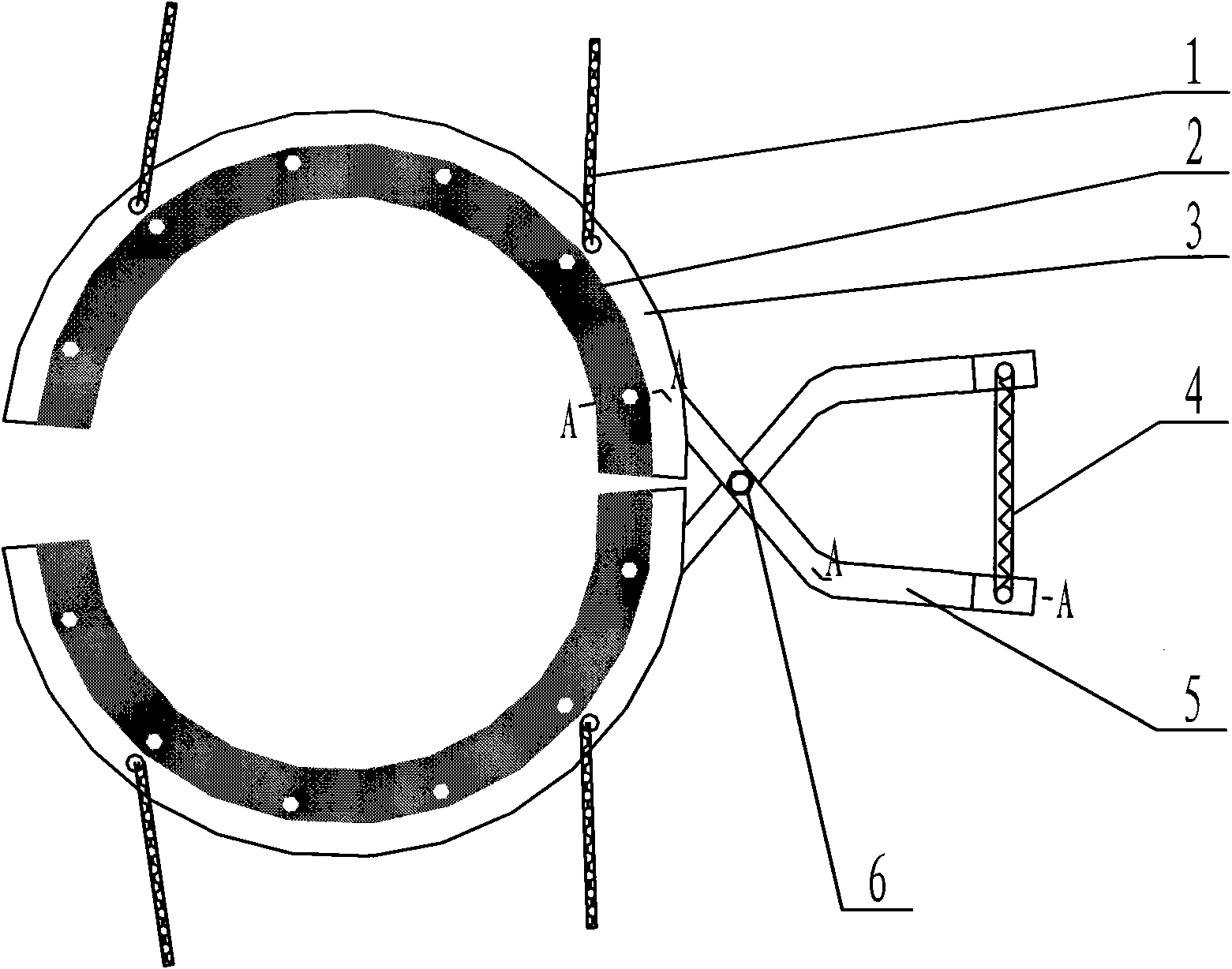

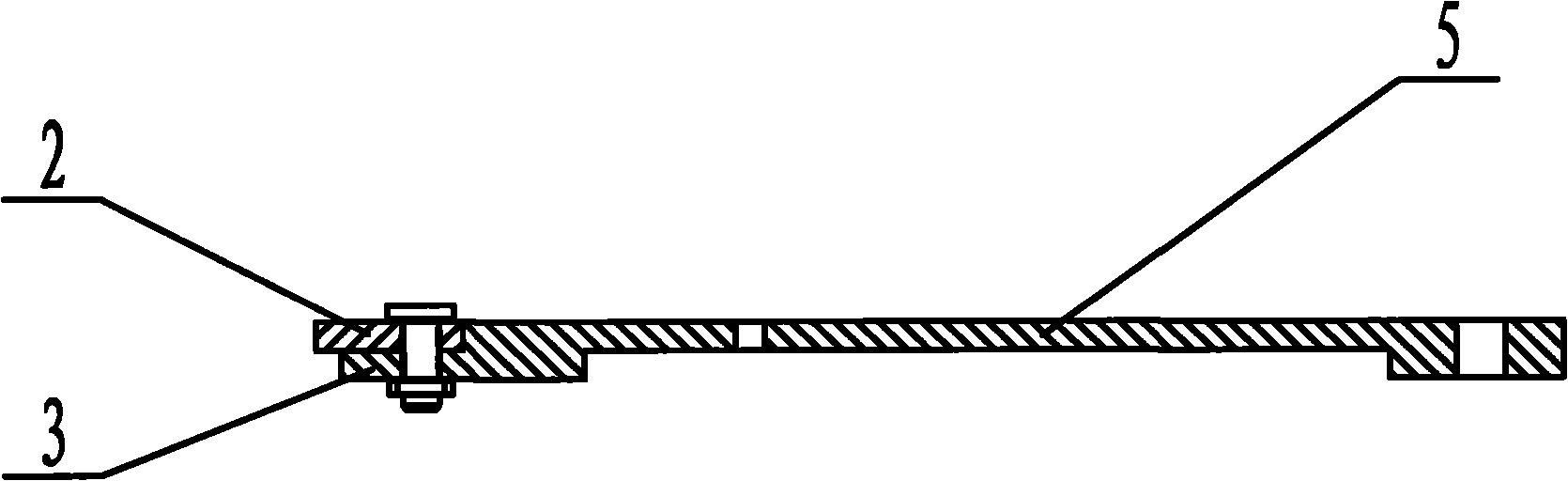

Method for preventing end-face spray quenching cracking of quenching piece by changing spray angle

InactiveCN101012491AReduce cooling intensityIncrease cooling intensityFurnace typesHeat treatment process controlDielectricQuenching

The invention discloses an end-face spray quenching crack-preventing method of quenching piece through changing spraying angle in the heat disposal domain of metal material, which is characterized by the following: placing quenching piece in the quenching equipment with pipe; making quenching piece with lateral and end faces; setting lateral face as rapid freezing face only; paralleling lateral face and pipe; setting the end face of quenching piece perpendicular to pipe; flowing quenching dielectric through pipe; displaying angle a (0-90 deg) for pipe and lateral face of quenching piece; fitting for cooling lateral face of quenching piece; avoiding crack effectively.

Owner:SHANGHAI JIAO TONG UNIV

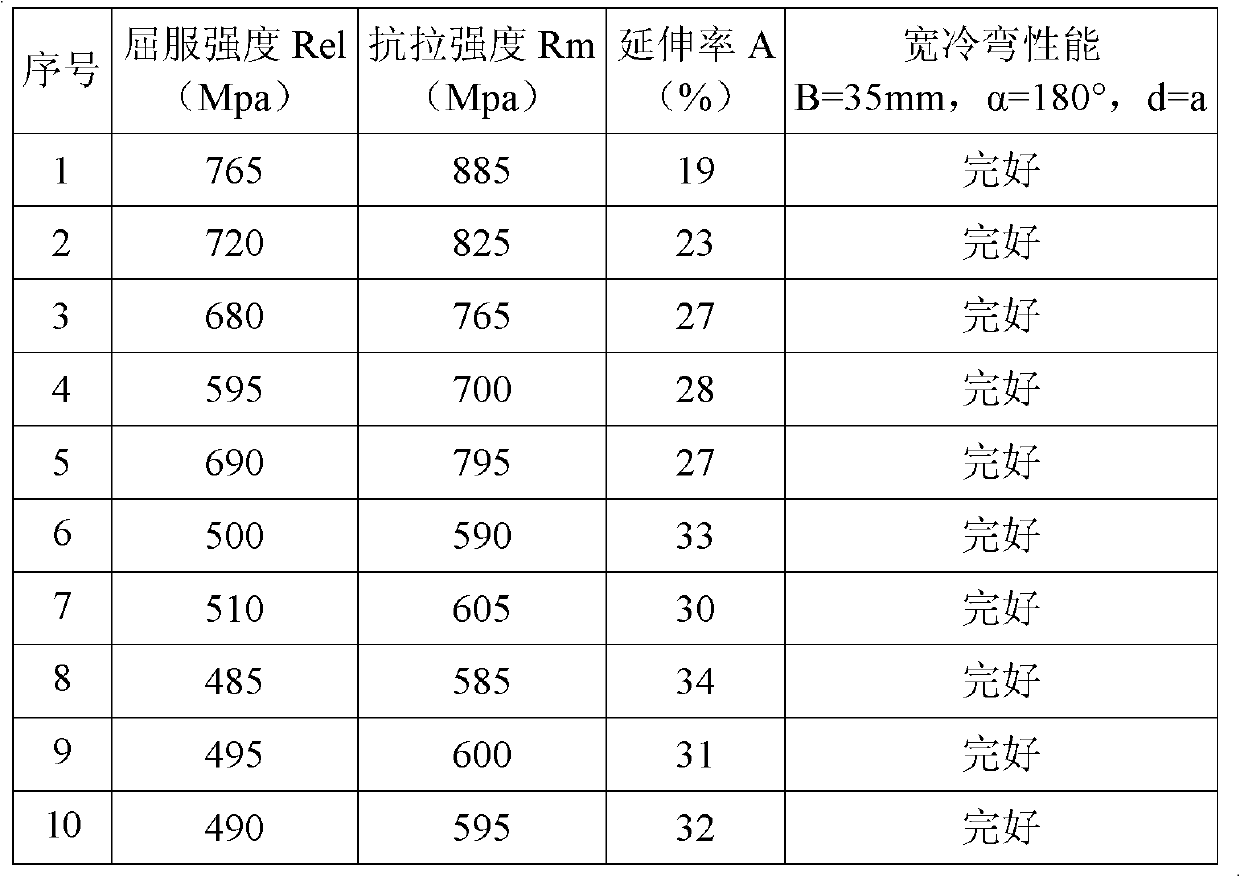

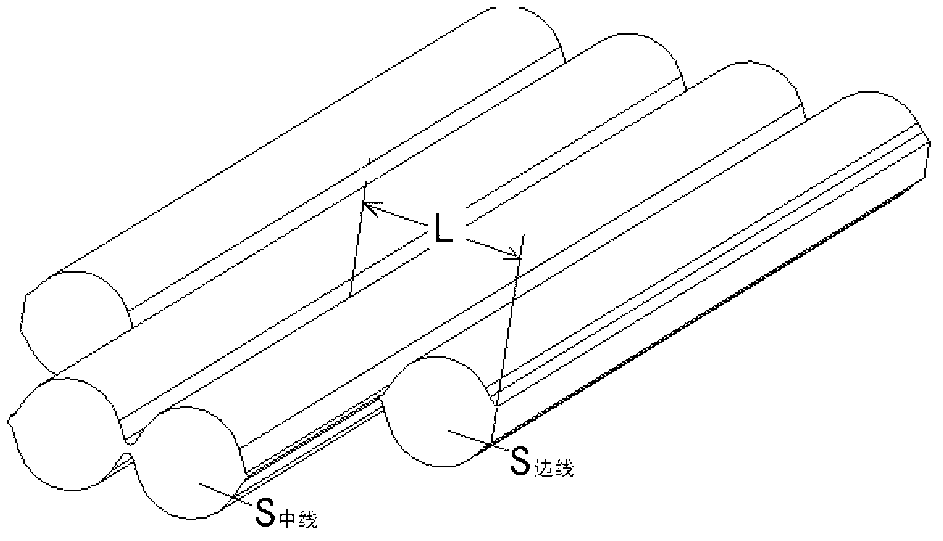

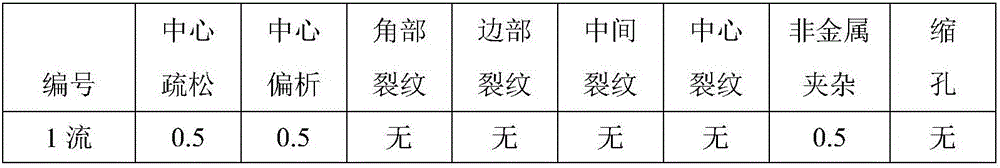

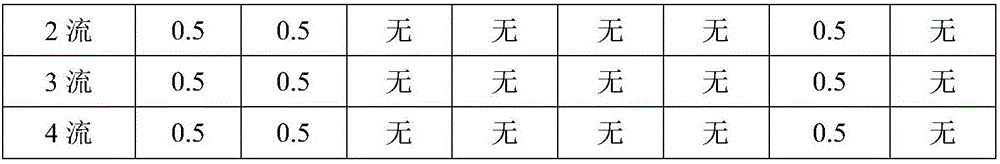

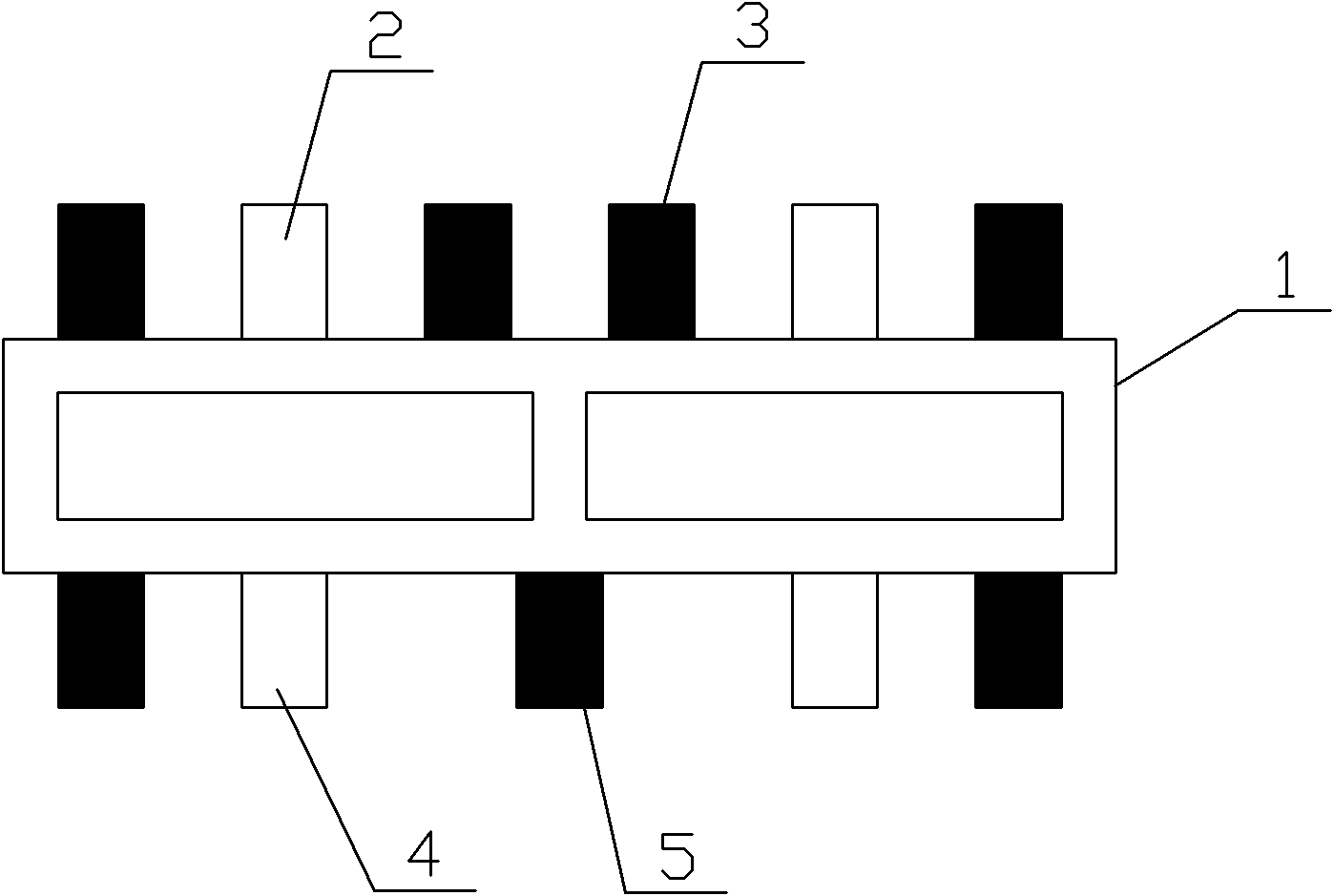

Controlling method for reduction of four-strand slitting line differences and structure property differences

ActiveCN103230940AReduce cooling intensityReduce poor tissue mechanical propertiesRoll mill control devicesMetal rolling arrangementsRebarEngineering

The invention relates to a controlling method for reduction of four-strand slitting line differences and structure property differences and belongs to the technical field of production of steel for construction steel bars. A relation model of line differences and hole patterns L and a simulating calculation model of the hole pattern filling degree L are built for instructing the hole pattern design effectively. The four-strand difference is -31mm through calculation under the condition that the mill springing is 0.2mm, and accordingly, the test development cycle is decreased greatly, and the test risk and the test cost are reduced; and accidents of wave bending, disorderly steel on cooling beds, steel stacking at flying shearing positions and the like are reduced, and the yield is improved. Besides, by means of a controlled rolling and controlled cooling technology, the usage amount of micro-alloy can be reduced apparently, and the tenacity of materials is enhanced simultaneously. Utilization of the controlled rolling and controlled cooling technology on steel bar products of large and medium specifications is mature, and as for four-strand slitting of steel bar products of small specifications in a range of phi 12mm to phi 14mm, through horizontal adjustment of different circular seam openings of four strands, the four-strand cooling uniformity is improved apparently, and the four-strand structure property stability is improved; and the four-strand yield strength Rel is smaller than or equal to 25 MPa, and the tensile strength is smaller than or equal to 20 MPa.

Owner:SHOUGANG CORPORATION +1

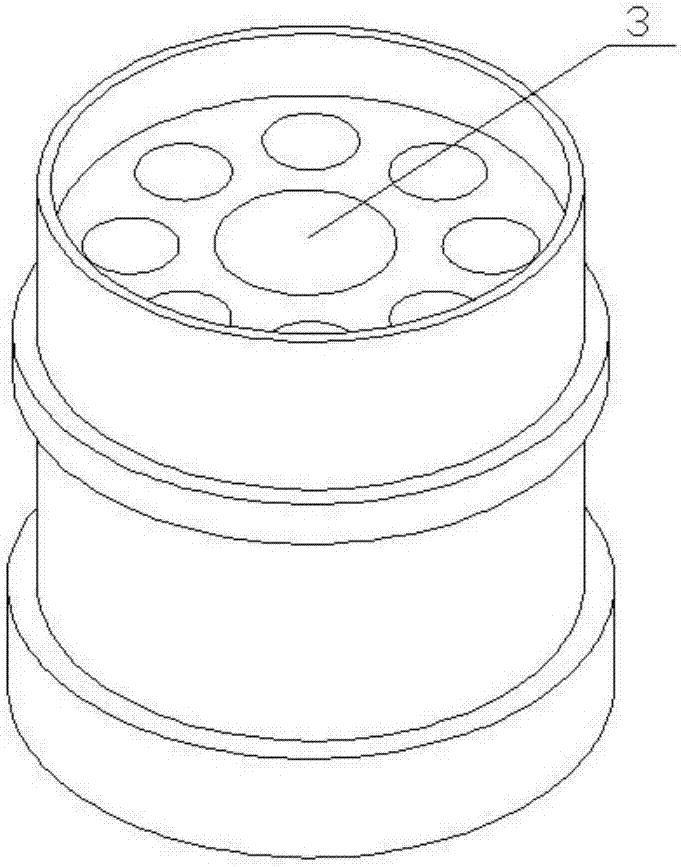

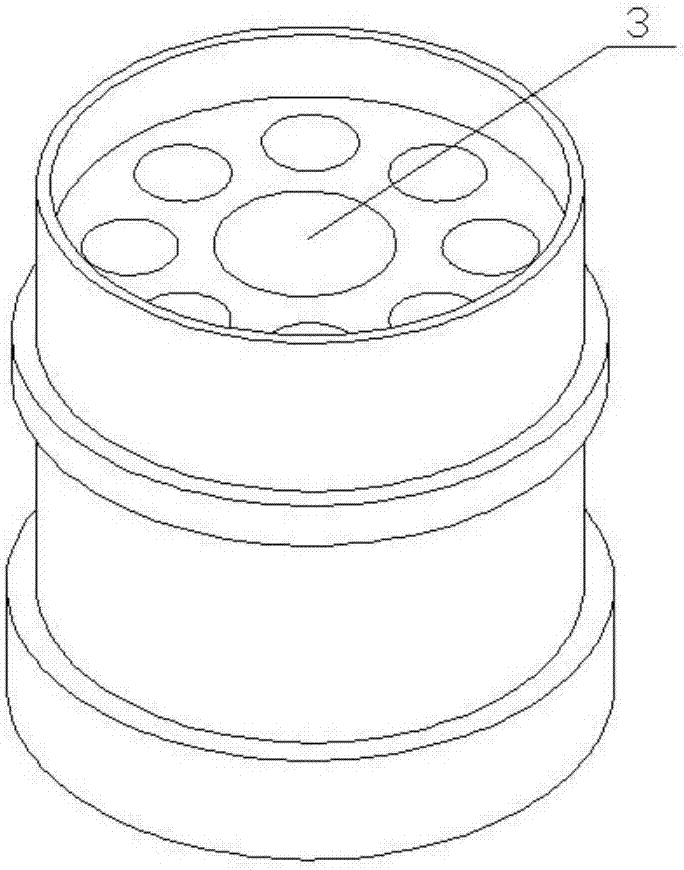

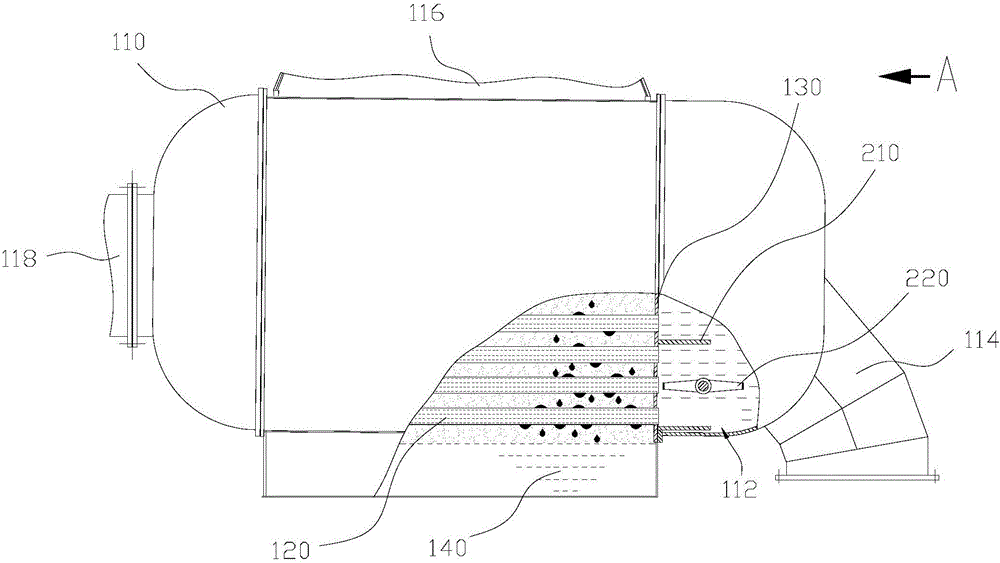

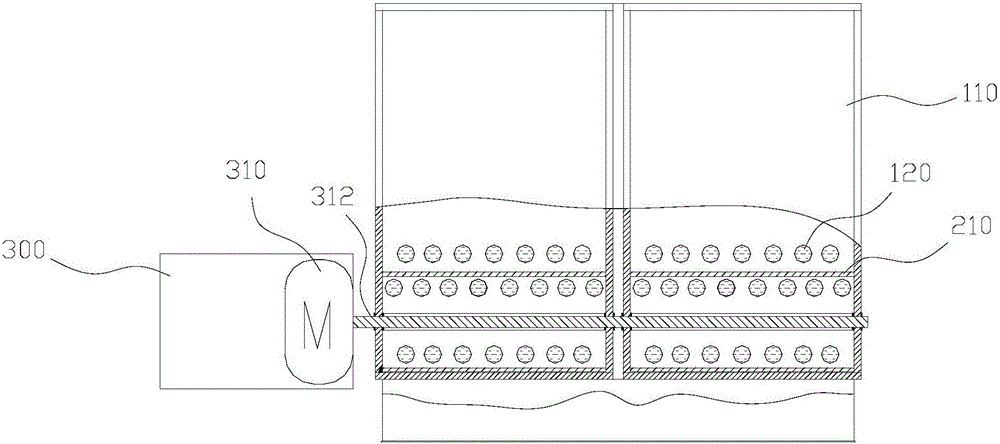

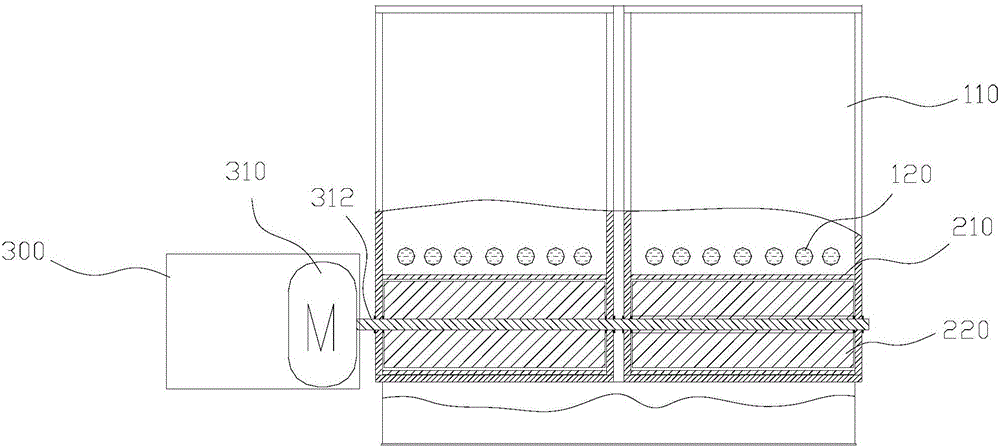

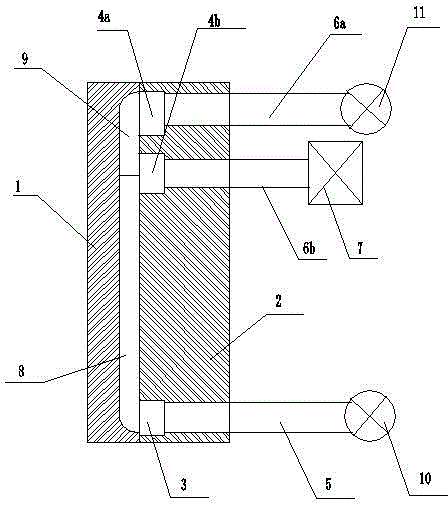

Crystallizer with changeable cooling intensity in semicontinuous casting of aluminum alloy

The invention provides a crystallizer with changeable cooling intensity in semicontinuous casting of aluminum alloy. The crystallizer is provided with an upper water cavity and a lower water cavity; a decompression cavity is arranged at the bottom of the upper water cavity; decompression cavities are arranged on the top and the bottom of the lower water cavity; a third group of cooling water holes are arranged on the decompression cavity of the upper water cavity; a first group of cooling water holes are arranged on the decompression cavity at the top of the lower water cavity; a second group of cooling water holes are arranged on the decompression cavity at the bottom of the lower water cavity; the first group of cooling water holes and the second group of cooling water holes are in a same vertical plane and are in intersection with the third group of cooling water holes; the angles of the first group of cooling water holes and the second group of cooling water holes are bigger than 40 degrees; and the angles of the third group of cooling water holes are less than 40 degrees. According to the invention, two groups of cooling water flow with high incident angles are adopted, and the pressure of cooling water flow with the high incident angle can be greatly reduced under the same quantity of cooling water flow, so that the water returning phenomenon caused by excessive pressure and surface cracks of a cast ingot caused by the water returning phenomenon can be effectively avoided.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Soft-water cooling pipeline control method for blast furnace

ActiveCN104152618AEasy to adjustThe amount of water does not affectBlast furnace detailsCooling devicesExpansion tankBrick

A soft-water cooling pipeline control method for a blast furnace belongs to the field of metallurgy. Flow division is conducted at a water outlet pipe on a cooling wall in the tuyere area of a blast furnace; the flow is gathered in a middle water return ring pipe through a small branch pipe and returned to a water return main pipe at the top of the blast furnace through a main pipe; when the temperature of the copper cooling walls at the furnace waist and the furnace bosh is reduced to be lower than 45 DEG C, a middle water return flow control valve is opened, and a cooling wall water outlet main valve is closed, so that the water flow rate of more than five cooling walls of the furnace body is 1.0-2.6 m / s, and the water flow rate of the fifth cooling wall or below of the furnace body is 2.3-2.6 m / s; when the temperature of carbon bricks on the side wall of the hearth is higher than 400 DEG C, the middle water return flow control valve is opened, meanwhile, the cooling wall water outlet main valve is opened, the total water amount of the system is increased, the water speed of 1-5 cooling walls of the furnace cylinder reaches 2.8 m / s, the water speed of the cooling wall of the furnace body reaches 2.5 m / s, and the pressure of the water inlet main pipe of the system is supplemented by adjusting the nitrogen pressure of an expansion tank to be 0.8 MPa. According to the invention, under the condition of not influencing the cooling strength of the furnace cylinder, the cooling strength above the furnace waist is reduced and bonding of a furnace lining is avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

Method for manufacturing large-size heat-treatment aluminum alloy slab ingot capable of being strengthened

The invention provides a method for manufacturing a large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, and relates to a method for manufacturing the aluminum alloy slab ingot. The method for manufacturing the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened mainly solves the problems that as for an aluminum alloy slab ingot prepared in the prior art, the casting yield is low, and wide and thick slabs with excellent properties cannot be rolled out. The method comprises the first step of material weighing, the second step of smelting, the third step of casting melt preparation and the forth step of molding, and the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened is obtained. By means of the method, according to the prepared large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, the yield strength ranges from 98 N / mm<2> to 120 N / mm<2>, the tensile strength ranges from 182 N / mm<2> to 201 N / mm<2>, and the elongation percentage in a casting state ranges from 9.56% to 14.7%. By means of the method, the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

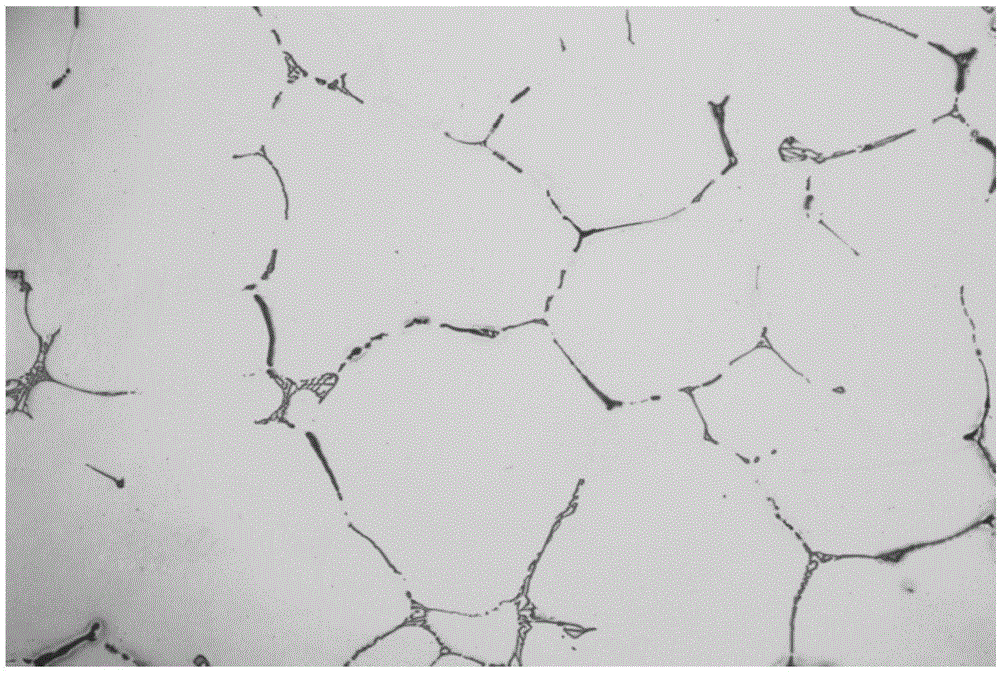

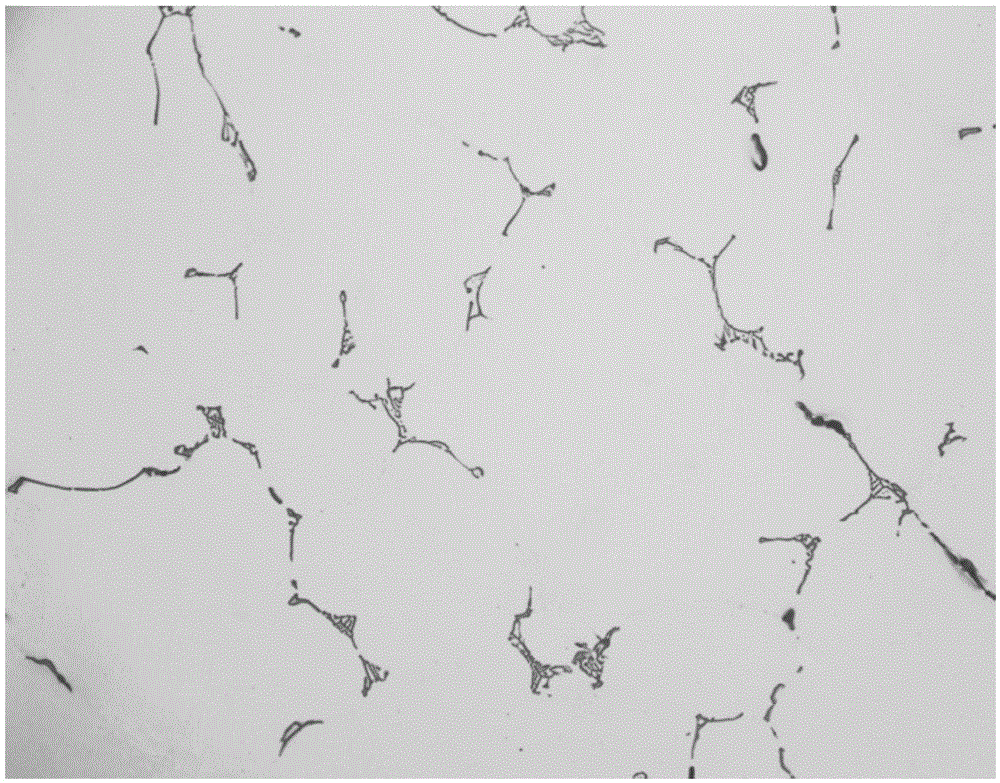

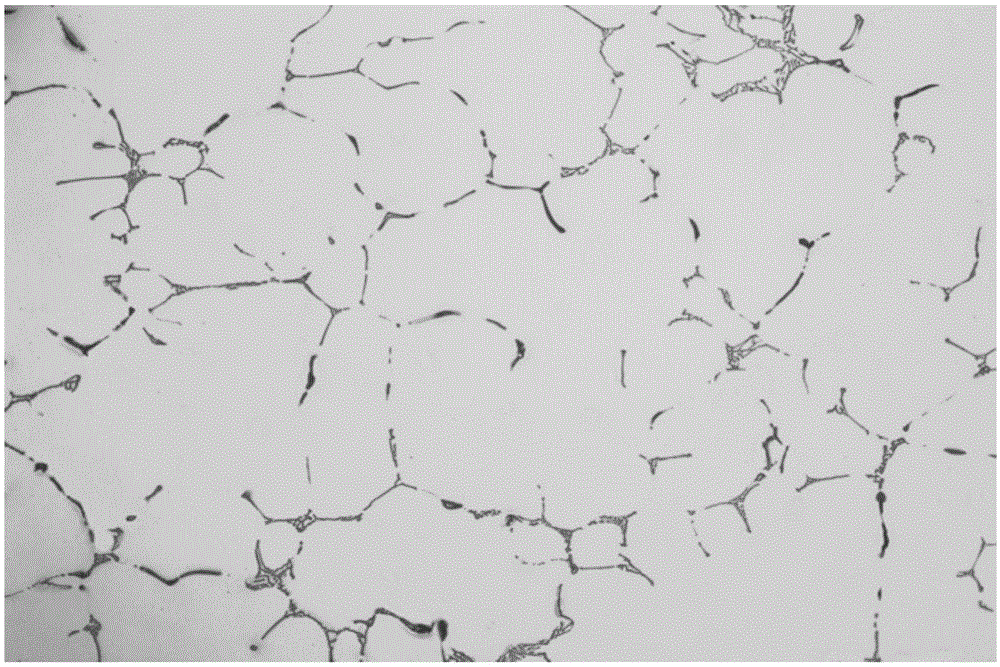

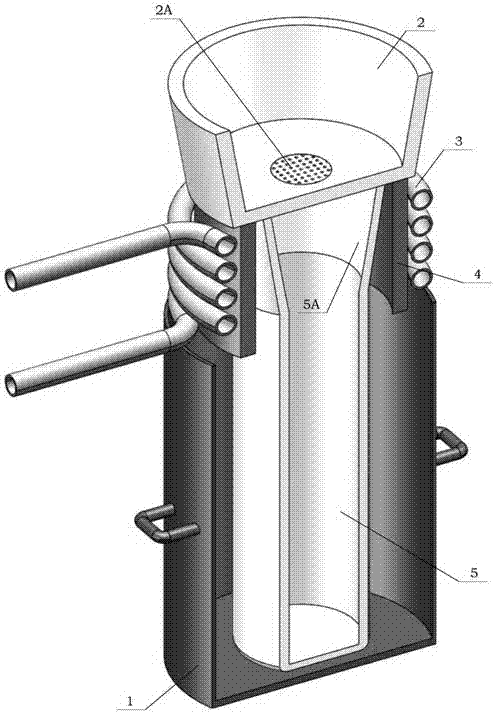

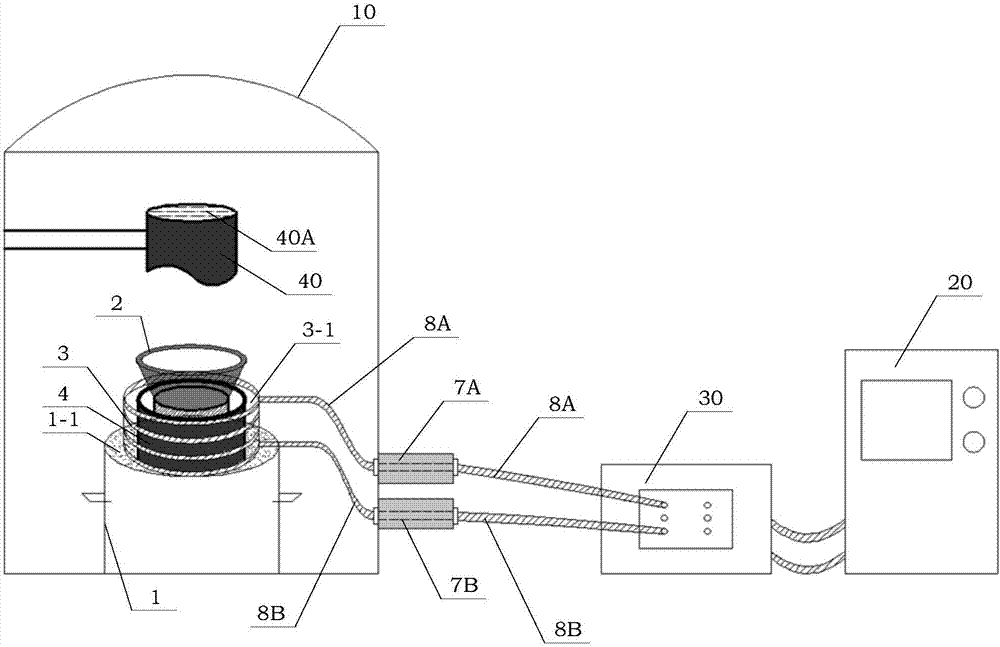

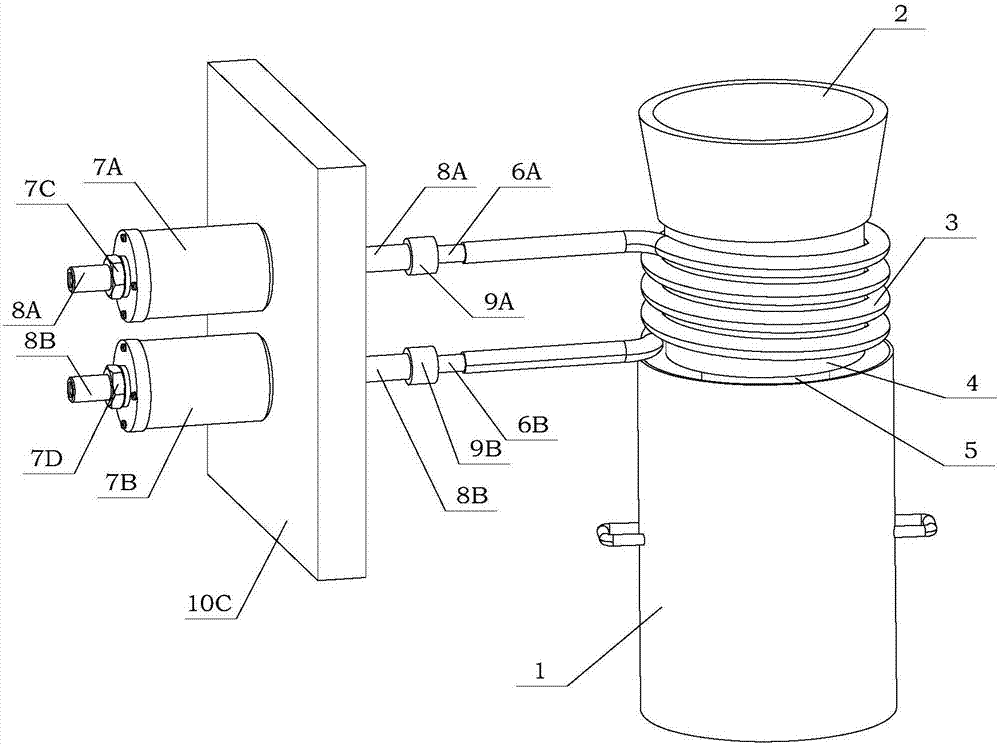

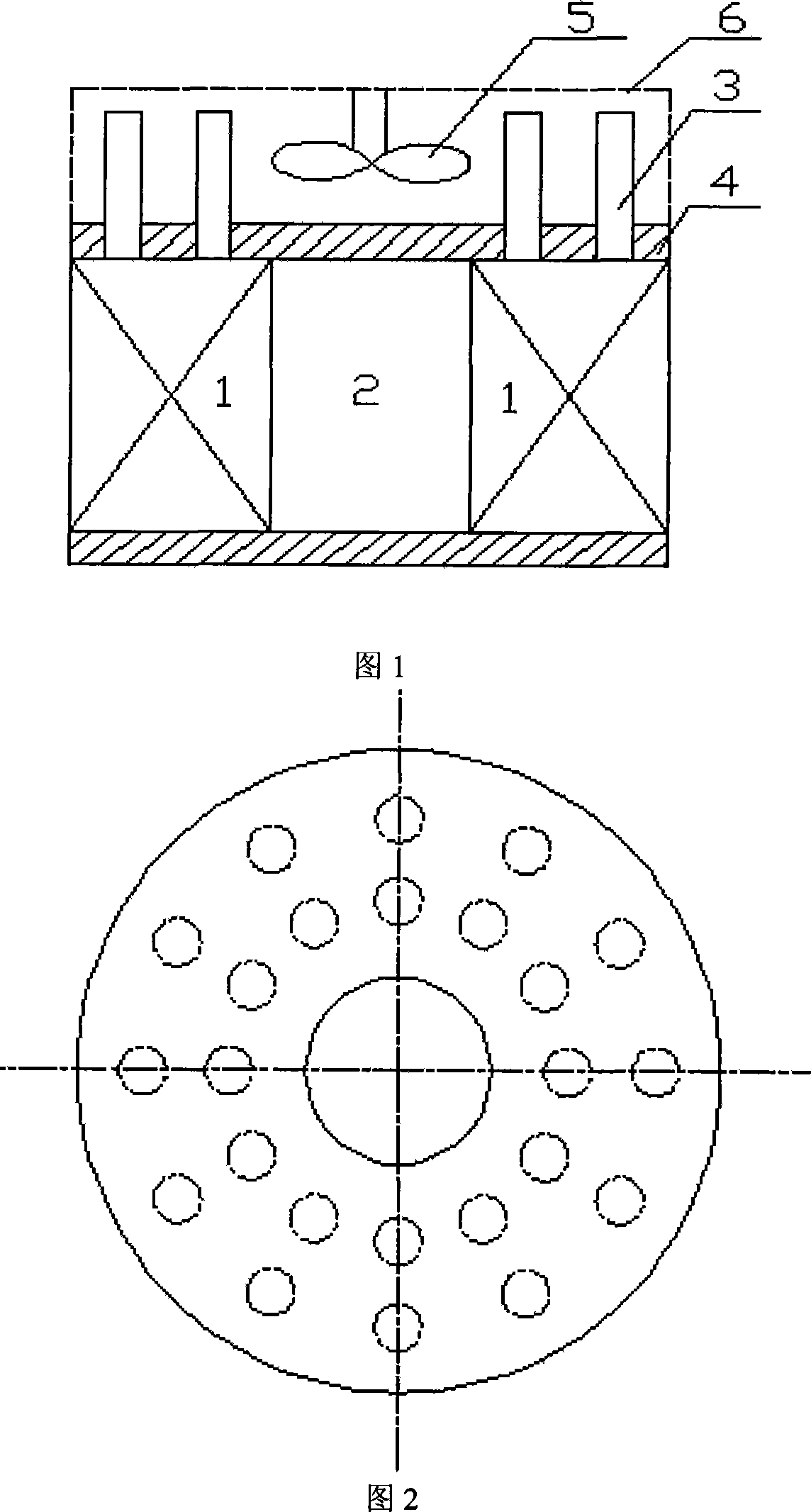

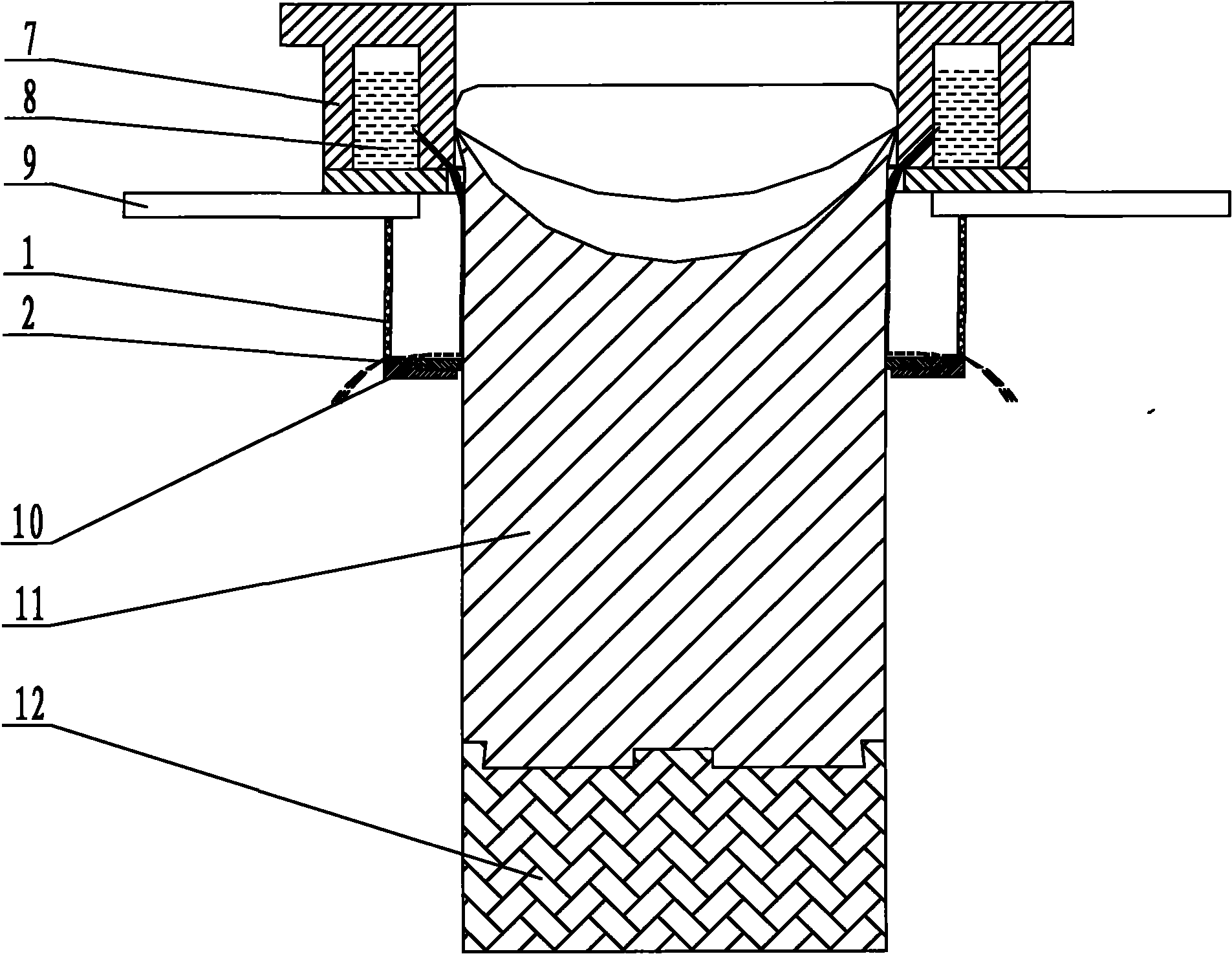

Sequential solidification technology device and method used in vacuum smelting equipment

The invention discloses a sequential solidification technology device and method used in vacuum smelting equipment. An induction heating coil is placed in a dead head section of an ingot die, and the feeding capacity of metal liquid in a dead head is enhanced through an induction heating method; a bottom cooling device with the cooling area smaller than the area of the cross section, at the bottom position of the ingot die, of a casting is arranged at the bottom of an ingot die base, the solid-liquid interface angle is reduced, and the metal liquid in the ingot die after pouring can be sequentially solidified from bottom to top. The solidification process control method is applicable to production of metal bar castings in the vacuum smelting equipment. Through the sequential solidification technology device and method, macroshrinkage and shrinkage porosity in alloy bar castings can be eliminated, the casting quality and the technology yield are improved, and the production efficiency is greatly improved.

Owner:BEIHANG UNIV

Large-size and high-strength super hard hollow billet and manufacturing method thereof

The invention relates to a hollow billet and a manufacturing method thereof, and especially relates to a large-size and high-strength super hard hollow billet and a manufacturing method thereof. The purpose of the invention is to solve the problems of low yield, large production workload and difficult process control of casting of aluminum alloy hollow ingots prepared in the prior art. The large-size and high-strength super hard hollow billet comprises Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, B and Al. The manufacturing method comprises the following steps: 1, weighing; 2, smelting; 3, refining and casting of melt; and 4, molding. The method is mainly used for manufacturing the large-size and high-strength super hard hollow billet.

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

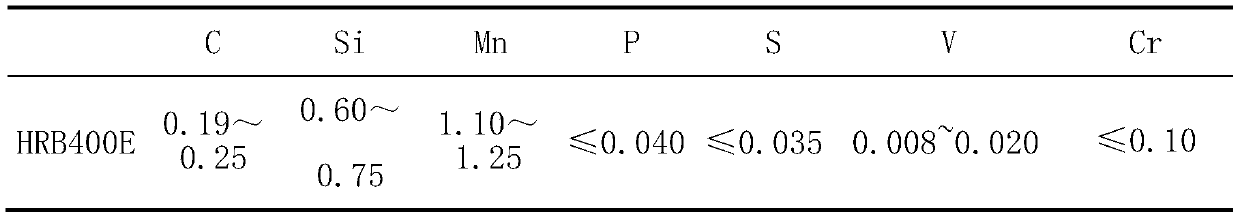

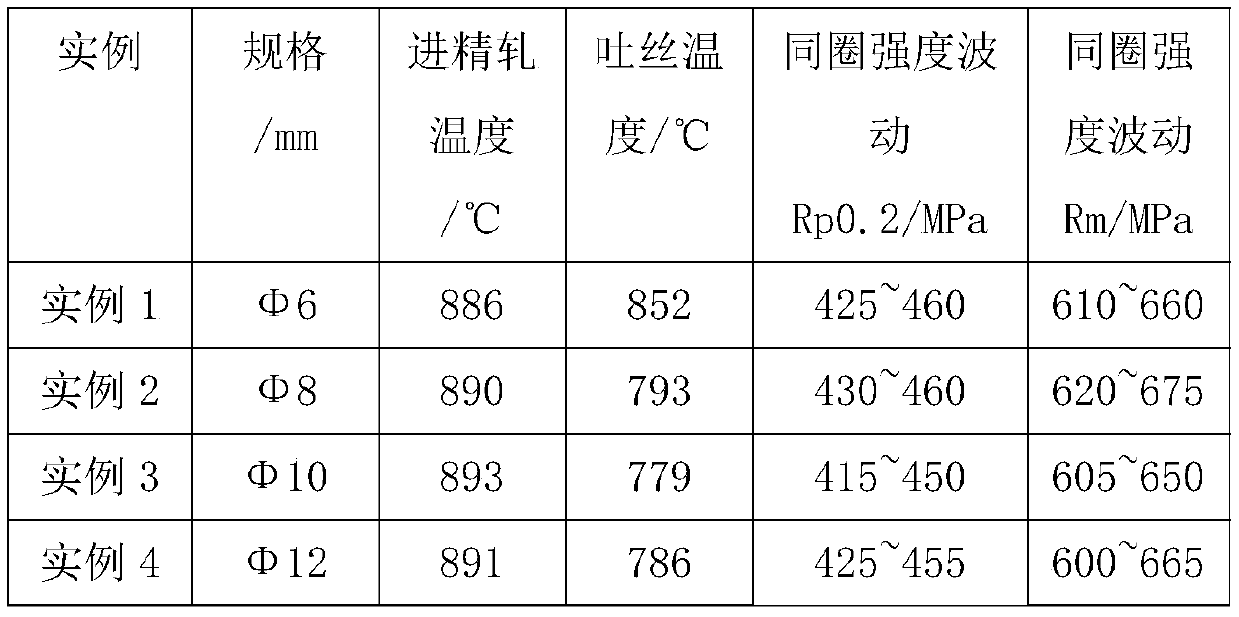

Method for controlling fluctuation of same-circle yield strength of HRB400E wire rod twisted steel and HRB400E wire rod twisted steel

ActiveCN111455281AReduce resistanceReduce finish rolling temperatureTemperature control deviceManufacturing convertersWire rodTemperature control

The invention provides a method for controlling the fluctuation of the same-circle yield strength of HRB400E wire rod twisted steel and the HRB400E wire rod twisted steel with small fluctuation difference of the same-circle yield strength. The method for control the fluctuation of the same-circle yield strength of the HRB400E wire rod twisted steel comprises the following steps that A, component control in a smelting stage is carried out; B, after smelting, controlled cooling equipment is used before finish rolling for controlling the finish rolling inlet temperature; and C, after finish rolling, the controlled cooling equipment is used for reducing the laying temperature, and the laying temperature is controlled to range from 765 DEG C to 865 DEG C. The HRB400E wire rod twisted steel withthe small fluctuation difference of the same-circle yield strength comprises the components of, in percentage by weight, 0.19 wt% - 0.25 wt% of C, 0.60 wt% - 0.75 wt% of Si, 1.10 wt% - 1.25 wt% of Mn, less than or equal to 0.040 wt% of P, less than or equal to 0.035 wt% of S, less than or equal to 0.035 wt% of S, 0.008 wt% - 0.020 wt% of V, and less than or equal to 0.10 wt% of Cr. According to the method for controlling the fluctuation of the same-circle yield strength of the HRB400E wire rod twisted steel, the fluctuation of the same-circle yield strength is controlled within 40 MPa.

Owner:LIUZHOU IRON & STEEL

Casting method for steel-copper compound cylinder

InactiveCN107199326AImprove corrosion resistanceImprove wear resistanceCylindersLiquid/solution decomposition chemical coatingMetal cylinderSurface finishing

A casting method for a steel-copper compound cylinder includes the steps of three dimensional modeling, casting technology design and technology simulation and optimization, steel base heat treatment, machining-tool machining and welding, steel base surface treatment, preheating treatment of the steel base before production, borax leaching, copper alloy smelting, pouring the copper alloy into the steel base, centrifugal treatment and cooling solidification to the room temperature, and obtaining the steel-copper compound cylinder. The casting method solves the difficult problems of compound casting technology and compound material elements of the steel-copper cylinder; and the compound strength of the bi-metal cylinder is high, the rate of finished products is high, the cost is low, the size of cylinders is not limited, the molding process is easy to control, and the quality is stable.

Owner:安徽恒利增材制造科技有限公司

Rust-resistant hot rolled ribbed bar and production process thereof

The invention discloses a rust-resistant hot rolled ribbed bar and a production process thereof. The chemical components of the ribbed bar comprise C, Si, Mn, V, Cr, P and S, wherein the percentages by weight of the chemical components are as follows: 0.20-0.25% of C, 0.40-0.60% of Si, 0.90-1.10% of Mn, 0.010-0.020% of V, 0.15-0.25% of Cr, not larger than 0.042% of P, not larger than 0.040% of S and the balance of iron and unavoidable impurities. The production process mainly comprises the following steps: (1) preparation of blast furnace molten iron; (2) top-blown converter smelting; (3) LF furnace molten steel refining; (4) continuous casting; (5) rolling steel production; (6) cooling treatment. The rust-resistant hot rolled ribbed bar disclosed by the invention has the advantages that the chemical components of the ribbed bar are optimized, the addition amount of alloy elements is adjusted, the alloy cost is greatly reduced, the rolled cooling strength is reduced, the mechanical properties of the bar are guaranteed, damage of the strong water penetration cooling process on iron oxide coating on the surface of the ribbed bar after rolling is avoided as well, and the rust resistance of the ribbed bar is guaranteed.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

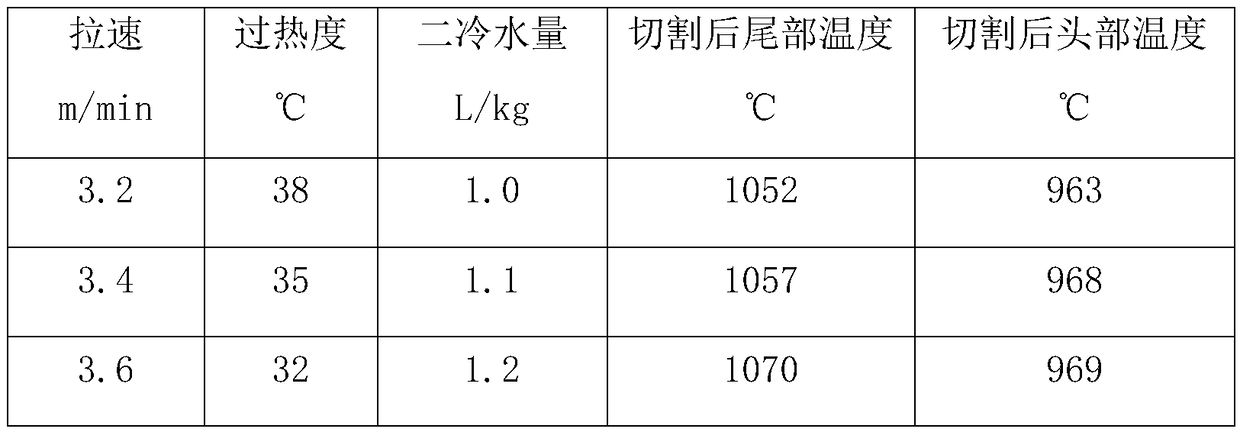

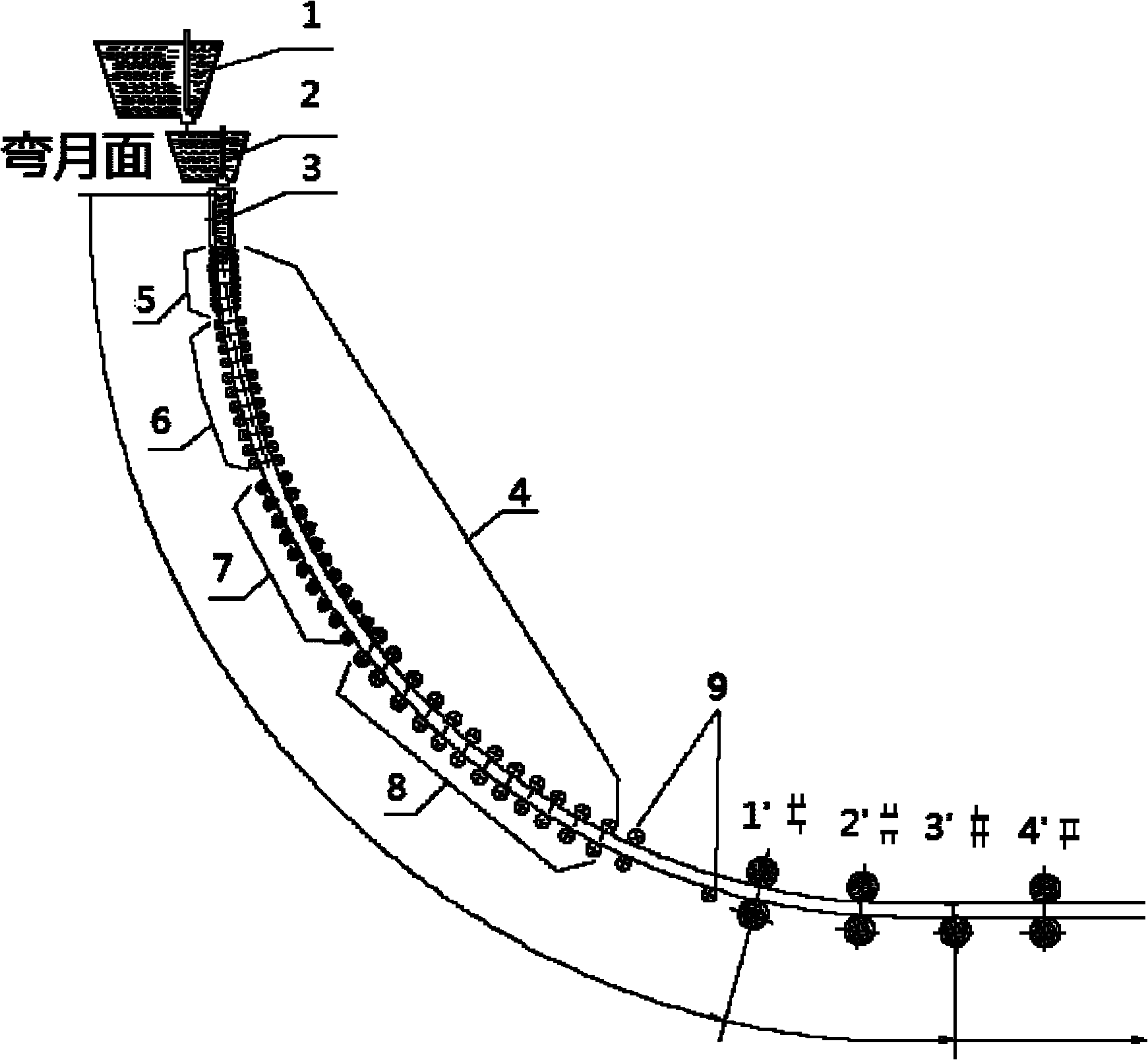

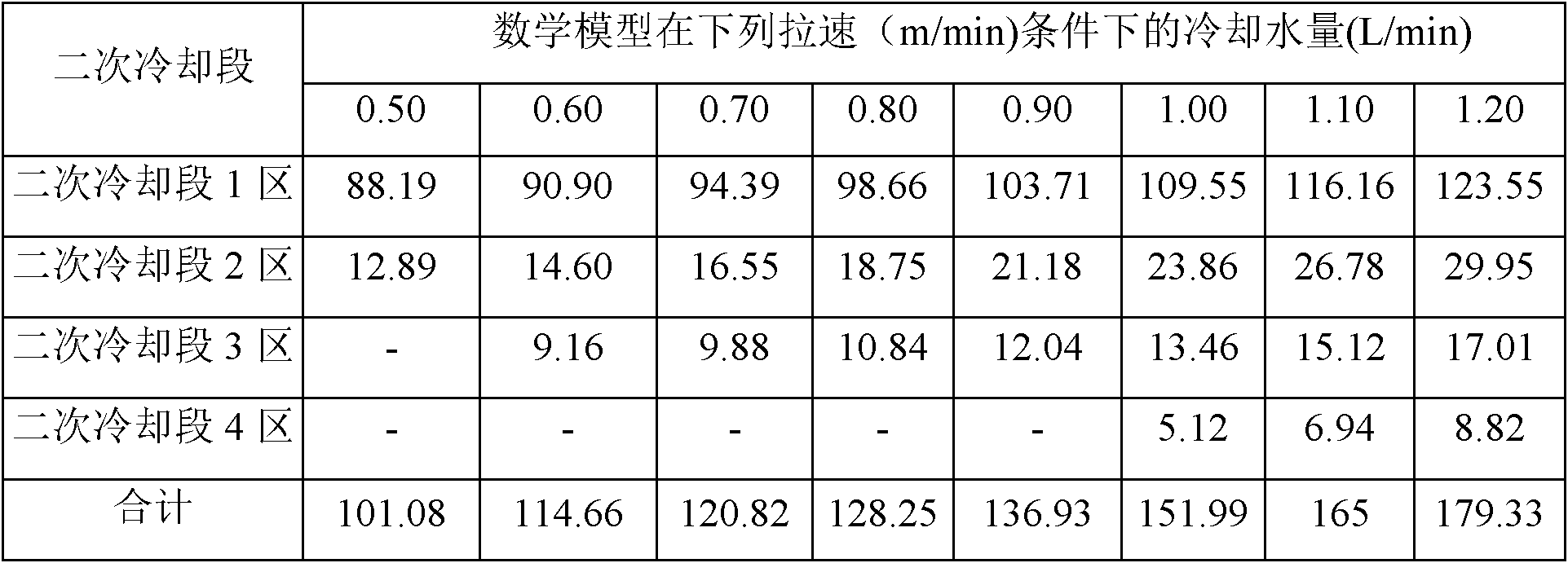

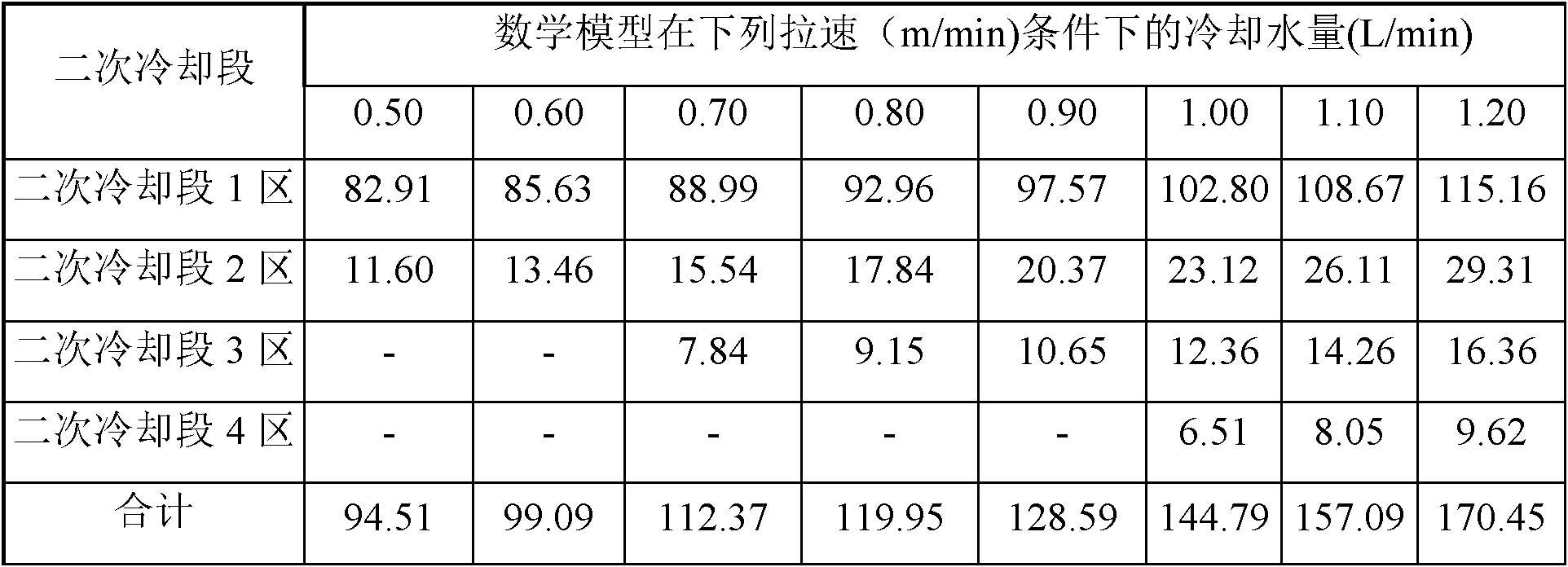

High casting speed continuous casting method of small billet directly rolled from long product

InactiveCN109465412AIncrease pulling speedIncrease the surface temperature of the slabSteelmakingTemperature control

A high casting speed continuous casting method of a small billet directly rolled from a long product belongs to the technical field of steelmaking and continuous casting. The specific steps and parameters of the method are as follows: the cross section size of the small billet involved in the method is 130mm*130mm-160mm*160mm, the basic circular arc radius range of a continuous casting machine is8-11m; the casting speed of the continuous casting machine is controlled; [P] less than or equal to 0.0250wt% in steel is controlled; the molten steel temperature and the superheat degree of a tundish, the cooling water flow of a crystallizer are controlled, and secondary cooling adopts automatic water distribution, and the like; and the temperature of a casting blank is controlled after the casting blank is cut so as to complete the method. The method has the advantages of meeting the requirement of a direct rolling process through temperature control of the casting blank, effectively reducing the production cost, and laying a foundation for the successful application of the long product direct rolling technology in industrial production.

Owner:SHOUGANG CORPORATION

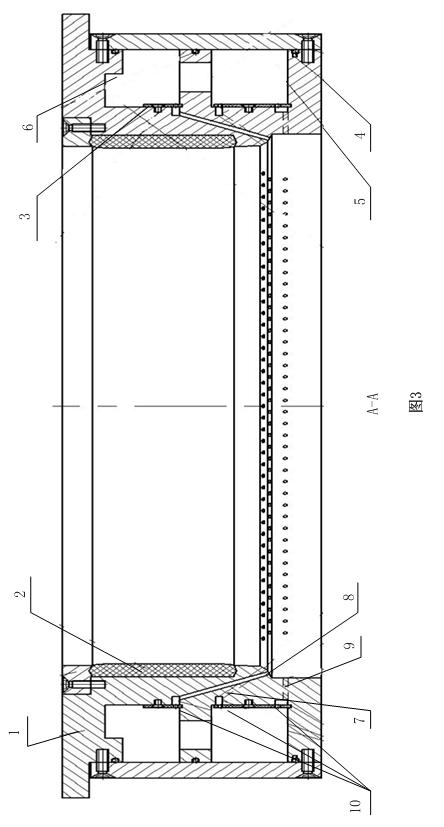

Heat pipe type electromagnetic deironing device

InactiveCN101147890ALow running costHigh operating costsTransformers/inductances coolingMagnetic separationEvaporationElectromagnetic shielding

The present invention relates to an electromagnetic iron-removing device extensively used in the mine, electric power and coal industry, in particular, it relates to a heat-piper type electromagnetic iron-removing device. It includes the following several portions: circular ring hollow cavity for placing electromagnetic coil, heat-pipe evaporation stage, magnetic core, heat-pipe condensation stage, working medium and intermediate partion board. Said invention also provides its working principle and its concrete operation method.

Owner:JIANGSU UNIV

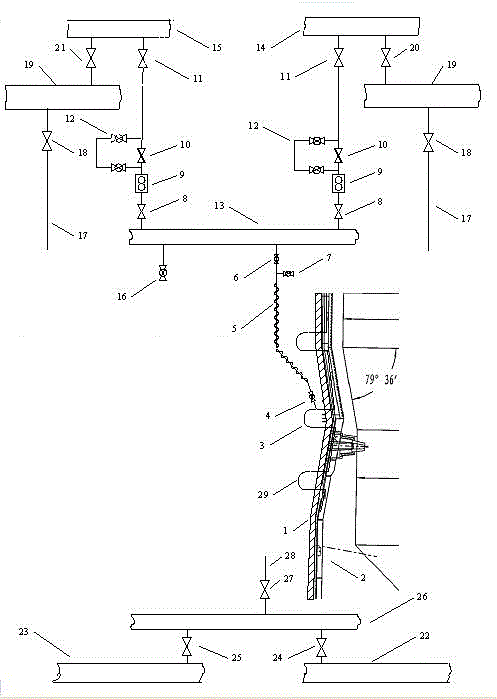

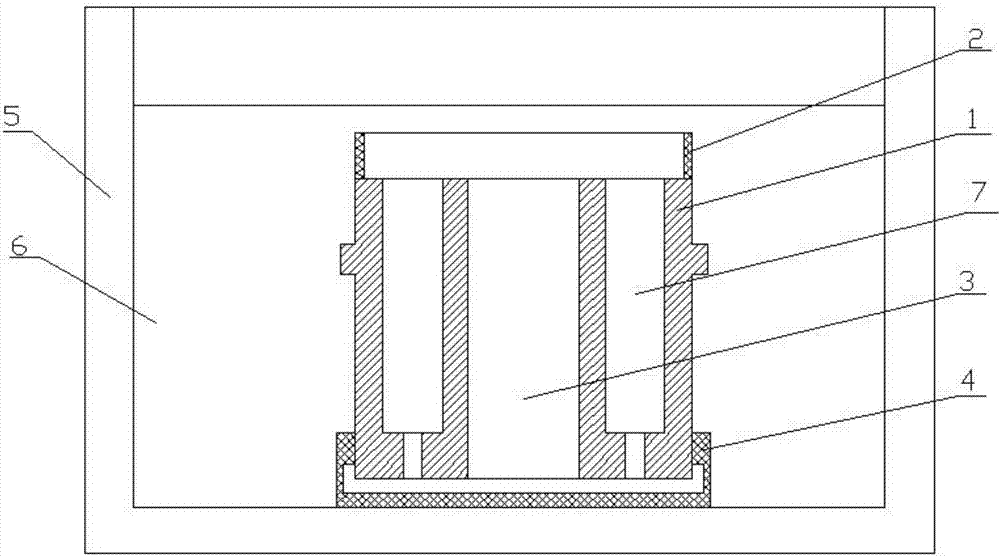

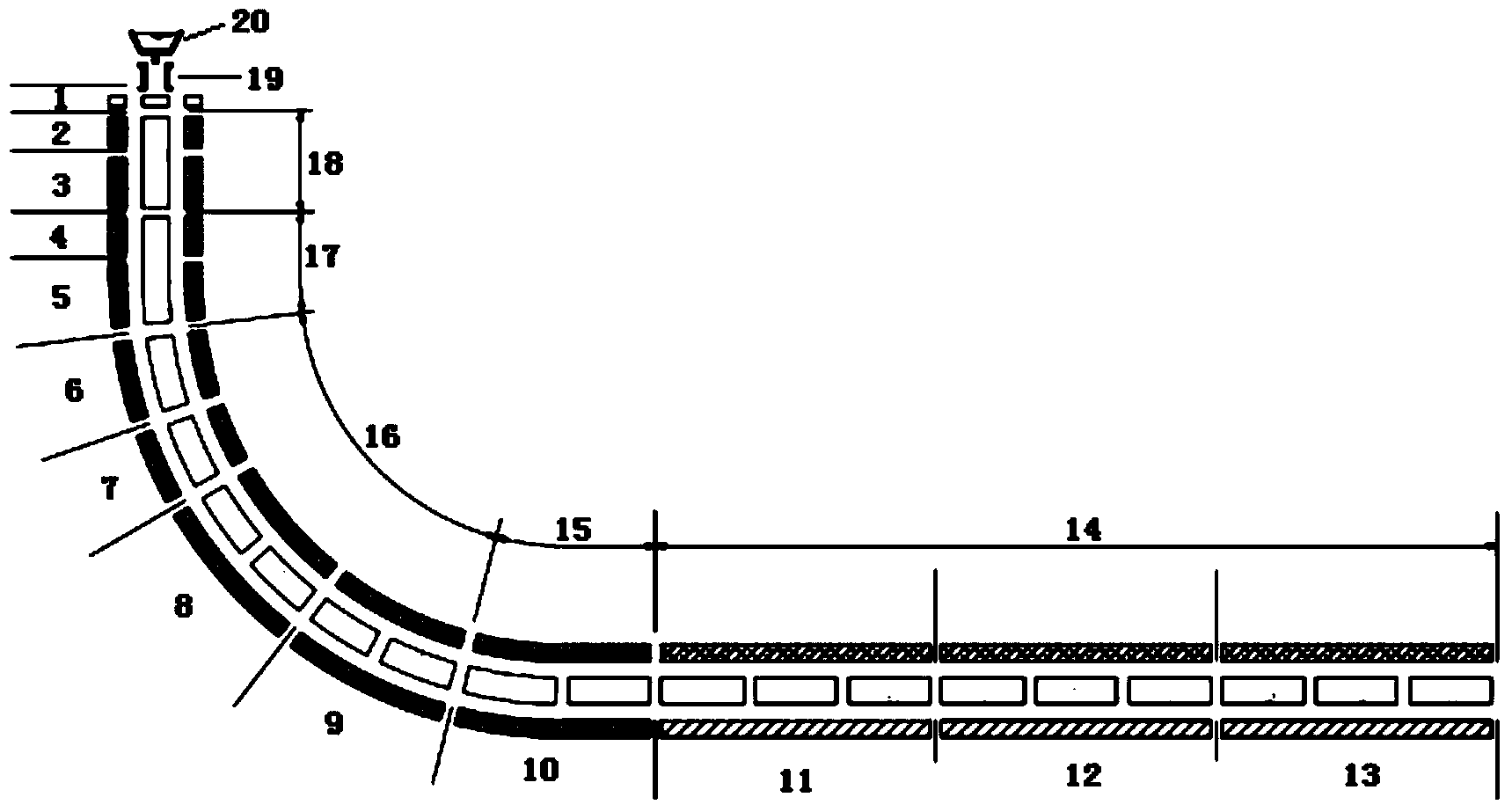

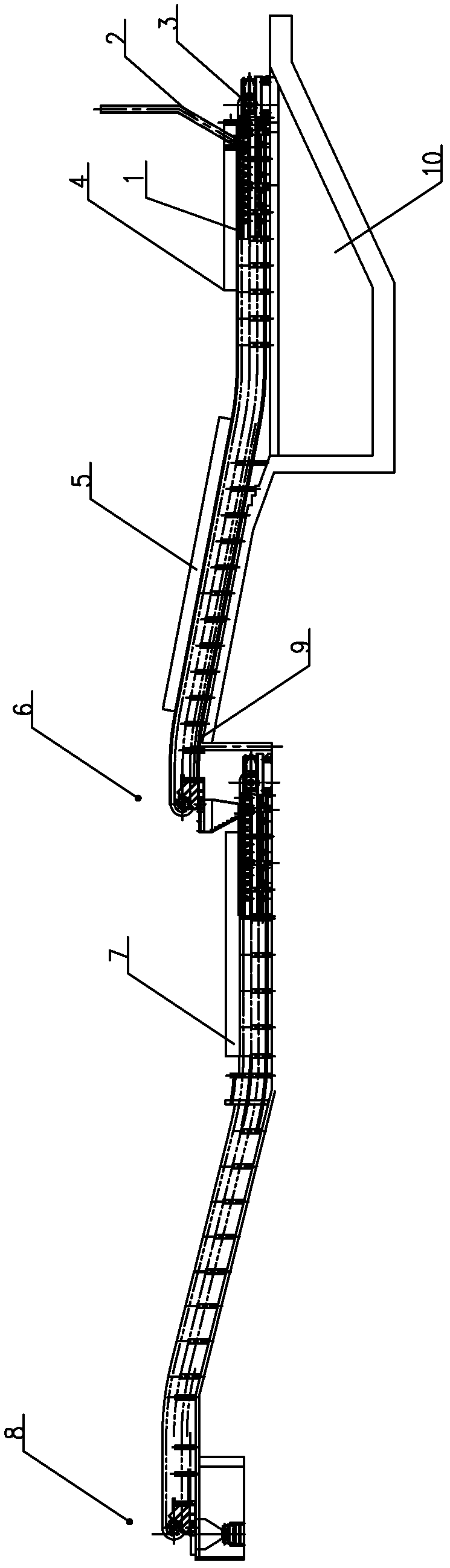

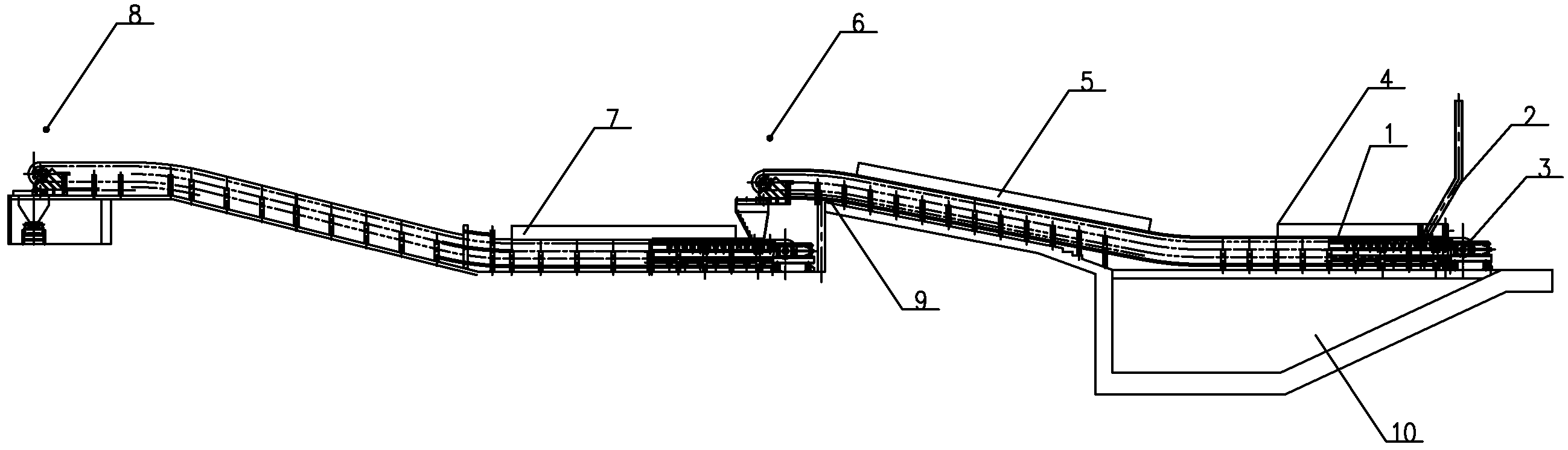

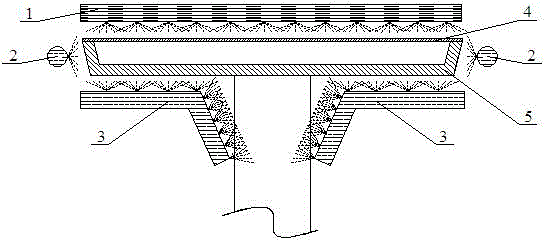

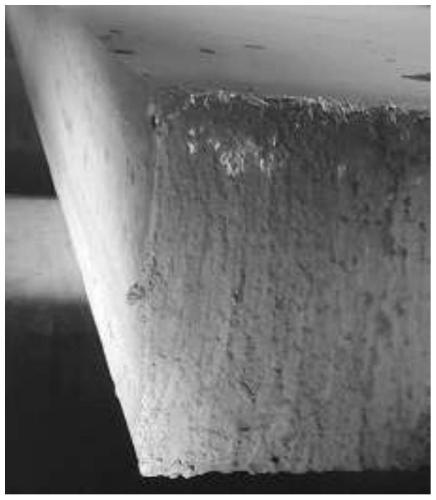

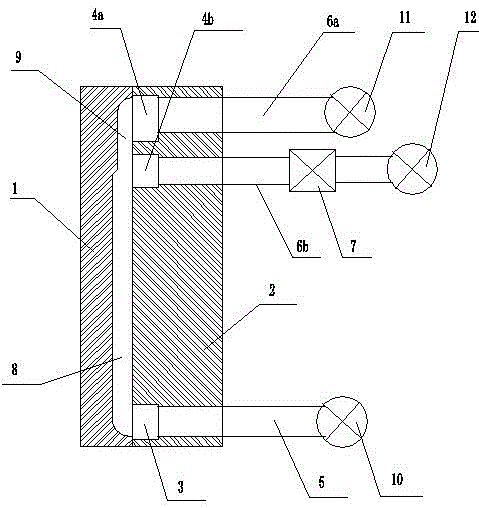

Secondary-cooling water starting method for reducing head-slab scrap rate of extra-thick slab

ActiveCN103894574AReduce cooling intensityReduce the probability of rejectionThermoplasticSteelmaking

The invention discloses a secondary-cooling water starting method for reducing the head-slab scrap rate of an extra-thick slab and belongs to the technical field of steelmaking and continuous casting. The thickness specification range of the applicable continuous casting slab ranges from 300 to 600mm while the width specification range of the same ranges from 1600 to 3000mm. The secondary-cooling water starting method includes that after continuous casting is started and a slab head enters from a first secondary cooling zone (1) to a fifth secondary cooling zone (5) during secondary cooling, a traditional secondary-cooling water starting mode is adopted, namely starting secondary-cooling water the moment when the slab head enters the starting position of the zone; after the slab head enters a sixth secondary cooling zone (6) and enters the starting position in the zone, water of the zone is not started immediately; when the slab head moves forward for 1 to 5 meters in the zone, the secondary-cooling water in the zone is started; the distance between the starting position of the sixth secondary cooling zone (6) and the upper opening of a crystallizer is from 7 to 10 meters, and a seventh secondary cooling zone (7) to a fourteenth secondary cooling zone (14) and the sixth secondary cooling zone (6) adopt the same mode to start the secondary-cooling water. By the secondary-cooling water starting method, cooling intensity of the head slab can be reduced, straightening temperature and high-temperature thermoplastic can be improved, and the scrap rate of the head slab due to generation of transverse cracks on the surface of the head slab can be reduced. The secondary-cooling water starting method has the advantages that the process is easy to implement.

Owner:SHOUGANG CORPORATION

Continuous-casting protection slag for CAS treated ship plate structural steel

The invention relates to continuous-casting protection slag for CAS treated ship plate structural steel. The protection slag is composed of, by weight, 30 percent to 39 percent of CaO, 24 percent to 33 percent of SiO2, six percent to 13 percent of Na2O, five percent to 9.5 percent of F, 0.9 percent to 1.9 percent of optimized elemental carbon, three percent to six percent of Al2O3, three percent to eight percent of MgO, 0.7 percent to 1.6 percent of Li2O, and 3.0 percent to 5.0 percent of Fe2O3. The viscosity of the slag is controlled between 0.07 Pa S and 0.08 Pa S. According to the physical properties of the continuous-casting protection slag, the melting point is 1020 DEG C to 1090 DEG C, the viscosity is 0.07 Pa S and 0.08 Pa S (1300 DEG C), CaO / SiO2 is 1.1 to 1.3, and H2O is smaller than or equal to 0.5 percent. According to the slag, the melting point of the slag can be reduced, the alkalinity can be improved, the unit consumption of the protection slag can be improved, the viscosity of the protection slag can be reduced, and therefore in the continuous casting process, the melting speed and the flowing-in speed are stably and dynamically balanced, and therefore lubrication of a primary blank shell of an inner plate blank of a crystallizer is ensured, and the aim of stable and smooth production of the CAS treated ship plate steel is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Direct reduction iron cooling device

InactiveCN102586532AWell mixedAccurate and adjustable frequency conversion speed regulationHandling discharged materialSlagEngineering

The invention discloses a direct reduction iron cooling device which comprises high-temperature chain scraper conveyors, a first cooling section, a second cooling section and a third cooling section, wherein the first cooling section, the second cooling section and the third cooling section are arranged along the conveying direction and respectively provided with a flowmeter and a valve, and the water volume can be adjusted; and the high-temperature chain scraper conveyors are provided with infrared thermometers and can be adjusted according to a cooling condition. In the invention, two high-temperature chain scraper conveyors are arranged, so that reduction iron and water can be mutually agitated when the high-temperature chain scraper conveyors run, and the reduction iron and the water are more uniformly mixed; the tail parts of the two chain scraper conveyors are both provided with the infrared thermometers, and variable frequency speed regulation is adopted to the chain scraper conveyors; the three cooling sections are all provided with the flowmeters and water volume regulation devices, so that the whole cooling process can be controlled; the bottoms of the chain scraper conveyors are provided with water washing pipes, and when disintegrating slag accumulation appears, the water washing pipes are opened to wash the disintegrating slag into a slag bath for treatment.

Owner:SHAGANG GROUP +1

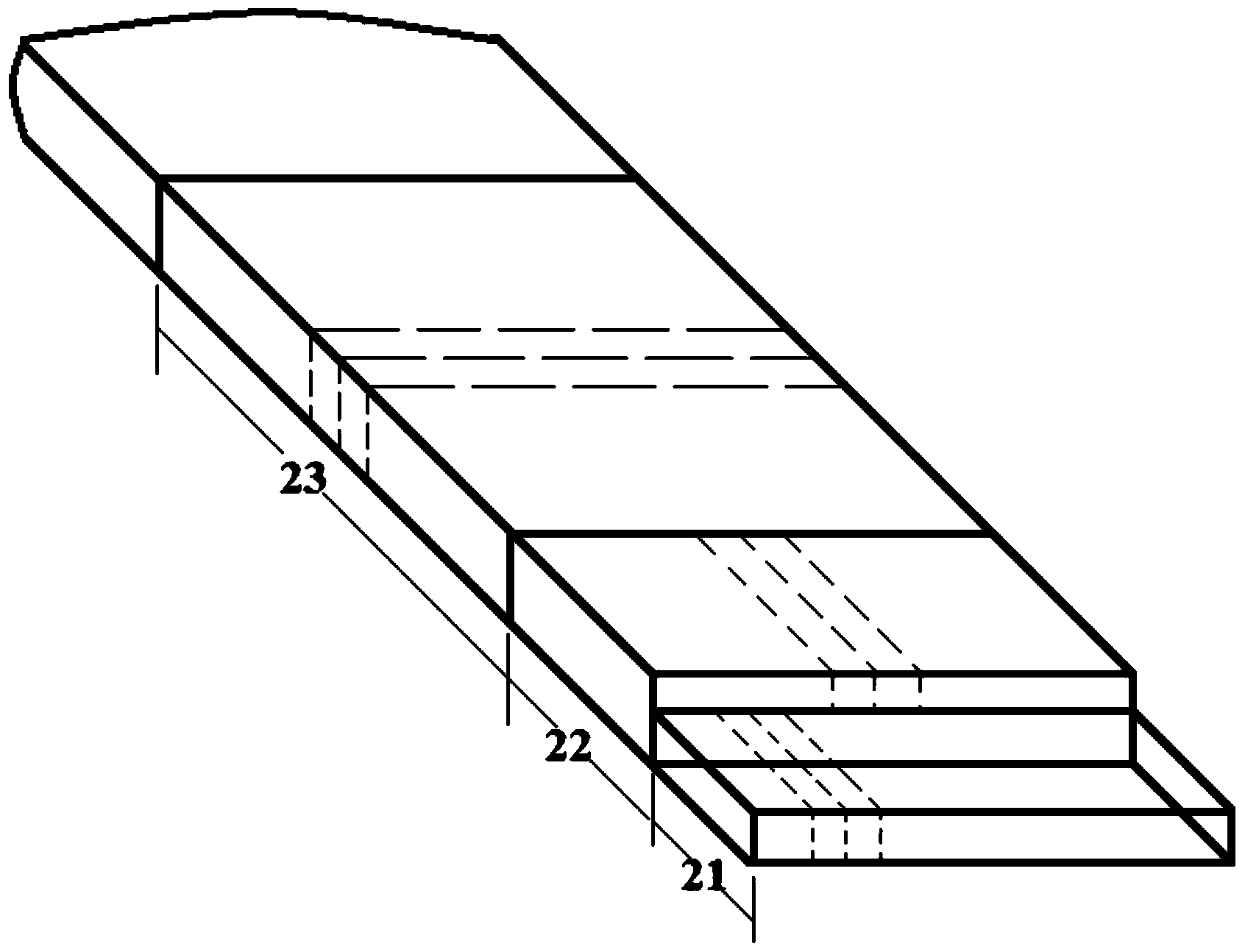

Manufacturing technology for continuously casting and rolling aluminum alloy plate strips

InactiveCN106077539AFlexible switchingIncrease cooling intensityMetal rolling arrangementsManufacturing technologySlag

The invention discloses a manufacturing technology for continuously casting and rolling aluminum alloy plate strips. The manufacturing technology comprises the steps of smelting, continuous casting and rolling and winding and specifically comprises the steps that dosing, fusing stirring, refining treatment, slag skimming, standing, grain refining treatment, degassing, filtering and slag removing are carried out to obtain an aluminum alloy solution; then the aluminum alloy solution is cast horizontally, enters a die cavity and is cooled to obtain a cast blank; the die cavity is formed in the manner that a steel strip closes the edge of a crystallization wheel groove, and the side faces of the periphery of the die cavity are uniformly covered with a plurality of nozzles used for spraying cooling water; after being straightened, the obtained cast blank is subjected to hot continuous rolling three times; and then shearing and winding are carried out to obtain the plate strips. The casting and cooling manners are improved, the structure property of the cast blank is improved greatly, the thickness of the cast blank can reach 38-45 mm, the width can reach 500-800 mm, the equipment investment is small, in the production process, alloys can be switched flexibly, equipment is small in loss and large in yield, the product quality is stable, and the production cost is low.

Owner:河南省圣昊新材料股份有限公司

Method for producing low-carbon Ni-Mo alloy steel by billet caster

InactiveCN106825463AReduce cooling intensityDoes not produce strong warmingTundishElectromagnetic stirring

A method for producing low-carbon Ni-Mo alloy steel by a billet caster belongs to the technical field of continuous casting in steelmaking. P in steel is controlled to < / =0.0140% with S to < / =0.0060%; temperature of molten steel in a tundish is controlled to 1540-1550 DEG C; flow of cooling water in a crystallizer is 100-150 m<3> / h; automatic water distribution is adopted for secondary cooling, under the specific water quantity of 0.8-1.2 L / kg; the crystallizer has electromagnetic stirring parameters, the frequency of 3-5 Hz and current of 250-350 A; casting speed of the billet cast is controlled to 2.3+ / -0.1 m / min, corner temperature of each blank is 900-1100 DEG C before entering a tension leveler; the blanks are cooled slowly after leaving a line. The method has the advantages that the method is reasonable and effective and basis is laid for the successful industrial production of low-carbon Ni-Mo alloy steel.

Owner:SHOUGANG CORPORATION

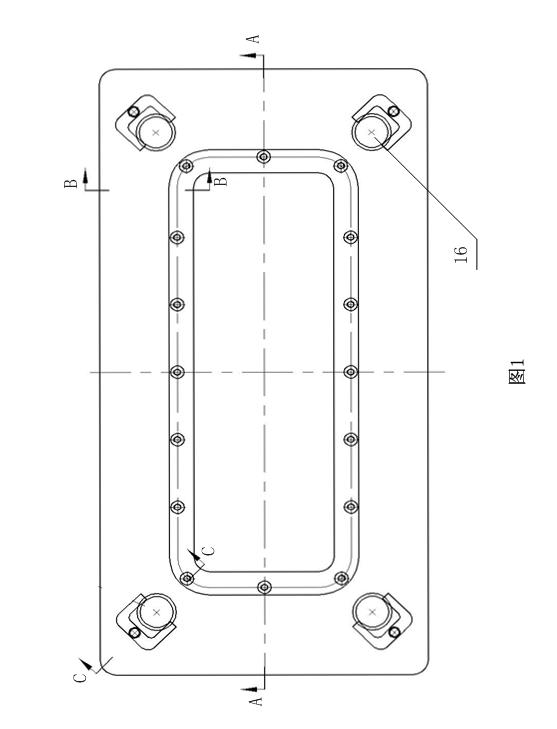

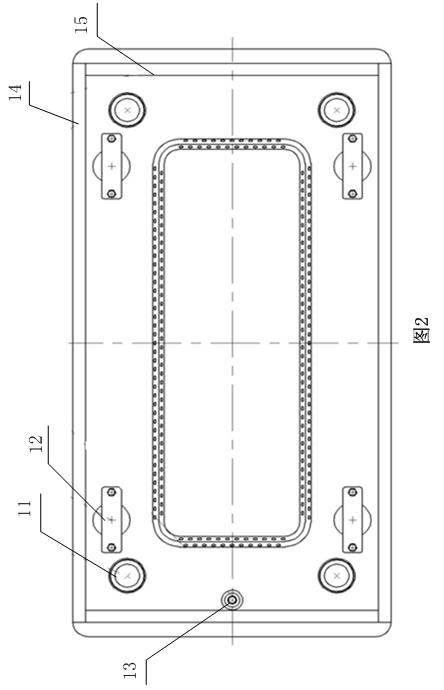

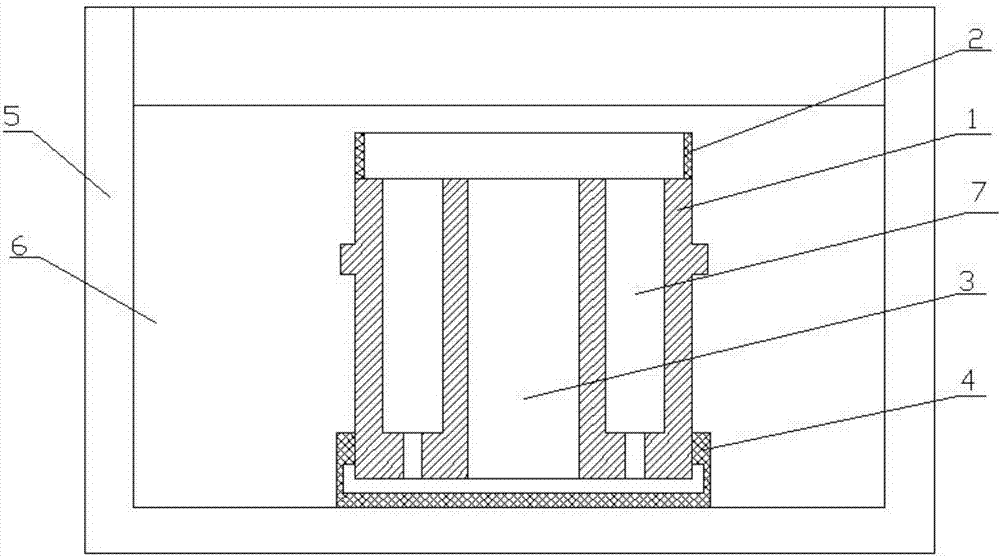

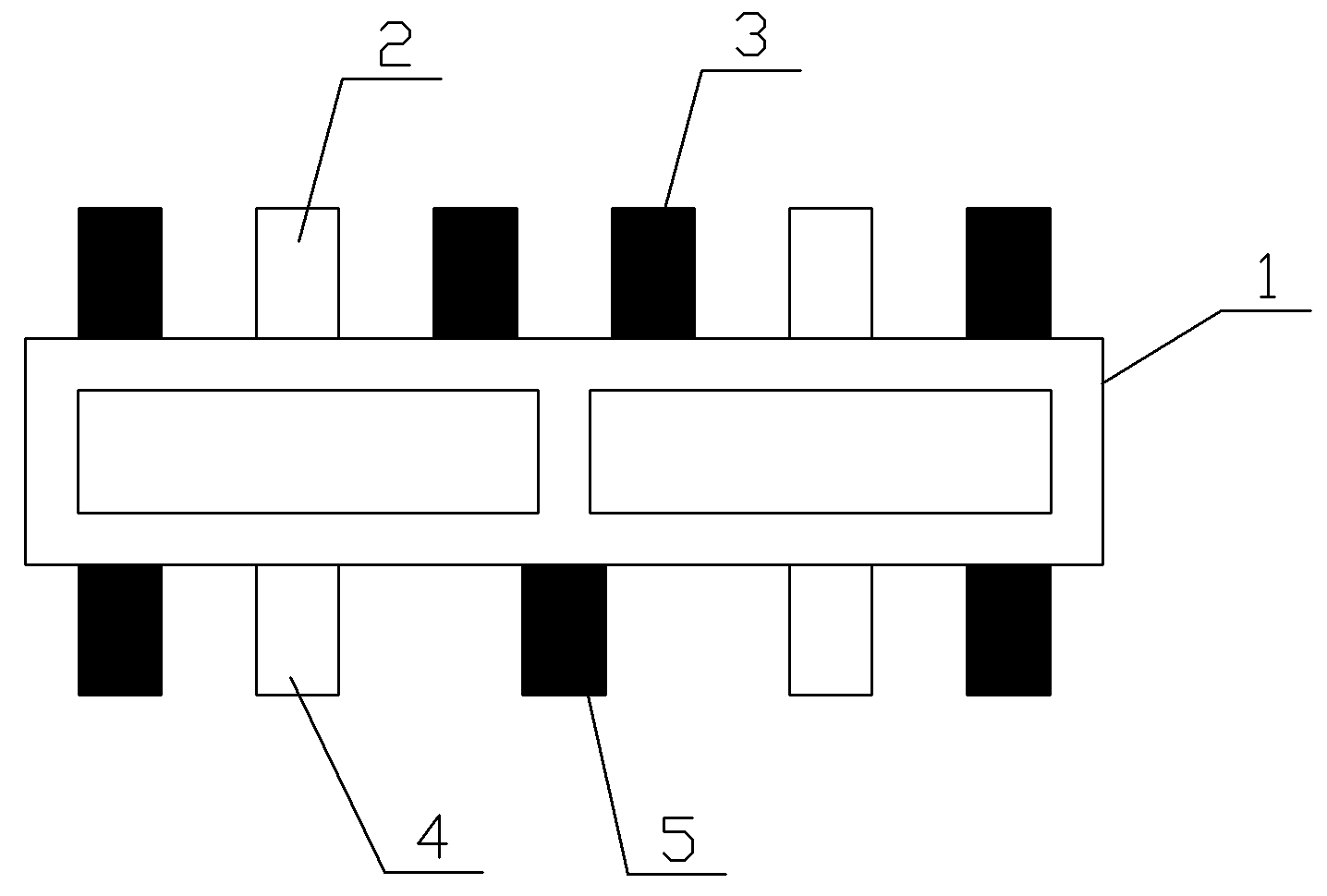

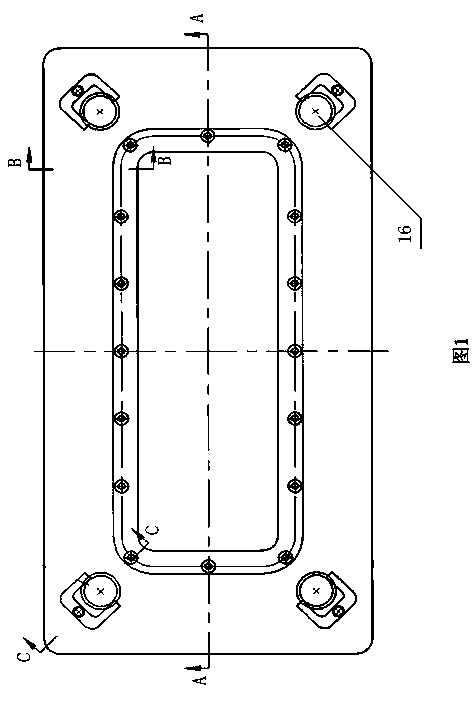

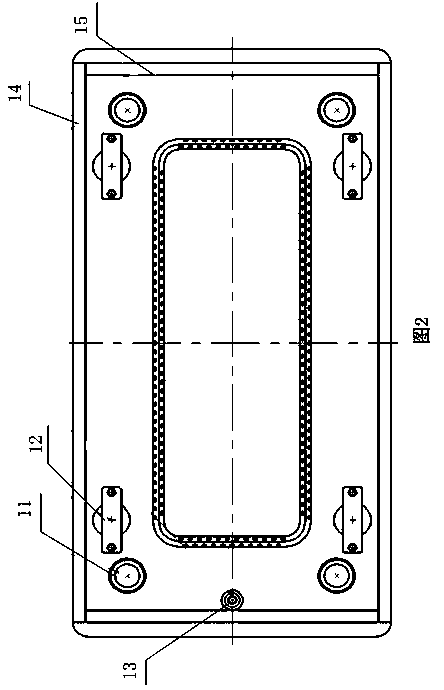

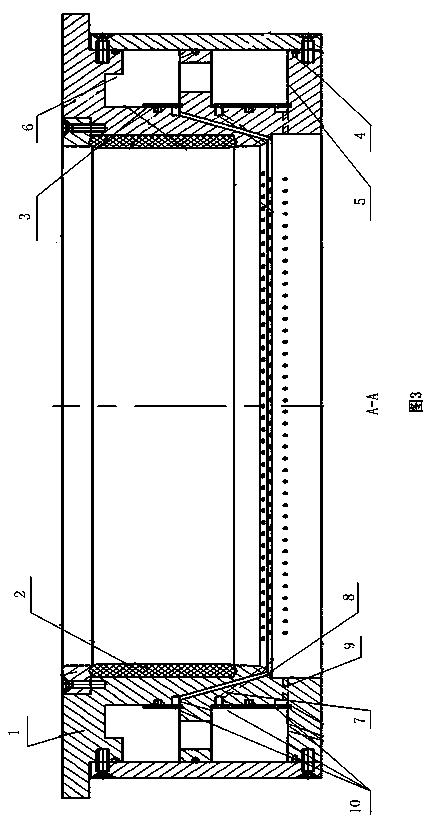

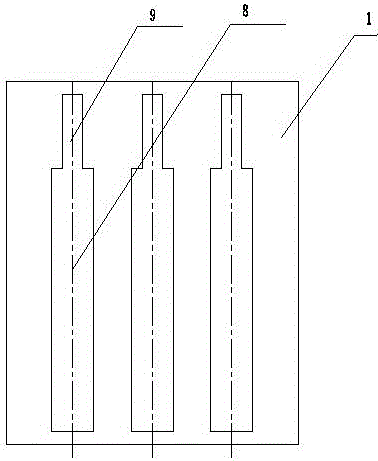

Crystallizer

The invention discloses a crystallizer, belonging to crystallizing devices, which structurally comprises a shell body of the crystallizer, wherein upper water outlets and upper water inlets are arranged on the upper part of the shell body of the crystallizer; lower water outlets and lower water inlets are arranged on the lower part of the shell body of the crystallizer; the upper water inlets and the lower water inlets are respectively two in quantity; the upper water inlets and the lower water inlets are symmetrically arranged; the amount of the upper water outlets is larger than the amount of the lower water outlets; and the lower water outlets and the lower water inlets are arranged in a staggered mode. Compared with the prior art, the crystallizer of the invention has the advantages that the temperature on the surface of cast ingots is reduced so that the tissues of the upper surfaces and the lower surfaces of the cast ingots are uniform; the cooling strength of a graphite plate on the crystallizer is enhanced, and the cooling strength on the lower surface of the crystallizer is reduced so that the upper and the lower cast ingots in the crystallizer can be simultaneously crystallized; the abrasion degree of the graphite plate on the lower surface of the crystallizer is improved to a certain extent; and the service life of the graphite plate is increased, and the like, therefore, the crystallizer has good popularization and application values.

Owner:CNMC ALBETTER ALBRONZE

Automatic adjusting system and method for water inflow flow speed of condenser cooling pipes

ActiveCN106017122AImprove heat exchange efficiencyAdjust cooling intensitySteam/vapor condensersEngineeringCooling pipe

The invention relates to an automatic adjusting system and method for the water inflow flow speed of condenser cooling pipes. The automatic adjusting system for the water inflow flow speed of the condenser cooling pipes comprises a condenser assembly, an adjusting assembly and a control device. The condenser assembly comprises a condenser shell, the multiple cooling pipes and a pipe plate. The condenser shell is provided with a water inlet chamber. The adjusting assembly comprises partition plates and a baffle capable of rotating by itself. The partition plates are arranged in the water inlet chamber and include the first partition plate and the second partition plate which are fixed to the outer side of the pipe plate in a spaced manner. The baffle is arranged between the first partition plate and the second partition plate and provided with a first matching part and a second matching part which are symmetrically arranged. The control device comprises a power mechanism. The output end of the power mechanism is fixedly connected with the baffle. The control device controls rotation of the baffle through the power mechanism. According to the automatic adjusting system and method for the water inflow flow speed of the condenser cooling pipes, the heat exchange efficiency of the condenser and equipment running safety can be improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Cooling method of square and round billet continuous casting billet during tundish replacement

The invention discloses a cooling method of square and round billet continuous casting billet during tundish replacement. The cooling method of square and round billet continuous casting billet during the tundish replacement comprises the following steps: during the tundish replacement, a crystallizer is stopped; continuous casting billets which are remained on a secondary cooling section are cooled for 0.5 to 1.5 minutes by using 75% to 85% cooling water of all zones of the secondary cooling section before the crystallizer is stopped; cooling is stopped until the tundish replacement is stopped, the crystallizer is started, and the continuous casting billets are cooled according to the cooling water required by steel grades after the tundish replacement. The cooling method of square and round billet continuous casting billet during the tundish replacement can effectively reduce casting billet cooling intensity during the tundisn replacement and avoid failing of the tundish replacement due to the fact that the casting billets are too cold on the secondary cooling section and pouring can not be achieved, and meanwhile, the cooling method of square and round billet continuous casting billet during the tundish replacement can ensure successful tundish replacement, and can be widely applied to the square and round billet arc-shaped continuous casting machine tundish replacement pouring field.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for producing stainless steel slab by radian chamfer crystallizer continuous casting machine

The invention discloses a method for producing a stainless steel slab by a radian chamfer crystallizer continuous casting machine. The method comprises the steps of molten iron dephosphorization, TSRfurnace smelting, LF refining and continuous casting; and according to the continuous casting process, the radius R of a chamfer arc of a crystallizer is 80-82 degrees, the diameter width of the chamfer arc is 39-40 mm, the flow rate of cooling water in a copper plate water tank of the chamfer crystallizer is 7.9-8.2 m / min, the water quantity of the narrow surface of the chamfer crystallizer is 450-550 L / min, and the water quantity of the wide surface is 3800-4200 L / min. Compared with the prior art, the method adopts molten iron pre-dephosphorization and TSR furnace desulfurization process, the soft blowing and calming time is prolonged by an LF furnace, low oxygen, low phosphorus and low sulfur are realized, and inclusions are controlled; cooling parameters of the crystallizer and a fan-shaped section are designed to adopt a conventional pressing mode and electromagnetic stirring so as to slow down the corner cooling strength of a casting blank and eliminate corner cracks and sharp corners; the edge loss phenomenon of a hemmed part of hot rolled steel is avoided; and therefore, the depth and the width of a slit line of a steel coil product are reduced, the product quality is improved, and the economic benefits are greatly improved.

Owner:SHANDONG TAISHAN STEEL GROUP

Wide slab longitudinal crack control process

InactiveCN111761039ASuitable for production conditionsReduce cooling intensityCrazingManganese sulfide

The invention discloses a wide slab longitudinal crack control process, and relates to the technical field of continuous casting processes. The manganese-sulfur ratio is improved by reducing the massfraction of sulfur, manganese and the sulfur are combined to generate manganese sulfide, and the manganese sulfide is a plastic inclusion so that the sensitivity of cracks can be effectively reduced;high-alkalinity casting powder has lower heat-conducting property and higher crystallization rate so that the defect of surface cracks a cast slab caused by peritectic reaction can be effectively overcome; the cooling intensity of a crystallizer is properly reduced so that the cooling non-uniformity can be effectively relieved, and then a uniform slab shell is obtained; and the overall taper of the crystallizer is set in a proper interval, so that serious abrasion of a slab shell and a copper plate caused by the too large overall taper is avoided, the situation that the two side faces of the cast slab are bulged due to the fact that an initial slab shell cannot be effectively supported due to the fact that a gap between the initial slab shell and the copper plate becomes large due to the too small overall taper is also avoided, and through the arrangement, the occurrence rate of longitudinal cracks can be greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

Crystallizer with changeable cooling intensity in semicontinuous casting of aluminum alloy

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Water baffle plate device suitable for aluminum alloy circular ingot half-continuous casting

The invention provides a water baffle plate device suitable for aluminum alloy circular ingot half-continuous casting, which comprises a clamping mechanism, a clamping ring and heat resistant rubber. A pair of handles is arranged at the rear end of the clamping mechanism, and a pair of clamping paws is arranged at the front end of the clamping mechanism; a semicircular clamping ring is arranged on each clamping paw; an annular groove is formed on the inner wall of each semicircular clamping ring; half annular heat resistant rubber is embedded into the annular groove of each semicircular clamping ring; the two half annular heat resistant rubbers are clamped opposite to form an integral circular loop; and a steel rope is chained on each semicircular clamping ring. When a water baffle plate is needed, the heat resistant rubber is jointed to the surface of the cast ingot by clamping the handle via a spring to baffle the dropping cooling water, and then the cooling strength of the cast ingot on the lower part of the water baffle plate is weakened; meanwhile, high-temperature melting body in a liquid cave on the upper part of the cast ingot reheats the cast ingot so as to achieve self-tempering effect of the cast ingot and effectively reduce the inner casting stress; and the casting requirement of the aluminum alloy can be better met.

Owner:苏州有色金属研究院有限公司

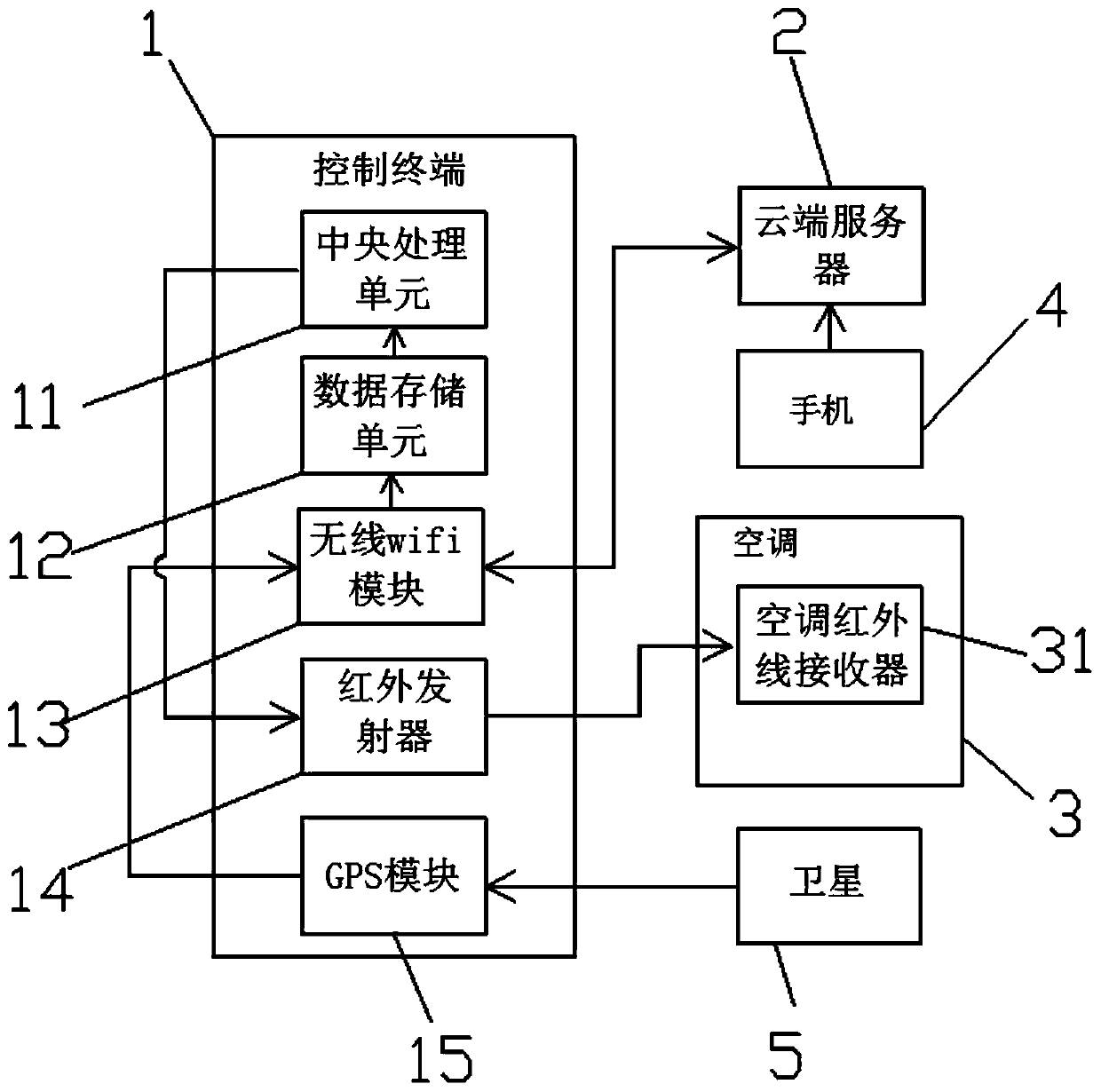

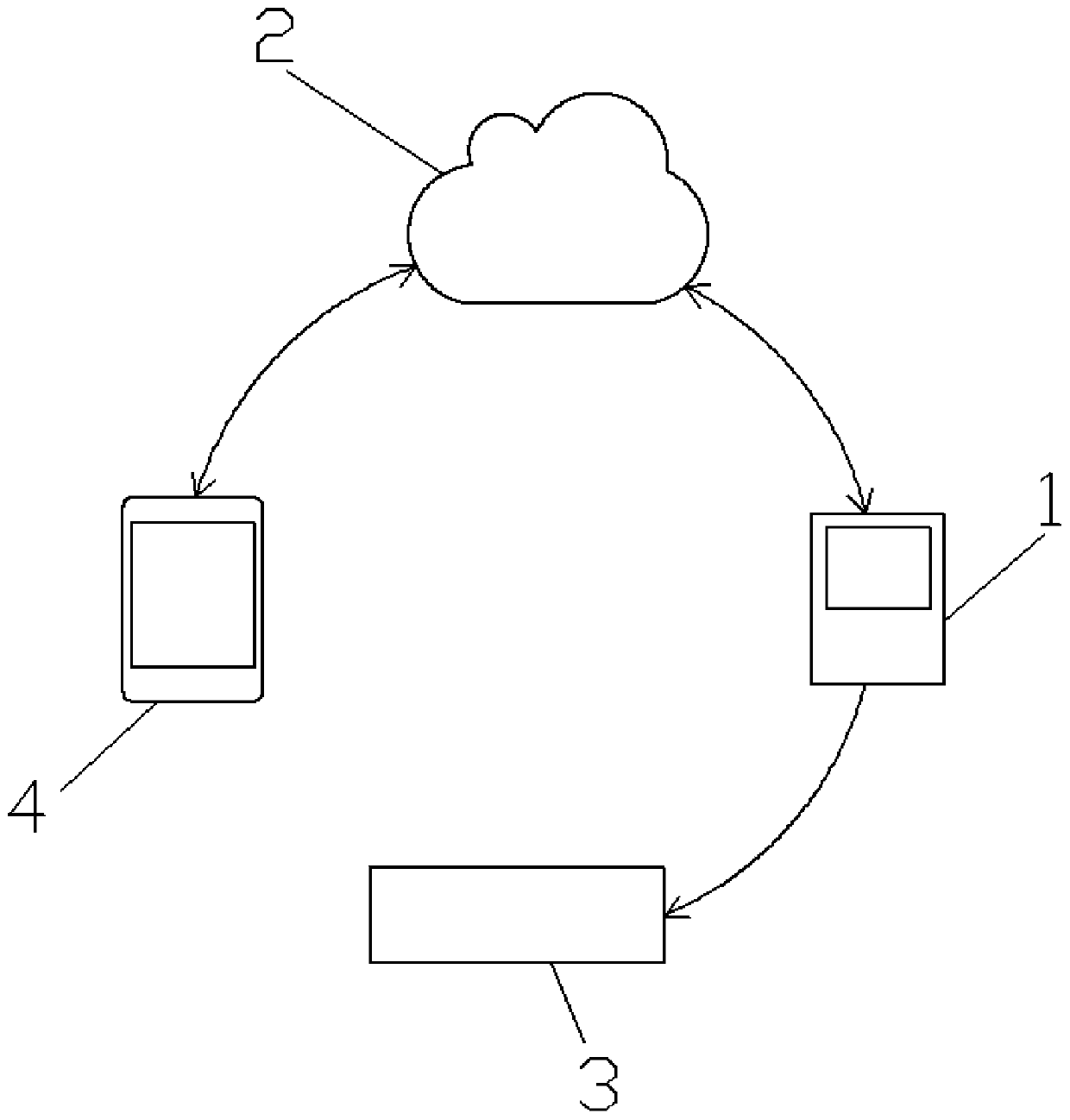

Central air conditioner cold and heat regulation system

InactiveCN110986303AReduce cooling intensityPlay the role of energy savingMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsThe Internet

The invention discloses a central air conditioner cold and heat regulation system and belongs to the technical field of air conditioners. According to the technical scheme, the central air conditionercold and heat regulation system is characterized by being provided with a control terminal; the control terminal can be connected with the internet through a wireless wifi module so as to be connected with a cloud server; a GPS module arranged in the control terminal uploads positioning data to the cloud server to obtain the real-time local indoor temperature, so that an air conditioner is regulated and controlled according to changes of outdoor temperature to realize intelligent cold and heat regulation; the control terminal can compare and analyze the real-time local temperature informationobtained from the cloud server with the air conditioner temperature value set before, controls the set temperature of the air conditioner to be raised correspondingly if the outdoor temperature is reduced and on the contrary, controls the set temperature of the air conditioner to be reduced; the central air conditioner cold and heat regulation system can carry out regulation according to requiredtemperature changes. When the air conditioner cannot provide a suitable temperature for sleepers at the set value in winter, the central air conditioner cold and heat regulation system controls the air conditioner to carry out heating and controls the air conditioner to reduce the cooling intensity when cooling is not required in summer.

Owner:邱煌庆

Crystallizer capable of preventing continuous casting slab defects

The invention discloses a crystallizer capable of preventing continuous casting slab defects and belongs to the technical field of crystallizers. The crystallizer capable of preventing the defects comprises a copper plate and a water tank, wherein the copper plate is provided with a cooling water tank, the water tank is provided with a water inlet chamber and a plurality of water outlet chambers, the cooling water tank is communicated with the water inlet chamber and the water outlet chambers, at least one of the plurality of the water outlet chambers is arranged in a meniscus area, and at least one is arranged below the meniscus area. The sectional area of the cooling water tank is decreased in the meniscus area, the water outlet chambers can be connected with a valve, the water flow of the meniscus area is adjusted by controlling the water flow, the cooling intensity of the meniscus area of the crystallizer is reduced, the shrinkage change amplitude of the meniscus area is reduced, formation and growth of continuous casting slabs are more uniform, cracks of the continuous casting slabs are effectively prevented or reduced, and the quality of the continuous casting slabs is improved.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com