Water baffle plate device suitable for aluminum alloy circular ingot half-continuous casting

A semi-continuous, aluminum alloy technology, used in the field of water baffle devices, can solve the problems of reducing the internal stress of the ingot, easy cracking, and large internal stress, and achieve the advantages of improving the yield of the ingot, long working life, and reducing the internal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

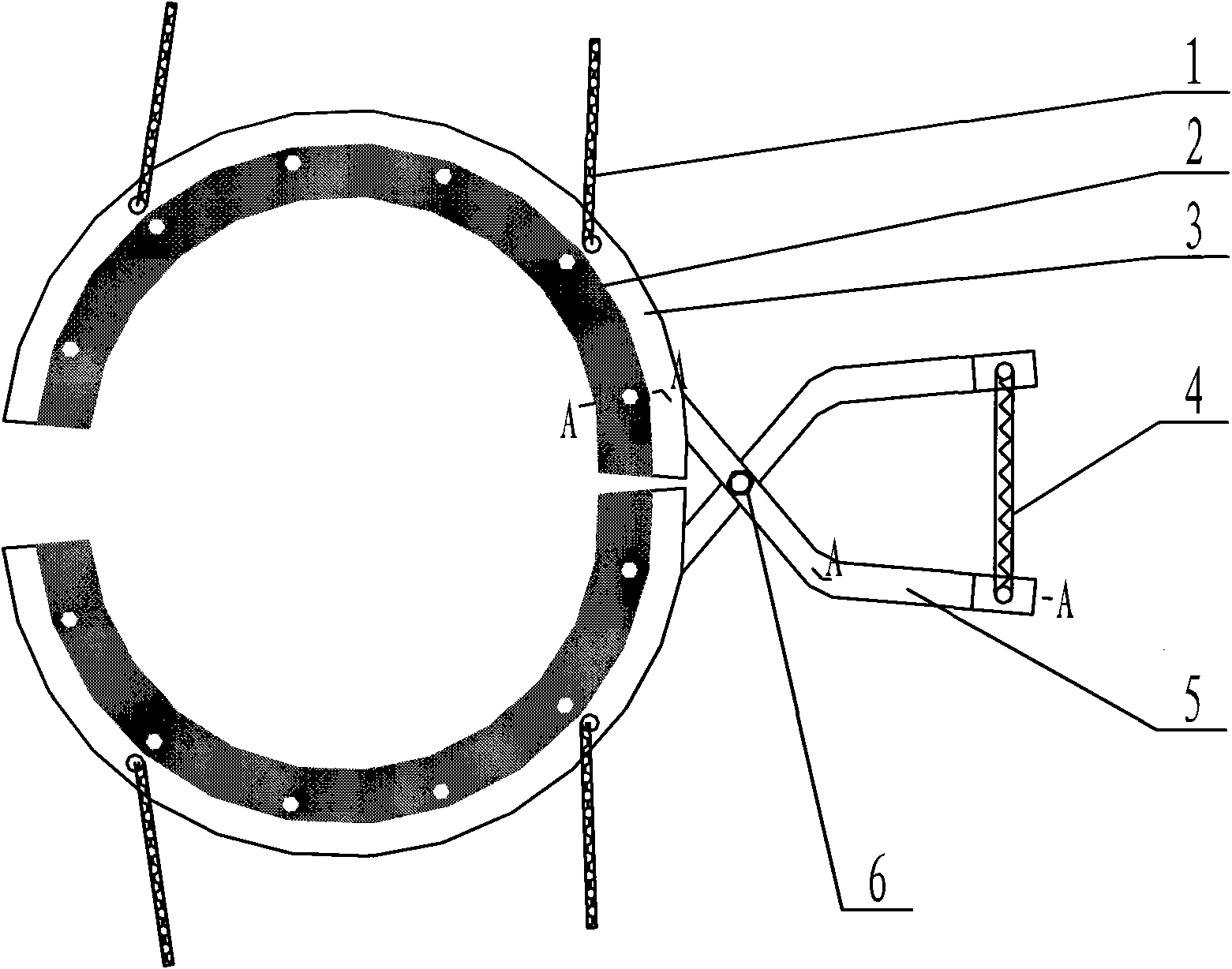

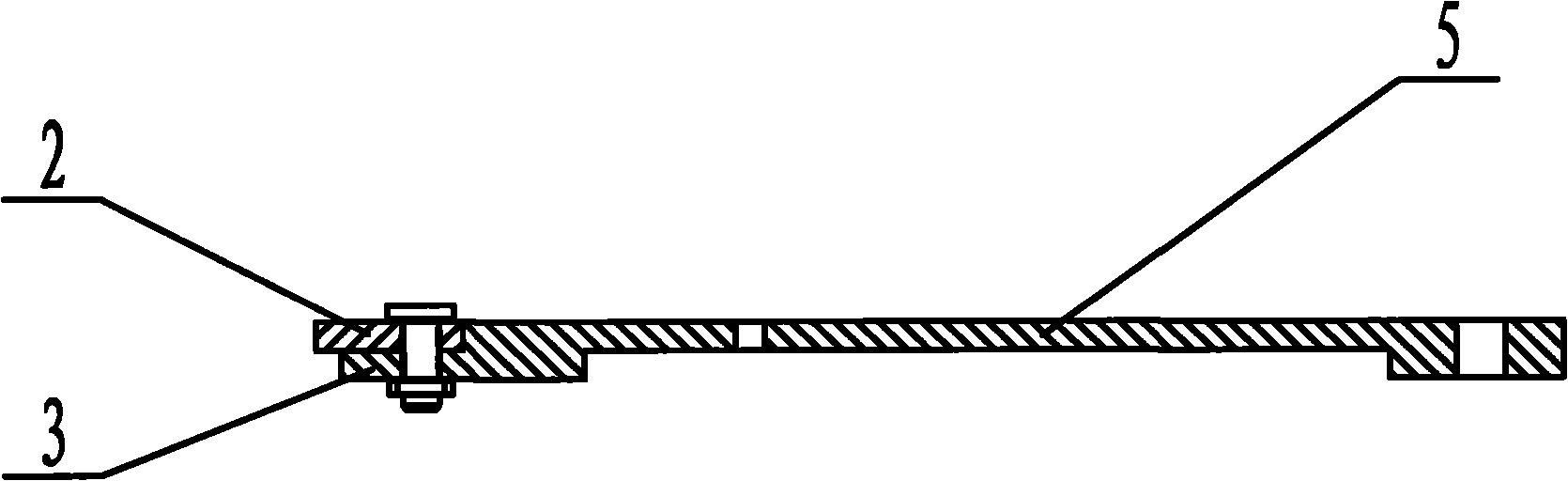

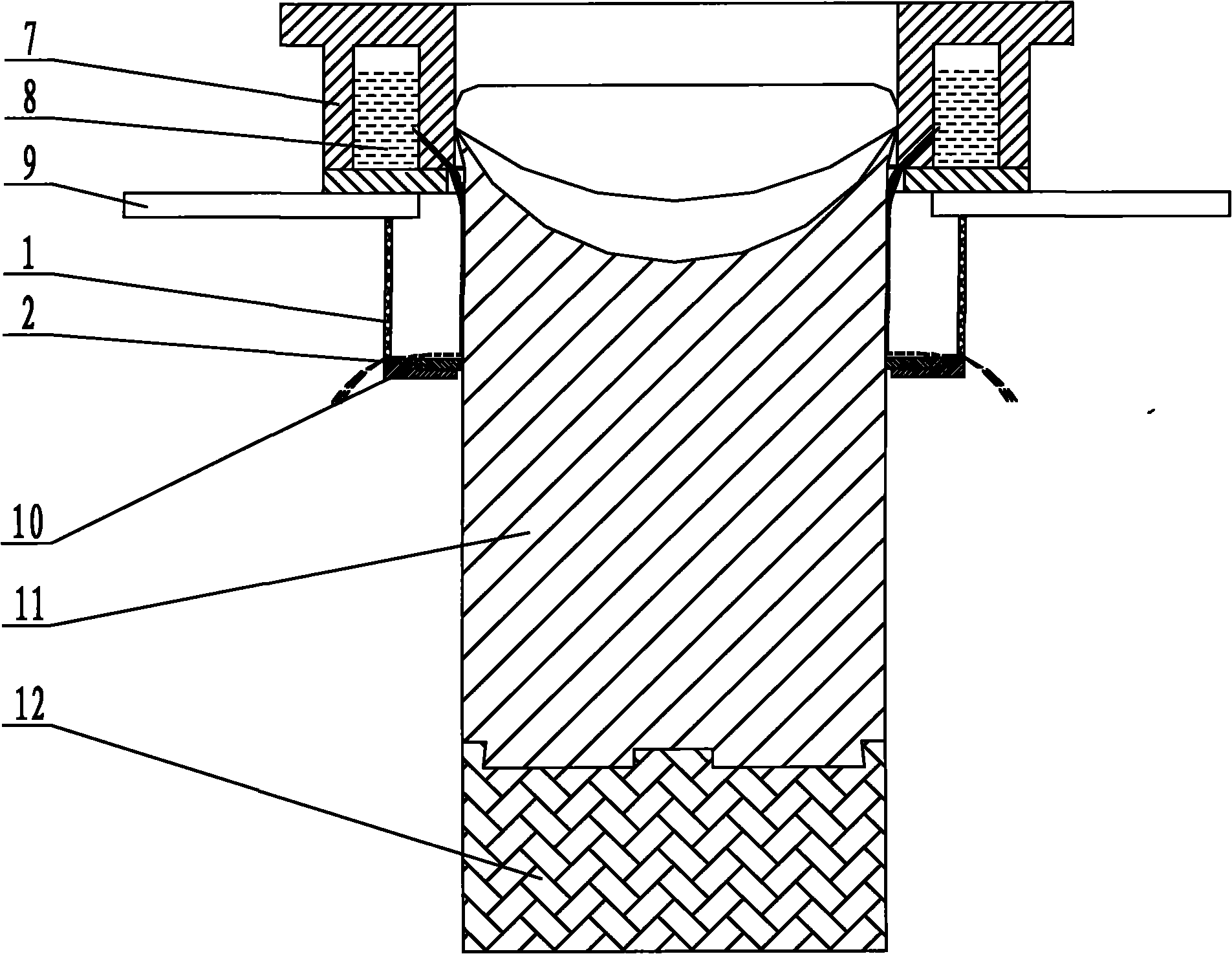

[0020] Such as figure 1 , figure 2 As shown, the water barrier device suitable for semi-continuous casting of aluminum alloy round ingots includes a clamping mechanism, a semicircular snap ring and a semicircular heat-resistant rubber. The rear end of the clamping mechanism is a pair of handles 5, and the clamping mechanism The front end of the front end has a pair of jaws, and a semicircular snap ring 3 is arranged on each jaw, and the inner wall of each semicircular snap ring 3 has an annular groove, and in the annular groove of each semicircular snap ring 3 Embed the semi-annular heat-resistant rubber 2, and fasten the semi-annular heat-resistant rubber 2 with the semi-circular snap ring 3 through bolts. The hot rubber clips form a complete circular loop; in addition, two steel cables 1 are connected to each semicircular snap ring, a total of four steel cables are evenly and symmetrically distributed in a ring. A spring 4 is installed between the handles 5 at the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com